Electronic Toy Manufacturer:

Engineering the Future of Interactive Play

In the rapidly evolving landscape of 2026, the definition of a toy has shifted from a static object to a sophisticated interactive experience. As a premier electronic toy manufacturer, Unstoyppable stands at the intersection of hardware innovation and character storytelling. We understand that electronics are the heartbeat of the modern license; they provide the personality, the voice, and the "magic" that defines a brand in the digital age. Our smart toy development China infrastructure is designed to handle the complexities of modern mechatronics, ensuring that your IP is powered by reliable, high-performance circuitry that fits seamlessly into the palm of a child’s hand.

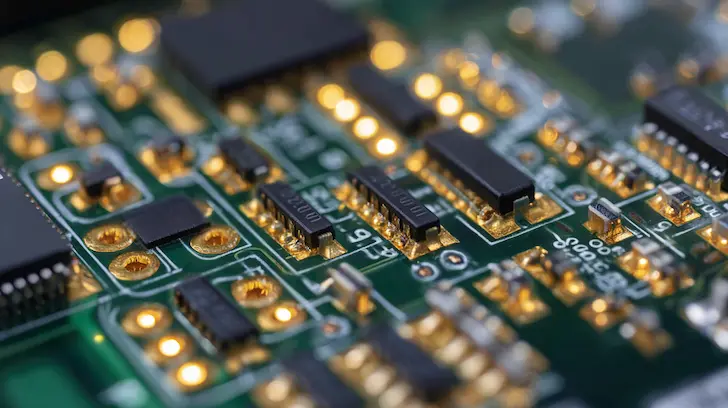

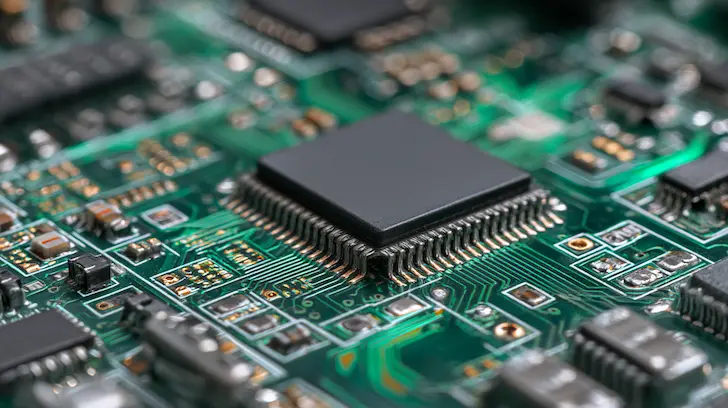

Low-Power Microcontroller Optimization

Our 2026 engineering protocols prioritize ultra-low-power microcontrollers (MCUs) that extend play-life while minimizing thermal output. By optimizing the firmware at the chip level, we ensure that character movements and sounds are fluid and responsive. This technical precision is essential for interactive character electronics where any latency in the "trigger-to-response" loop can break the immersion of the play experience. We utilize high-speed SMT (Surface Mount Technology) lines to populate boards with 0201 components, allowing us to pack Bluetooth modules, sound chips, and motor drivers into the tightest spatial constraints.

Durability-First Component Sourcing

Unlike consumer electronics meant for adults, smart toy development China requires components that withstand the high-G forces of drops and the vibrations of mechanical movement. We source industrial-grade oscillators and ruggedized capacitors to ensure that the electronic "brain" of your toy remains functional after years of rigorous play. Every PCBA undergoes automated optical inspection (AOI) and functional circuit testing (FCT) before it ever meets its plastic housing, ensuring a zero-defect rate for your licensed merchandise manufacturing projects.

6-Axis Gyroscopes and Accelerometers

By embedding 6-axis inertial measurement units (IMUs), we enable toys to "know" their orientation. Whether it is a spaceship that makes engine noises when banked or a doll that "goes to sleep" when laid down, our electronic toy manufacturer expertise ensures the motion-to-sound mapping is flawless. We use advanced filtering algorithms to distinguish between intentional play and accidental movement, providing a sophisticated user experience that aligns with the highest standards of entertainment merchandise manufacturing.

Bring Your Character to Life with Smart Technology

In the 2026 market, connectivity is the key to consumer engagement. Let our engineers build the digital soul of your next licensed masterpiece.

Over-The-Air (OTA) Firmware Updates

To future-proof your product, we incorporate OTA update capabilities. This allows license holders to push new character voices, seasonal dialogue, or even new play modes to the toy long after it has left the retail shelf. This "Toy-as-a-Service" model is a hallmark of smart toy development China in 2026, ensuring that the hardware remains relevant and updated with the latest brand content. Our secure bootloader technology ensures these updates are encrypted, maintaining IP protection in China manufacturing.

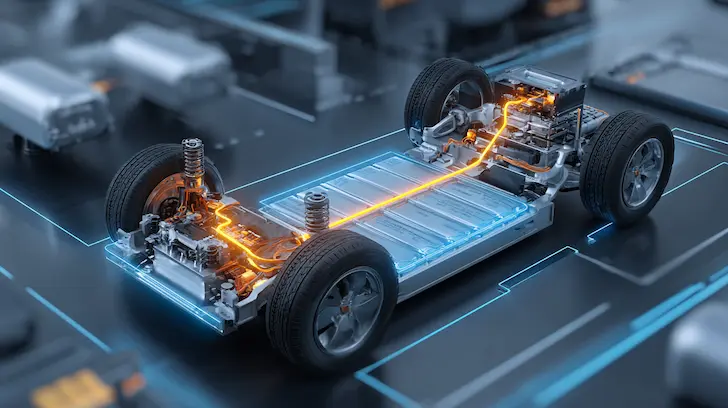

Power Management & Battery Safety:

The 2026 Gold Standard

With the increasing power demands of LEDs, speakers, and motors, power management for electronic toys is a critical safety and performance pillar. Unstoyppable utilizes high-cycle lithium-ion (Li-ion) and NiMH battery technologies with integrated protection circuits to ensure every play session is safe.

The Technological Edge: At Unstoyppable, we don't just put batteries in toys; we engineer intelligent systems. By combining high-density PCBA design, advanced sensory integration, and secure BLE connectivity, we provide the technical foundation for the world's most successful smart toys. Lead the 2026 retail landscape with the power of Unstoyppable’s electronic engineering.

Precision Housing:

Injection Molding for Electronic Toy Integrity

In the sophisticated world of 2026 electronic toy manufacturing, the outer shell is far more than a decorative container. It is a high-performance mechanical infrastructure engineered to shield delicate internal circuitry while delivering a premium user experience. At Unstoyppable, we bridge the gap between high-tech hardware and durable physical assets. Our approach to injection molded electronic toys prioritizes structural "survivability" and aesthetic refinement, ensuring that the character's housing remains as flawless as the software inside. For global brands, this means a product that can withstand the rigors of heavy play while maintaining the high-fidelity sound and visual brilliance expected from top-tier entertainment assets.

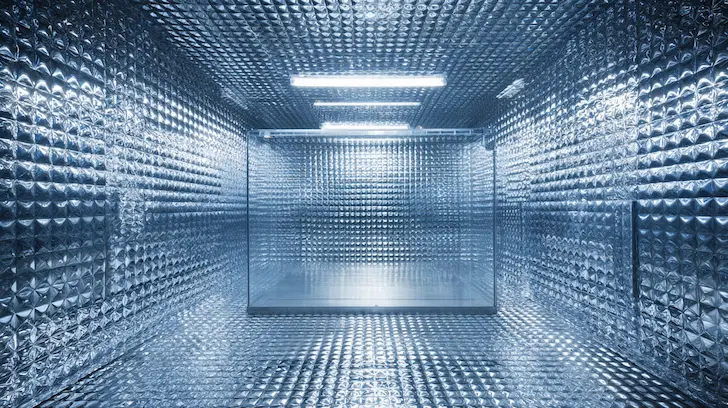

Acoustic Chamber Engineering:

High-Fidelity Sound from the Inside Out

A primary differentiator for modern licensed toys is audio quality. Traditional toys often suffer from "tinny" sound or rattle due to poor mechanical design. In 2026, Unstoyppable utilizes advanced acoustic chamber engineering within the injection mold design to create resonant, high-clarity environments for high-fidelity toy speakers.

Internal Ribbing and Resonance Control

Using 3D acoustic modeling, we design internal ribbing and baffles directly into the plastic housing. These structural elements serve two purposes: they reinforce the shell for durability and act as acoustic waveguides to direct sound waves toward the speaker port without internal echo. This eliminates the "hollow plastic" sound, providing a rich, deep audio profile that enhances the character's voice or music. By optimizing the air volume within the injection molded electronic toys, we achieve a frequency response usually reserved for high-end consumer electronics.

Anti-Static Additives in Injection Molding

We utilize specialized anti-static additives blended directly into the ABS or Polycarbonate resin during the high-precision injection molding process. These additives create a dissipative surface that prevents the buildup of static electricity. This is essential for toys featuring capacitive touch zones or Bluetooth modules, where internal components are in close proximity to the user's touch. Unlike topical sprays, these internal additives provide permanent protection that will not wear off over the product's lifespan.

Strategic Grounding and Shielding

Beyond material science, our electronic toy manufacturer expertise includes the engineering of internal "EMI shields" and grounding paths. For high-frequency devices, we can apply conductive coatings to the interior of the housing or utilize metal-insert molding to create a Faraday cage effect. This protects the interactive character electronics from external interference and ensures the toy passes global EMC (Electromagnetic Compatibility) standards with ease.

Seamlessly Blend Hardware with Housing

Don't let poor housing design compromise your high-tech hardware. Protect your investment with ESD-safe, acoustically optimized enclosures.

See Our Molding Capabilities | Learn About Tooling Excellence

Reinforced Screw Bosses and Thread Integrity

For toys requiring permanent closure, we utilize reinforced screw bosses with molded-in brass inserts or specialized thread-forming screws designed for thermoplastics. This prevents the plastic from stripping or cracking over time, a common failure point in lower-tier manufacturing. By maintaining a 1.5mm to 3.0mm wall thickness around critical mounting points, we ensure that the internal PCBA design for toys remains perfectly aligned with the exterior buttons and sensors, even after a 2-meter drop test.

In-Mold Decoration (IMD):

Interactive Surfaces and Hidden Displays

Visual interfaces in 2026 have moved beyond physical buttons. Unstoyppable utilizes In-Mold Decoration (IMD) and "Dead-Front" printing to create futuristic, interactive surfaces for smart toy development China.

The Industrial Advantage: At Unstoyppable, we treat the toy's housing as a critical piece of hardware. By integrating acoustic engineering, ESD protection, and In-Mold Decoration, we deliver a high-velocity toy injection molding solution that protects your electronics and elevates your brand. Build your next smart product on a foundation of mechanical excellence.

Global Compliance for Smart Toys:

EMC, RF, and 2026 DPP Mandates

In the high-tech landscape of 2026, launching an interactive product requires navigating a complex web of electromagnetic and digital regulations. At Unstoyppable, we view regulatory adherence as the ultimate bridge to market entry rather than a hurdle. As a specialized electronic toy manufacturer, we provide a fortified "regulatory gatekeeper" service that ensures your product meets every international standard for safety and connectivity. From shielding your brand against costly recalls to ensuring seamless customs clearance, our electronic toy safety testing protocols are designed to protect both the child user and the license holder’s global reputation. We ensure that every smart character you produce is a masterpiece of legal and technical compliance.

EMC & RF Certification:

Navigating the Wireless Frontier

For any toy featuring Bluetooth toy manufacturing or Wi-Fi connectivity, managing radio frequency (RF) emissions is paramount. In 2026, global spectrum authorities have tightened their oversight of "Smart" consumer goods to prevent interference with critical communication networks. Unstoyppable manages the entire certification lifecycle, ensuring your product is ready for global distribution.

FCC, CE-RED, and SRRC Mastery

Our engineering team coordinates EMC testing for interactive toys to ensure full compliance with the FCC (Federal Communications Commission) in the United States, the CE-RED (Radio Equipment Directive) in the European Union, and the SRRC (State Radio Regulation of China). By performing pre-compliance testing in our partner laboratories during the PCBA design for toys phase, we identify and mitigate potential EMI (Electromagnetic Interference) issues before final certification. This proactive approach saves months of delay and ensures a smooth, FCC compliant toy manufacturer experience for our clients.

Lead-Free and Non-Toxic Electronics

We utilize 100% lead-free soldering processes and source RoHS compliant electronics China. Every resistor, capacitor, and IC on our boards is screened for phthalates, cadmium, and hexavalent chromium. This commitment to "clean" electronics ensures that your product is safe for disposal and recycling, aligning with the 2026 mandates for sustainable toy manufacturing. By providing a verified ethical supply chain, we allow your brand to lead in environmental corporate social responsibility.

WEEE Registration and Take-Back Strategies

To assist our partners in meeting EU 2026 standards, we provide guidance on WEEE labeling and producer responsibility. Our products are designed for "easy disassembly," allowing recyclers to separate the battery and PCBA from the injection molded electronic toys housing. This forward-thinking engineering not only meets current law but future-proofs your brand against the tightening regulations of the coming decade.

Future-Proof Your Electronic Toy Line

In 2026, digital transparency is the key to consumer trust. Partner with a manufacturer that masters the new digital and safety landscape.

Supply Chain Traceability

The DPP also captures the origin of critical components, such as the Li-ion battery and the primary microcontroller. By providing this level of transparent supply chain manufacturing, Unstoyppable helps license holders meet the 2026 ESG (Environmental, Social, and Governance) reporting requirements. This data is stored on secure, decentralized ledgers, ensuring the information remains permanent and tamper-proof.

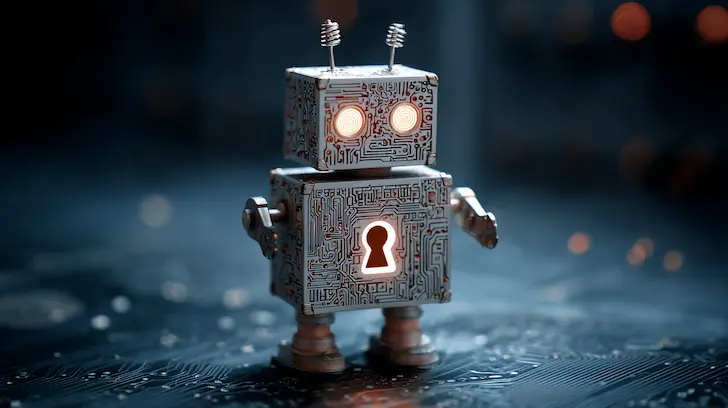

Firmware Security & IP Protection:

Safeguarding the Code

For a 2026 electronic toy manufacturer, protecting the software is as important as protecting the physical mold. Our firmware security protocols ensure that your character’s voice, personality, and proprietary sounds remain exclusive to your brand.