The Foundation of Quality:

Pre-Production and Character Engineering

The journey of a world-class licensed product begins long before the first injection mold is fired. In the professional toy manufacturing process step-by-step, the pre-production phase is the most critical stage for ensuring brand integrity and financial viability. This stage is where creative vision meets industrial reality. At Unstoyppable, we specialize in the meticulous conversion of 2D concept art and 3D digital sculpts into manufacturing blueprints that are fully optimized for the factory floor. By focusing on character engineering for toys at the onset, we eliminate the technical friction that often occurs when moving from a digital render to a physical object. Our methodical approach ensures that the "Soul" of the character—its proportions, its silhouette, and its personality—is preserved while being adapted for high-volume efficiency through design for mass production toys.

Color Fidelity and Pantone Matching

A character’s color is its visual signature. During the pre-production audit, we translate the digital RGB/CMYK colors from your style guide into precise Pantone Plastic Standards. This ensures that the hue of a superhero's suit or a cartoon character’s skin remains consistent across millions of units. Because different resins (like ABS vs. PVC) absorb pigments differently, our toy material engineering team performs color-matching tests early in the process. This proactive step guarantees that your retail-ready licensed product production maintains 100% color accuracy, satisfying even the most demanding licensor requirements.

Proportional Feasibility and Silhouette Integrity

Characters designed for animation often have gravity-defying features—tiny ankles supporting large heads or flowing capes with impossible thickness. Character engineering for toys involves adjusting these digital models to stand on their own or to be securely mounted to a base. We utilize advanced CAD software to add "hidden" draft angles and part separations that allow the toy to be easily removed from a mold without distorting the character's likeness. This careful balancing act ensures the final product is a faithful 3D representation of the 2D original.

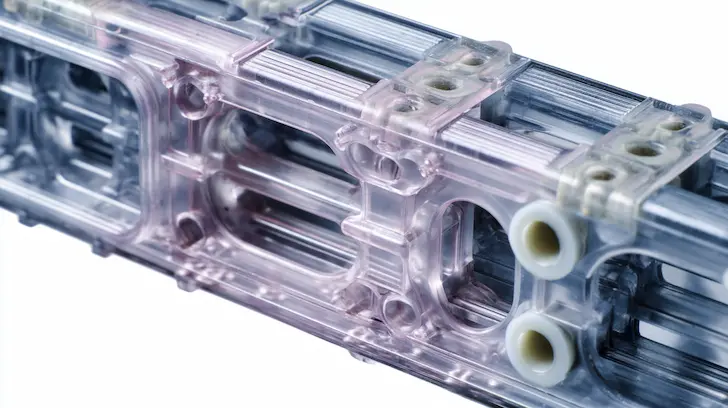

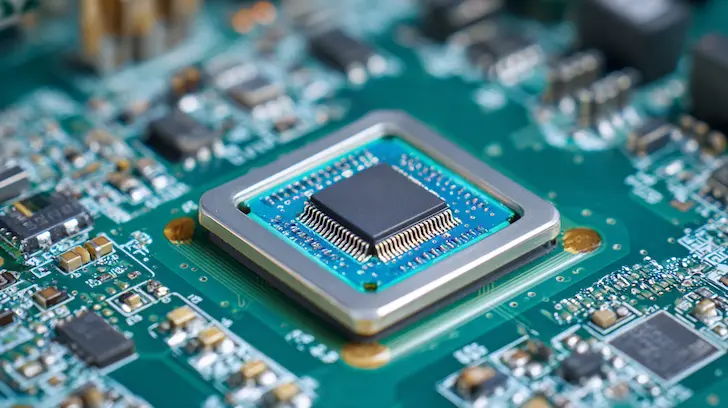

Wall Thickness and Material Flow

Uniform wall thickness is essential for preventing "sink marks" (depressions in the plastic) and ensuring structural integrity. During the engineering phase, we analyze the "Flow Front" of the molten plastic as it enters the mold. By optimizing wall thickness, we ensure the material reaches every extremity of the character—like the tip of a sword or the point of an ear—with consistent density. This level of technical precision is what differentiates a premium collectible from a generic plaything.

Transform Your Concept into a Production-Ready Masterpiece

Avoid costly redesigns and manufacturing delays. Let our experts conduct a professional feasibility audit of your character designs today.

The "Golden Sample" Development

The "Golden Sample" is the final, pre-production prototype that is painted and finished to look exactly like the mass-produced version. This sample serves as the legal benchmark for quality. It is the sample that is sent to third-party toy lab testing for certification and is used by the QC team as the reference for AQL inspection in toy manufacturing. Our ability to produce high-fidelity Golden Samples that perfectly match the eventual output of our mold development and injection tooling is a core strength of the Unstoyppable process.

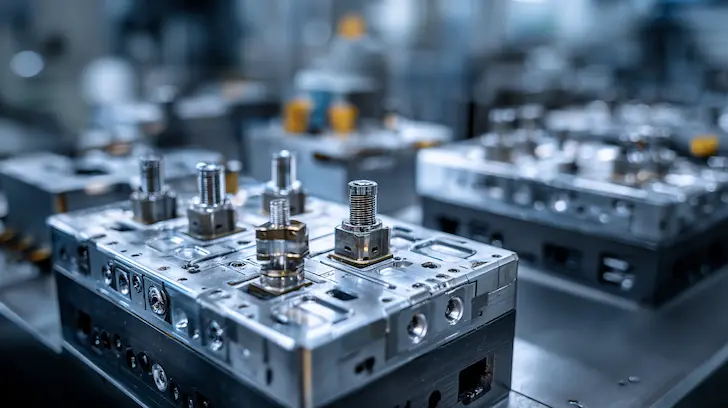

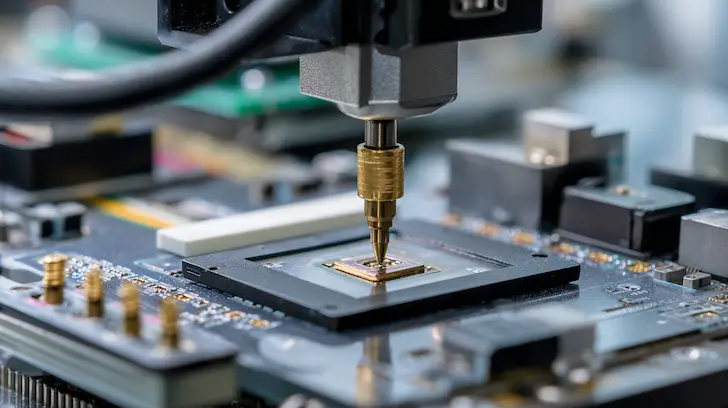

Precision Tooling:

The Art of Steel and Cavities

Once the Golden Sample is approved, we move to the most capital-intensive part of the process: mold development and injection tooling. This is where the digital design is etched into hardened steel.

Pro-Tip for Brands: The most expensive changes are the ones made after the mold is cut. By investing in professional character engineering for toys during the pre-production phase, you save thousands in potential tooling modifications and weeks of lost time. Measure twice, engineer once.

The Engine Room:

Advanced Molding and Precision Decoration Techniques

Once the blueprints are finalized and the steel is cut, the toy manufacturing process step-by-step moves into its most high-energy phase: mass production. This is the stage where raw polymer resins are transformed into the tangible characters that fans adore. As a premier injection molded toy manufacturer, Unstoyppable oversees a production environment where mechanical force meets artistic precision. Every second of the licensed toy production workflow is calibrated to ensure that the 50,000th unit is as flawless as the first. This "Engine Room" of manufacturing relies on a synergy of high-speed automation and meticulous hand-finishing, ensuring that every character's "Visual DNA" is preserved in a durable, high-fidelity physical form.

Toy Material Engineering:

Selecting the Perfect Polymer

The tactile "feel" of a toy is just as important as its appearance. Through expert toy material engineering, we select resins that balance durability, flexibility, and chemical safety.

ABS for Structural Precision

Acrylonitrile Butadiene Styrene (ABS) is the gold standard for parts requiring high impact resistance and dimensional stability. Because ABS is a rigid thermoplastic, it is the ideal material for the structural "bones" of a toy or for characters with sharp, crisp mechanical details. Our injection molded toy manufacturer protocols ensure that we use only high-purity ABS, providing a smooth surface finish that is perfect for secondary paint applications.

The Injection Cycle:

Consistency Through Automation

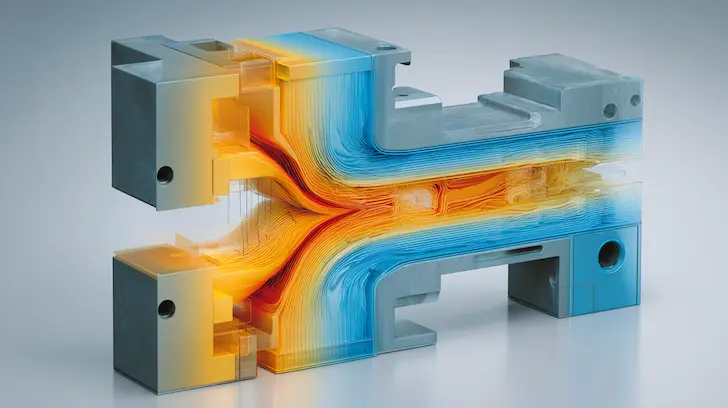

The heart of an automated toy manufacturing China facility is the injection molding machine. This process is a rhythmic cycle of heat and pressure, managed with scientific accuracy.

Temperature and Pressure Control

In the licensed toy production workflow, consistency is everything. Our machines utilize advanced PLC (Programmable Logic Controller) systems to maintain the plastic melt temperature within a +/- 1-degree margin. High-pressure injection ensures that the molten plastic fills every microscopic detail of the mold cavity. This precision prevents "short shots" and ensures that fine textures, such as the weave on a character's costume, are rendered perfectly on every unit.

Scale Your Production Without Sacrificing Character Accuracy

Your IP deserves a manufacturer that understands the science of the mold. Partner with Unstoyppable for high-fidelity production.

Explore Injection Molding Capabilities | See PVC Figure Solutions

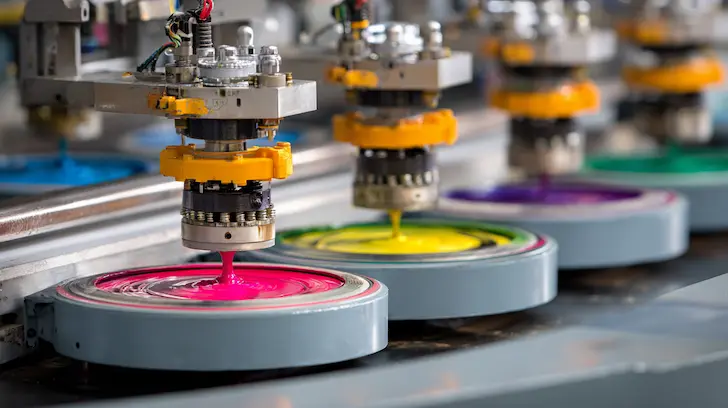

Pad Printing (Tampo) for Micro-Details

Pad printing is the primary technique used to apply high-resolution graphics—such as character eyes, emblems, and intricate patterns—to curved or textured surfaces. We utilize multi-color pad printing machines that can overlay several layers of ink with a registration accuracy of 0.1mm. This ensures that a character’s eyes are always perfectly centered and expressive, maintaining the high standards expected from an authorized Disney product manufacturer.

Spray Painting and Weathering Effects

For larger areas of color or sophisticated gradients and shading, we employ precision spray painting. Using custom-made copper masks (stencils), our artisans apply layers of paint to create depth and realism. Whether it is the metallic sheen on a robotic figure or the "weathered" look of a warrior’s armor, these techniques add a premium "collectible" quality to the mass-produced toy. All paints used are lead-free and specifically formulated for adhesion to phthalate-free toy materials.

Final Functional Testing

Every electronic toy undergoes a "100% Functional Test" before it moves to final assembly. We verify that every button press triggers the correct sound and that every LED illuminates at the intended brightness. By combining electronic complexity with structural durability, we create "smart" toys that stand up to years of play. This comprehensive approach to the toy manufacturing process step-by-step ensures that your interactive IP functions flawlessly from the moment the consumer pulls the "Try Me" tab.

Industrial Insight: Mass production is a marathon of consistency. By utilizing automated toy manufacturing China and high-grade toy material engineering, we remove the variables that cause defects. Quality is not an accident; it is the result of a controlled process.

The Final Mile:

Assembly, Safety Verification, and Global Logistics

The final phase of the toy manufacturing process step-by-step is where disparate molded components, electronic modules, and decorative elements converge to become a completed product. This stage is a high-precision operation that demands a balance between human craftsmanship and mechanical efficiency. At Unstoyppable, we recognize that the "Final Mile" of production is just as important as the first mold. Our assembly lines are designed for retail-ready licensed product production, ensuring that the transition from a pile of parts to a packaged unit is seamless, safe, and fully documented. By integrating world-class toy manufacturing logistics with rigorous safety checks, we ensure that your product is ready to withstand the journey from our factory floor to the most competitive retail shelves in the world.

Adhesive Application and Hand-Finishing

When complex geometries or multi-material designs are involved, we use high-grade, non-toxic adhesives applied via precision dispensers. Our assembly stations are staffed by skilled technicians who perform the final hand-finishing, ensuring that every joint is clean and every moving part, such as an action figure's articulation, moves with the exact degree of resistance specified during the engineering phase. This attention to detail is what defines our retail-ready licensed product production as premium-tier.

Integrated Quality Assurance:

The AQL Shield

Quality assurance is not a final destination; it is a continuous thread woven into every station of the assembly line. Our primary tool for maintaining mass-production excellence is the AQL inspection in toy manufacturing.

Get Your Toys to the Retail Shelf Faster

Precision assembly and bulletproof logistics are the keys to a successful launch. Let our experts handle your 2026 fulfillment plan.

See Our Logistics Solutions | Explore Quality Control Protocols

Retail-Ready Fulfillment and Supply Chain Transparency

In 2026, being a manufacturer means being a logistics partner. We ensure that your products arrive at their destination ready for immediate sale, without the need for secondary processing.

The Art of Retail-Ready Packaging

We specialize in the application of retail-specific elements, including GTIN/EAN barcodes, RFID tags for inventory tracking, and custom blister or window-box packaging. Our packaging is designed to protect the character during toy manufacturing logistics while providing maximum shelf impact. We ensure that all "Age Warnings" and "Choking Hazard" icons are correctly positioned to meet the legal requirements of the destination market, whether that be the US, EU, or beyond.

Toy Manufacturing Process FAQ

What is the typical lead time for a new toy project?

How many samples are produced before mass production begins?

What is the difference between OEM and ODM in the toy process?

How do you ensure the final product matches the approved prototype?

Logistical Insight: The value of a manufacturer is proven in the fulfillment stage. By utilizing retail-ready licensed product production and global distribution for licensed products, we ensure your brand moves effortlessly from concept to consumer. We manage the complexity so you can celebrate the launch.