The Strategic Importance of Certified Licensed Product Manufacturing

In the high-stakes world of global retail, licensed product manufacturing represents a unique intersection of creative artistry and rigorous industrial compliance. For brand owners and intellectual property (IP) holders, the manufacturing process is not merely about production volume; it is about the physical manifestation of a brand’s reputation. When dealing with globally recognized characters from franchises like Disney, Marvel, or Warner Bros, the margin for error is non-existent. A single compliance failure or a compromise in product safety can lead to catastrophic brand devaluation and legal repercussions.

At Unstoyppable, we serve as the premier gateway for enterprises seeking world-class manufacturing solutions. By operating as a high-level trading and management entity in China, we bridge the gap between complex Western brand requirements and the specialized technical capabilities of certified factories. Our mission is to ensure that your licensed merchandise is produced in an environment that prioritizes IP security, ethical labor standards, and uncompromising quality control.

The Evolution of the Chinese Manufacturing Ecosystem

Modern Chinese factories are no longer just assembly lines; they are centers of engineering excellence. The concentration of the supply chain in regions like Guangdong allows for unparalleled speed-to-market. From raw material sourcing (phthalate-free plastics and eco-friendly fabrics) to specialized tooling and final retail packaging, every component is available within a tight geographic radius. This integration reduces lead times and minimizes the carbon footprint associated with inter-factory logistics.

Unstoyppable:

Your Bridge to Certified Excellence

Navigating thousands of potential vendors in China is a daunting task for any IP holder. This is where Unstoyppable provides its greatest value. We are not just a middleman; we are your boots-on-the-ground compliance partner. We work exclusively with a vetted network of factories that hold active Disney FAMA (Facility and Merchandise Authorization) and BSCI certifications. By acting as the central management point, we ensure that the factories adhere to your specific brand style guides while maintaining the technical precision required for complex character likenesses.

Are you ready to scale your production with a partner that understands the nuances of IP law?

Learn more about how we safeguard your designs on our IP Security & Factory Compliance page.

BSCI & Ethical Labor:

Non-Negotiable for Modern Retail

Beyond brand-specific authorizations, the Business Social Compliance Initiative (BSCI) provides a standardized framework for social responsibility. In an era where consumers demand transparency, having a BSCI certified toy factory in your supply chain is essential. BSCI audits cover 11 core labor rights, including occupational health and safety and environmental protection. By partnering with Unstoyppable, you gain access to factories that are regularly audited, ensuring your products are "ethical by design." This is a critical component for placing goods in major big-box retailers like Walmart, Target, or Carrefour.

OEM vs. ODM:

Tailoring Your Manufacturing Model

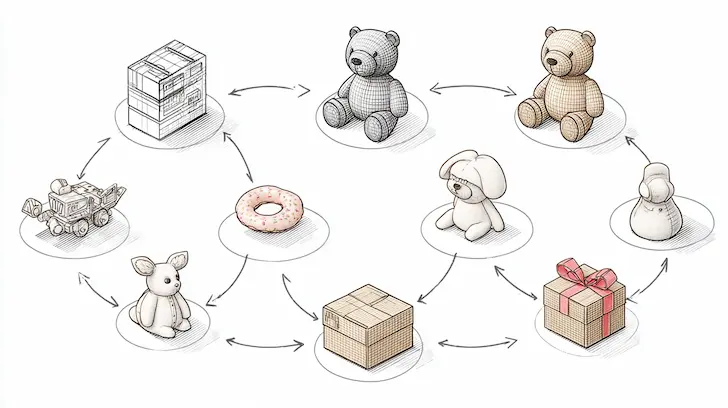

Every licensed project has different requirements depending on the stage of product development. Understanding whether you need an OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) model is key to optimizing your budget and timeline.

Which Model Fits Your Strategy?

The choice between OEM and ODM often depends on your internal resources. If you have a finalized "Golden Sample," our OEM capabilities ensure high-fidelity mass production. If you are looking to innovate within a license—for example, creating a new line of collectible vinyl figures—our ODM engineering team can provide the technical R&D necessary to bring that vision to life while staying within the constraints of the IP's style guide.

By integrating these high standards into our daily operations, Unstoyppable doesn't just manufacture toys; we build resilient supply chains. Whether you are a startup with a fresh character license or a multinational corporation managing a legacy franchise, our infrastructure in China is designed to scale with your ambitions. We invite you to explore our Product Manufacturing Capabilities to see the wide array of materials and technologies we can deploy for your next campaign.

Ensuring Intellectual Property Integrity in the Production Cycle

In the specialized field of licensed product manufacturing, the greatest asset is the intellectual property itself. At Unstoyppable, we recognize that a character is more than just a design; it is a multi-billion dollar asset that requires rigorous protection. Intellectual property integrity involves two distinct but overlapping disciplines: technical precision in "on-model" reproduction and the physical security of the supply chain to prevent unauthorized "gray market" goods. Our protocols are designed to eliminate the risks of IP leakage, counterfeiting, and design infringement while maintaining the highest levels of manufacturing efficiency in China.

Pantone Color Matching and Material Texture

Color consistency is non-negotiable in character product manufacturing. A character’s signature hue must remain identical across different materials, from molded plastic to dyed textiles. We utilize the Pantone Matching System (PMS) to ensure that the "Spider-Man Red" on a plastic shield exactly matches the red fabric of a backpack. Our material engineers also focus on tactile fidelity—ensuring that textures, whether they be the skin of an alien creature or the metallic sheen of a robot's armor, are reproduced according to the licensor’s creative vision.

For a deeper look at our technical development process, visit our dedicated page on Engineering & Prototyping.

Step 2:

Precision Tooling and Injection Molding

The "soul" of a plastic toy lies in its mold. Our mold development and injection tooling process uses high-grade steel to ensure durability over long production runs. For collectible figure manufacturing, we use multi-cavity molds with advanced cooling systems to prevent warping and sink marks. This technical precision is what allows us to achieve the fine details found in modern entertainment merchandise, such as intricate hair strands or costume textures that are less than 0.5mm deep.

Step 3:

Scaled Mass Production Under FAMA Supervision

Once the "Golden Sample" is approved by the licensor, mass production begins. Our factories operate under strict Disney FAMA authorization, which means the facility is subject to unannounced social and technical audits. Our assembly lines utilize a combination of automated spray-painting (for base colors) and hand-painting/pad-printing (for fine details like eyes and logos). This hybrid approach ensures that we can meet the high volume demands of a global movie launch while maintaining the artistic quality of a premium collectible.

Stop worrying about IP theft and production delays.

Your brand deserves a manufacturing partner that treats your IP as if it were their own. Discover how our security protocols can give you peace of mind.

Learn how we protect your brand at every stage of Product Manufacturing Capabilities.

Scrap Destruction and Component Reconciliation

What happens to a toy that fails quality control? In many factories, these "seconds" are sold out the back door. Unstoyppable mandates a strict scrap destruction protocol. Any defective part—be it a mispainted head or a warped limb—is crushed or shredded under the supervision of our QC managers. We perform "component reconciliation," where we track the quantity of raw materials issued versus the number of finished goods and scrap produced. If the numbers don't match, production is halted until the discrepancy is found.

Limited Access Production Zones

For highly sensitive projects, such as toys for an unreleased film, we establish "Dark Zones" within the factory. These are physically partitioned areas with restricted badge access, where photography is strictly prohibited. This ensures that leaked photos of upcoming characters do not appear on social media before the official marketing campaign begins. Our secure supply chain for licensed products is designed to keep your secrets safe until the "street date."

Meeting Global Standards:

Toy Safety and Retail Compliance

European Market:

EN71 Standards

For products entering the European Union, compliance with EN71 is mandatory. This standard is divided into several parts, including mechanical and physical properties (Part 1), flammability (Part 2), and the migration of certain elements (Part 3). Our licensed toy manufacturing process includes pre-production lab testing to ensure that materials—whether they are soft plush fabrics or rigid PVC—are free from harmful levels of heavy metals and chemicals like lead or cadmium.

United States Market:

ASTM F963 and CPSIA

In the U.S., the ASTM F963 is the comprehensive standard for toy safety. This includes rigorous "use and abuse" testing, such as drop tests, torque tests, and tension tests, to ensure that small parts (which could pose choking hazards) do not detach during play. Furthermore, the Consumer Product Safety Improvement Act (CPSIA) mandates strict limits on phthalates and lead content. Unstoyppable works exclusively with third-party accredited laboratories (such as SGS, Intertek, or BV) to provide certified test reports for every production batch.

To learn more about our specific laboratory testing and quality gates, visit our pillar page on Toy Quality & Safety Compliance.

Ensure Your Products Are 100% Compliant

Don't risk your reputation with non-compliant goods. We provide full transparency and certified lab reports for every project. Speak with a Compliance Expert today.

Specialized Packaging:

Blind Boxes and Collectibles

For the "kidult" and collectible markets, the packaging is often as important as the toy itself. We specialize in retail-ready packaging manufacturing, including window boxes with UV-spot coating, embossed foil accents, and "blind-box" configurations for mystery collectible series. Our engineers design internal blister trays that pass "transit testing," ensuring that delicate collectible figures reach the consumer without a single scratch.

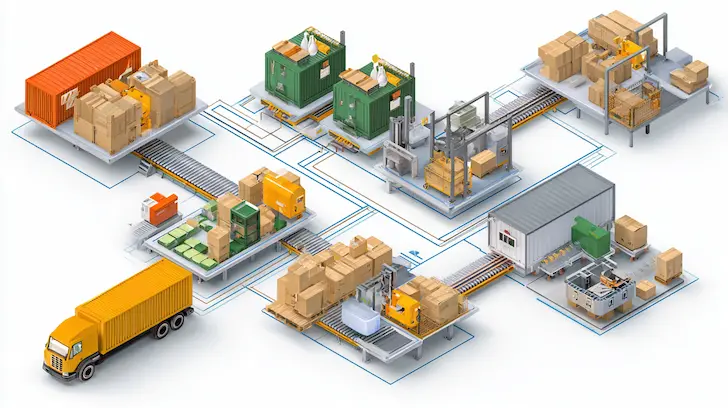

Global Fulfillment and Logistics Management

Navigating customs and international freight can be a bottleneck. Unstoyppable manages the logistics chain from the factory floor to the port of destination. We handle the complex documentation required for customs & export for toys, ensuring that the correct HS codes are used to minimize duty costs while maintaining full compliance with international trade laws.

Discover how we streamline the journey from factory to shelf on our Logistics & Retail Fulfillment page.