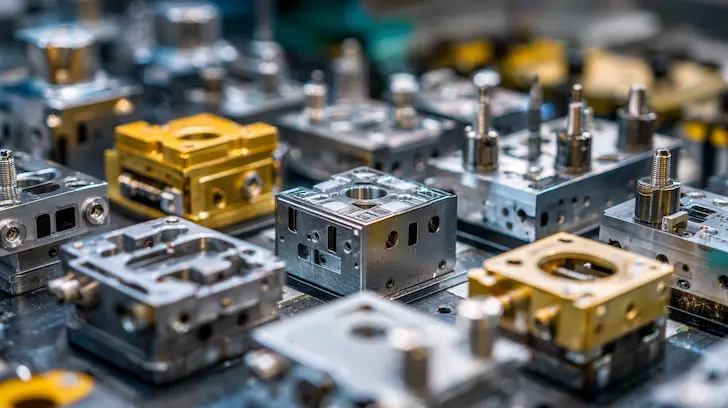

Mold Development & Injection Tooling:

The Steel Foundation of Scale

In the global landscape of licensed merchandise, the physical mold is the most significant capital asset a brand possess. It is the industrial heart of the production line, responsible for transforming raw resin into millions of identical, high-fidelity character replicas. At Unstoyppable, mold development injection tooling is approached with the reverence of master craftsmanship and the precision of aerospace engineering. For the 2026 market, we have elevated our standards to ensure that every tool we build is a "legacy asset"—designed to maintain microscopic detail from the first shot to the ten-millionth. By focusing on superior metallurgy and high-precision toy molds, we provide IP holders with the security that their character’s likeness is preserved with absolute consistency, regardless of production volume. Our steel tool manufacturing China facility specializes in creating high-performance environments where speed and quality coexist, ensuring your retail launch is supported by the strongest foundation possible.

S136 and NAK80:

The Gold Standard for Mirror Finishes

We utilize S136 stainless steel tooling specifically for projects requiring a "mirror finish" or high-transparency components. S136 is prized for its exceptional corrosion resistance and its ability to take a diamond-grade polish, which is essential when molding clear visors or glossy collectible eyes. For characters requiring intricate textures and high dimensional stability, we employ NAK80 steel. This pre-hardened steel is ideal for high-precision toy molds because it maintains its shape under extreme thermal cycles, ensuring that parts fit together with zero-gap precision over the course of a multi-year production lifecycle. By investing in these premium grades, we ensure that the "perceived value" of your product remains high, as every unit retains the sharp edges and smooth surfaces of the original sculpt.

Corrosion Resistance and Maintenance Reduction

Many popular toy materials, particularly PVC, release corrosive vapors during the injection process. Our steel tool manufacturing China protocols utilize high-chromium alloys that naturally resist this chemical wear. This choice is a proactive strategy to reduce downtime; by using S136 stainless steel tooling, we minimize the frequency of mold polishing and repair, which directly translates to a more stable "Landed Cost" for the IP holder. A durable mold is a profitable mold, and we ensure your tool is built to thrive in a high-output industrial environment.

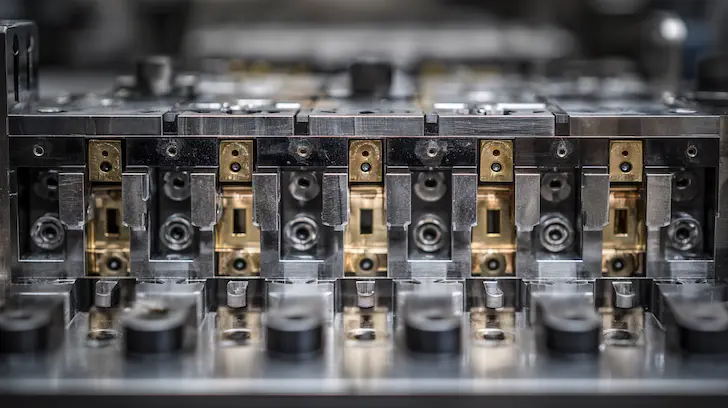

Optimizing Cost-Per-Unit for Retail Success

High-cavity tooling is the most effective way to reduce the cost of steel tool manufacturing China operations. By producing 16 parts in a single cycle rather than 2, we drastically reduce the machine-time cost and energy consumption per unit. This efficiency is passed directly to our partners, allowing for more competitive retail pricing or higher margins. Our high-precision toy molds are engineered to cycle faster and last longer, making Unstoyppable the ideal partner for high-volume entertainment merchandise.

Invest in Longevity

Your character's legacy is etched in steel. Partner with a leader in high-precision tooling to ensure your IP remains flawless across millions of units.

Explore Engineering Blueprints | See R&D Tooling Innovations

EDM and Texture Etching for Hyper-Realism

For details that are too fine for a traditional cutting tool, we utilize Electrical Discharge Machining (EDM). By using precision-shaped electrodes, we "burn" microscopic textures directly into the S136 or NAK80 steel. This technique is used to create hyper-realistic fabric patterns or to etch branding and safety warnings into hidden areas of the figure. This level of high-precision toy molds expertise ensures that your product has a tactile, high-end finish that consumers can feel, elevating the brand’s perceived quality and distinguishing it from generic competitors.

The 2026 Tooling Lifecycle:

Preventative Maintenance & IP Consistency

A mold is a living tool that requires constant care to perform at its peak. Unstoyppable implements a comprehensive "Preventative Maintenance" protocol to protect your investment and ensure long-term mold development injection tooling success.

The Tooling Advantage: Superior character products begin with superior steel. By utilizing S136 stainless steel tooling, multi-cavity engineering, and EDM precision, Unstoyppable provides the industrial foundation your brand needs for global dominance. Trust the leader in high-precision toy molds for your next 2026 project.

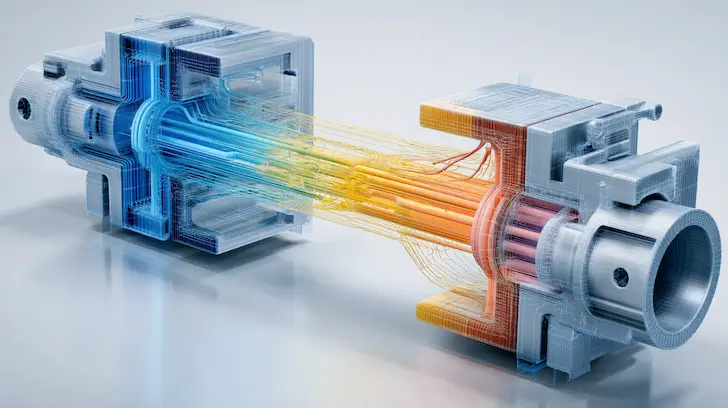

Advanced Injection Physics:

Optimizing Flow for Flawless Figures

The creation of a high-end licensed collectible is a battle against the physical laws of thermodynamics and fluid dynamics. At Unstoyppable, we move beyond simple manufacturing by applying advanced injection physics to every project. For the 2026 market, precision toy molding China involves a deep understanding of how molten polymers behave under extreme pressure within the confined geometry of a character sculpt. By mastering the "invisible" variables—thermal gradients, shear rates, and pressure drops—we eliminate the common defects that plague lower-tier production. Our focus on toy mold flow analysis ensures that every figure emerges from the tool with structural perfection and surface purity. This analytical approach not only enhances the aesthetic quality of your IP but also significantly reduces the "Landed Cost" by maximizing production yield and minimizing cycle times. When physics is mastered, the result is a flawless figure that stands as a testament to engineering excellence.

CAD Mold-Flow Simulation:

Predictive Engineering for 2026

Before a single block of S136 steel is cut, we conduct a comprehensive "digital birth" of your product. Using 2026 AI-driven toy mold flow analysis, we simulate the entire injection process in a virtual environment to ensure total reliability.

Identifying Air Traps and Knit Lines Pre-emptively

Our simulation software predicts exactly how the molten ABS, PVC, or specialized resin will fill the cavity. By analyzing the "front" of the material flow, we identify potential "air traps" where pockets of gas could be compressed, causing burn marks or voids. We also locate where different flow fronts meet—known as knit lines or weld lines. Through precision toy molding China expertise, we adjust the mold design to move these lines to inconspicuous areas or eliminate them entirely by varying the wall thickness. This predictive 3D modeling ensures that the character's face and primary focal points remain pristine and structurally sound.

Eliminating Material Waste and "Sprues"

Traditional cold runner systems create a "tree" of wasted plastic that must be trimmed and recycled. In contrast, hot runner injection systems keep the plastic in a molten state within the manifold, delivering it directly into the cavity. This is an environmentally conscious and cost-effective choice, as it virtually eliminates material waste. For high-volume licensed merchandise manufacturer projects, the savings in raw material alone can significantly lower the overall production budget while maintaining a cleaner factory environment.

Precision Thermal Gating for Delicate Details

Because the plastic is kept at a consistent temperature right up to the gate, hot runner injection systems prevent "cold slugs" from entering the mold. This is essential for delicate character features, such as fine hair strands or thin capes, where a sudden drop in temperature would cause the plastic to freeze prematurely. By maintaining thermal equilibrium, we ensure that every cavity in a multi-cavity tool is filled with identical material properties, providing the consistency that global brands demand.

MASTER THE FLOW

Superior physics leads to superior products. Consult with our mold flow engineers today to optimize your character's injection cycle for maximum quality and minimum cost.

Explore Injection Capabilities | Learn About DFM Optimization

Reducing Cycle Times and Landed Costs

By extracting heat more efficiently, we can reduce the cooling time by up to 30%. In a high-volume run of 500,000 units, this time saving is massive. It allows for faster throughput on the injection machines, lowering the machine-hour cost and ensuring that your licensed merchandise reaches the retail market faster. This intersection of 3D-printed tooling and toy cooling cycle optimization represents the cutting edge of 2026 toy manufacturing.

Gating for Aesthetics:

The Art of the Invisible Entry

The "gate" is the umbilical cord where the part is fed. In precision toy molding China, we treat injection molding gate placement as an art form, ensuring that the necessary "scar" of production is completely hidden from the consumer's eye.

The Analytical Advantage: We don't just fill molds; we engineer the flow. Through AI-driven mold flow analysis, conformal cooling, and strategic gating, Unstoyppable delivers precision toy molding China that sets new benchmarks for 2026. Ensure your IP is manufactured with the highest scientific standards in the industry.

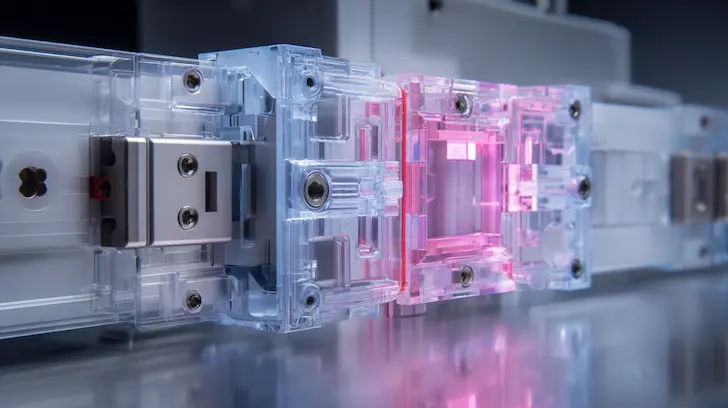

Integrated Tooling Tech:

In-Mold Decoration and Digital Traceability

As we navigate the industrial landscape of 2026, the definition of a "toy mold" has evolved from a simple shaping tool into a sophisticated platform for multi-material integration and digital intelligence. At Unstoyppable, our automated toy tooling systems are designed to do more than just replicate form; they are engineered to apply permanent decoration and embed legal traceability directly during the injection cycle. This technical integration represents the future of licensed merchandise manufacturer standards, where aesthetics, functionality, and compliance are fused into a single high-efficiency process. By utilizing advanced IML toy manufacturing and multi-shot molding, we provide IP holders with a product that is not only visually stunning but also "smart" and fully compliant with the latest global regulations. Our visionary approach to mold development injection tooling ensures that your character is protected, traceable, and premium in every sense.

In-Mold Labeling (IML) for Toys:

Permanent Aesthetic Fusion

Traditional post-molding decoration, such as stickers or standard pad printing, can be susceptible to wear and tear. Our 2026 IML toy manufacturing process solves this by integrating the graphic directly into the part's structure.

High-Definition Graphics Fused with Plastic

Using printing film for injection molding, we utilize robotic arms to place a pre-printed, high-definition film inside the mold cavity before the resin is injected. As the molten plastic fills the mold, it fuses with the film, making the graphic an inseparable part of the toy’s wall. This in-mold labeling for toys technique is ideal for characters with complex chest emblems, intricate tech-panel details, or vibrant patterns that must be scratch-proof and fade-resistant. This automated toy tooling ensures that the character’s decoration remains perfect throughout the product's entire lifecycle, providing a level of durability that post-production methods simply cannot match.

Seamless Integration of Hard and Soft Resins

Through 2K mold development injection tooling, we can create a figure with a rigid ABS structural frame and "overmolded" soft TPE or TPU grips, clothing, or skin textures. This creates a seamless, high-strength bond between materials without the need for adhesives. It is the preferred method for licensed toy manufacturer in China projects that demand ergonomic excellence and a "multi-textured" tactile experience. By engineering these high-precision toy molds to handle dual-injection, we provide a premium feel that distinguishes your character from single-material competitors.

Enhanced Durability and Structural Integrity

2K tooling doesn't just improve the look; it enhances the toy structural integrity. Because the two materials are fused at a molecular level during the molten phase, there is no risk of the soft parts peeling or detaching. This is a vital component of safety-compliant character design, particularly for products intended for younger audiences or high-intensity play. This automated toy tooling approach ensures your product is as durable as it is beautiful.

Future-Proof Your Production

Stay ahead of the competition with 2026-ready manufacturing. Leverage our automated 2K tooling and in-mold decoration technologies for your next global launch.

Explore Advanced Polymers | Secure Your Intellectual Property

Interchangeable Inserts:

Versatility in Tooling

To maximize the value of your investment, we utilize "Modular Insert" technology. This allows the IP holder to use a single master mold base for multiple character variants. By simply swapping out a "face insert" or an "accessory insert," we can produce different expressions or outfits using the same high-precision toy molds. This automated toy tooling strategy saves tens of thousands of dollars in new tooling costs and allows for rapid "chase" variant production, keeping your product line fresh and exciting for collectors.