Why China Remains the Global Epicenter for Licensed Toy Production

As we navigate the industrial landscape of 2026, China has solidified its position as the indispensable China toy manufacturing hub, accounting for approximately 70-80% of the world’s total toy output. For global brand owners and IP holders, a licensed toy manufacturer in China is no longer just a source of labor, but a high-tech partner capable of executing complex character product manufacturing at a scale that remains unmatched by any other region. At Unstoyppable, we leverage this vast infrastructure to offer a seamless bridge between Western creative vision and Eastern manufacturing prowess. By operating at the heart of this ecosystem, we provide our clients with the agility to respond to rapid market shifts while maintaining the absolute highest standards of quality and compliance required by the world's most prestigious entertainment franchises.

Strategic Hubs:

Chenghai and Yangzhou

Our plastic and electronic toy manufacturing is centered in Chenghai, Shantou. Known as the world's toy capital, Chenghai produces approximately 70% of China’s plastic toys. The region’s 2026 evolution into "Smart Creation" means our partners there utilize over 50,000 specialized companies, offering mold accuracy within 0.005mm. This precision is essential for collectible figure manufacturer projects and complex injection molded toy manufacturer lines. Simultaneously, our plush toy manufacturer China operations are anchored in Yangzhou. This hub is world-renowned for its textile expertise, where we integrate the latest 2026 trends in recycled fabrics and high-fidelity embroidery to create licensed merchandise that feels as premium as the brands they represent.

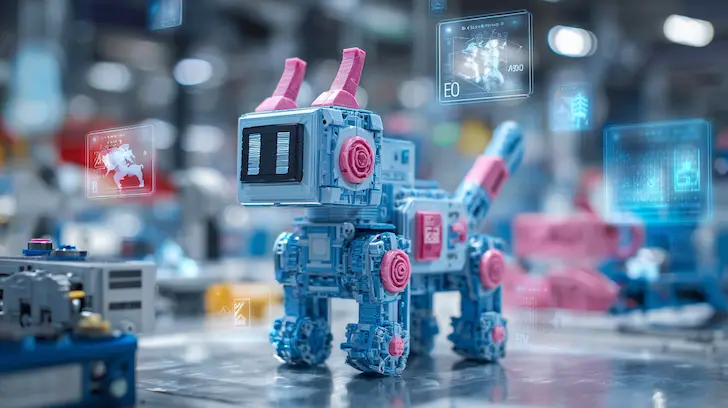

From "Low Cost" to "High Value":

The 2026 Tech Shift

The narrative of China manufacturing has shifted decisively from simple labor to advanced toy tooling R&D and "Dark Factory" automation. In 2026, Unstoyppable’s partner factories employ AI-driven quality control and robotic assembly arms that operate with minimal human intervention. This shift ensures that high-fidelity character molding is consistent across millions of units. We are now seeing the rise of "Phygital" toys—physical products that interact with digital environments via RFID and NFC technologies. By choosing a licensed toy manufacturer in China like Unstoyppable, you are gaining access to this 2026 technological frontier, ensuring your licensed brand expansion is built on the most innovative platforms available.

Secure your brand's future with a partner who understands the high stakes of licensed production.

Expertise in Disney FAMA and ILS compliance is what separates a successful launch from a legal nightmare. Let us protect your IP and your reputation.

Explore Licensed Product Manufacturing | Verify Our FAMA Compliance

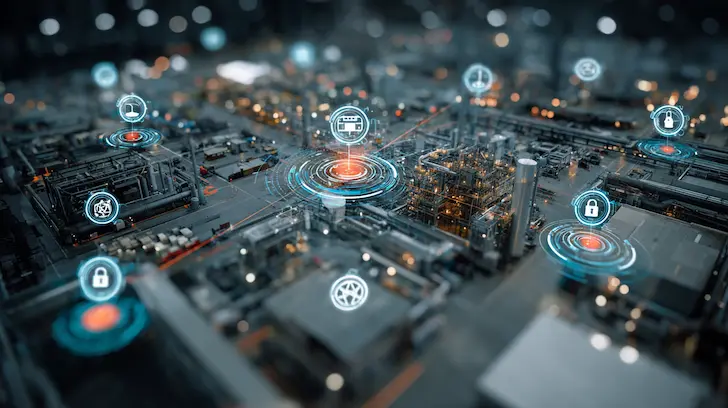

Bulletproofing Your IP:

Security Protocols for Global Brands

One of the most frequent concerns for brand owners is IP protection in China. In 2026, the legal framework in China has matured significantly, but the primary defense remains rigorous on-site operational security. At Unstoyppable, we don't just follow the rules; we set a higher standard for confidential licensed product manufacturing.

Securing Your Vision:

Operational Best Practices

We implement a multi-layered strategy to secure your vision. This begins with NNN Agreements (Non-Use, Non-Disclosure, and Non-Circumvention) which are specifically drafted for the Chinese legal system, providing much stronger protection than a standard Western NDA. Within the factory, we utilize restricted access zones where only authorized personnel can enter the molding and assembly areas for sensitive character products. Our digital infrastructure uses end-to-end encrypted file transfers for all toy prototyping manufacturer files and CAD drawings, ensuring your IP never enters the public domain.

Precision Engineering Meets Global Safety Standards

High-Fidelity Engineering:

3D Scanning and Resin Injection

We utilize high-resolution 3D scanning and haptic digital sculpting to ensure that the physical prototype is a perfect mirror of the source material. Once the geometry is finalized, our mold development & injection tooling team employs Pantone-matched resin injection. This process ensures that the color is "baked into" the material itself, providing a depth and durability that surface painting alone cannot achieve. By controlling the molecular consistency of the resins, we maintain perfect color fidelity throughout a production run of millions. This level of technical control is essential for collectible figure manufacturer standards, where fans demand perfection in every silhouette and shade.

Maintaining Style Guide Compliance at Scale

Consistency is the hallmark of professional character product manufacturing. We implement a rigorous "Master Sample" protocol, where the approved golden sample development process output serves as the immutable benchmark for the entire run. Our on-site engineers perform hourly visual and mechanical audits to ensure style guide compliance is maintained across multiple assembly lines. We use automated colorimetry to detect even the slightest deviation in hue, ensuring that every character—whether it is a pvc figure manufacturer project or an injection molded toy—looks identical regardless of the production batch. This dedication to consistency is why the world’s leading licensors trust Unstoyppable to handle their most sensitive IP.

The Green Mandate:

Phthalate-Free and Lead-Free Excellence

Modern retail buyers and parents prioritize safety above all else. At Unstoyppable, phthalate-free toy materials and lead-free coatings are the standard, not an upgrade. We utilize non-toxic, medical-grade plastics and water-based, UV-cured paints that provide a premium finish without the use of harmful chemicals. This commitment to "clean manufacturing" ensures that your products are compliant with the CPSIA compliance manufacturing act and the EU's REACH regulations. By using these high-tier materials, we provide a product that is safe for the youngest consumers and environmentally responsible, aligning with the sustainable toy manufacturing trends of 2026.

Quality isn't just a goal; it's a legal requirement.

Protect your brand from recalls and customs delays with 2026-compliant engineering and testing.

Transparent Compliance Documentation

We believe that transparency builds partnership. Our ERP production tracking system allows clients to view and download testing reports and safety certifications as they are issued. This digital paper trail provides the accountability required by major retailers like Walmart, Target, and Amazon. In 2026, being a licensed toy manufacturer in China means providing not just the product, but the complete data set that proves its integrity. At Unstoyppable, we provide that certainty, ensuring your entertainment merchandise manufacturing project is a benchmark for global safety and technical excellence.

Technical execution is where the promise of a brand meets the reality of the consumer experience. By mastering character-accurate manufacturing and staying at the forefront of toy safety standards 2026, Unstoyppable ensures your licensed products are winners in the market. We invite you to learn more about our AQL inspection processes in our Quality Control section or explore our Manufacturing Capabilities to see how we can bring your vision to life safely and beautifully.

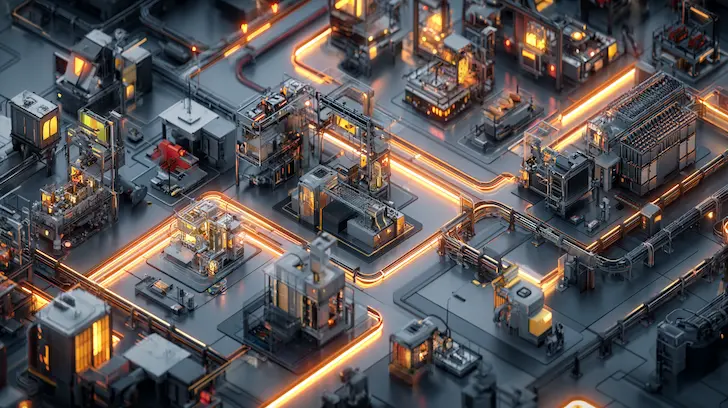

Future-Proofing Your Supply Chain:

Scale and Sustainability

In the high-stakes world of 2026 commerce, the agility of a licensed toy manufacturer in China is measured by its ability to pivot between precision craftsmanship and massive industrial output. As global markets become more volatile, the necessity for a scalable toy production China strategy has never been more vital. At Unstoyppable, we provide a robust infrastructure that harmonizes aggressive growth targets with the ethical demands of the 2026 green mandate. We ensure that our partners can scale their operations with confidence, knowing that their global toy logistics and environmental footprint are managed by experts. By bridging the gap between high-volume capacity and eco-conscious engineering, we empower your brand to lead the market in both profitability and corporate responsibility.

Optimizing the Landed Cost for Major Retailers

Scalability is only effective if it remains profitable. We integrate our production cycles with advanced logistics & retail fulfillment strategies to manage the "Landed Cost" for our clients. By optimizing carton dimensions during the retail-ready packaging manufacturer phase and leveraging high-volume shipping lanes, we ensure that the per-unit cost remains competitive even as volumes increase. This is crucial for brands looking to secure shelf space in big-box retailers like Walmart or Target, where margins are tight and global toy logistics efficiency is a prerequisite for partnership. At Unstoyppable, we make sure your success is as sustainable financially as it is operationally.

The 2026 Green Mandate:

Eco-Friendly Licensed Toys

The 2026 retail landscape is defined by the green mandate, a global shift where consumers and regulators demand transparency and environmental stewardship. Sustainable toy manufacturing is no longer a niche offering; it is the new standard for licensed toy manufacturers in China who wish to remain relevant in the European and North American markets.

Scale Your Brand Without Compromising the Planet.

Our 2026 Green Mandate solutions allow you to reach millions of fans with sustainable toy manufacturing that meets the highest global standards.

Transparent Production Tracking

To support this level of scale and complexity, Unstoyppable utilizes a state-of-the-art ERP production tracking system. This platform provides our clients with real-time, 24/7 visibility into their custom licensed product development milestones. You can track the status of your mold development & injection tooling, monitor AQL inspection results, and receive live updates on global toy logistics status. This transparency eliminates the "black hole" of overseas manufacturing, ensuring that your marketing and retail teams are always working with accurate data. In 2026, information is as valuable as the product itself, and our ERP ensures you are always in control of your retail-ready fulfillment.