Safeguarding Intellectual Property:

A Multi-Layered Security Framework

In the competitive landscape of licensed product manufacturing, your intellectual property (IP) is your most valuable currency. For brands collaborating with manufacturing partners in China, the fear of "gray market" goods, design leakage, or outright counterfeiting is a significant barrier to entry. However, at Unstoyppable, we believe that manufacturing in China doesn't have to be a risk. By implementing a "Fortress Approach"—a multi-layered security framework that combines Chinese legal maneuvers with physical operational barriers—we ensure that your Disney FAMA and BSCI certified production remains exclusive to your brand.

Effective IP protection is not a single document; it is a proactive culture. It begins long before the first mold is cut and continues until the final retail unit is sold. Our strategy is built on three unbreakable pillars: legal registration through the China National Intellectual Property Administration (CNIPA), enforceable NNN Agreements, and a modular manufacturing strategy that ensures no single entity holds the keys to your entire kingdom.

Strategic Registration of Design Patents for Character Shapes

For licensed toy manufacturers, the physical form of a character is the IP. To prevent unauthorized factories from using your character's likeness, we assist our clients in filing for Design Patents. These patents protect the aesthetic appearance of a product—its shape, pattern, and color. In the toy industry, having a design patent is the most effective way to shut down copycats on platforms like Alibaba or JD.com. Without this local registration, a factory could technically manufacture "similar" products legally within China, even if they are clearly infringing on your global rights.

Securing Trademarks and Logos Before Production

Trademark squatting is a real threat. Opportunistic individuals often scan global trade shows to find emerging brands and register their names in China before the brand owner does. At Unstoyppable, we mandate that trademarks for logos and brand names (including their Chinese phonetic equivalents) are secured before any sensitive data is shared with our network of factories. This ensures that your brand remains yours, preventing a manufacturer from holding your brand name hostage or selling "overrun" stock under your own label.

Don't let your innovation become someone else's profit.

A single filing error can cost years of litigation. Protect your brand from day one. View our comprehensive IP Protection in China Manufacturing guide or explore our advanced Anti-Counterfeit Manufacturing Systems.

Why Your NNN Agreement Must Be China-Centric

An NNN Agreement is only a deterrent if it has "teeth." We ensure all agreements are written in Chinese as the governing language and are subject to the jurisdiction of Chinese courts. We also include "Liquidated Damages" clauses—pre-agreed financial penalties that must be paid immediately upon proof of breach. Because these contracts are enforceable locally, Chinese manufacturers take them far more seriously than a foreign-language NDA that would require an expensive, international lawsuit to enforce.

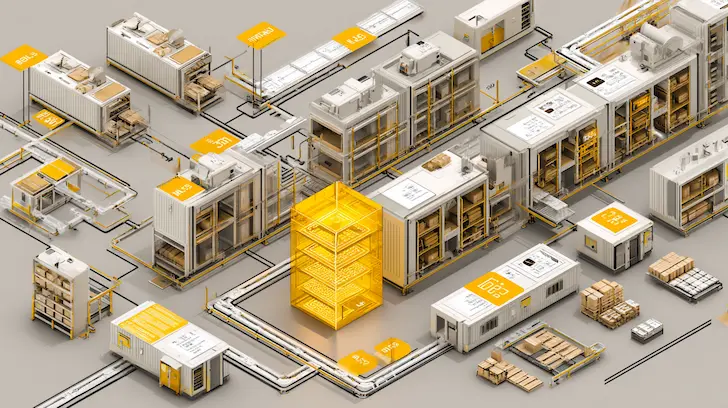

Modular Manufacturing:

Preventing "The Big Picture" Leakage

Even with the best legal contracts, Unstoyppable takes security a step further through operational compartmentalization, also known as Modular Manufacturing. The logic is simple: a factory cannot steal a product if they don't know what the final product actually is.

By combining these legal and operational safeguards, Unstoyppable provides a level of security that standard trading companies cannot match. Our deep understanding of IP protection in China manufacturing allows you to leverage the world's best production infrastructure without the traditional risks. We invite you to explore our Audited Factory Network to see how we select partners who value integrity as much as innovation.

Factory Compliance:

Meeting the Gold Standards of Global Retail

In the modern era of licensed product manufacturing, a factory’s technical capability is only half of the equation. The other, often more critical half, is its compliance status. Global retailers and multi-billion dollar IP holders no longer view social audits as optional "extras"; they are mandatory gatekeepers. At Unstoyppable, we operate with a transparent philosophy: ethical manufacturing is the only sustainable way to protect a brand’s long-term value. Our network is built exclusively around facilities that undergo rigorous third-party evaluations to ensure safety, fair labor, and environmental stewardship.

For any brand looking to place products in major retail chains like Walmart, Target, or Amazon, or for those licensing characters from the world's largest entertainment franchises, understanding the nuances of Disney FAMA, BSCI, and Sedex is essential. These aren't just acronyms; they are comprehensive frameworks designed to eliminate the risks of "modern slavery," child labor, and unsafe working conditions from your supply chain.

Understanding Disney FAMA (Facility and Merchandise Authorization)

The Disney FAMA (Facility and Merchandise Authorization) is the pinnacle of compliance in the toy and merchandise industry. Disney’s International Labor Standards (ILS) program is designed to ensure that Disney-branded products are manufactured in a manner that is consistent with the brand’s reputation for integrity. Without an active FAMA, a factory cannot legally produce or ship any Disney-branded goods.

The Step-by-Step FAMA Application Process

Navigating the FAMA process can be complex for newcomers. Unstoyppable simplifies this by managing the documentation and audit schedule through our specialized compliance team:

Comparative Analysis:

Geographic and Retailer Preferences

Understanding where your product will be sold is the first step in deciding which audit to prioritize. Generally, BSCI (Business Social Compliance Initiative) is the preferred framework for European retailers, particularly in Germany, the Netherlands, and Scandinavia. If you are targeting retailers like Lidl, Aldi, or Decathlon, a BSCI audited toy factory is almost always required.

On the other hand, Sedex (SMETA - Sedex Members Ethical Trade Audit) is the standard of choice for many UK and US-based retailers. Brands like Walmart, Tesco, and Marks & Spencer utilize the SMETA 4-Pillar audit to verify everything from labor rights to environmental impact and business ethics. At Unstoyppable, we manage these certifications so that your licensed merchandise is "retail-ready" for any global market.

Retailers won't stock your product without the right audits.

Avoid the nightmare of a rejected shipment. We ensure every factory in your project meets the specific requirements of your end-retailer. Verify our FAMA Compliant Factory status or see how we manage BSCI & Sedex Audited Toy Factories.

Preventing "Modern Slavery" and Labor Exploitation

The toy industry is labor-intensive, which unfortunately makes it a target for labor exploitation. The IETP focuses heavily on preventing "Modern Slavery" by monitoring recruitment practices and ensuring workers are not subjected to excessive overtime without consent or proper compensation. By working with Unstoyppable, you are choosing a transparent supply chain manufacturer. We utilize the IETP framework to monitor our production lines, ensuring that your entertainment merchandise manufacturing is not built on the exploitation of workers.

The Business Value of Ethical Manufacturing

Beyond the moral imperative, there is a clear business case for ethical compliance. Products manufactured in BSCI and Sedex audited toy factories face fewer delays at customs, are less likely to be subject to social media boycotts, and gain access to the world's most lucrative retail shelves. In 2026, a brand's "Social License to Operate" is just as important as its business license. Unstoyppable provides you with that license through our rigorous, multi-level audit management system.

Whether you are producing high-end collectible figures or mass-market promotional merchandise, our commitment to factory compliance remains the same. We invite you to explore our Transparent Supply Chain and Ethical Toy Manufacturing pages to see the depth of our commitment to social responsibility.

Physical Security Protocols:

From the Tooling Room to the Shipping Container

Establishing 100% Legal Ownership of Tooling

We ensure that all manufacturing contracts explicitly state that the client maintains 100% legal ownership of all molds, dies, and specialized tooling. This isn't just a formality; it includes a "Tooling Repossession" clause. This allows Unstoyppable to physically remove the molds from a factory at a moment's notice—without a court order—if a breach of contract is suspected. By maintaining this leverage, we ensure that our partner factories remain fully aligned with your brand’s interests.

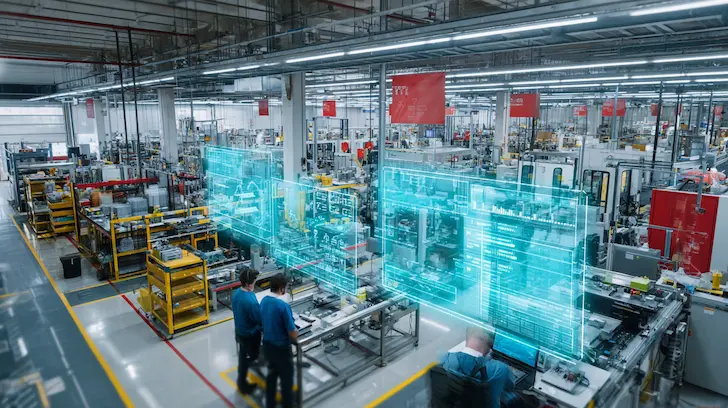

Physical GPS and RFID Tracking on Molds

In 2026, manual logs are no longer sufficient. We utilize industrial RFID tags and, for high-value tooling, embedded GPS trackers within the mold base. These sensors provide real-time data on the mold's location and usage. If a mold is moved from its designated storage library to an injection machine outside of scheduled production hours (the notorious "Third Shift"), our ERP production tracking system triggers an immediate alert. This creates a digital "chain of custody" for your most vital physical assets.

Unalterable Random Chains for Blind Boxes

The "Blind Box" market is highly susceptible to tampering. To protect the integrity of "chase" figures (rare variants), we implement Unalterable Random Chains. By using automated packing lines integrated with our ERP, the distribution of rare items is randomized by an algorithm and recorded on a private blockchain. This ensures that even factory workers do not know which specific boxes contain the rare variants, preventing internal theft and ensuring a fair experience for your customers.

Your IP is only as safe as the factory's back door.

Learn how we combine technology and boots-on-the-ground presence to secure your designs. Explore our [Confidential Licensed Product Manufacturing] solutions or see our [Transparent Supply Chain Manufacturing] in action.