The Engineering Foundation:

Translating Imagination into Industrial Reality

In the competitive landscape of 2026, the transition from a creative spark to a retail-ready masterpiece requires more than just artistic vision; it demands a rigorous engineering foundation. At Unstoyppable, we serve as the technical bridge between your intellectual property and the complex realities of mass production. As a specialized licensed product manufacturer, our engineering team ensures that every curve, joint, and material choice is optimized for structural integrity, safety compliance, and cost-efficient manufacturing. We don't just build toys; we engineer durable brand legacies with full IP protection.

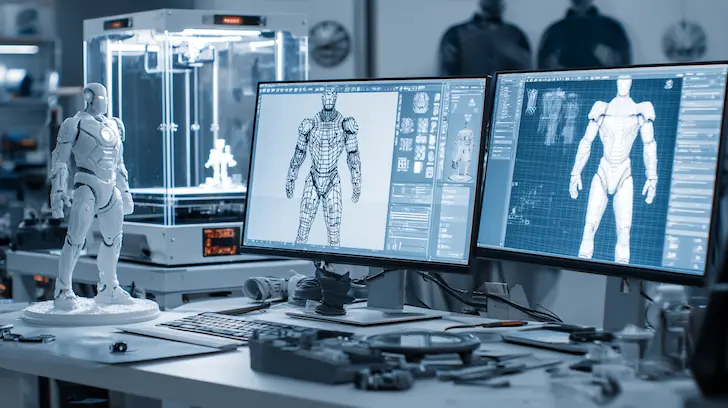

From 2D Style Guides to High-Precision 3D CAD

We begin by converting your 2D character sheets and turnarounds into high-precision 3D CAD (Computer-Aided Design) data. Utilizing industry-standard software like SolidWorks, ZBrush, and Rhino, our engineers meticulously build the digital geometry. This is where we interpret perspective and depth that might be "cheated" in 2D drawings. By establishing a robust digital master, we ensure that every subsequent step—from mold development to assembly—is based on identical, flawless data, preventing the "design drift" that often plagues less experienced factories.

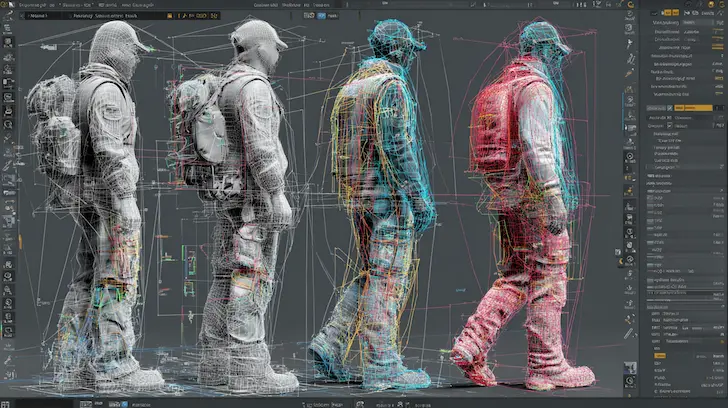

The "Anatomy of a Toy":

Balancing Aesthetics with Internal Support

A beautiful exterior is only as good as the structure supporting it. Our engineers design the "internal anatomy" of the toy, incorporating hidden structural supports, screw bosses, and "ribbing" to prevent warping and sink marks during the cooling process. We balance the wall thickness of the plastic to ensure it is lightweight for shipping but rigid enough to survive the rigorous play of a child. This internal engineering is invisible to the consumer but critical for passing ASTM F963 and EN71 safety standards.

Substrate Selection:

ABS, PVC, and Beyond

We select substrate materials based on the target age-grade and functional needs of the part. For example, we typically utilize ABS (Acrylonitrile Butadiene Styrene) for rigid internal skeletons or building blocks due to its high impact resistance and dimensional stability. For the softer, more tactile outer "skin" of a figure, we use high-grade PVC or TPE (Thermoplastic Elastomer). By engineering the interaction between these different materials, we create products that are both indestructible and comfortable to handle.

The Chemistry of Safety:

Phthalate-Free and BPA-Free Polymers

Safety is the non-negotiable cornerstone of our manufacturing technology. Our materials are engineered to be 100% phthalate-free, BPA-free, and lead-safe. In 2026, we have moved toward "Bio-Balanced" polymers that replace traditional fossil-fuel-based plasticizers with vegetable-oil-derived alternatives. These advanced materials provide the same flexibility and vibrant color-retention as traditional plastics but with a significantly lower toxicity profile, ensuring your brand is always protected from shifting global chemical regulations.

A great toy begins with flawless data.

Our Character Engineering for Toys team ensures your IP is structurally sound and ready for the world.

Request a Technical Design Review or explore our Toy Material Engineering standards.

Our FEA simulations include drop test simulations onto hard concrete, tension tests for small parts (to prevent choking hazards), and compression tests for heavy playsets. By simulating these real-world play scenarios in a digital environment, we ensure that your product is "Born Tough." This proactive engineering approach is why Unstoyppable is the preferred partner for high-stakes entertainment merchandise manufacturing, where failure is not an option.

The result of this rigorous foundation is a "production-ready" design that is optimized for our Prototyping Stage. From here, we move into physical validation, ensuring that the digital brilliance we've engineered translates perfectly into a tangible Golden Sample. Our product manufacturing capabilities are designed to take this flawless engineering and scale it to global retail volumes without a single compromise in quality.

Rapid Prototyping:

De-risking Development with 2026 Technology

In the fast-paced world of licensed product manufacturing, the bridge between a digital 3D model and a mass-produced retail unit is built through physical validation. Rapid prototyping is the essential phase where we identify potential challenges, refine aesthetics, and ensure mechanical functionality before investing in expensive steel tooling. At Unstoyppable, we leverage 2026’s most advanced additive manufacturing and subtractive machining technologies to provide our clients with a clear, tangible roadmap to success. By utilizing a multi-stage iterative process, we effectively de-risk your investment, ensuring that the final product is a perfect realization of your brand’s vision.

Prototyping is a strategic safeguard. It is a collaborative journey that allows brand owners, engineers, and stakeholders to hold the product in their hands, evaluate its "shelf presence," and test its play features. Our toy prototyping manufacturer services are designed to be agile, allowing for rapid adjustments that save months of time during the licensed toy manufacturing cycle. We provide the physical proof that your concept is not only beautiful but also ready for the rigors of the global market.

Toy Prototyping Manufacturer:

The Multi-Stage Iteration Process

A high-quality toy evolves through several distinct physical forms. Each stage of the toy prototyping manufacturer process serves a specific purpose, from basic aesthetic checks to complex mechanical endurance testing. By following this structured path, we guarantee that every detail is polished to perfection.

Visual Prototype (Looks-Like):

Aesthetic Approval and Form Study

The Visual Prototype, often called the "Looks-Like" sample, focuses entirely on the product’s exterior. We utilize high-resolution SLA (Stereolithography) resin printing to capture every microscopic detail of your character’s sculpt. These models are typically monochromatic or basic-colored and are used to evaluate proportions, silhouette, and character likeness. It is the first time a 2D design becomes a 3D reality, providing the perfect opportunity for brand owners to provide "on-model" creative feedback before any mechanical complexity is added.

Golden Sample Development Process:

The Final Benchmark

The culmination of the prototyping journey is the Golden Sample. This is the single most important physical asset in the entire licensed merchandise manufacturing workflow. The Golden Sample is the final, approved version of the product that has passed all creative, mechanical, and safety reviews.

The Master Reference for Mass Production and QC

The Golden Sample Development Process creates a "contractual benchmark." Once approved, this sample is locked in a secure environment and serves as the master reference for our AQL inspection in toy manufacturing. Mass-produced units are compared directly against the Golden Sample for color accuracy, weight, joint tension, and finish. Having a physical Golden Sample ensures that there is zero ambiguity during the OEM manufacturing phase, protecting your brand from "quality fade" during long production runs.

Don't guess—validate your vision with precision.

Our Toy Prototyping Manufacturer services slash development time by up to 40% using 2026 technology. See our [Golden Sample Development Process] in action or learn more about our [Design for Mass Production (DFM)] strategies. Explore Prototyping Solutions.

Simplifying Assembly to Reduce Error and Cost

During the DFM review, our engineers look for ways to simplify the toy manufacturing logistics. We aim to reduce the total part count by combining components where possible and designing "self-aligning" parts that can only be assembled in one way. This "Poka-Yoke" (mistake-proofing) approach drastically reduces human error on the assembly line, ensures consistent quality, and lowers the overall landed cost in manufacturing for our clients.

Draft Angles and Wall Thickness Optimization

For a product to be successfully injection molded, it must follow specific geometric rules. We meticulously calculate and implement Draft Angles—a slight taper on the sides of the part—which allows the plastic to slide out of the steel mold without friction or damage. We also optimize Wall Thickness to ensure even cooling. Uniform walls prevent "sink marks" (dents in the plastic) and warping, ensuring that every piece of your custom licensed product development project is structurally perfect and aesthetically flawless.

The journey from a digital concept to a physical masterpiece is a precision-driven process. By mastering rapid prototyping and the Golden Sample process, we provide you with the confidence to move into the mold development and injection tooling phase with total peace of mind. We invite you to explore our Custom Licensed Product Development and Toy Manufacturing Process pages to see how we carry this excellence through to final delivery.

Precision Tooling:

The Heart of Mass Production

In the world of high-volume licensed product manufacturing, the transition from a hand-painted prototype to a million-unit retail run is made possible by the precision of steel tooling. Engineering a toy for mass production is an art form that requires deep technical expertise in thermodynamics, material science, and mechanical engineering. At Unstoyppable, we view mold development as an investment in your brand’s reputation. A high-quality mold ensures that every unit—from the first to the ten-millionth—maintains the same crisp detail and structural integrity that defined your Golden Sample. By utilizing 2026's most advanced toy manufacturing technology, we deliver tooling solutions that optimize cycle times and ensure your entertainment merchandise manufacturing project stays on schedule and under budget.

Choosing the Right Material:

Al-Mold vs. Steel-Mold

For every project, we evaluate the projected volume to determine the ideal mold substrate. While Aluminum Molds (Al-Mold) offer a lower entry cost and faster fabrication time—making them excellent for low-volume specialty runs or limited-edition collectibles—they have a shorter lifespan. For true OEM manufacturing solutions at scale, we utilize high-grade Steel Molds. We use P20 steel for standard production and S136 stainless steel for high-gloss or transparent parts that require extreme corrosion resistance and a life-cycle of over 500,000 shots. These steel tools provide the thermal stability required for consistent 24/7 production, protecting your IP security by ensuring the final products never lose their sharp, "on-model" features.

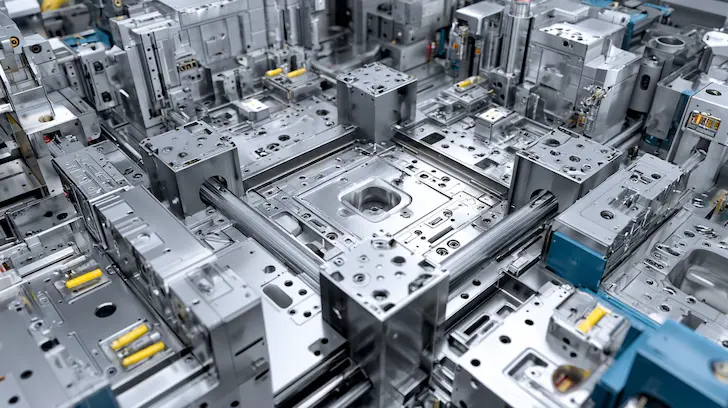

Efficiency Through Multi-Cavity Molds

To reduce your per-unit cost, we specialize in Multi-Cavity Mold design. By engineering a single mold to produce multiple parts (or multiple sets of parts) in a single injection cycle, we drastically increase output and reduce the landed cost in manufacturing. Our mold development and injection tooling process includes sophisticated "runner" systems that ensure molten plastic reaches every cavity simultaneously, preventing the imbalances that cause part variation. This is the Unstoyppable standard for efficiency.

Precision is the difference between a toy and a collectible.

Our Mold Development & Injection Tooling team is ready to bring your engineering blueprints to life. Explore our Tooling Capabilities or request a quote for Advanced Toy Tooling R&D.

Conformal Cooling:

Reducing Cycle Times and Warping

Traditional molds use straight cooling channels, which often leave "hot spots" in complex toy geometries. We utilize Conformal Cooling—3D-printed metal mold inserts with cooling channels that follow the exact contour of the toy part. This ensures perfectly even cooling, which eliminates warping and sink marks while reducing cycle times by up to 30%. For our clients, this translates to faster lead times for seasonal manufacturing and a more consistent product that meets the highest toy quality and safety compliance standards.

Laser Texturing for Realistic Skin and Fabric

To achieve the ultra-realistic textures found in modern collectible figure manufacturing, we utilize Laser Texturing on our steel molds. Instead of traditional chemical etching, a high-precision laser carves microscopic patterns directly into the steel. This allows us to replicate the exact grain of leather, the weave of fabric, or the pores of character skin directly onto the plastic surface. These details are permanent and incredibly crisp, ensuring that your character product manufacturing stands out in a crowded retail environment.