EN71 Compliant Toy Manufacturer:

Navigating European Safety Standards with Precision

For any global brand or media franchise, the European Union represents one of the most lucrative yet stringently regulated markets in the world. Success in this region is predicated on a partnership with an EN71 compliant toy manufacturer that possesses a deep technical understanding of the "Toy Safety Directive" 2009/48/EC. At Unstoyppable, we act as a strategic shield for our clients, ensuring that every licensed product—from intricate PVC collectibles to high-volume injection-molded playsets—exceeds European toy safety standards. Our manufacturing philosophy is rooted in proactive risk mitigation; we don't just test for compliance at the end of the line; we engineer it into the very fiber of the product. By mastering the complexities of EN71, we provide our partners with the technical documentation and physical product integrity required to secure CE marking for licensed toys, allowing for frictionless entry into all EU member states and the UK.

EN71 Part 1:

Mechanical and Physical Properties

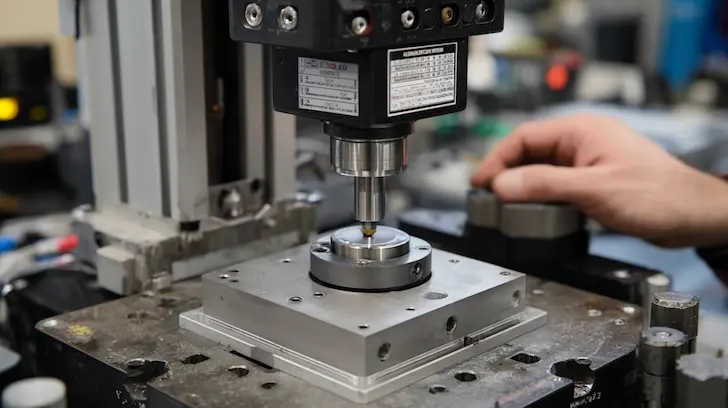

This is the foundation of toy safety. EN71 Part 1 mechanical testing focuses on the structural integrity of the toy. It ensures that under "foreseeable abuse"—dropping, pulling, twisting, or biting—the toy remains safe for the intended age group. We utilize specialized laboratory equipment to simulate these stresses during the prototyping phase. Our expertise in mechanical testing for toys allows us to identify potential failure points in a character's limbs or accessories, reinforcing them long before mass production begins. This meticulous attention to physical behavior is what prevents the catastrophic "small parts" hazards that lead to costly recalls.

EN71 Part 2:

Flammability Protection

Safety also encompasses how a material reacts to heat. While often associated with plush toys, EN71 Part 2 is equally critical for hard plastic toys that may include fabric elements or complex hair fibers. We utilize flame-retardant additives and conduct "rate of spread" tests to ensure that our products meet the highest safety benchmarks. As an experienced EN71 compliant toy manufacturer, we verify that all materials—including the printing film and surface coatings—possess thermal stability, ensuring that your IP is protected from both a legal and safety perspective.

Age-Specific Engineering for Under-36 Months

The requirements for infants are significantly higher. For toys intended for children under 36 months, we implement "fail-safe" engineering. This includes the elimination of all small parts, the use of ultra-durable phthalate-free toy materials, and specialized sonic welding techniques that create unbreakable seams. By understanding the nuances of licensed toy compliance EU, we help brand owners correctly categorize their products and engineer them to meet the specific "intended use" benchmarks of European regulators.

Secure Your Entry into the European Market

Don't let regulatory hurdles stall your global expansion. Partner with an EN71 expert to ensure your IP meets every European benchmark from the first prototype to the final shipment.

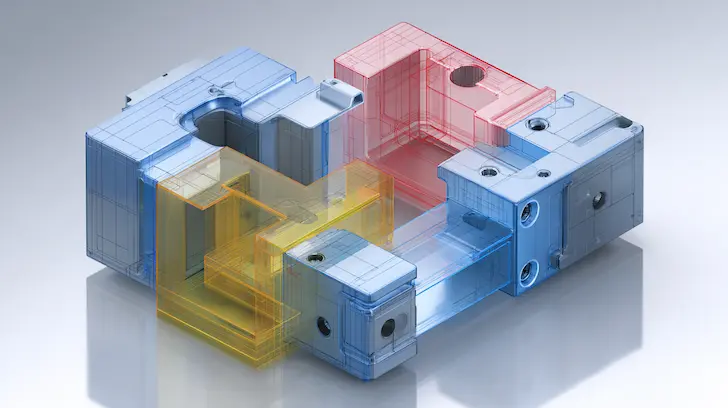

Advanced Polymer Selection for Stress Resistance

We select high-purity resins like "Impact-Modified ABS" or "High-Density Polyethylene" that are characterized by their high elongation at break. This means that instead of shattering under the EN71 "Torque Test" (twisting force), the material flexes and holds its integrity. Our EN71 compliant toy manufacturer status is bolstered by our ability to match the right material to the specific mechanical demands of the toy's pose and function. Whether it is a rigid action figure or a flexible PVC figure manufacturer project, the structural chemistry is always optimized for EU safety.

The CE Mark Guarantee:

Mastering the Technical File

Manufacturing a safe toy is only half the battle; the other half is proving it. The CE marking for licensed toys is a declaration that the product meets all applicable EU safety directives.

The Unstoyppable Shield: In the European market, safety is the ultimate brand value. By combining EN71 Part 1 mechanical testing with sophisticated design for compliance and CE marking expertise, we ensure your brand remains "Unstoyppable." Let us handle the complexity of EU regulations so you can focus on the creativity of your IP.

EN71-3 Chemical Compliance:

Advanced Material Engineering and Toxin-Free Production

Beyond the physical structure of a toy lies a complex chemical ecosystem that must be rigorously managed to satisfy the European Union's stringent safety directives. As an industry-leading EN71 compliant toy manufacturer, Unstoyppable prioritizes non-toxic toy materials at the molecular level. The EN71-3 standard specifically regulates the migration of certain elements from toy materials, ensuring that even if a child ingests or comes into contact with the toy, the bio-availability of heavy metals remains well below harmful thresholds. Our technical optimization process involves a comprehensive screening of all raw resins, pigments, and additives. By implementing advanced toy material engineering, we ensure that every product we manufacture—from complex action figures to soft-touch teething elements—upholds a standard of heavy metal free toy production that is unrivaled in the Chinese manufacturing sector. For 2026, our focus is on chemical transparency and the elimination of migration risks through high-purity polymer selection.

The 19 Elements Rule:

Mastering Migration Limits

The core of EN71-3 compliance is the "Migration of Certain Elements" test. This protocol does not just measure the total content of a substance; it measures the amount that could potentially be absorbed by the human body. As a specialized EN71 compliant toy manufacturer, we maintain strict control over the 19 regulated elements.

Monitoring Lead, Cadmium, and Organic Tin

Our EN71-3 migration testing focuses heavily on the most high-risk elements, including lead, cadmium, antimony, barium, and mercury. We utilize Inductively Coupled Plasma (ICP) spectroscopy to analyze material samples down to parts-per-million (ppm). This is particularly vital for licensed merchandise manufacturer projects where vibrant colors are required. We exclusively use organic, heavy-metal-free pigments to achieve brilliant hues without compromising the heavy metal free toy production standards. By controlling the pigment-to-resin ratio, we ensure that the migration levels for elements like organic tin and chromium (VI) remain significantly lower than the EU's maximum permissible limits.

Analyzing Graphics for Sub-Surface Safety

Our In-Mold Decoration (IMD) process utilizes specialized printing film for toy materials that is chemically matched to the base resin. Before production, the inks used on these films undergo rigorous EN71-3 migration testing. We verify that the curing process for these films locks in the pigments, preventing any leaching or migration. Because the film is thermally fused to the toy, it provides a more stable chemical surface than traditional spray paints. This innovation is essential for character product manufacturing, where the intricate facial details must remain safe and vibrant under all conditions.

Phthalate-Free EU Standards and Plasticizers

For toys containing soft components, adhering to phthalate-free EU standards is mandatory. We utilize non-phthalate plasticizers (such as DOTP or DINCH) in our PVC figure manufacturer projects and soft-goods production. Our R&D team ensures that these alternatives provide the necessary flexibility without the endocrine-disrupting risks associated with traditional phthalates. This commitment to phthalate-free toy materials ensures that your products are ready for the most sensitive age categories in the European market.

Guarantee Chemical Integrity for Your IP

Safety is found in the molecules. Explore our catalog of EN71-3 certified materials and discover how we deliver high-definition, non-toxic finishes for global brands.

Learn About Phthalate-Free Production | Explore Material Science

Clean-Room Compounding:

Preventing Cross-Contamination

A chemical violation often occurs not from the primary resin, but from accidental contamination during the production process. We mitigate this risk through disciplined factory management.

High-Purity Material Handling Protocols

To maintain heavy metal free toy production, we implement "Clean-Room Compounding" protocols for our most sensitive EN71-3 projects. This involve dedicated material hoppers, stainless steel delivery lines, and isolated mixing areas to prevent cross-contamination from other industrial runs. By treating toy material engineering with the same rigor as medical device manufacturing, we ensure that high-purity medical-grade TPE or ABS remains "pure" from the moment the pellet arrives at our BSCI audited toy factory to the moment the finished product is packed. This level of quality control is what makes Unstoyppable a trusted EN71 compliant toy manufacturer for the world's largest entertainment franchises.

The Purity Standard: At Unstoyppable, we believe that chemical safety is the ultimate expression of quality. By mastering EN71-3 migration testing and printing film safety compliance, we provide a manufacturing environment where toxin-free production is the baseline. Partner with us to ensure your brand stands for purity, safety, and excellence.

Rigorous Validation:

Third-Party Testing and FAMA-Certified Manufacturing

The journey from a digital sculpt to a European retail shelf is paved with rigorous verification and industrial accountability. At Unstoyppable, we recognize that being an EN71 compliant toy manufacturer requires more than just high-quality engineering; it demands a transparent and verifiable audit trail. Our toy quality assurance protocols are designed to bridge the gap between Chinese manufacturing excellence and the strict legal requirements of the EU market. By integrating third-party toy lab testing into our core workflow, we provide IP holders with the empirical evidence needed to satisfy customs officials, retail buyers, and safety advocates alike. Our commitment to FAMA compliant manufacturing China and BSCI audited toy factory standards ensures that your products are not only safe for children but are produced under the highest ethical and social conditions, a prerequisite for any major media franchise operating in 2026.

BSCI and Sedex:

The Pillars of Social Compliance

Our BSCI audited toy factory network provides the social accountability that global brands demand. These audits verify fair wages, workplace safety, and the prohibition of forced labor. By maintaining a Sedex-compliant supply chain, we allow our partners to bypass the complex and often prohibitive process of individual factory vetting. This ethical transparency is a critical component of licensed toy compliance EU, ensuring that your brand is protected from the reputational risks associated with unverified manufacturing. When you partner with Unstoyppable, you are choosing a network that is already pre-approved by the world's most demanding retailers.

FAMA Compliance:

The Gold Standard for Disney and Beyond

For brands handling Disney, Marvel, or Star Wars IP, FAMA compliant manufacturing China is non-negotiable. The Facility and Merchandise Authorization (FAMA) is a testament to a factory's ability to meet the most stringent security and labor standards in the world. We facilitate the entire FAMA certification process, ensuring that the production site for your character product manufacturing is fully authorized and ready to produce official merchandise. This level of authorization is the ultimate "green light" for global distribution.

Batch Testing:

Preventing "Quality Fade"

Quality must be maintained from the first unit to the last. To prevent "quality fade"—the gradual degradation of material purity or structural integrity during a long run—we implement batch testing protocols. Every 5,000 or 10,000 units, samples are pulled directly from the production line and re-sent for EN71-3 migration testing. This ensures that the printing film and resins used in the middle of the run are identical in purity to those used at the start. This continuous monitoring is what makes Unstoyppable a reliable EN71 compliant toy manufacturer for multi-year production contracts.

Navigate EU Compliance with Confidence

Your entry into the European market should be seamless. Get a comprehensive quote for your EN71-certified, FAMA-authorized production run today.

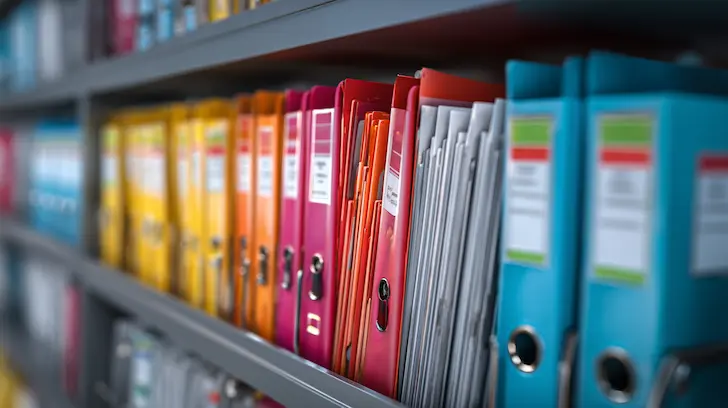

EN71 Technical File Preparation

The EN71 technical file preparation is the final bridge to the market. We compile all CAD drawings, material safety data sheets (MSDS), lab reports, and factory audits into a single, digital dossier. This file is kept on record for 10 years, as required by EU law, ensuring that you are always ready for a market surveillance audit. This comprehensive secure supply chain for licensed products management is why Unstoyppable is the preferred partner for entertainment brands looking for a "plug-and-play" manufacturing solution in China.