PVC Figure Manufacturer:

Engineering High-Fidelity Character Collectibles

In the competitive landscape of 2026, being a premier PVC figure manufacturer requires more than just standard molding capabilities; it demands a deep mastery of polymer chemistry and material engineering. At Unstoyppable, we recognize that the modern collector and the global regulator both demand a product that is as safe as it is visually stunning. The era of generic "soft vinyl" has transitioned into the age of medical-grade PVC toys—materials that offer superior tactile feedback, incredible detail retention, and absolute chemical transparency. By leveraging our transparent supply chain manufacturing, we provide license holders with the "Smart PVC" formulations necessary to lead the market in both quality and compliance.

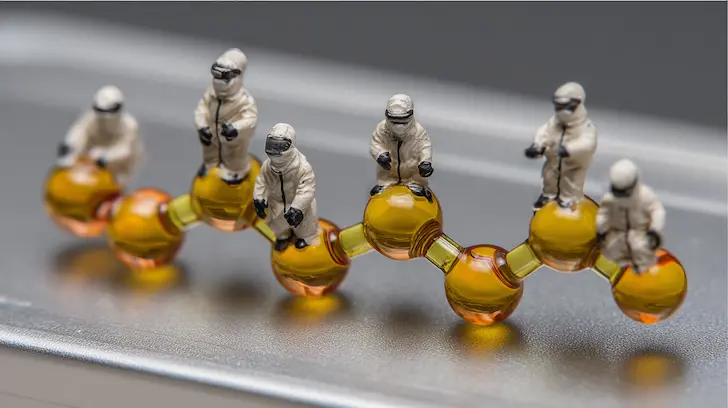

Molecular Stability and REACH Consistency

ATBC is the preferred choice for sustainable vinyl figure production because of its exceptional molecular stability. Unlike cheaper plasticizers that may migrate to the surface over time (causing that unwanted "sticky" feeling), our ATBC-PVC blends remain stable for decades. This ensures that the fine textures and paint applications on your figures remain pristine, preserving the "mint-in-box" value that collectors prize. Furthermore, our materials are fully REACH compliant, meaning they pass every test for Substances of Very High Concern (SVHC), allowing your brand to move freely through EU customs without administrative friction.

Enhanced Tactile Durability

Beyond safety, ATBC-PVC offers a superior "hand-feel." It provides a warmer, more organic touch compared to older vinyl formulations. For a PVC figure manufacturer, this material property is essential when recreating skin tones or fabric textures on a 1/6 scale collectible. It allows for a level of micro-detail that captures every pore and fiber, elevating the final product from a simple toy to a piece of character art. Our toy material engineering team works directly with resin suppliers to ensure that our ATBC blends are optimized for the specific fluidity required in high-pressure injection molds.

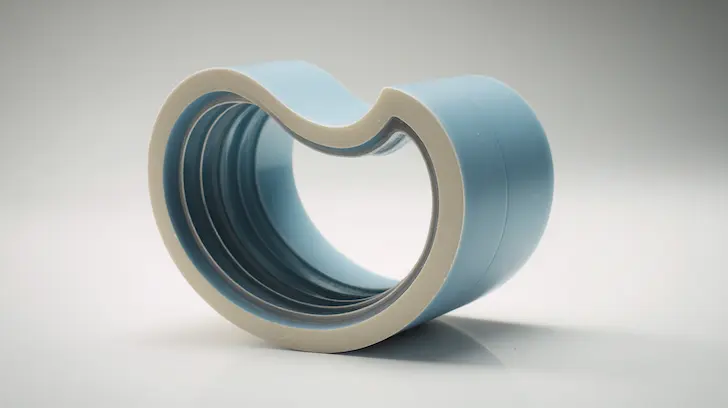

Shore 70A for Flexible Aesthetics

In contrast, elements such as flowing hair, dynamic capes, or intricate clothing accessories are manufactured using a more flexible Shore 70A or 75A blend. This flexibility is vital for character-accurate soft toys and figures, as it allows these parts to be bent during assembly without snapping. It also adds a layer of safety, ensuring that pointed edges—like a character's stylized hair—remain pliable enough to pass "sharp point" safety tests while retaining the sharp visual edge required by the style guide. This hybrid approach to hardness is what defines premium plush toy craftsmanship and figure engineering in 2026.

Elevate Your Character's Tactile Quality

Safety is the new luxury in the 2026 collectibles market. Don't settle for yesterday's plastics when you can lead with medical-grade PVC toys.

View Our Non-Toxic Materials | Explore Advanced Material Science

Eliminating the "Shelf Lean"

One of the primary failures in traditional PVC manufacturing is the "shelf lean"—where a figure begins to tilt over time due to its own weight. By integrating ABS "bones" into the legs and ankles of our figures, we ensure they remain upright for the lifetime of the product. This hybrid approach is a hallmark of a world-class collectible figure manufacturer, providing the reliability that retail partners and collectors demand.

Medical-Grade Clarity:

The Science of Translucent Effects

In the world of entertainment merchandise manufacturing, visual effects like ice, fire, magic blasts, or glowing energy are essential. Achieving these requires high-purity, medical-grade resins that provide perfect clarity without the "cloudiness" associated with standard toy-grade plastics.

The Material Advantage: At Unstoyppable, we believe that the soul of a figure is found in its chemistry. By mastering ATBC-PVC manufacturing, Shore hardness calibration, and hybrid material integration, we provide our partners with a product that is safe, stable, and visually superior. Build your 2026 collectible strategy on the foundation of Unstoyppable’s chemical excellence.

High-Steel Tooling and Precision Injection Molding for Figures

In the high-stakes world of 2026 character merchandising, the transition from a digital 3D sculpt to a physical retail product is where the true value of a collectible figure manufacturer is proven. Achieving the hyper-detailed textures and gravity-defying poses required by modern entertainment brands demands a mastery of the PVC injection molding process that goes far beyond basic toy production. At Unstoyppable, we view every figure as an industrial puzzle. Our engineering protocols are designed to solve the challenges of mass-market scalability while preserving the artistic nuance of the original creator. By utilizing high-precision steel molds and advanced part-separation logic, we ensure that your IP is rendered with absolute fidelity and structural permanence.

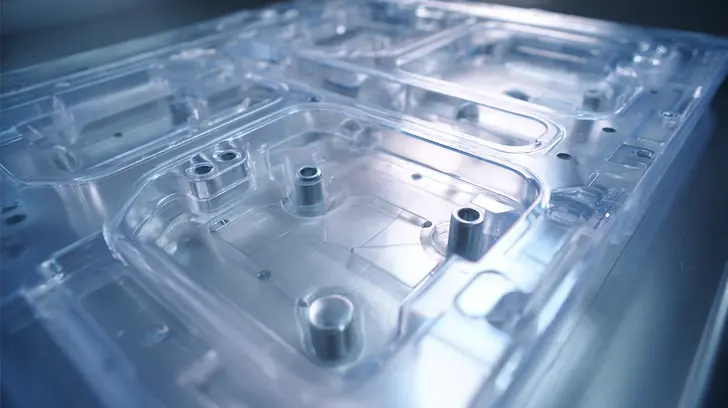

S136 Stainless Steel Tooling:

The Architecture of Detail

The quality of a PVC figure is a direct reflection of the steel used to create it. For 2026 production runs, Unstoyppable utilizes S136 high-grade Swedish stainless steel for our mold cores and cavities. This material is chosen for its exceptional hardness, corrosion resistance, and ability to hold a mirror-grade polish, which is essential for the smooth surfaces and sharp edges required in premium collectible manufacturing.

Micro-Texture Retention and Mold Longevity

High-grade S136 steel allows our high-precision steel molds to maintain 0.2mm textures—such as fabric weaves, skin pores, or mechanical etching—over the course of 500,000+ injection shots. Unlike softer steels that degrade and cause "flash" (excess plastic at the seams), our high-steel tooling ensures that the first unit off the line is identical to the last. This durability is a cornerstone of our sustainable toy manufacturing approach, as it reduces the need for tool refurbishment and ensures a consistent, zero-defect output for high-volume figure production.

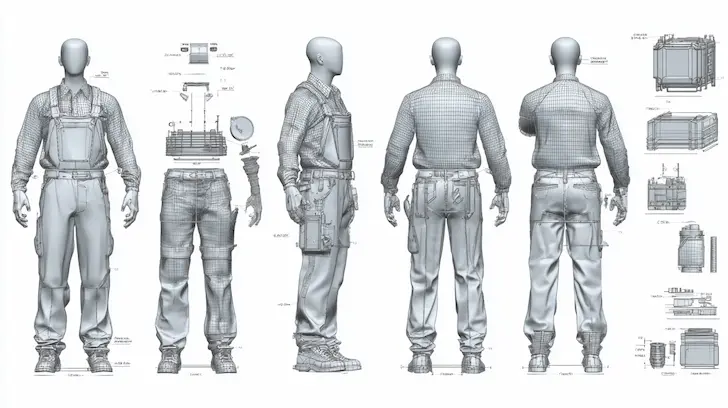

Breaking Down the Character Geometry

Our engineering team deconstructs a single character design into anywhere from 15 to 30 individual parts. By separating the head, limbs, torso, hair tufts, and accessories into distinct injection components, we can optimize the mold-pull direction for each piece. This design for mass production toys strategy allows us to capture extreme detail on all sides of a limb—something that is physically impossible in a single-mold "monolithic" pour. Each part is designed with proprietary "male-female" keys (pegs and sockets) to ensure a perfect, flush fit during final assembly.

Engineering for Dynamic Balance

When a figure is separated into multiple parts, we can strategically vary the internal thickness of different components. We often use solid injection for lower-body "anchor" parts and hollow-core injection for upper-body elements. This PVC injection molding process optimization creates a low center of gravity, ensuring that even the most aggressive, leaning poses remain stable on the retail shelf or collector's display without the need for unsightly support pillars.

Master the Art of the Dynamic Pose

Premium collectibles demand premium engineering. Leverage our high-precision steel molds and multi-part figure assembly expertise to bring your most complex characters to life.

Preventing Sink Marks and Flow Lines

By simulating the liquid plastic's path through the mold, we can adjust injection pressure and temperature in real-time to prevent "sink marks" (depressions caused by uneven cooling) and "flow lines" (visible streaks). This is especially important for liquid injection molding toys and translucent parts, where internal clarity is paramount. Our engineering-first approach guarantees a smooth, uniform surface that provides the perfect canvas for high-fidelity paint apps.

Ultrasonic Welding vs. Cold Glue:

Permanent Bonding Solutions

The final integrity of a multi-part figure depends on how it is bonded. In 2026, toy safety compliance requires that joints be "break-proof," meaning they must not separate into small parts that could pose a choking hazard. Unstoyppable employs two primary technical bonding methods to meet these standards.

The Industrial Edge: Premium figures are not "made"—they are engineered. By combining S136 high-steel tooling, complex part separation, and ultrasonic welding, Unstoyppable provides the technical infrastructure required to manufacture the world's most detailed licensed collectibles. Invest in the precision that your fans expect and your brand deserves.

High-Fidelity Finishing:

Pad Printing, Water Transfer, and Global Safety

In the world of high-end collectibles, the "deco" (decoration) phase is where a character's soul is truly realized. By 2026, the technical requirements for surface finishing have evolved to include not only aesthetic perfection but also absolute chemical safety and digital traceability. As a premier PVC figure manufacturer, Unstoyppable utilizes an advanced decoration pipeline that merges robotic precision with the latest in sustainable ink chemistry. We understand that for a licensed brand, a slight misalignment in eye printing or a faint chemical odor can devalue the entire product line. Our facility is engineered to eliminate these risks, ensuring your figures meet the 2026 gold standard for premium collectible manufacturing.

12-Color Pad Printing Systems:

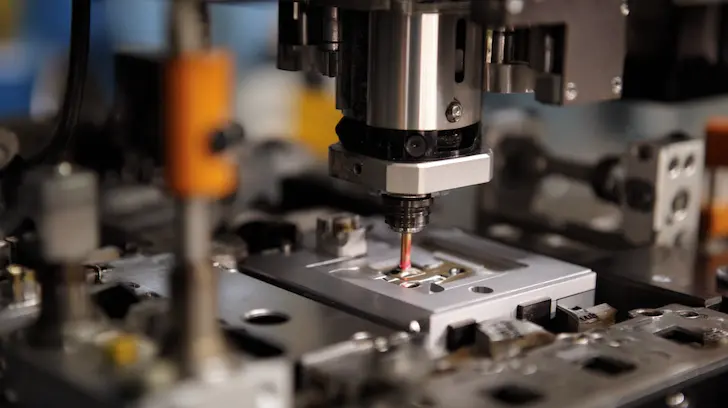

Robotic Facial Precision

The eyes and face of a figure are the most scrutinized elements of any character product. Traditional manual painting often lacks the consistency required for high-volume figure production. To solve this, Unstoyppable employs state-of-the-art 12-color pad printing for PVC figures, utilizing automated silicone pad systems that deliver pixel-perfect registration.

Achieving Pixel-Perfect Eye Alignment

Our 2026-spec pad printers are equipped with CCD (Charge-Coupled Device) camera sensors that verify the position of the figure's head before the pad makes contact. This ensures that complex iris details, highlights, and eyelash gradients are applied with a tolerance of less than $0.05mm$. By using multiple "hits" of ink in a single pass, we can create depth and life in a character's gaze that was previously only possible via hand-painting. This automated quality inspection figures process guarantees that every unit in a 100,000-piece run looks identical to the approved golden sample.

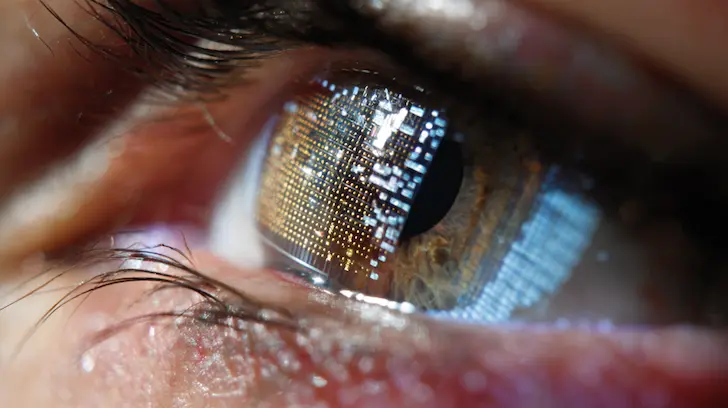

Distortion-Free Pattern Application

The water transfer film toys process involves floating a specialized printing film on a temperature-controlled water bath. As the figure part is dipped, the water pressure forces the ink to wrap around every curve and "under-cut" without distorting the pattern's scale. This is the preferred method for licensed merchandise manufacturer projects requiring high-detail repeating patterns on armor, clothing, or display bases. Our 2026 specialized dipping arms use 6-axis motion control to ensure the entry angle is perfectly consistent, eliminating the "seam lines" typical of lower-quality hydro-dipping.

UV-Curable & Lead-Free Inks:

The "Clean-Deco" Initiative

Safety in 2026 is as much about the paint as it is about the plastic. Unstoyppable’s "Clean-Deco" initiative ensures that all decorative applications are 100% lead-free and free from volatile organic compounds (VOCs). We have transitioned to UV-curable toy inks to provide a safer, more durable finish.

Future-Proof Your Collectible Line for the 2026 Market

Regulatory compliance shouldn't be a headache. Partner with Unstoyppable and let our PVC production architects handle the complexities of the new digital product passport toys mandates.

The DPP Traceability Loop:

Digital Proof of Authenticity

In 2026, the digital product passport toys (DPP) is the ultimate gatekeeper for global retail. Unstoyppable integrates this requirement directly into the physical product through the "DPP Traceability Loop."

Immutable Data Integration

We laser-etch or pad-print a unique, high-security Data Matrix code onto the base or a hidden joint of every figure. This code acts as a portal to an immutable cloud record containing the figure's EN71 and ASTM F963 lab results, the specific batch of phthalate-free toy materials used, and its FAMA compliant factory origins. This transparency protects your brand from liability and allows customs officials to fast-track your shipments through "green lanes" by instantly verifying licensed product provenance.