Injection Molded Toy Manufacturer:

Engineering Durable Licensed Assets

In the landscape of 2026 global retail, the role of an injection molded toy manufacturer has shifted from simple assembly to complex material science. At Unstoyppable, we recognize that for world-class license holders, the physical integrity of a character is as vital as its visual design. High-fidelity custom plastic toy production China now requires a sophisticated understanding of polymer behavior, thermal dynamics, and chemical purity. We provide an engineering-first approach to high-precision injection molding, ensuring that every component—from the smallest gear to the main chassis—exhibits the exact mechanical properties required for safety, durability, and brand prestige.

ABS (Acrylonitrile Butadiene Styrene) for Structural Rigidity

For the majority of high-end figures and playsets, ABS is the industry standard. This thermoplastic is prized for its high impact resistance and toughness. In ABS toy manufacturing, we utilize virgin-grade resins to ensure a high-gloss finish and a "heavy" hand-feel that denotes quality. Its superior dimensional stability allows our engineers to maintain tight tolerances, ensuring that multi-part assemblies fit together with a satisfying "click" that reflects premium toy craftsmanship.

PP (Polypropylene) and POM (Polyoxymethylene) for Functional Parts

When a design requires a "living hinge"—a thin section of plastic that can bend repeatedly without breaking—we utilize specialized Polypropylene (PP). Its fatigue resistance is unmatched for lids, caps, and folding components. For mechanical internal systems, such as gearboxes in electronic toy manufacturer projects, we deploy Polyoxymethylene (POM), also known as Acetal. POM provides the high stiffness, low friction, and excellent dimensional stability necessary for parts that must move smoothly against one another without wearing down over time.

Maintaining Tensile Strength in Bio-Resins

The engineering hurdle with bio-plastics has traditionally been brittleness. In 2026, Unstoyppable utilizes specialized additives that enhance the molecular cross-linking within bio-resins. This ensures that the high-precision injection molding process results in a part with high tensile strength, capable of withstanding the torque and tension required for character product manufacturing. We bridge the gap between environmental responsibility and industrial-grade performance.

Don't Gamble with Material Integrity

In the 2026 market, material failure is a brand-killer. Partner with a manufacturer that understands the chemistry of success.

Consult Our Resin Engineers | Explore Non-Toxic Material Catalogs

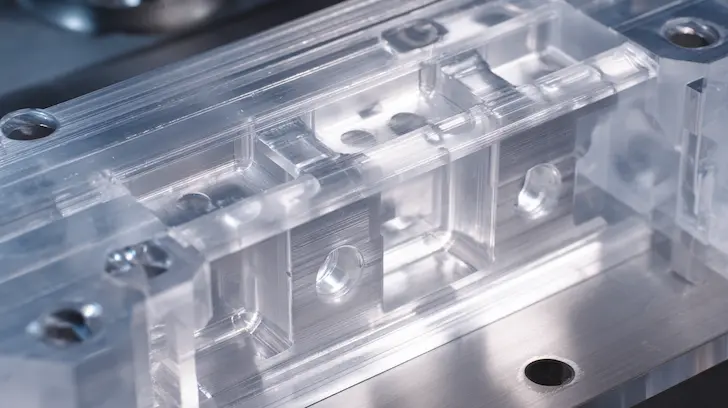

Advanced Cooling Line Engineering

To prevent "sink marks" (surface depressions) and warping, our molds feature conformal cooling channels. These are 3D-printed or precision-drilled paths that follow the geometry of the part, ensuring an even temperature drop across the entire surface. By maintaining thermal equilibrium, we ensure that the high-velocity toy injection molding process remains consistent across millions of cycles, providing our clients with retail-ready licensed products that are perfectly flat and dimensionally accurate.

Medical-Grade Purity:

Ensuring Zero Chemical Migration

In 2026, the definition of food-grade plastic toys has expanded to include a "medical-grade" mindset for all products intended for children. Unstoyppable utilizes high-purity virgin resins to eliminate the risk of contamination and chemical leaching.

The Engineering Advantage: At Unstoyppable, we treat ABS toy manufacturing as a high-stakes engineering discipline. By combining advanced resin selection, shrinkage control mathematics, and medical-grade purity, we deliver a product that is not only character-accurate but industrially superior. Build your 2026 brand on the foundation of Unstoyppable’s material mastery.

Advanced Tooling Solutions:

Multi-Cavity Molds for Global Retail Scale

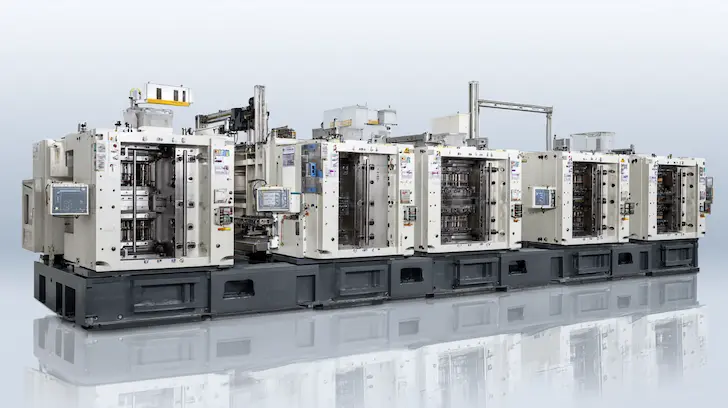

In the high-stakes environment of 2026 entertainment retail, the ability to scale from a prototype to millions of units in a matter of weeks is the defining factor of a successful product launch. At Unstoyppable, our high-speed toy injection molding infrastructure is engineered for velocity and cost-efficiency. We bridge the gap between complex character design and mass-market feasibility by utilizing advanced plastic toy tooling China strategies that maximize output while minimizing the per-unit investment. For brands managing global movie tie-ins or seasonal retail resets, our tooling solutions provide the industrial horsepower necessary to meet aggressive deadlines without a single compromise in aesthetic quality.

S136 Stainless Steel:

The Foundation of Tooling Longevity

The lifespan and precision of an injection mold are entirely dependent on the metallurgy of its core. As a specialized injection molded toy manufacturer, we utilize high-grade S136 stainless steel for our production-grade tools. This Swedish-origin steel is the gold standard for 2026 manufacturing due to its exceptional hardness and resistance to the corrosive nature of certain thermoplastic resins.

Mirror-Polished Finishes and Flash Prevention

S136 steel is capable of achieving a mirror-polished finish, which is essential for producing the "high-gloss" surfaces required for premium licensed figures. More importantly, its extreme dimensional stability prevents the tool from deforming under the immense pressures of high-speed toy injection molding. This stability ensures that the parting lines remain perfectly tight, preventing "flash"—that excess plastic bleed often seen in lower-quality toys. By investing in S136 tooling, we guarantee a million-cycle tool life, ensuring that the 1,000,000th unit is as crisp and detailed as the first.

16-Cavity and 32-Cavity Engineering

By deploying 16-cavity or 32-cavity molds, we can produce dozens of parts every 15 to 20 seconds. This high-velocity toy injection molding approach drastically reduces the machine-time cost allocated to each unit. For massive retail rollouts, this scalability is essential. Our DFM for toy manufacturing (Design for Manufacturing) phase focuses on balancing the "runner system" within these complex molds to ensure that molten plastic reaches every cavity at the exact same pressure and temperature, guaranteeing uniform weight and quality across all parts.

Scalable Output for Movie Launches

When a global media franchise launches a film, the demand for merchandise is instantaneous and massive. Our automated injection molding lines are designed to run 24/7 with minimal human intervention. By utilizing multi-cavity toy molds, we provide the capacity to generate hundreds of thousands of units per week, ensuring that retail shelves remain stocked during peak demand periods. This is the industrial standard for entertainment merchandise manufacturing in 2026.

Accelerate Your Time-to-Market

In the world of licensed retail, timing is everything. Maximize your production ROI with our high-speed toy injection molding and multi-cavity expertise.

Explore Our Tooling Solutions | Learn About DFM Optimization

Reduced Cycle Times and Better Aesthetic Finishes

Hot runner systems allow for faster injection cycles because there is no "runner" that needs to cool and harden before ejection. This speed increase can improve production output by up to 20%. Furthermore, because the plastic stays at a consistent temperature until it hits the cavity, we significantly reduce "flow lines" and "knit lines," resulting in a superior aesthetic finish that is ready for pad printing for PVC figures or further decoration.

In-Mold Decoration (IMD):

Fusing Graphics with Plastic

For toys that require high-durability graphics—such as logos, eyes, or complex textures—standard surface printing can sometimes fail under heavy play. Unstoyppable utilizes In-Mold Decoration (IMD), a process where a specialized printing film is inserted into the mold before injection.

The Industrial Advantage: At Unstoyppable, we believe that efficiency is the byproduct of superior engineering. By combining S136 steel tooling, multi-cavity toy molds, and In-Mold Decoration, we provide a high-velocity toy injection molding environment that protects your margins and your brand's reputation. Trust the shop floor where technology meets scale.

Automated Compliance:

Ensuring Zero-Defect Safety in Injection Molding

In the high-stakes landscape of 2026, the final phase of production serves as the ultimate gatekeeper for brand integrity. At Unstoyppable, we recognize that for global license holders, a single defective unit is a significant liability. Our automated quality control toys protocols are designed to eliminate human error through a sophisticated "Digital Thread" that tracks every component from the resin silo to the retail shelf. By integrating real-time monitoring and robotic stress-testing, we ensure that your products exceed ASTM F963 injection molded toys standards and European EN71 requirements. We provide a fortified shield against recalls, ensuring your licensed product safety is mathematically guaranteed before the first container is ever sealed.

AI-Driven Vision Systems:

The Future of Surface Integrity

Manual inspection is a relic of the past in 2026. To maintain the high-precision injection molding standards expected by premium entertainment brands, Unstoyppable utilizes AI-driven vision systems. These high-speed cameras are mounted directly onto our automated injection molding lines, scanning 100% of the output in real-time.

Real-Time Defect Detection at 0.1mm Resolution

Our neural-network-trained cameras detect surface imperfections as small as $0.1mm$. This includes identifying "silver streaks," minor flash, or "short shots" that the human eye might miss during high-speed toy injection molding. By catching these variances at the source, our system automatically diverts sub-standard parts for recycling, ensuring that only flawless components proceed to the multi-part figure assembly stage. This level of automated quality control toys is essential for maintaining the prestige of high-end collectibles and licensed assets.

Automated Tension and Torque Rigs

Every batch undergoes automated tension and torque testing that simulates years of aggressive play in a matter of seconds. Our robotic rigs apply precise Newtons of force to limbs, heads, and accessories to ensure no component can be detached or broken into a choking hazard. This data is logged directly into our ERP production tracking system, providing a permanent record that your ASTM F963 injection molded toys are structurally superior. We turn safety from a checkbox into a core engineering achievement.

Impact and Drop-Test Compliance

Using high-speed gravity-drop simulators, we verify that our ABS toy manufacturing blends maintain their integrity even when dropped from heights exceeding standard consumer-safety requirements. This "Over-Engineering" approach ensures that even under extreme circumstances, your product remains intact, protecting both the child and your brand’s reputation for quality in custom plastic toy production China.

Secure Your Brand's Future

In 2026, compliance is not an option—it is a competitive necessity. Partner with a manufacturer that treats licensed product safety as a core engineering discipline.

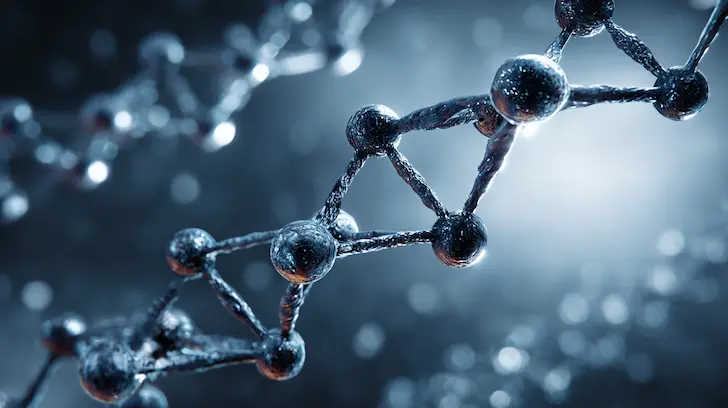

Anti-Counterfeit "DNA":

Molecular Authentication

To provide 100% IP security, Unstoyppable offers the integration of microscopic chemical tracers—what we call "Anti-Counterfeit DNA"—directly into the plastic resin during the injection molded toy manufacturer process. These tracers are invisible and do not affect the plastic’s mechanical properties. However, they can be detected by a specialized handheld scanner at any point in the global supply chain. This allows you to instantly prove licensed product authenticity and distinguish genuine goods from unauthorized "backdoor" production or counterfeits. We provide the technical evidence to defend your IP globally.