OEM Licensed Product Manufacturing:

Bridging the Gap Between IP and Retail

In the high-stakes landscape of 2026, OEM Licensed Product Manufacturing has evolved into a sophisticated discipline where artistic fidelity meets industrial precision. For global brands, media franchises, and entertainment giants, the challenge is no longer just finding a factory; it is about securing a partner capable of manifesting a complex digital IP into a physical product that commands retail shelf space. At Unstoyppable, we specialize in high-tier OEM manufacturing solutions that prioritize the integrity of your intellectual property. Our approach ensures that every unit produced—from a high-detail collectible to a mass-market plush—serves as a flawless ambassador for your brand. By merging Western-managed oversight with the elite technical capacity of our audited factory network in China, we provide the security, quality, and scalability required to thrive in the modern toy and merchandise economy.

Defining the 2026 OEM Landscape

Modern OEM Licensed Product Manufacturing involves a deep integration of character engineering for toys and toy quality and safety compliance. It is a process that begins long before the machines start running. It starts with a comprehensive analysis of the brand’s "Style Guide"—the definitive blueprint for character proportions, Pantone colors, and tactile textures. For a licensed toy manufacturer in China, success is measured by "On-Model" accuracy. This means the final product is an exact physical replica of the character seen on screen, maintaining the emotional connection that fans have with the IP. Our role at Unstoyppable is to ensure that this fidelity is preserved across 50,000 or 5,000,000 units, utilizing advanced toy tooling R&D to capture details that generic factories often overlook.

The Unstoyppable Bridge:

Western Management Meets Asian Scale

Unstoyppable acts as a critical Western-managed bridge in the toy manufacturing process. We understand that communication is the primary failure point in overseas production. By providing a local, English-speaking management layer that is physically present in the production hubs of China, we translate the high expectations of Western IP holders into actionable factory instructions. This ensures that the confidential licensed product manufacturing requirements of major studios like Disney, NBCUniversal, or Warner Bros. are respected at every stage. We bridge the cultural and technical gap, providing our clients with the peace of mind that their custom licensed product development is being handled by a partner who speaks the language of brand equity and retail excellence.

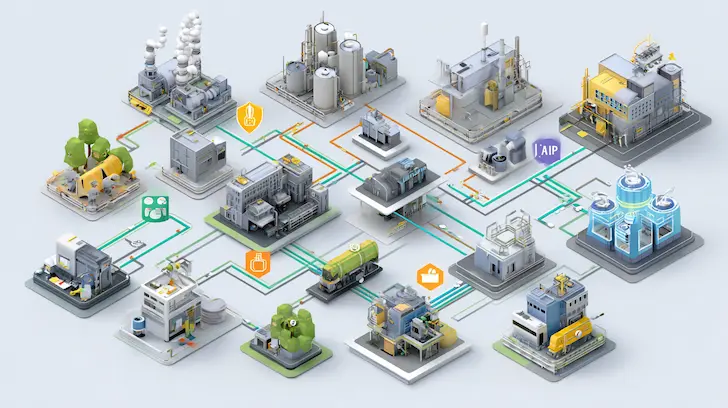

Accessing Specialized Machinery Without Bias

Our OEM manufacturing solutions give you the power of a "Mega-Factory" with the agility of a boutique studio. Because we are not locked into a single facility's production schedule, we can move your licensed merchandise project to the head of the line in the facility that best suits the product's requirements. This access includes high-precision 5-axis CNC machines for mold development & injection tooling, automated paint-spraying robotics, and third-party toy lab testing facilities that are integrated into the production hub. This flexibility allows us to optimize the landed cost in manufacturing by selecting production paths that minimize waste and maximize container density through Design for Mass Production (DFM).

Your brand's physical identity is too valuable to leave to chance.

Partner with the experts who prioritize IP integrity and technical precision in every OEM Licensed Product Manufacturing run.

Securing the Digital DNA During Mass Production

During the toy manufacturing process, we implement "Serialized Tooling" and anti-counterfeit manufacturing systems. Every mold created in the mold development & injection tooling phase is tracked via an internal GPS and RFID system. This prevents the unauthorized use of molds for "night shifts" or "over-runs" that often plague the licensed toy manufacturer China market. By controlling the "Digital DNA" of the mold and the physical output of the machine, Unstoyppable ensures that every unit produced is an authorized, authentic, and high-quality representation of your brand. This transparent supply chain manufacturing is the cornerstone of our identity, providing the ultimate protection for your investment in OEM Licensed Product Manufacturing.

The foundations of a successful OEM partnership are built on more than just industrial capacity; they are built on a shared commitment to brand excellence and intellectual safety. By choosing the Unstoyppable hybrid model, you are securing a transparent supply chain that is designed for the demands of 2026. Whether you are navigating the complexities of character product manufacturing or preparing for a global retail rollout, our infrastructure is ready to scale with your vision. We invite you to explore our Engineering & Prototyping capabilities or learn more about our FAMA and BSCI status in the IP Security & Factory Compliance pillar to see how we can make your next launch truly Unstoyppable.

Scaling Your Vision:

From Golden Sample to Global Distribution

In the high-speed world of OEM licensed product manufacturing, success is defined by the ability to scale rapidly while maintaining surgical precision. Once the golden sample development process is finalized and approved by the IP holder, the challenge shifts from creative engineering to industrial mobilization. In 2026, the global market demands a licensed merchandise manufacturer that can pivot as quickly as a viral social media trend. At Unstoyppable, we provide the infrastructure necessary to move from a limited boutique run to a multi-million unit global rollout. We ensure that every character product manufacturing cycle is backed by a robust toy manufacturing logistics strategy, guaranteeing that your products arrive at retail on time, in full, and in perfect condition.

The "Street Date" Protocol:

Precision Timing

In manufacturing for media franchises, missing a "Street Date" is a catastrophic failure. Retailers and studios coordinate product launches down to the minute. Our OEM licensed product manufacturing process includes a strict "Street Date" protocol. This involves working backward from the launch date to set rigid milestones for third-party toy lab testing, AQL inspection in toy manufacturing, and customs clearance. We synchronize our global distribution for licensed products with your marketing calendar, ensuring that inventory is staged in regional warehouses and ready for the 12:01 AM launch. Precision timing is how we ensure your retail-ready licensed product production succeeds on a global stage.

Sustainable OEM Sourcing:

The Green Mandate of 2026

The 2026 manufacturing environment is defined by environmental accountability. Sustainable toy manufacturing is no longer an optional "extra"—it is a core retail requirement. Unstoyppable leads the way in integrating eco-friendly practices into the OEM manufacturing solutions workflow without sacrificing the aesthetic or functional quality of the licensed goods.

Lead the Market with Sustainable OEM Excellence.

Future-proof your brand by integrating sustainable toy manufacturing and 2026-compliant logistics into your production line.

Explore Our Green Initiatives | Optimize Your Logistics Chain

The ERP Production Tracking System:

Real-Time Transparency

The greatest threat to OEM licensed product manufacturing is the "Information Black Hole"—the period between placing an order and receiving a shipping notice. Unstoyppable eliminates this through our proprietary ERP production tracking system. This platform provides our clients with 24/7 visibility into every stage of their custom licensed product development.

From the moment toy material engineering begins to the final AQL inspection, every milestone is logged digitally. You can track the progress of your mold development & injection tooling, view real-time automated toy safety testing results, and monitor the loading of containers. This level of transparent supply chain manufacturing allows your marketing and retail teams to make data-driven decisions based on actual factory progress. With Unstoyppable, you are never left wondering about the status of your licensed merchandise; you have the data at your fingertips.