Manufacturing for Entertainment Brands:

Turning Digital IP into Physical Reality

In the vibrant and fast-paced world of 2026 media, the journey from a digital render to a fan’s hands is a high-stakes performance. Manufacturing for entertainment brands is no longer just about mass production; it is about capturing the "magic" of a franchise and anchoring it in a tangible, high-quality physical product. At Unstoyppable, we act as the premier bridge between global studios and the retail market. We understand that for streaming giants, cinematic powerhouses, and gaming titans, the merchandise is an extension of the storytelling experience. Our entertainment merchandise manufacturing solutions are engineered to meet the extreme demands of modern hype cycles, ensuring that every collectible, plush, and action figure resonates with the authenticity of the original IP. By combining visionary streaming brand product development with rigid industrial discipline, we ensure your franchise’s physical presence is as legendary as its digital debut.

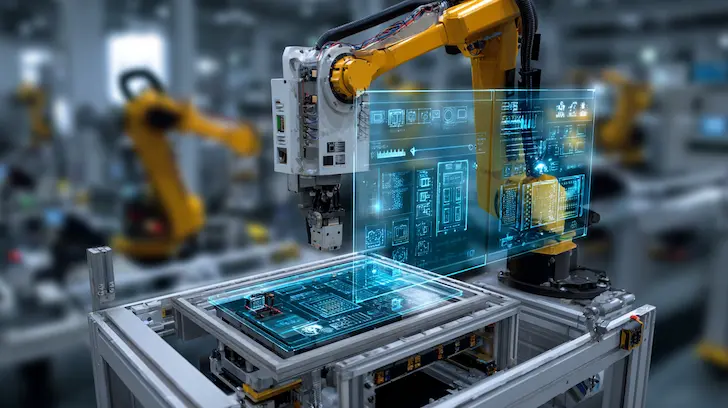

From Digital CGI to Character Engineering

When a studio shares their high-poly assets, our team of experts utilizes character engineering for toys to translate those complex digital files into manufacturable parts. We take the intricate textures of a superhero’s suit or the subtle facial expressions of an animated protagonist and adapt them for injection molded toy manufacturer processes. This phase is critical; it is where we determine the articulation points, the material density, and the assembly logic that allows a digital character to function as a durable, screen-accurate physical object. Our engineers ensure that the "soul" of the character is preserved through every step of the custom licensed product development pipeline.

Technical Prototype Validation

Before mass production begins, we produce high-fidelity prototypes that serve as the "north star" for the project. Using advanced 3D printing and hand-painting techniques, we create a physical representation that studios use for final approval. This process ensures that when the entertainment merchandise manufacturing phase kicks off, the resulting products are exactly what the fans expect. By mastering the golden sample development process, we eliminate the risk of aesthetic drift, ensuring that the final retail product is a perfect mirror of the on-screen icon.

Securing the Supply Chain from Leakage

Our commitment to ip security factory compliance extends beyond the factory walls. We manage a secure supply chain for licensed products that monitors the movement of components and waste materials. Even defective parts or "scraps" from the injection molded toy manufacturer process are destroyed under supervision to ensure that no unauthorized character fragments ever leave the facility. This holistic approach to security ensures that your "Big Reveal" remains a surprise for the audience, protected by the most robust anti-counterfeit manufacturing systems in the industry.

Bring Your Franchise to Life

Partner with a studio-approved toy manufacturer that speaks the language of entertainment and respects the sanctity of your IP.

Maintaining Quality During High-Volume Surges

Rapid scaling never comes at the expense of quality. Our toy quality and safety compliance teams remain embedded in every factory, using AQL inspection in toy manufacturing to ensure that the 1,000,000th unit is identical to the first. By utilizing standardized mold development & injection tooling across our network, we maintain consistency in character product manufacturing regardless of the production volume. This ability to balance "speed-to-market" with "brand-standard-quality" is what makes us a leader in streaming brand product development.

FAMA as the Foundation:

The Gold Standard for Studios

In the entertainment sector, ethical compliance is the price of entry. For brands like Disney, Marvel, and Star Wars, a FAMA compliant factory in China is the only acceptable manufacturing destination.

Executive Summary: Manufacturing for entertainment brands requires a rare combination of creative empathy and industrial might. At Unstoyppable, we bridge this gap by providing studio-approved toy manufacturer services, character engineering for toys, and FAMA compliant distribution. We turn your digital dreams into the retail sensations of 2026. Your IP is our passion.

Engineering the Icons:

Technical Precision in Entertainment Merchandise

In the specialized realm of 2026 fandom, the "Super-Fan" demographic demands a level of realism that blurs the line between a retail product and a cinematic prop. Achieving screen-accurate toy production requires a sophisticated fusion of high-level industrial engineering and artisanal craftsmanship. At Unstoyppable, we recognize that entertainment brands rely on visual fidelity to maintain brand equity. Our entertainment-grade collectible manufacturing process is designed to capture the nuance of every sculpt, the texture of every costume, and the specific "sheen" of cinematic materials. By leveraging high-fidelity character moulding and advanced material science, we transform iconic digital assets into physical masterpieces that satisfy the most discerning collectors. Technical precision is the vehicle through which we deliver the emotional connection fans have with their favorite franchises.

Moulding the Legend:

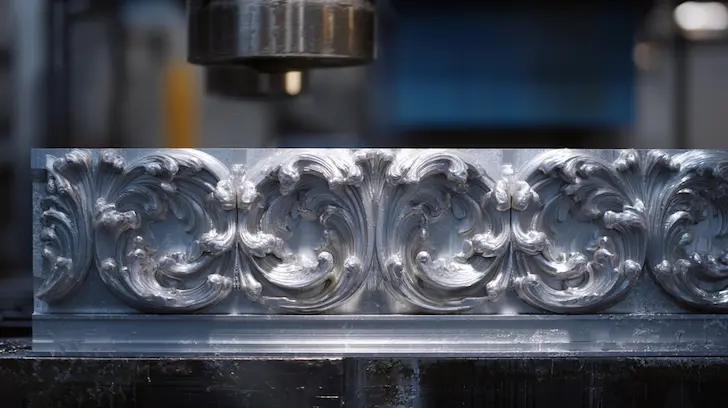

Microscopic Detail and Tooling Excellence

The foundation of any legendary character figure lies in the tool. To achieve the hyper-detailed facial expressions and intricate armor textures seen in modern blockbusters, our advanced toy tooling R&D team pushes the boundaries of traditional mold making.

High-Fidelity Character Moulding Techniques

We utilize ultra-precision CNC machining and EDM (Electrical Discharge Machining) to create multi-cavity molds with tolerances measured in microns. This allows our injection molded toy manufacturer lines to replicate microscopic details, such as the skin pores of an alien creature or the woven fiber patterns of a superhero’s suit. By utilizing Beryllium copper inserts in high-detail areas of the mold, we ensure superior heat dissipation, which results in a sharper "crispness" of the plastic part. This technical rigor ensures that the character engineering for toys performed during the digital phase is perfectly preserved in the physical pvc figure manufacturer output.

Differentiating Play-Line from Deluxe Collector Editions

We provide a spectrum of phthalate-free toy materials that allow brands to target different market segments. For standard play-lines, we utilize high-impact ABS and durable PVC that prioritize playability and safety. For "Deluxe" or "Master" editions, we engage in "Material Alchemy"—mixing resins with metallic powders to create a cold-to-the-touch "Die-Cast" feel, or utilizing ultra-soft, "flesh-like" TPE for hyper-realistic skin. This character-accurate material engineering ensures that the weight, balance, and surface friction of the product align with the fan’s expectations of a premium collectible.

Soft-Touch Finishes and Composite Materials

Many iconic entertainment characters feature costumes with mixed textures—leather, metal, and fabric. We replicate these through the strategic use of over-molding and soft-touch sprays. By applying a specialized matte "rubberized" coating over injection molded toy manufacturer parts, we can simulate the appearance of tactical gear or organic skins. This technical versatility is essential for custom licensed product development, where the goal is to create a multi-material aesthetic using efficient, mass-production techniques. Every gram of material is chosen for its ability to enhance the screen-accurate toy production values of the final unit.

Achieve Cinematic Quality on the Retail Shelf

Elevate your merchandise with high-fidelity character moulding and advanced printing for licensed toys.

Explore Character Engineering | See PVC Sculpting Capabilities

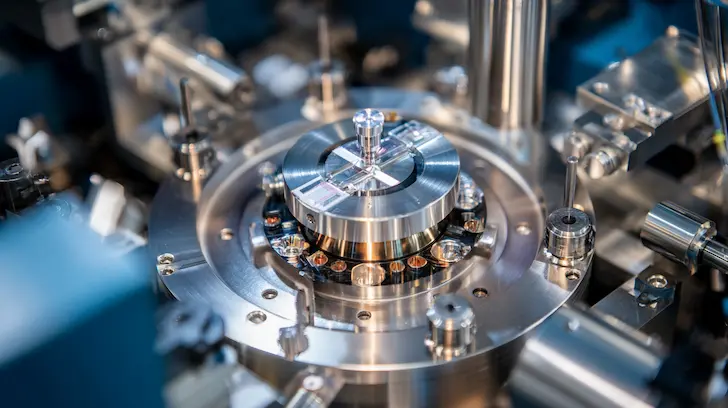

High-Fidelity Vacuum Metallization

For characters with metallic or robotic elements, we employ vacuum metallization and electroplating. This creates a true mirror-finish that is superior to standard metallic paints. By applying a protective UV-cured topcoat, we ensure that the metallic finish is resistant to fingerprints and oxidation, maintaining the "out-of-the-box" luster for years. This attention to decorative detail is what distinguishes Unstoyppable as a premier entertainment merchandise manufacturer, capable of delivering the luxury finish that "Super-Fans" prioritize.

Electronic Integration:

Bringing Screen Moments to Life

In 2026, the most successful entertainment toys are interactive. We specialize in the electronic toy manufacturer sector, integrating technology that adds a fourth dimension to the character.

Technical Execution Note: Manufacturing for entertainment brands is a commitment to the fan experience. Through character-accurate material engineering and high-fidelity character moulding, we ensure that every unit produced is a worthy representative of the brand's legacy. At Unstoyppable, we don't just make toys; we engineer icons.

Global Rollouts:

Compliance and Logistics for Major Media Franchises

The successful launch of a global media franchise is a logistical ballet that requires perfect timing and unshakeable integrity. In 2026, media franchise product logistics have evolved beyond mere transportation; they are now a strategic component of the brand's narrative. At Unstoyppable, we specialize in the high-stakes world of synchronized global releases. We understand that for a studio executive, the nightmare scenario is a "shelf-out" during a premiere or a compliance scandal that tarnish a billion-dollar IP. Our systems are engineered to provide total peace of mind, ensuring that your entertainment supply chain compliance is ironclad and your products arrive exactly when the "Hype Cycle" peaks. By leveraging our studio-audited factory network, we guarantee that the ethical journey of the product is as pristine as the characters themselves.

The "Zero-Day" Launch:

Mastering Global Street-Date Fulfillment

In the entertainment industry, timing is the ultimate currency. A "Zero-Day" launch means that toys must be physically present in tens of thousands of retail locations across multiple continents the moment the credits roll on a 2026 summer blockbuster.

Coordinating Global Distribution for Licensed Products

Achieving global street-date fulfillment requires a manufacturer that manages production and logistics as a single, unified stream. We utilize predictive toy manufacturing logistics to account for maritime transit times, customs clearance windows, and inland distribution delays. Our ERP system tracks every container, providing real-time visibility into the movement of your assets. This high-level coordination ensures that retail partners—from mass-market hypermarkets to specialized hobby shops—receive their inventory in perfect sync with your global marketing campaign. This logistical precision is why Unstoyppable is the preferred partner for manufacturing for entertainment brands that cannot afford a second of delay.

The Studio-Audited Factory Network

Every facility within our studio-audited factory network undergoes rigorous, recurring inspections. By maintaining BSCI & Sedex audited toy factory status, we provide the documented proof of fair wages, safe working conditions, and zero child labor that major studios demand. This transparency is vital for brands that represent "Family Fun" and wholesome entertainment. We treat compliance as a continuous process, not a one-time certificate, ensuring that your entertainment supply chain compliance is always audit-ready for Disney, Warner Bros, or Netflix inspectors.

FAMA Compliance:

The Studio Standard

For Disney and Marvel licensees, FAMA compliant distribution is the non-negotiable standard. We ensure that every injection molded toy manufacturer and plush toy manufacturer China partner we utilize is fully authorized under the Disney Facility and Merchandise Authorization (FAMA) program. This provides an additional layer of protection, ensuring that your entertainment merchandise manufacturing project is handled by professionals who understand the legal and ethical weight of working with world-class IP. Our commitment to ethical toy manufacturing China ensures that your brand’s story remains positive from the factory floor to the fan’s home.

Dominate the 2026 Retail Landscape

Secure your franchise’s supply chain with a partner that understands the stakes of a global premiere.

Sustainable Retail-Ready Solutions

As fans become more environmentally conscious, we offer sustainable toy manufacturing packaging options. This includes plastic-free internal trays made from molded pulp or FSC-certified paper structures that maintain the high-end look of character product manufacturing without the ecological footprint. By optimizing the size and weight of our packaging, we also improve your media franchise product logistics efficiency, reducing shipping costs while meeting the "Green" requirements of modern global retailers.

Post-Launch Agility:

Managing the Long-Tail of Fandom

A franchise’s life continues long after the movie premiere. Our entertainment merchandise manufacturing model is built for the "Long-Tail," allowing for rapid re-orders and seasonal expansions.