The Blueprint of Success:

Mastering the Toy Manufacturing Process

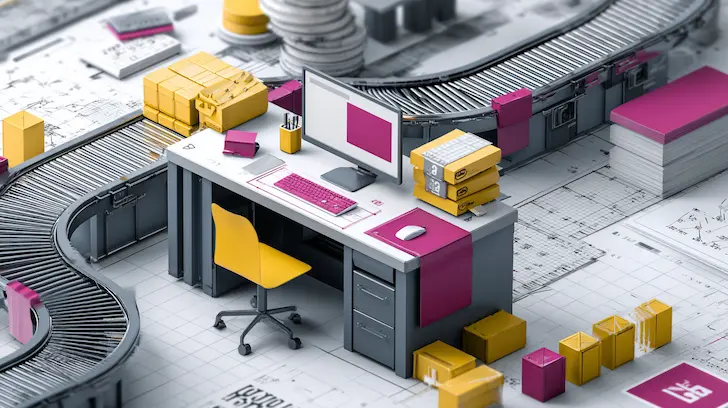

Navigating the complex landscape of licensed product manufacturing requires a deep understanding of the intersection between creative artistry and industrial engineering. In 2026, the global toy market demands higher fidelity, stricter safety, and faster turnaround times than ever before. Success is built upon a foundation of technical knowledge and strategic planning. At Unstoyppable, we serve as your educational and operational partner, transforming the daunting task of OEM manufacturing solutions into a streamlined, transparent journey. By mastering the toy manufacturing process step-by-step, brand owners and licensees can mitigate risks, protect their intellectual property, and ensure that the final product hitting retail shelves is a perfect realization of their original vision.

How OEM Manufacturing Solutions Optimize Each Stage

Professional OEM manufacturing solutions provide the specialized oversight needed to prevent errors at these stages. During tooling, for instance, an expert manufacturer identifies potential "sink marks" or "air traps" in the mold design before the steel is cut, saving weeks of rework. In the assembly phase, automated toy safety testing is integrated to ensure that every collectible figure manufacturer run maintains structural integrity. By leveraging these solutions, you ensure that efficiency is high and the landed cost in manufacturing is kept to a minimum without sacrificing the premium feel of the licensed product.

From Style Guide to Retail Shelf:

Maintaining Character Fidelity

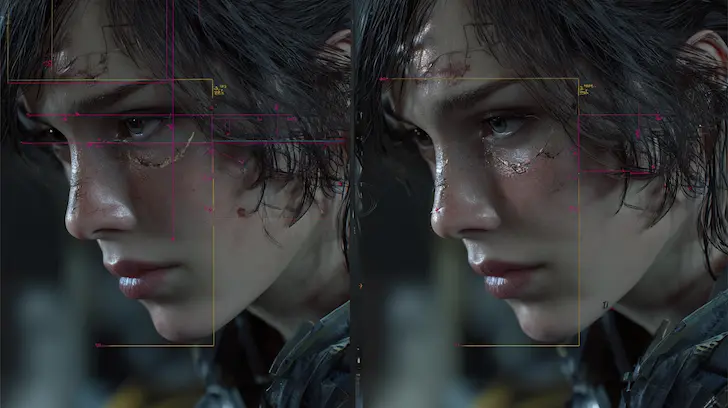

A style guide is the definitive "Bible" for any media franchise. These documents, often exceeding 200 pages, dictate everything from the specific Pantone shades of a character's eyes to the exact radius of a logo’s curve. Interpreting these guides requires an expert licensed merchandise manufacturer who understands that "close enough" is never sufficient in the world of global fandom.

Success starts with the right roadmap.

Understanding the journey is the first step to a successful launch. Explore our detailed Toy Manufacturing Process Step-by-Step or learn How Licensed Products Go From Concept to Mass Production.

Explore the Step-by-Step Process or Download our Manufacturing Checklist Today.

How Licensed Products Go From Concept to Mass Production

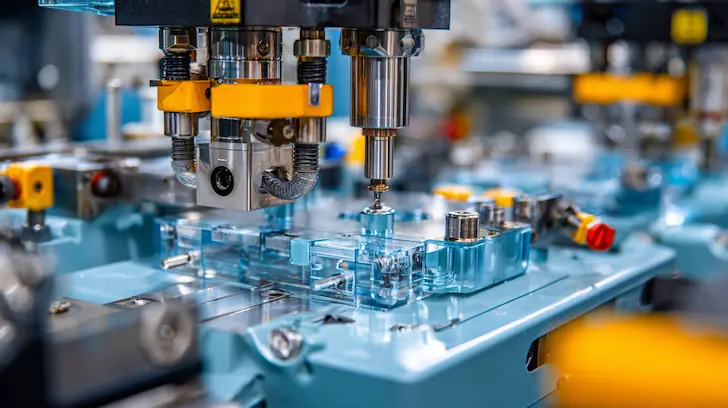

The "Hand-off" between creative designers and factory engineers is the most critical moment in the toy manufacturing process. It is the point where artistic vision meets the physical constraints of plastics, polymers, and production lines. A successful hand-off ensures that the final licensed toy manufacturer China output is both beautiful and buildable.

The Creative-to-Engineering Hand-off

When a designer delivers a character concept, our toy prototyping manufacturer team evaluates the "buildability." We identify areas where the design might be too fragile for a child’s toy or where a joint might interfere with the character's aesthetic. We facilitate a collaborative dialogue between the IP holder’s creative team and our production engineers. This ensures that the ODM licensed product development remains true to the artist's intent while being perfectly suited for the injection molded toy manufacturer environment.

The blueprint of success in the toy industry is a living document that requires constant oversight and technical expertise. From interpreting a complex entertainment merchandise manufacturing style guide to executing high-precision injection molded toy manufacturer runs, Unstoyppable provides the transparency and skill needed for the modern market. We invite you to continue your education by exploring our Engineering & Prototyping section or learning more about Toy Quality & Safety Compliance to ensure your brand's future is secure.

Deciphering the Compliance Code:

Safety Standards and Ethical Audits

In the global toy industry of 2026, compliance is the definitive gateway to market entry. For a licensed product manufacturer, navigating the intricate web of international safety standards and ethical mandates is a core operational requirement. At Unstoyppable, we recognize that safety is a multifaceted discipline encompassing chemical purity, mechanical integrity, and social responsibility. As regulatory bodies in the United States and the European Union tighten their oversight, the role of a licensed merchandise manufacturer shifts from simple production to comprehensive risk management. We ensure that every product, from the smallest PVC figure manufacturer project to complex electronic toy manufacturer items, adheres to the highest global benchmarks, protecting both the end consumer and the integrity of the IP holder's brand.

EN71 vs ASTM Toy Standards Explained:

A 2026 Comparison

Understanding the technical nuances between the European EN71 compliant toy manufacturer standards and the American ASTM F963 compliant manufacturer requirements is essential for any brand with global ambitions. While both frameworks aim to prevent injuries, their methodologies and specific testing thresholds often differ, requiring a sophisticated approach to toy material engineering and product design.

A Deep Technical Dive into Global Standards

The ASTM F963 standard is the mandatory benchmark for the US market, enforced by the CPSC. It focuses heavily on mechanical hazards, flammability, and the presence of heavy elements. Key tests include the "use and abuse" simulations—drop tests, torque tests, and tension tests—designed to ensure that no character product manufacturing results in sharp edges or small parts that pose a choking hazard. Conversely, EN71 is the European standard that is part of the CE marking requirement. While it shares many mechanical testing goals with ASTM, it is historically more stringent regarding chemical migration (EN71-3) and organic chemical compounds (EN71-9). In 2026, the gap between these standards is closing as both regions adopt more aggressive stances on phthalate-free toy materials and bisphenol restrictions. At Unstoyppable, we design for "Dual-Compliance," ensuring every custom licensed product development meets the strictest version of any shared requirement between the two regions.

What Is FAMA Compliance in Manufacturing:

The Disney Standard

In the world of licensed product manufacturing, the Facility and Merchandise Authorization (FAMA) is widely considered the "Holy Grail." This certification is Disney’s proprietary authorization, indicating that a factory has passed rigorous audits for both physical security and labor practices. For any brand looking to produce entertainment merchandise manufacturing at the highest level, working with a FAMA compliant factory in China is a non-negotiable requirement.

Why FAMA is Essential for Licensed Goods

FAMA compliance is about more than just a certificate; it is a holistic verification of IP security and factory compliance. Disney and other major studios use FAMA to ensure that their products are manufactured in environments that prevent IP theft and adhere to strict ethical codes. As a leading licensed merchandise manufacturer, Unstoyppable manages a dedicated network of FAMA-authorized facilities. We act as your liaison, ensuring that all OEM manufacturing solutions are executed within these pre-approved hubs. This eliminates the risk of "sub-contracting" to unverified third parties—a common pitfall that can lead to the immediate revocation of a licensing agreement.

Safety is the foundation of toy retail.

Deepen your expertise with our guide on EN71 vs ASTM Toy Standards Explained or learn What Is FAMA Compliance in Manufacturing.

Compare EN71 vs ASTM Standards | Request a Factory Audit Consultation

The Role of Social Audits in Modern Retail

A BSCI & Sedex audited toy factory provides documented proof of fair wages, safe working conditions, and the absence of child or forced labor. These audits are critical for protecting a brand's public image in an era of high-speed social media accountability. At Unstoyppable, we ensure our transparent supply chain manufacturing includes up-to-date audit reports for every factory in our ecosystem. This allows our clients to market their products as ethically sourced, which is a significant value-add for the modern parent who prioritizes corporate social responsibility (CSR).

Protecting Public Image with Ethical Manufacturing

Ethical toy manufacturing China is about risk mitigation. A single negative report about factory conditions can lead to massive boycotts and the termination of licensing deals. By utilizing audited factory network China partners, Unstoyppable shields your brand from these vulnerabilities. We manage the "Human" side of licensed product manufacturing with the same technical precision we apply to mold development & injection tooling. This comprehensive approach ensures that your brand remains a symbol of joy and integrity, from the factory floor to the final consumer.

Deciphering the compliance code is a continuous process of education and adaptation. By staying at the forefront of EN71 vs ASTM changes and maintaining a FAMA compliant factory in China network, Unstoyppable ensures your toy manufacturing process is future-proof. We invite you to explore our Toy Quality & Safety Compliance section or read our guide on Toy Manufacturing Process Step-by-Step to see how safety is woven into every stage of production.

Strategic Planning:

Optimizing Timelines and Avoiding Costly Pitfalls

In the high-stakes environment of 2026 licensed product manufacturing, time is just as critical as the quality of the sculpt. Strategic planning is the engine that drives a successful launch, transforming a creative concept into a retail victory. At Unstoyppable, we specialize in lead time planning for seasonal manufacturing, ensuring that our partners navigate the complexities of global supply chains with precision. Avoiding common manufacturing errors requires more than just luck; it requires a data-driven approach to toy manufacturing logistics and a deep understanding of the "factory floor" realities. By integrating advanced technology with decades of hands-on experience, we help you master the calendar and protect your brand from the "Black Swan" events that often derail unoptimized production cycles.

Why a Christmas Launch Begins in January

To have products on shelves by October, the mold development & injection tooling must be completed by June. This means character engineering for toys and golden sample development must occur in the first quarter of the year. Starting in January allows for the "buffer zones" necessary to handle revisions from the IP holder. It also accounts for the Chinese New Year factory hiatus, which can stall production for several weeks. By initiating the OEM manufacturing solutions process early, you ensure that your licensed merchandise is not competing for limited factory capacity during the mid-year peak, resulting in better pricing and more focused quality control.

Navigating Buffer Zones and Logistics

Strategic planning includes accounting for "Buffer Zones" in toy manufacturing logistics and customs clearance. In 2026, freight volatility and new customs & export for toys documentation requirements—like the 2026 EU Digital Product Passport—can add unexpected days to your timeline. We recommend a 4-week buffer between the final AQL inspection in toy manufacturing and the required ship date. This safety net allows for any re-testing or transit delays, ensuring your retail-ready licensed product production meets its "Street Date" without the need for expensive air freight. Our global distribution for licensed products strategy is built on this foundation of proactive timing.

ERP Production Tracking:

The Cure for Late Shipments

The greatest "failure" is a lack of visibility. Our proprietary ERP production tracking system provides real-time updates from the factory floor. This system tracks every milestone—from raw material arrival to automated toy safety testing results. By eliminating the "Black Hole" of information, we catch delays the moment they occur. If a tooling stage is falling behind by even 48 hours, the ERP alerts our management team, allowing us to deploy additional resources from our audited factory network to keep the project on track. This transparent supply chain manufacturing is why our clients enjoy a 99% on-time delivery rate.

Timing is the difference between a hit and a missed opportunity.

Optimize your 2026 launch with our expert Lead Time Planning for Seasonal Manufacturing or study our analysis of Common Failures in Toy Production.

Marketing sustainability is about transparency. By utilizing our secure supply chain for licensed products, you can provide consumers with proof of eco-friendly sourcing and ethical labor practices. Highlighting your use of recycled plastics or FSC-certified packaging as a core feature of your licensed line builds brand loyalty with the modern, environmentally conscious parent. This "Green Mandate" is not just a regulatory requirement; it is a significant opportunity for custom licensed product development to stand out on the retail shelf.