The Gold Standard of Toy Safety:

Navigating Global Regulatory Frameworks

In the high-stakes world of licensed product manufacturing, safety is the primary currency of brand trust. As we navigate the complexities of 2026, the regulatory landscape has undergone its most significant transformation in over a decade. At Unstoyppable, we operate as your proactive guardian, ensuring that every product not only meets but exceeds the stringent requirements of the world’s major markets. Our commitment to toy quality and safety compliance is foundational, providing OEM manufacturing solutions that de-risk your intellectual property and secure your place on the global retail shelf. Whether you are launching a flagship movie merchandise line or a niche collectible series, our engineering-led approach to compliance ensures a seamless path from the factory floor to the consumer's home.

The Digital Product Passport (DPP):

A New Era of Transparency

The most visible change in 2026 is the mandatory Digital Product Passport (DPP). Every toy model placed on the EU market must now carry a unique digital identity. We facilitate this by affixing a robust data carrier—typically a high-resolution QR code—directly onto the toy or its permanent label. This QR code links to a centralized EU registry containing the toy’s declaration of conformity, chemical safety assessments, and traceability data. This system empowers customs authorities and consumers alike to verify safety instantly. Our ERP production tracking system is fully synchronized with DPP requirements, managing the unique product and operator identifiers necessary for modern global distribution for licensed products.

Stricter Chemical Frontiers:

Halving Migration Limits

The 2026 EU Regulation has drastically tightened the limits for hazardous substances. Specifically, migration limits for heavy metals such as lead, arsenic, and mercury have been halved compared to 2009 standards. Furthermore, the 2026 rules introduce a generic ban on PFAS (Forever Chemicals) and endocrine disruptors, ensuring that materials are safer at the molecular level. Our toy material engineering team works exclusively with certified resin suppliers to guarantee that all substrates, coatings, and inks comply with these new, lower thresholds. We provide the technical documentation required to prove that your products are 100% free from restricted aromatic amines and allergenic fragrances, maintaining the highest levels of ethical toy manufacturing in China.

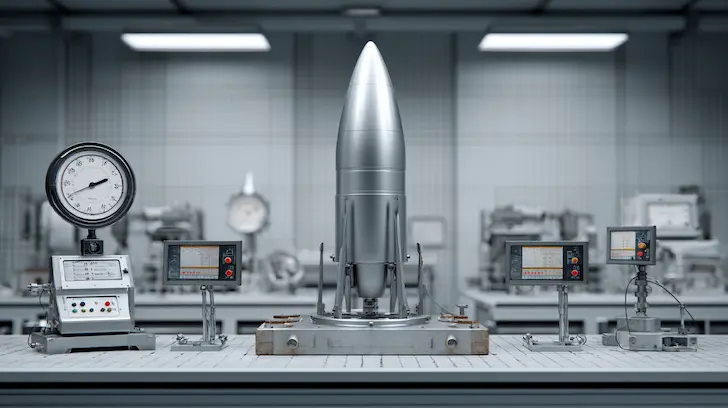

Mechanical Precision and Projectile Safety

Mechanical safety is where character engineering for toys meets real-world physics. The 2026 revisions to ASTM F963 have expanded the testing for kinetic energy in projectile toys and the durability of swallowable magnets. We utilize automated toy safety testing equipment to measure "impact force" and "tension strength" with scientific precision. By simulating years of heavy play through automated stress-testing rigs, we ensure that no small parts detach and no sharp edges emerge, even after the product has left the retail shelf. This proactive testing is why our entertainment merchandise manufacturing is trusted by the world's most protective IP holders.

Compliance is not a hurdle; it is your competitive advantage.

Our EN71 Compliant Toy Manufacturer protocols are already fully updated for the 2026 EU Safety Regulation (2025/2509).

Download our 2026 Compliance Checklist or learn how we ensure CPSIA Compliance Manufacturing.

100ppm Lead Limits and 0.1% Phthalate Thresholds

We strictly enforce the 100ppm total lead limit for all accessible substrates and an even more stringent 90ppm limit for paints and surface coatings. Furthermore, our phthalate-free toy materials initiative ensures that the eight regulated phthalates (including DEHP, DBP, and BBP) never exceed the 0.1% threshold. In 2026, we have expanded this to include the voluntary removal of all non-regulated bisphenols, offering a "clean label" advantage for your lifestyle product manufacturer projects. Our AQL inspection in toy manufacturing includes XRF (X-ray fluorescence) screening on the factory floor to catch any potential contamination before the product ever reaches a laboratory.

The Necessity of Permanent Tracking Labels for 2026

Traceability is the final pillar of CPSIA compliance. Every children's product must bear a permanent tracking label that is visible and legible. We ensure that your retail-ready licensed product production includes these marks, detailing the manufacturer’s name, the location and date of production, and the specific batch or run number. These labels are integrated into the product’s mold or permanently printed during the golden sample development process. This level of detail not only satisfies the CPSC but also streamlines logistics and retail fulfillment, allowing for surgical precision in the unlikely event of a product recall. With Unstoyppable, your brand is protected by a transparent supply chain manufacturing model that prioritizes safety above all else.

Navigating the global regulatory maze requires a partner with both local presence and international expertise. By mastering EN71, ASTM F963, and CPSIA, Unstoyppable provides the IP security and factory compliance needed to thrive in 2026. We invite you to explore our Toy Manufacturing Process or see how we manage IP Protection in China Manufacturing to see our full-spectrum commitment to excellence.

Chemical Integrity:

Beyond the Surface of Toy Materials

In 2026, the definition of toy safety has expanded from mere physical durability to deep chemical integrity. As a leading licensed product manufacturer, Unstoyppable recognizes that the molecular composition of a toy is just as critical as its structural engineering. The modern consumer, particularly within the entertainment merchandise manufacturing sector, demands total transparency regarding what goes into the products their children handle every day. We meet this demand through rigorous toy material engineering and a "safety-by-design" philosophy that eliminates toxic hazards before they ever reach the production line. Our commitment to non-toxic engineering ensures that your brand remains a symbol of trust and quality in a highly regulated global marketplace.

Sourcing "Bio-Balanced" Plasticizers

To maintain the flexibility and "hand-feel" required for plush toy manufacturer China projects and soft PVC figures, we utilize Bio-Balanced plasticizers. These innovative substances are derived from renewable organic feedstocks, such as vegetable oils, rather than fossil fuels. They provide the exact same mechanical properties as traditional phthalates—offering excellent durability and vibrant color retention—while being 100% phthalate-free toy materials. This transition allows our clients to market their products as "bio-based" and "clean," providing a significant competitive advantage in the premium retail sector.

The "Combined Exposure Assessment" Protocol

Safety in 2026 is no longer about testing chemicals in isolation. Unstoyppable utilizes the Combined Exposure Assessment protocol. This advanced scientific method evaluates how different chemical components within a single toy interact when exposed to saliva, sweat, or prolonged skin contact. By simulating "worst-case" play scenarios, we ensure that the cumulative effect of all materials remains well below safety thresholds. This holistic approach to toxicological risk assessment is a cornerstone of our IP protection and factory compliance, shielding your brand from the complexities of modern chemical sensitivities.

Your brand's safety is non-negotiable. We provide total peace of mind.

We offer Third-Party Toy Lab Testing at every stage of production. Explore our Phthalate-Free Toy Materials technology or Inquire about Automated Toy Safety Testing.

Automated Toy Safety Testing:

2026 AI-Driven Inspections

While human inspection is valuable, the 2026 manufacturing environment demands the precision of automated toy safety testing. By removing human fatigue and subjectivity from the equation, we provide a level of consistency that manual methods cannot replicate. Our BSCI audited toy factories are equipped with the latest AI-driven inspection modules, ensuring your custom licensed product development is flawless.

AI-Powered Optical Sensors for Micro-Defect Detection

We utilize AI-powered optical sensors on our assembly lines to scan every unit in real-time. These high-speed cameras are trained to detect "micro-defects" that are invisible to the naked eye, such as microscopic sharp edges on molded plastic or tiny detachments in plush toy seams. If a defect is detected, the automated toy safety testing system instantly diverts the unit for manual review. This 100% inspection rate is how we maintain zero-defect performance for high-stakes entertainment merchandise manufacturing launches.

In the world of licensed toy manufacturing, what you can't see matters most. Our advanced testing and material science capabilities ensure that the "invisible" side of your product is as high-quality as its visual design. We encourage you to learn more about our Toy Quality & Safety Compliance standards or explore our Audited Factory Network in China to see how we maintain these standards across every production line.

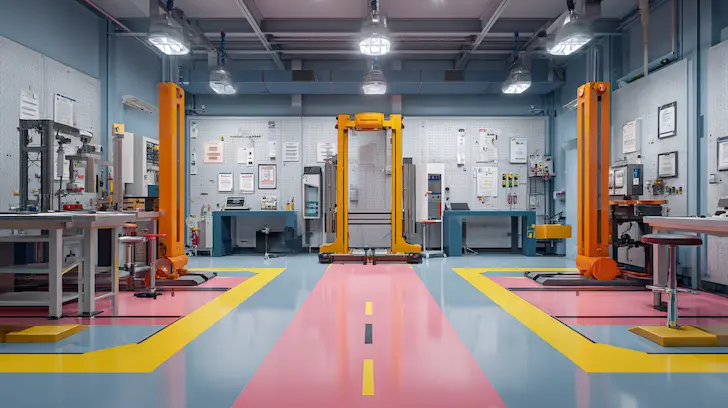

The Quality Fortress:

AQL Inspections and Final Certification

In the final stretch of the licensed toy manufacturing process, quality is not a matter of chance; it is a matter of statistical certainty. At Unstoyppable, we have built a "Quality Fortress" that surrounds your production, ensuring that every shipment arriving at your warehouse is retail-ready and brand-compliant. Our toy quality and safety compliance systems are anchored by rigorous on-site inspections and high-level factory audits. By implementing a standardized "Accept/Reject" logic, we provide IP protection and factory compliance that eliminates the risk of defective goods entering the stream of commerce. In 2026, where global retailers have zero tolerance for quality slips, our OEM manufacturing solutions offer the reliability you need to protect your reputation and your bottom line.

AQL Inspection in Toy Manufacturing:

Statistical Certainty

To manage high-volume production, we utilize the AQL (Acceptance Quality Limit) system, the international standard for professional quality control. Based on the ISO 2859-1 standard, AQL allows our AQL inspection in toy manufacturing teams to determine the quality of a massive production run by inspecting a mathematically significant random sample. This ensures that the inspection is both thorough and efficient, providing a high confidence level in the entire batch’s integrity.

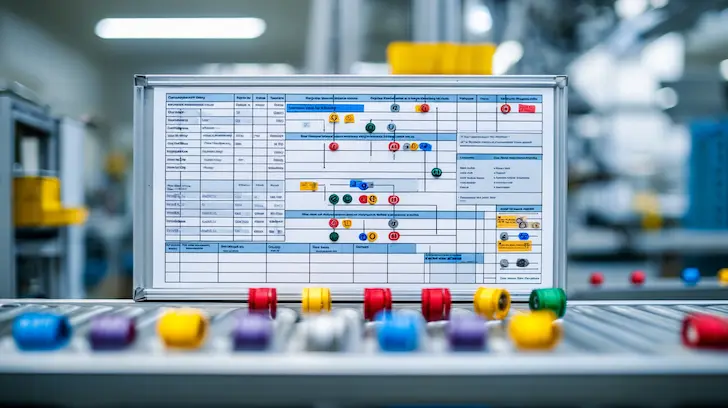

Defining the 2026 Standard for Licensed Toys

For entertainment merchandise manufacturing, where brand precision is paramount, Unstoyppable enforces a strict "Tier 1" AQL standard for 2026. This standard is divided into three critical categories of defects:

Ethical Manufacturing as a Quality Driver

It is a proven fact in licensed toy manufacturing in China: happy, well-trained, and fairly treated workers produce significantly fewer defects. A BSCI audited toy factory ensures that workers operate in safe, well-lit environments with proper training on toy manufacturing technology. When workers understand the safety implications of their tasks—such as the importance of a needle-detection scan in soft goods—the "human error" component of production is drastically reduced. By choosing Unstoyppable, you are investing in an ethical toy manufacturing China ecosystem that values both people and products.

Protect Your IP with Audited Excellence

Our AQL Inspection protocols and BSCI/Sedex factory network ensure your toys are safe, ethical, and retail-ready. Don't leave your brand to chance.

Explore our Audited Factory Network or Book a Quality Inspection for Your Project.