Plush Toy Manufacturer China:

Engineering Softness for Global Brands

In 2026, the global plush market has transcended the traditional "stuffed toy" category, evolving into a sophisticated domain of material science and emotional engineering. As a premier plush toy manufacturer China, Unstoyppable leads this transformation by integrating advanced textile technologies with high-compliance manufacturing. For global brand managers and license holders, a plush product is no longer just a physical asset; it is a tactile brand touchpoint that must meet rigorous sustainability benchmarks, aesthetic precision, and interactive capabilities. We don't just assemble toys; we engineer sensory experiences that define the next generation of premium plush toy craftsmanship.

Recycled rPET Plush Fabric:

From Bottles to Hugs

Our recycled rPET plush fabric represents the pinnacle of sustainable textile engineering. By utilizing GRS-certified (Global Recycled Standard) post-consumer plastic, we create fibers that mimic the ultra-soft "minky" feel of luxury plush while reducing carbon emissions by up to 30%. This material is processed through high-precision extrusion to ensure long-fiber integrity, resulting in a durable, non-shedding finish that is perfect for licensed toy manufacturer China projects where longevity is a core brand value.

Organic Bamboo Velour and GOTS-Certified Fillings

For brands targeting the eco-luxury or infant segments, we offer organic bamboo velour. This material is naturally hypoallergenic, anti-bacterial, and provides a unique "cool-to-the-touch" hand-feel that synthetic fibers cannot replicate. Paired with GOTS-certified organic cotton stuffing or recycled corn-fiber fill, our plush toys provide a 100% bio-based alternative for the conscious consumer. These sustainable plush toy materials 2026 are not just "green" labels—they are high-performance textiles engineered for the modern retail environment.

The "Luxury Hand-Feel":

GSM and Pile Height Precision

To achieve premium plush toy craftsmanship, we utilize advanced textile metrics to define softness. We offer bespoke fabric development where we control the GSM (Grams per Square Meter) weight and pile height to the millimeter. Whether your character requires a 400GSM ultra-dense "bunny fur" texture or a short-pile 1.5mm "minky" finish for detailed embroidery, our product manufacturing capabilities ensure consistency across millions of units. Our zero-shedding guarantee is a result of high-density base weaving, making our plush safe for all ages and resilient through machine washing.

Transform Your Character into a Premium Tactile Experience

In 2026, the touch of your product is as important as the look. Partner with Unstoyppable to access the most advanced sustainable plush toy materials 2026 catalog in the industry.

Explore Our Eco-Friendly Fabrics | Discover Advanced Material Science

Invisible Technology:

Maintaining the "Huggability" Factor

The hallmark of a well-engineered premium plush toy is that the technology is felt but not seen. We utilize ultra-thin, flexible wiring and miniaturized sensors to ensure that the "cuddle factor" is never sacrificed. Our toy manufacturing technology & automation allows us to integrate these components during the sewing process, ensuring that the electronics are securely anchored and tamper-proof, meeting the strictest EN71 and ASTM F963 safety standards for electronic toys. With Unstoyppable, your "Smart Plush" remains first and foremost a plush toy.

The Engineering Advantage: At Unstoyppable, we view plush manufacturing as a branch of technical engineering. By combining recycled rPET plush fabric, weighted therapeutic technology, and AI-driven interactivity, we provide license holders with a product that is environmentally responsible, emotionally resonant, and technologically superior. Build your 2026 plush strategy on the foundation of Unstoyppable’s material mastery.

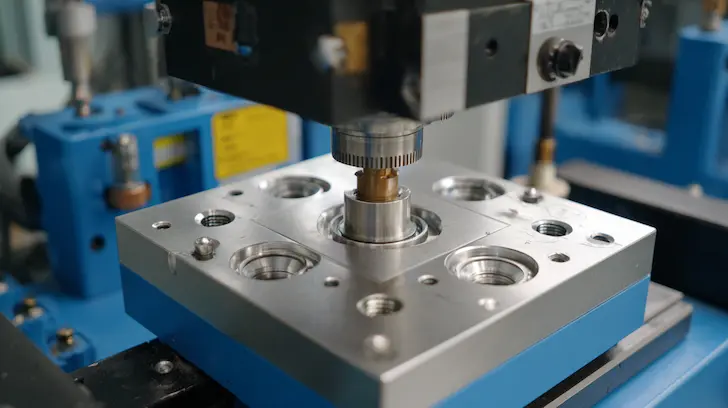

Precision Stitching and Scalable Assembly:

The Unstoyppable Process

Manufacturing soft goods at a global scale requires a rigorous synthesis of artisanal skill and industrial precision. In the 2026 landscape, the custom plush toy manufacturing process has evolved into a highly technical discipline where every millimeter of seam allowance is calculated to ensure 100% character fidelity. At Unstoyppable, we bridge the gap between creative vision and mass-market reality by deploying high-volume plush production systems that maintain the soul of the original IP. By digitizing the traditional sewing room and implementing automated checkpoints, we ensure that every unit—whether it is the 10th or the 100,000th—is an identical, high-quality representation of your brand’s most valuable assets.

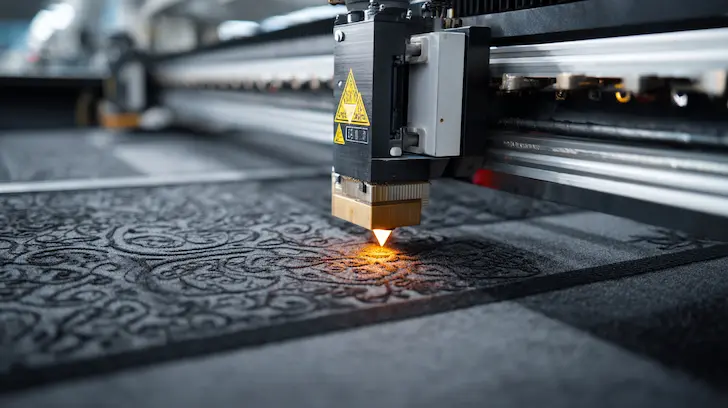

Optimized Fabric Yield and Sustainability

Digital patterning allows our engineers to perform "nesting" simulations, which optimize fabric placement to minimize waste. This efficiency is a core component of our sustainable plush toy materials 2026 initiative. By reducing off-cut waste through algorithmic precision, we lower the environmental footprint of each production run while ensuring that every centimeter of premium plush toy craftsmanship is utilized effectively. Efficiency and accuracy are, in our view, the same objective.

Automated Stuffing Systems:

Achieving Consistent Density

The "hugability" and silhouette of a plush toy are determined by the internal stuffing process. Inconsistent filling can lead to "lumpy" products or toys that cannot stand or sit as designed. Unstoyppable has revolutionized this stage by moving from manual stuffing to automated plush sewing technology and programmed filling systems.

Scale Your Production Without Losing the Details

Your IP deserves more than a "close enough" representation. Partner with a manufacturer that utilizes automated plush sewing technology to protect your brand's soul at scale.

Learn About Character Engineering | See Our Prototyping Phase

IP Security in the Sewing Room:

Safeguarding the Production Floor

For global entertainment brands, the sewing room can be a point of vulnerability if not managed with a secure supply chain for licensed products mindset. Unstoyppable treats the factory floor as a secure data environment, ensuring that your IP is protected from unauthorized overruns or leaks.

Real-Time Fabric and Component Reconciliation

Our high-volume plush production facilities utilize a closed-loop reconciliation system. Every meter of licensed fabric and every branded woven label is tracked via our ERP production tracking system. By comparing the digital cut-logs from our laser systems with the final unit count, we can account for $100\%$ of the raw materials. This unauthorized production prevention strategy ensures that "backdoor" production is a physical impossibility, maintaining the exclusivity of your licensed goods.

Capturing the Character’s Soul in Fabric

The golden sample development process is a five-stage journey:

1. Pattern Iteration: Creating the initial structural skin.

2. Material Matching: Selecting the exact GSM and pile height.

3. Proportion Refinement: Adjusting stuffing density for the perfect silhouette.

4. Detail Embroidery: Perfecting facial expressions.

5. Stress Testing: Subjecting the sample to AQL pull-tests and wash-cycles.

Only when this sample is signed off by your team do we lock the digital patterns for high-volume plush production.

Documentation for Retail Readiness

The final Golden Sample is accompanied by a full technical specification pack. This includes the bill of materials (BOM), the tension-strength requirements for every seam, and the toy safety regulation 2026 compliance roadmap. This documentation ensures that the transition from the prototype lab to the mass production line is seamless, maintaining character-accurate soft toys throughout the product's entire lifecycle.

The Mechanics of Excellence: In 2026, premium plush toy craftsmanship is achieved through a combination of high-tech automation and relentless attention to detail. By utilizing CNC laser cutting, automated stuffing systems, and biometric IP security, Unstoyppable provides a manufacturing environment where quality is guaranteed and IP is absolute. Trust the mechanics of modern plush assembly to bring your characters to life.

Global Compliance for Plush Toys:

Safety Standards in the 2026 Era

In 2026, the regulatory landscape for soft goods has undergone its most significant transformation in a decade. With the full implementation of the 2026 toy safety regulation EU (Regulation (EU) 2025/2509) and updated US standards, "compliance" is no longer a final hurdle—it is a competitive advantage. At Unstoyppable, we act as your strategic gatekeeper, ensuring that every product in your high-volume plush production line meets the world’s most stringent toxicity and mechanical benchmarks. By integrating transparency directly into our manufacturing infrastructure, we facilitate rapid market entry and absolute consumer peace of mind in an era of hyper-scrutiny.

The Mandatory Digital Product Passport (DPP) for Plush

Perhaps the most critical change in 2026 is the requirement for a digital product passport plush toys. Every toy model placed on the EU market must now carry a digital "birth certificate." Unstoyppable’s ERP production tracking system automatically generates this data, linking 3rd-party lab results, manufacturer credentials, and material origins to a unique data carrier (QR code) on the toy's permanent label. This allows customs authorities to perform "Green Lane" verifications instantly, significantly reducing the risk of port delays.

Physical Safety Protocols:

Beyond the Standard "Pull Test"

Plush toys are subject to intense physical interaction, requiring a Zero-Trust approach to mechanical integrity. Our 2026 safety protocols integrate automated precision with rigorous human oversight to eliminate mechanical failure points.

Future-Proof Your Plush Brand for the 2026 Regulatory Shift

Don't let new EU and US regulations stall your movie launch or retail rollout. Connect with Unstoyppable’s toy quality & safety compliance architects to secure your 2026 pipeline.

View Our Compliance Framework | See Our Audited Factory Network

The DPP Scan-to-Verify Experience:

Closing the Trust Loop

The digital product passport plush toys is more than a compliance burden—it is a powerful tool for licensed product authenticity. By scanning the QR code, consumers, retailers, and customs agents can access a wealth of verified information in their local language.

Verifying Ethical Origins and Material Content

The DPP provides a transparent view into the ethical toy manufacturing China process. Consumers can verify that the plush was produced in a Disney FAMA-certified facility and confirm the percentage of recycled rPET plush fabric used. This level of radical transparency builds brand loyalty, as parents in 2026 increasingly prioritize products that can prove their safety and sustainability claims via blockchain toy traceability.