Third-Party Toy Lab Testing:

The Gold Standard of Industrial Verification

In the global ecosystem of licensed merchandise, the distance between a manufacturing facility and a retail shelf is measured by the rigor of its validation. Third-party toy lab testing is the definitive benchmark of excellence, serving as the ultimate arbiter of safety and compliance. At Unstoyppable, we recognize that while internal quality control is essential for operational efficiency, only independent toy safety verification provides the legal and ethical "shield" required by world-class IP holders. For brands operating in 2026, the regulatory landscape is more complex than ever, necessitating a partnership with an accredited toy testing laboratory that possesses the technical authority to certify products for North American and European markets. This section explores why independent oversight is the non-negotiable pillar of our production philosophy, ensuring that your brand’s reputation remains as resilient as the products we create.

The Legal Shield for IP Holders

Utilizing CPSC accepted lab testing is a strategic move that shifts the burden of proof from the brand owner to a verified scientific entity. When an independent lab certifies that a product meets ASTM F963 DFM compliance, it provides an evidentiary layer that protects the license holder in the event of regulatory scrutiny. This external validation is the only way to satisfy the demanding safety departments of entertainment giants and major retailers. By insisting on third-party toy lab testing, Unstoyppable ensures that every character-driven product is backed by an unassailable record of safety.

Preventing the "Conflict of Interest" Trap

Independent verification eliminates the inherent conflict of interest that exists when a factory tests its own output. An accredited toy testing laboratory operates without the pressure of production deadlines or material cost concerns. Their only objective is the accurate assessment of the toy’s physical and chemical properties. This impartiality is what transforms a simple toy into a globally compliant asset, ready for distribution in the most sensitive markets.

The Declaration of Conformity (DoC) for Europe

Similarly, for the European market, the Declaration of Conformity is the manufacturer’s signature that the product meets EN71 design optimization and safety standards. This declaration must be supported by a technical file that includes comprehensive third-party toy lab testing reports. By managing this toy compliance testing services workflow, Unstoyppable provides a turnkey solution that secures the CE mark for your toys, ensuring they are "compliant by design" and "safe by verification."

Secure Your Brand’s Future

Excellence in production is only complete with excellence in verification. Ensure your toy production is backed by world-class, independent lab verification today.

Combatting "Quality Fade" Through Periodic Testing

Safety is not a one-time event; it is a continuous obligation. As an EN71 compliant toy manufacturer, we implement periodic third-party toy lab testing throughout the lifecycle of a product. If a production run lasts for several months, we pull samples at regular intervals to verify that the non-toxic toy materials and chemical signatures remain consistent. This prevents the gradual introduction of unauthorized additives or structural weaknesses, providing an ongoing guarantee of quality for the IP holder.

Risk Mitigation for Licensees:

Protecting Royalty Streams and Brand Health

For a licensee, the financial impact of a product recall extends far beyond the cost of the goods. It involves legal fees, retailer penalties, and the catastrophic loss of consumer trust. Third-party toy lab testing is the most cost-effective insurance policy a brand can hold.

The Final Verdict: In the eyes of a regulator, a toy is only as safe as its most recent lab report. By making third-party toy lab testing the heart of our toy quality assurance protocols, Unstoyppable provides the transparency and technical rigor required to scale your IP globally. Trust the science, protect the brand, and ensure your products are truly "Unstoyppable."

Rigorous Testing Protocols:

Mechanical Durability and Chemical Purity

The transition from a manufacturing blueprint to a retail-ready product requires a transition through intense scientific scrutiny. At Unstoyppable, our third-party toy lab testing workflow is designed to simulate years of intense play and environmental exposure in a condensed, clinical setting. This phase is defined by "Destruction Testing"—a process where independent toy safety verification experts attempt to find the breaking point of every component. By subjecting our injection molded toy manufacturer outputs to these extreme conditions, we verify that the polymer selection, such as high-impact ABS and flexible TPE, performs exactly as engineered. This scientific rigor ensures that every licensed product remains a safe embodiment of the IP it represents, meeting all global benchmarks for mechanical durability and molecular purity.

Physical Abuse Simulations:

Engineering Structural Resilience

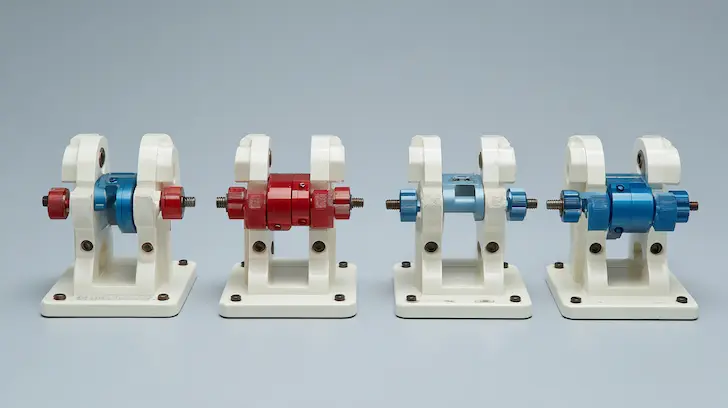

Mechanical safety is the first line of defense in toy manufacturing. Our labs utilize calibrated machinery to perform toy tensile strength testing and abuse simulations that mirror the unpredictable nature of childhood play.

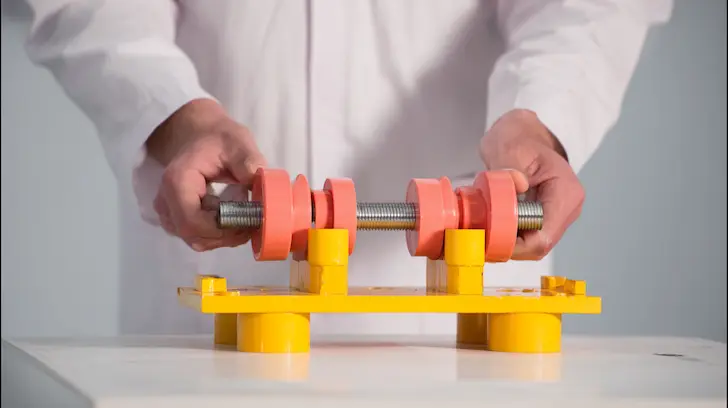

The Torque and Tension Test for Articulated Figures

For articulated action figures and complex character products, the joints and limbs are high-priority zones. Labs apply a specific amount of rotational force (torque) and linear pull (tension) to these components. As a leading ASTM F963 compliant manufacturer, we engineer our toy prototyping manufacturer samples to withstand forces exceeding 70 Newtons. This ensures that limbs remain securely attached to the torso, preventing the creation of hazardous small parts. We utilize high-grade resins like Polycarbonate or reinforced ABS for internal joint pegs, providing the structural backbone necessary to pass these rigorous mechanical screenings.

Printing Film Chemical Stability and Scratch Resistance

Traditional wet-spray painting is often replaced by advanced printing film for toy materials to ensure a more stable chemical bond. In the lab, technicians perform "cross-hatch" adhesion tests and "solvent rub" tests to verify the printing film chemical stability. This ensures that the graphics cannot be easily removed by friction or saliva. Furthermore, the film is scraped and analyzed via Inductively Coupled Plasma (ICP) spectroscopy to ensure that no lead, cadmium, or volatile organic compounds (VOCs) are present. This level of non-toxic toy materials verification is essential for maintaining the high aesthetic standards of media franchises while meeting EN71-3 migration testing requirements.

Soluble Element Migration Analysis

Chemical safety is not just about the presence of a substance, but its "bio-availability." Labs simulate the acidic environment of a child's stomach to measure the migration of 19 heavy metals. By utilizing virgin resins and food-contact grade pigments, our production consistently results in migration levels that are a mere fraction of the legal limits. This proactive approach to heavy metal migration analysis is a cornerstone of our toy quality and safety compliance, ensuring your IP is safe for consumers of all ages.

Don't Guess—Verify Your Safety

Safety is found in the molecular data. Explore our advanced material engineering and see how we pass the most rigorous lab screenings in the industry.

Explore Material Science | Learn About Phthalate-Free Standards

ASTM and EN71 Flammability Requirements

Thermal safety is paramount for fabric-based toys. Toy flammability testing involves exposing the material to a standardized flame and measuring the rate of spread. We utilize inherently flame-retardant synthetic fibers that melt away from heat sources rather than igniting. This ensures that our soft goods manufacturing projects meet the strict flammability benchmarks of both the ASTM F963 and EN71 Part 2 standards, providing a comprehensive safety solution for global brands.

The Small Parts Cylinder:

The Definitive Check for Under 3 Safety

The most iconic tool in any accredited toy testing laboratory is the "Small Parts Cylinder." This device is the definitive measure for preventing choking hazards in toys intended for children under 36 months.

Science-Backed Production: At Unstoyppable, we believe that if a toy can be broken, it should be broken in the lab, not the playroom. Our mastery of toy tensile strength testing and heavy metal migration analysis ensures your IP is resilient, compliant, and ready for the global stage. Partner with us to transform manufacturing data into consumer trust.

Streamlined Lab Coordination:

Accelerating Your Path to Global Retail

In the high-stakes world of licensed product distribution, manufacturing a high-quality item is only half the battle. The final hurdle to market success is the meticulous verification of that product through a structured, transparent logistical framework. At Unstoyppable, we specialize in SGS toy testing coordination and multi-agency lab management to ensure that the transition from the assembly line to the shipping container is seamless. We recognize that for our clients, the complexity of retail-ready compliance documentation can be a significant bottleneck. Therefore, we act as the central nervous system for your compliance needs, managing the sampling, testing, and certification phases with industrial precision. By maintaining a transparent supply chain manufacturing model, we provide the empirical evidence required to satisfy the world’s most demanding customs authorities and retail buyers.

Turnkey Lab Management:

Offloading Complexity from the Brand Holder

Navigating the requirements of third-party toy lab testing involves significant technical overhead. Our logistical team takes full responsibility for this process, allowing you to focus on your IP development while we handle the heavy lifting of safety verification.

Strategic Sampling and Test Plan Selection

The success of a lab audit depends on the selection of the correct "test plan." We analyze your product’s materials—such as ABS, PVC, and printing film—and its intended age grade to determine exactly which ASTM, EN71, or ISO standards apply. We handle the secure shipment of "production-grade" samples to the lab, ensuring they are representative of the final mass-produced goods. This proactive SGS toy testing coordination prevents the common error of over-testing or under-testing, optimizing both your budget and your time-to-market.

The Logistics of Periodic Testing

For long-term production contracts, we perform "Periodic Testing" every 6 to 12 months or every 10,000 to 20,000 units. This involves pulling fresh samples from the line and submitting them for updated heavy metal migration analysis and mechanical abuse tests. This ongoing independent toy safety verification ensures that the materials sourced in month twelve are as pure as those used in month one. It is a vital component of our toy quality assurance protocols, providing a constant safety net for your retail partners.

Maintaining the Technical File Trail

Every batch test result is added to the toy technical file preparation dossier. This archive serves as your brand’s insurance policy. Should a market surveillance authority in the EU or USA ever request proof of consistency, we provide the documented history of every batch run. This level of secure supply chain for licensed products management is why the world’s leading entertainment franchises trust Unstoyppable to handle their most sensitive IP.

Bridge the Gap to the Retail Shelf

Your entry into global markets should be frictionless. Contact our compliance team to manage your next third-party testing cycle and secure your retail readiness.

Explore FAMA Factory Compliance | Master Toy Logistics & Customs

The FAMA Connection:

Integrating Social and Safety Audits

For licensors like Disney, Universal, and Warner Bros, safety is only one part of the equation. Social accountability is equally critical. We synthesize BV toy safety audits with ethical certifications to provide a holistic compliance profile.

Synchronizing Safety and Ethics

A FAMA compliant factory in China must be able to prove that its products are safe and that its workers are treated fairly. Our toy technical file preparation includes the social audit reports (BSCI or Sedex) alongside the physical lab reports. This combined "Social + Safety" dossier is the ultimate gold standard for licensed merchandise manufacturer success. It allows you to prove to your licensor that every unit produced is a reflection of their brand’s global values, from the carbon footprint of the injection molded toy manufacturer process to the final non-toxic finish.