Eradicating IP Vulnerability:

Sophisticated Solutions for Brand Protection

In the high-stakes world of licensed product manufacturing, your Intellectual Property (IP) is the bedrock of your brand's value. In 2026, as global markets become more interconnected and digital design files more portable, the risks associated with IP theft have evolved. Traditional protective measures that relied solely on legal contracts are now insufficient on their own. At Unstoyppable, we provide a robust, tech-enabled shield for your assets. We move beyond the standard Non-Disclosure Agreement (NDA) to implement physical, digital, and procedural barriers that ensure your designs remain exclusive to you. Our proactive stance on IP protection in China manufacturing is designed to provide peace of mind to major studios and independent license holders alike, turning security into a foundational element of the production lifecycle.

The Unstoyppable Secure Protocol:

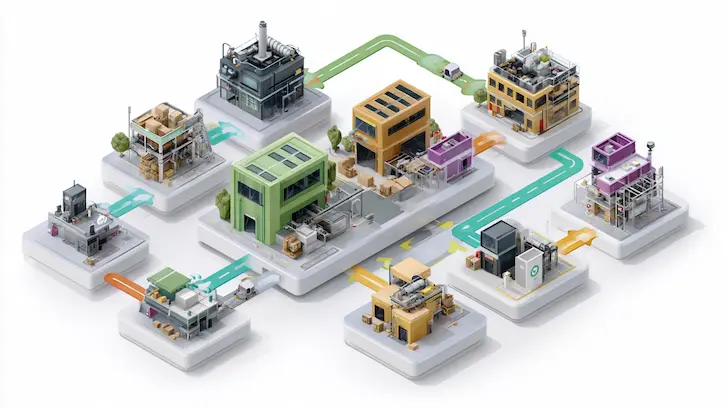

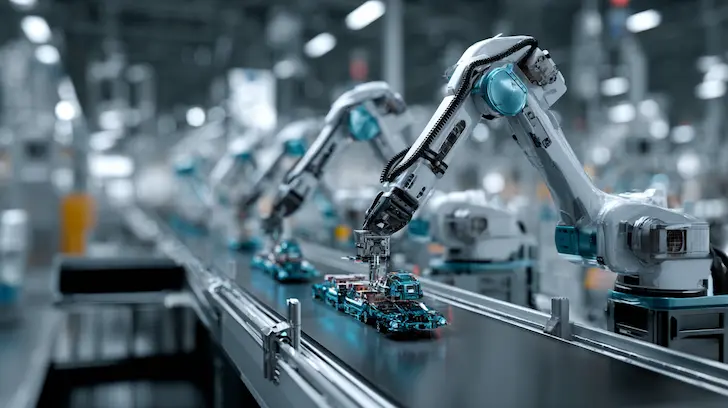

Compartmentalized Production

One of our most effective strategies for confidential licensed product manufacturing is the compartmentalization of the production chain. Rather than allowing a single facility to possess the full "recipe" for your product, we split the manufacturing process across our audited factory network. For example, the high-precision injection molded toy body might be produced in one high-security facility, while the specialized internal electronics or unique paint applications are handled at a separate, specialized site. Final assembly is then conducted under the direct supervision of Unstoyppable’s own on-site quality control officers. This ensures that no single factory has the complete technical data or tooling required to replicate your product independently. It is a sophisticated method of IP protection in China manufacturing that renders unauthorized reproduction nearly impossible.

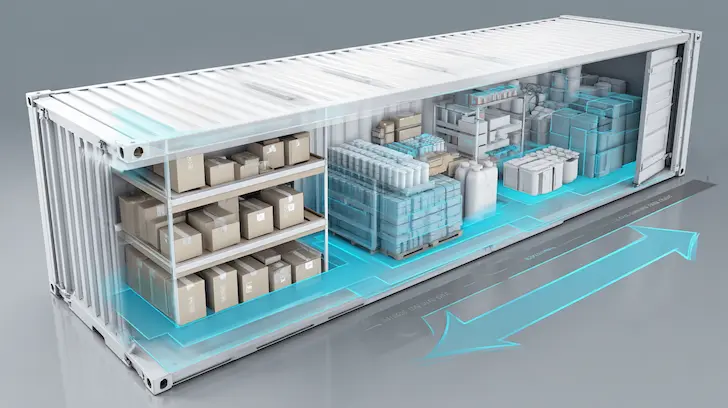

2026 Blockchain-Verified Production Tracking

As we navigate 2026, data integrity is paramount. Unstoyppable integrates Blockchain-verified production tracking into our manufacturing workflow. Every stage of the licensed merchandise manufacturer process—from the initial procurement of raw phthalate-free toy materials to the final AQL inspection—is recorded on an immutable ledger. This provides an unbreakable chain of custody. Each unit produced is assigned a unique digital identity, ensuring that 100% of the output is accounted for. This prevents the "leakage" of authentic units into unauthorized channels and provides the IP holder with a real-time, audit-ready map of their inventory's journey from the factory floor to the shipping container.

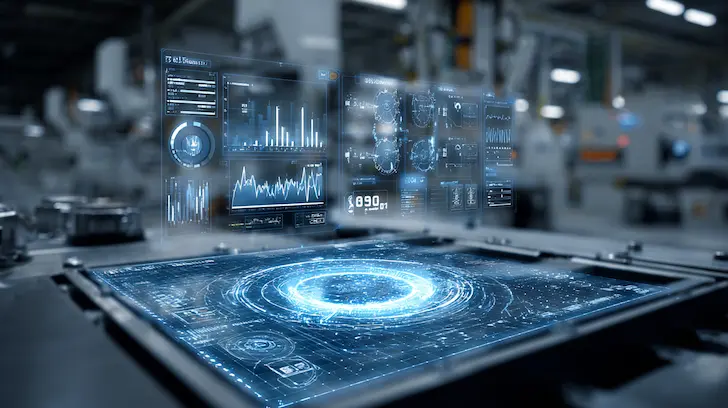

Eliminating "Ghost Shifts" via ERP Integration

A "Ghost Shift" is when a factory runs unauthorized production cycles using the client's materials and molds. We eliminate this risk through our ERP production tracking system, which monitors the specific consumption rates of raw materials against the machine's cycle times. If the injection molding machines are active but the ERP does not show an authorized order, our system triggers an immediate alert. Because we control the supply of critical components—such as specialized electronic toy manufacturer chips or unique fabrics for soft goods manufacturing—we ensure that the factory only has the exact resources needed for your authorized volume. This strict material reconciliation is a cornerstone of secure supply chain for licensed products.

Your IP is your most valuable asset. Don't leave it to chance.

Success in 2026 requires a partner who understands the technical nuances of brand protection. Learn more about How to Protect IP When Manufacturing in China or discover the specifics of our Anti-Counterfeit Manufacturing Systems.

Learn IP Protection Strategies | Speak to an IP Security Expert Today

Disney FAMA Compliance:

The Gold Standard of Security

Unstoyppable operates exclusively within Disney FAMA compliant factories in China. This certification is not just about labor standards; it is also a rigorous benchmark for IP security and factory compliance. A FAMA compliant factory must demonstrate that it has the administrative and physical infrastructure to protect licensed assets from unauthorized use or disclosure. By working within this framework, we provide entertainment brands with a pre-vetted environment that is already optimized for confidential licensed product manufacturing. Our compliance status is your guarantee that your IP is being handled by a licensed merchandise manufacturer that is regularly audited by the world’s most protective brand owners.

Effective IP protection in China manufacturing is a combination of high-tech digital tracking, strategic production fragmentation, and rigorous physical security. By choosing Unstoyppable, you are choosing a partner that treats your intellectual property with the same reverence as the creators themselves. We invite you to explore our IP Security & Factory Compliance pillar page or read our detailed guide on How to Protect IP When Manufacturing in China. Your brand's future depends on the security of its past and present designs—ensure they are Unstoyppable.

Navigating Regulatory Minefields:

Ensuring Global Market Access

In the globalized economy of 2026, the regulatory landscape for children’s products has reached a new level of complexity. For any licensed product manufacturer, staying ahead of these shifts is the only way to ensure uninterrupted market access. At Unstoyppable, we view compliance not as a hurdle, but as a competitive advantage. The transition into 2026 has brought about landmark changes in chemical restrictions, mechanical safety requirements, and digital transparency. Our OEM manufacturing solutions are built on a foundation of rigorous safety protocols, ensuring that your licensed merchandise is fully prepared for the scrutiny of customs officials and consumer watchdogs in North America, Europe, and beyond. By partnering with us, you are securing a transparent supply chain manufacturing process that prioritizes consumer health and brand reputation above all else.

Eliminating "Forever Chemicals":

The Role of Phthalate-Free Toy Materials

2026 marks a critical turning point in chemical safety, specifically regarding the ban on PFAS, often known as "Forever Chemicals." Our toy material engineering team has successfully transitioned all production lines to 100% PFAS-free alternatives. Furthermore, we maintain a strict focus on phthalate-free toy materials and the elimination of heavy metals like lead and cadmium. By using only virgin, high-grade resins for our injection molded toy manufacturer projects, we eliminate the risk of contamination often found in recycled plastics. This commitment to toy quality and safety compliance ensures that your brand is associated with purity and safety, which is essential for entertainment merchandise manufacturing targeted at young children.

The "Fail-Safe" Lab Testing Process

To guarantee compliance, we employ a "Fail-Safe" testing protocol using CPSC-accepted third-party labs such as SGS, Intertek, and BV. This process involves testing at three distinct stages: raw material pre-screening, "Golden Sample" verification, and final random mass-production testing. Our third-party toy lab testing is not just a final check; it is a continuous loop of verification. We ensure that every batch of licensed merchandise carries a valid Children’s Product Certificate (CPC) for the US or a Declaration of Conformity (DoC) for the EU, backed by the most current 2026 testing standards. This rigorous oversight is why Unstoyppable is a trusted name in licensed merchandise production.

The Unstoyppable Audit Advantage

Our BSCI & Sedex Audited Toy Factory network is the cornerstone of our failure-prevention strategy. Unlike a traditional trading company, we maintain a permanent presence in our partner factories. This constant on-site oversight ensures that the factory adheres to the Disney FAMA standards for social responsibility and safety at every hour of the day. Our ethical toy manufacturing China protocols mean that your products are made in facilities that prioritize worker safety and environmental stewardship, which in turn leads to higher product quality and lower defect rates. We ensure that every facility in our network is a FAMA compliant factory in China, providing the highest level of IP security and factory compliance.

Compliance is non-negotiable for retail success.

Stay ahead of the 2026 mandates with a partner that specializes in global safety. Read our guide on How to Meet Global Toy Safety Standards or explore why Factories Fail at Licensed Merchandise Production.

Navigating the 2026 regulatory minefield is a technical challenge that requires a dedicated partner. By focusing on safety by design, automated toy safety testing, and a BSCI & Sedex Audited Toy Factory network, Unstoyppable ensures your licensed product manufacturing remains profitable and compliant. We invite you to explore our Toy Quality & Safety Compliance section or read about our IP Security & Factory Compliance to see how we protect your brand's future across every dimension.

Financial Optimization:

Protecting Your Margins and Timelines

In the highly competitive 2026 landscape of licensed merchandise manufacturing, profitability is determined long before the first unit is sold. For IP holders and licensees, the challenge lies in maintaining premium product quality while combatting rising logistics costs and volatile trade tariffs. At Unstoyppable, we view financial optimization as a core engineering discipline. Our approach to OEM manufacturing solutions integrates fiscal responsibility into the creative process, ensuring that your character product manufacturing projects are as profitable as they are iconic. By focusing on landed cost reduction and rigorous launch preparation, we empower our partners to scale with confidence, protecting margins against the unpredictable nature of global trade.

Design for Manufacturing (DFM):

The 0.5mm Difference

Engineering efficiency is the most effective way to lower costs. Our toy material engineering team conducts a comprehensive DFM review for every project. By thinning a plastic wall by just 0.5mm or slightly adjusting the geometry of a PVC figure manufacturer sculpt, we can significantly reduce raw material consumption and cooling times in the injection molded toy manufacturer process. These micro-adjustments, when scaled across 100,000 units, result in substantial savings. Furthermore, we optimize retail-ready packaging dimensions to eliminate "dead air." A 5% reduction in box size can often increase container density by 15-20%, effectively saving tens of thousands of dollars in trans-pacific freight costs for a single movie launch. This level of landed cost in manufacturing optimization ensures that more of your budget goes toward marketing and IP development.

HS Code Optimization and 2026 Tariff Navigation

The 2026 global trade environment requires expert navigation of the Harmonized System (HS). A product’s classification determines its import duty, and minor design choices can lead to major tax implications. Our customs & export for toys experts perform "HS Code Optimization" during the engineering & prototyping phase. By ensuring your product is classified under the most favorable (and accurate) tariff heading—such as "educational toy" versus a standard "plastic figurine"—we help you lower import duties legally and effectively. This proactive strategy is essential for licensed toy manufacturers in China who need to maintain competitive pricing in the North American and European markets.

"Agile Scaling" Based on Trailer Engagement

In 2026, we use data to drive production volumes. Our "Agile Scaling" model allows clients to start with a conservative 50,000-unit commitment and ramp up to 500,000 units based on real-time trailer engagement and social media sentiment. If a character goes viral on TikTok, our ERP production tracking system allows us to instantly activate additional capacity within our audited factory network. This responsiveness ensures you capture 100% of the market demand without the risk of massive overstock if a franchise underperforms. It is the ultimate strategy for manufacturing for media franchises.

ERP Production Tracking System:

The Cure for Late Shipments

The "Black Hole" of production—the period where the client has no idea if their goods are actually being made—is the primary cause of launch failures. Unstoyppable solves this with our ERP production tracking system. Every project milestone is tracked in real-time, from the arrival of phthalate-free toy materials to the final AQL inspection in toy manufacturing. Our clients receive 24/7 visibility via a secure dashboard, allowing them to provide accurate updates to their retail partners. This transparent supply chain manufacturing builds trust and ensures that everyone, from the factory floor to the retail buyer, is synchronized for a flawless launch.

Is your production timeline movie-ready?

Don't let a "Black Hole" in your supply chain derail your launch. Discover how to Prepare Manufacturing for a Movie Launch and Reduce Landed Cost in Manufacturing today.