ASTM F963 Compliant Manufacturer:

Mastering the Gold Standard for US Toy Safety

Navigating the North American retail landscape requires a partnership with a highly specialized ASTM F963 compliant manufacturer. In the United States, the Consumer Product Safety Commission (CPSC) mandates that all toys intended for use by children 12 years of age and under must meet the rigorous US toy safety standards codified under ASTM F963. At Unstoyppable, we view these regulations as an engineering blueprint rather than a hurdle. By integrating safety protocols into the very first stages of licensed toy manufacturing USA, we ensure that every product—from complex electronic gadgets to static collectible figures—is physically, mechanically, and chemically optimized for the American consumer. In 2026, staying ahead of CPSC toy regulations means employing advanced Design for Manufacturing (DFM) strategies that eliminate hazards at the source, ensuring a seamless path from the factory floor to major US retailers like Walmart, Target, and Amazon.

Engineering for the 2026 Safety Landscape

Modern toy safety focuses heavily on high-risk components such as button cell batteries, high-powered magnets, and expanding materials. Our toy quality and safety compliance team ensures that your IP is developed using the most current engineering data. We focus on "foreseeable abuse" simulations, which anticipate how a child might interact with a toy in the real world. This proactive engineering stance allows us to build robust licensed toy manufacturing USA solutions that protect the end-user while safeguarding the brand owner from the catastrophic financial and reputational damage of a product recall.

The Essential Benchmark for US Market Entry

Success in the US market is built on trust. By adhering to the US toy safety standards, Unstoyppable provides brand holders with the technical foundation necessary to issue a Children’s Product Certificate (CPC). This certificate is the primary document required by US Customs and Border Protection and major retailers to prove that the product has been tested by a CPSC accepted third party lab. Our role as your manufacturing partner is to ensure that every technical file is complete, every test report is current, and every product is inherently safe.

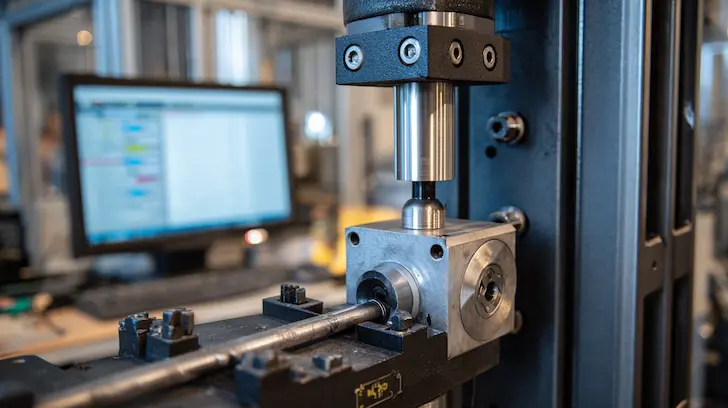

Seam Strength and Structural Reinforcement

For toys that consist of multiple molded parts, the seam is often the weakest point. We utilize high-frequency sonic welding and advanced adhesives to create permanent bonds that exceed the requirements of CPSC toy regulations. By reinforcing internal ribbing and optimizing the wall thickness of the plastic shell, we create a structural integrity that prevents the toy from splintering into sharp edges, even when subjected to extreme compression or twisting forces. This is the hallmark of premium licensed toy manufacturing USA.

Ensure Your US Market Launch is Bulletproof

Excellence in North American safety is an engineering achievement. Consult with our ASTM compliance engineers today to audit your product designs for the 2026 US market.

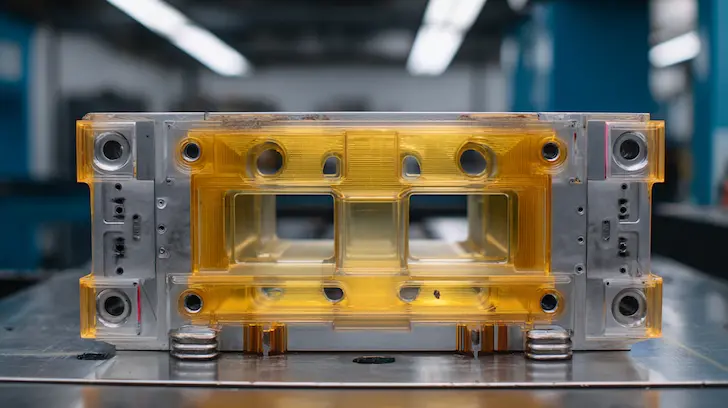

Strategic Wall-Thickness and Energy Dissipation

Our DFM process includes precise calculations for wall thickness—typically ranging from 2.0mm to 3.5mm for high-impact zones. We utilize toy mold flow analysis to ensure that the plastic cools uniformly, preventing internal stresses that could lead to brittle failure points. By adding internal radiused corners and energy-dissipating ribbing, we ensure the toy remains intact after multiple drops. This technical dedication to physical and mechanical toy testing is what allows Unstoyppable to deliver retail-ready products that withstand the rigors of the American playroom.

Age Grading Strategy:

Technical Differentiation for Safety

The ASTM F963 standard applies different criteria based on the intended age of the child. A successful ASTM F963 compliant manufacturer must be adept at engineering products specifically for these tiers.

The Unstoyppable Advantage: In the US market, safety is not a choice; it is a foundational requirement. By mastering ASTM F963 compliant manufacturing through superior physical and mechanical toy testing and polymer science, we provide our clients with the peace of mind that their products are "Unstoyppable." Let us handle the technical complexity of CPSC compliance so you can focus on scaling your brand.

Chemical Integrity:

Heavy Metal Limits and Non-Toxic Material Engineering

In the framework of North American commerce, the chemical composition of a toy is subject to the most intense scrutiny of any consumer product category. Achieving ASTM F963-17 chemical compliance is a sophisticated exercise in molecular management and supply chain discipline. At Unstoyppable, we treat chemical safety as an absolute metric of manufacturing quality. Our lead-free toy manufacturing protocols are designed to exceed the baseline requirements of the Consumer Product Safety Improvement Act (CPSIA), ensuring that every component—from the base substrate to the final decorative flourish—is chemically inert and safe for long-term interaction. By focusing on non-toxic toy materials at the source, we provide IP holders with a robust defense against chemical migration risks, positioning their products as the safest choice for American families and premium retailers alike.

Soluble Heavy Metal Testing:

Precision Beyond the 8 Elements

ASTM F963-17 mandates strict limits on the solubility of eight specific heavy metals. As an expert ASTM F963 compliant manufacturer, we utilize advanced laboratory techniques to ensure these elements remain trapped within the material matrix or are eliminated entirely from the production cycle.

Mastering the "Big Eight" via ICP-MS Analysis

Our ASTM F963-17 chemical compliance workflow centers on the monitoring of Lead (Pb), Antimony (Sb), Arsenic (As), Barium (Ba), Cadmium (Cd), Chromium (Cr), Mercury (Hg), and Selenium (Se). We employ Inductively Coupled Plasma Mass Spectrometry (ICP-MS) to detect these elements at the parts-per-billion level. This high-sensitivity testing ensures that the "soluble" portion of these metals—the amount that could be extracted by stomach acid if swallowed—is effectively non-existent. By maintaining levels significantly below the CPSC-mandated thresholds, we ensure a 100% pass rate during final third-party toy lab testing, providing a foundation of safety for every licensed toy manufacturing USA project.

In-Mold Decoration for Chemically Inert Graphics

Our printing film for mass production is pre-certified for the North American market. Instead of applying paint to a finished toy, we fuse high-definition films directly into the plastic during the injection molding process. These films are engineered using UV-cured, VOC-free inks that contain zero lead or heavy metals. This technical optimization ensures that the character's vibrant colors and intricate details are "locked" within the surface layer, making them resistant to saliva and friction. This method is the definitive solution for character product manufacturing where high-detail aesthetics must coexist with absolute ASTM F963-17 chemical compliance.

Durability as a Safety Feature

A decorative finish that flakes or peels is a physical and chemical hazard. By using printing film for toy materials, we create a finish that is structurally part of the toy itself. This permanent bond ensures that graphics remain intact throughout the toy's lifecycle, preventing the ingestion of small paint chips. This high-durability approach is essential for maintaining the premium "licensed look" required by entertainment brands while meeting the non-toxic toy pigments standards of the US market.

Don't Risk a CPSC Recall

Chemical safety is the silent guardian of your brand's reputation. Discover how our clean-room compounding and pre-certified printing films guarantee 100% chemical integrity.

Learn About Phthalate-Free Standards | Explore Advanced Material Science

High-Performance Phthalate-Free Materials

In addition to heavy metals, we manage the migration of plasticizers. Our phthalate-free toy materials utilize high-performance alternatives like DOTP or DINCH, which provide the flexibility required for PVC figure manufacturer projects without the endocrine-disrupting risks. By balancing polymer flexibility with chemical stability, we ensure your product remains soft and tactile while staying fully compliant with the latest US phthalate-free toy materials mandates.

Food-Contact Grade Pigments:

Safety by Design

We treat every toy with the same chemical reverence as a product intended for food contact. This "food-grade" philosophy ensures that even "mouthable" toys are safe for the youngest consumers.

The Molecular Advantage: At Unstoyppable, we believe that chemical safety is the ultimate expression of quality. By mastering ASTM F963-17 chemical compliance through non-toxic toy materials and printing film safety USA standards, we deliver products that are safe to the core. Let us protect your brand through scientific manufacturing excellence.

Industrial Accountability:

CPSC-Accepted Lab Testing and Global Documentation

In the final phase of North American production, the transition from factory floor to retail shelf is governed by strict industrial accountability. Being a premier ASTM F963 compliant manufacturer requires more than engineering excellence; it demands a flawlessly executed validation ecosystem. At Unstoyppable, we provide a turnkey solution that encompasses CPSC accepted third party lab coordination, ethical factory auditing, and comprehensive certification management. This systematic approach ensures that your licensed toy manufacturing USA project is backed by a robust audit trail, satisfying the compliance departments of major retailers and federal customs agents alike. By managing the complexities of ASTM toy testing workflow and FAMA compliant factory China standards, we ensure that your product arrives at its destination 100% "ready-to-sell," protecting your brand from the logistical bottlenecks that often hinder global toy launches.

The CPC Process:

Your Passport to US Retail

For any children's product entering the United States, the Children’s Product Certificate (CPC) is the most critical document in the supply chain. We treat Children’s Product Certificate (CPC) preparation as a core manufacturing deliverable.

Streamlining Compliance for Walmart, Target, and Amazon

A CPC is a legal statement that certifies the toy meets all applicable US toy safety standards. As your manufacturing partner, we compile the necessary data from CPSC accepted third party lab reports and material specifications to draft a precise CPC. This document is essential for clearing US Customs and is a mandatory requirement for listing products on major e-commerce platforms like Amazon or securing shelf space at big-box retailers. Our toy quality assurance protocols ensure that every CPC is accurate, up-to-date with 2026 regulations, and easily accessible for retail compliance audits, providing you with a frictionless entry into the North American market.

Coordinating with UL, QIMA, and SGS

Our ASTM toy testing workflow involves submitting production-grade samples to labs such as UL, QIMA, or SGS for exhaustive "Use and Abuse" testing. These labs subject the toy to extreme torque, tension, and compression to verify that our physical and mechanical toy testing simulations in the factory were accurate. By managing this coordination on your behalf, we ensure that the testing is performed according to the correct age-grading and product category, preventing the common "testing loop" errors that cause production delays. This professional lab management is a cornerstone of our retail-ready licensed product production.

Validation of Chemical and Mechanical Integrity

The lab verification process covers both the invisible (chemical) and the visible (mechanical). From lead-free toy manufacturing confirmation to the verification of battery compartment security, the third-party report serves as the final seal of approval. By utilizing labs that are recognized globally, we ensure that your licensed merchandise manufacturer reports are accepted by every major safety authority in North America, streamlining your path to global distribution.

Bridge the Gap from China to the US Retail Shelf

Excellence in production is only complete with excellence in validation. Get a comprehensive quote for your ASTM F963 certified, retail-ready production run today.

Explore Independent Lab Testing | Review Packaging Solutions

Battery and Magnet Security:

Technical Execution

For electronic or magnetic toys, ASTM F963 imposes some of its strictest mechanical requirements. Our engineering for mass production team utilizes recessed, captive screws for battery compartments, ensuring they are inaccessible to children without a tool. For magnets, we utilize ultrasonic welding to encapsulate them within internal housings, meeting the "Magnet Soak Test" and "Impact Test" requirements. This technical execution is what allows us to remain a top-tier ASTM F963 compliant manufacturer for the most complex electronic toy manufacturer projects.