Diversified Manufacturing:

Scaling Your Vision Across All Categories

Specialized Fabric Sourcing and rPET Initiatives

"Hand-Feel" Engineering for Character Authenticity

PVC Figure Manufacturer:

High-Detail and "Skin-Feel" Finishes

Vinyl Toy Manufacturer:

Rotocasting and the Sofubi Trend

The vinyl toy manufacturer sector has seen a massive resurgence, driven by the urban vinyl and "Sofubi" (soft vinyl) trends. Unstoyppable utilizes the rotocasting process, where liquid vinyl is spun within a heated mold to create hollow, lightweight, yet incredibly durable figures. This technique is ideal for designer art toys that require a unique aesthetic. We offer various degrees of vinyl hardness and transparency, allowing for creative effects like "crystal" clears, glow-in-the-dark additives, and metallic flake infusions that resonate with the modern collector community.

Whether you need a soft companion or a rigid collectible, our multi-category expertise ensures brand consistency.

Explore our Plush Toy Manufacturer China capabilities or see our PVC Figure Manufacturer portfolio to start your project.

Backpacks, Stationery, and Functional Merchandise

We specialize in the creation of retail-ready licensed bags, ranging from ergonomic school backpacks to high-end fashion totes. Our soft-goods expertise allows us to combine durable materials like 600D Polyester and Vegan Leather with character-specific features such as 3D molded silicone zipper pulls and custom-printed inner linings. Beyond bags, we support lifestyle product manufacturing for stationery sets, tech accessories (like silicone AirPods cases), and home décor items like character-themed cushions and lamps.

Meeting Aesthetic Standards of Premium Lifestyle Brands

Lifestyle products require a different design sensibility than toys; they must be functional, durable, and aesthetically sophisticated. We work closely with brand owners to ensure that the integration of the IP is tasteful and high-quality. This includes utilizing advanced toy material engineering to create hybrid products—such as a backpack with a built-in plush character or a desk lamp with a high-fidelity injection molded base. Our BSCI audited toy factories are equipped to handle these multi-material assemblies, ensuring that your lifestyle range is produced ethically and delivered on time for seasonal retail windows.

Smart Toys and Electronics:

2026 Tech Integration

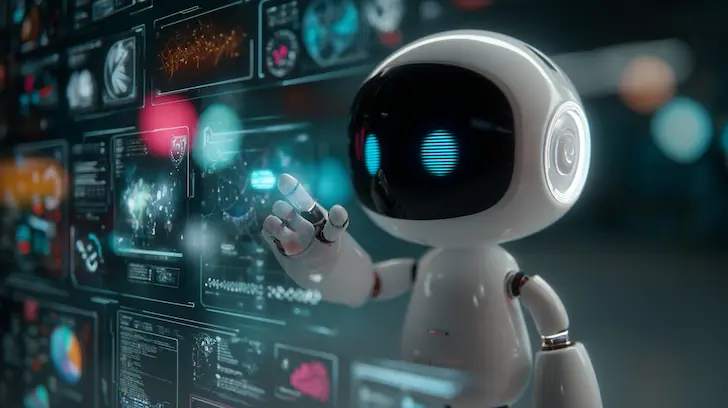

The toy industry in 2026 is undergoing a profound digital transformation. No longer confined to plastic shells, modern playthings are evolving into sophisticated interactive systems that bridge the gap between physical reality and digital imagination. As a forward-thinking licensed product manufacturer, Unstoyppable integrates the latest semiconductor technology and software engineering into our production lines. We help brands move beyond static objects to create "living" products that engage, educate, and evolve alongside the child. Our expertise as a leading electronic toy manufacturer ensures that your brand stays at the forefront of this high-tech revolution while maintaining the highest levels of safety and IP security.

Seamless Connectivity:

Bluetooth and App Integration

Modern licensed toys are now hubs of interactivity. We integrate Bluetooth-connected toy modules that allow figures and playsets to communicate with dedicated mobile apps or tablets. This connectivity enables "over-the-air" (OTA) updates, meaning your character can receive new stories, seasonal voice lines, or updated games long after it has left the retail shelf. This dynamic content delivery turns a one-time purchase into a long-term service platform, fostering deeper brand loyalty.

Voice Recognition and High-Fidelity Audio

True immersion requires a toy that can listen and respond. Our electronic toy manufacturer division utilizes advanced Digital Signal Processing (DSP) to enable clear voice-recognition capabilities even in noisy environments. By using high-fidelity speakers and noise-canceling microphones, we ensure that character voices sound "on-model" and responses are instantaneous. This technology allows children to have "contextual conversations" with their favorite characters, bringing the magic of entertainment franchises into the real world with unprecedented realism.

Adaptive AI and Personalized Engagement

We implement "Adaptive AI" layers that allow a toy to learn from a child’s responses. If a child shows a preference for a specific story or game, the toy adjusts its future interactions to match those interests. This personalization ensures that every play session feels unique. For licensed character products, this means the character can remember a child’s name, their favorite color, or their progress in a learning game, creating an emotional bond that a static toy simply cannot match.

Privacy First:

Secure Offline Processing and COPPA Compliance

With great tech comes great responsibility. Safety and privacy are our highest priorities. To protect child data, Unstoyppable prioritizes offline, "Edge-AI" processing. By running the AI models directly on the toy's hardware rather than the cloud, we ensure that no voice recordings are transmitted over the internet, effectively neutralizing the risk of data leaks. Our systems are built to be COPPA (Children’s Online Privacy Protection Act) and GDPR-K compliant by design, using hard-coded "guardrails" that prevent the AI from generating inappropriate content or soliciting personal information. We ensure your brand is associated with innovation, not privacy concerns.

The future of play is interactive.

Don't let your brand fall behind in the 2026 tech race. Join the revolution with our [Electronic Toy Manufacturer] division or see how we use [Manufacturing Technology & Automation] to lower your landed costs. Explore our Smart Toy Solutions.

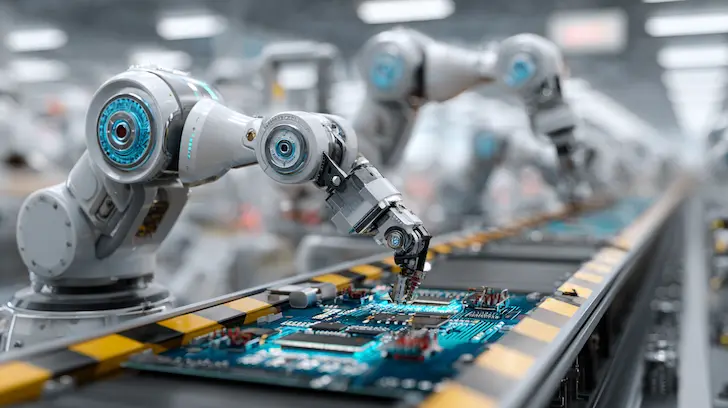

Real-Time ERP Monitoring and Quality 4.0

Our ERP production tracking system provides a real-time digital twin of the factory floor. Every electronic component is tracked via serial number through the SMT (Surface Mount Technology) line. This allows for "Quality 4.0"—a data-driven approach where sensors monitor the temperature, humidity, and solder-paste volume for every single board. If a single parameter drifts out of spec, the system pauses production instantly. This rigorous monitoring is how we achieve 0% defect rates in complex electronic assemblies, protecting your brand from the costs and reputation damage of product recalls.

Automated Safety and Functional Testing

Before any electronic toy is packed, it passes through an Automated Safety Testing station. Here, specialized rigs perform "stress-testing" on the battery modules, verify the signal strength of the Bluetooth antennas, and run diagnostic software to ensure the AI responses are within the approved guardrails. By removing manual testing from the equation, we ensure a level of consistency that satisfies the world's most demanding retailers and toy safety regulators. This is the Unstoyppable advantage: where world-class engineering meets high-volume efficiency.

Whether you are developing a STEM-focused robot or an AI-enhanced collectible figure, our product manufacturing capabilities provide the technical backbone you need. We invite you to learn more about our Automation Technologies and see how we integrate safe AI into modern play. Returning to the Unstoyppable Index will provide a complete overview of our end-to-end manufacturing ecosystem.

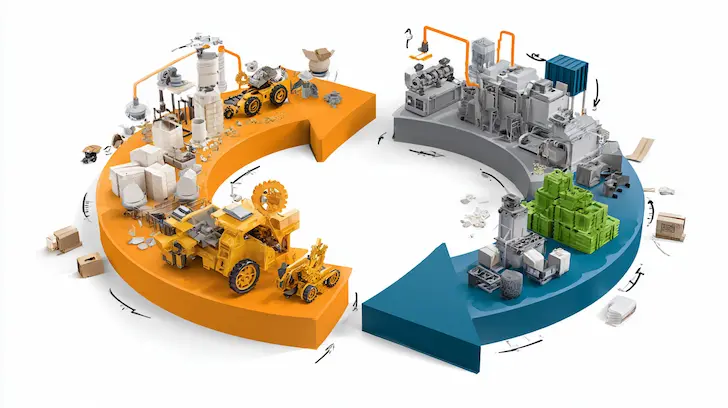

Specialty Collectibles and The Sustainable Future

As the global toy market bifurcates into high-end "Kidult" collectibles and mass-market retail, the demands on product manufacturing capabilities have never been higher. Today’s consumers expect a convergence of artistry, ethical responsibility, and supply chain transparency. At Unstoyppable, we are positioned at the forefront of this shift, combining artisan-level finishing for collectors with pioneering sustainable toy manufacturing technologies. Our 2026 framework ensures that your brand does not just occupy a shelf space but leads the industry in material innovation and retail-ready fulfillment.

High-Fidelity 3D Printing for "Golden Samples"

Before moving to mass production, we utilize high-fidelity 3D printing (SLA and DLP) to create rapid prototypes that serve as the "Golden Sample." This allows brand owners to approve every microscopic detail—from the texture of a character's fabric undersuit to the realism of a hand-painted head sculpt—before expensive steel molds are cut. This design for mass production (DFM) approach minimizes errors and ensures that the final PVC figure manufacturer run is 100% faithful to the original digital sculpt.

Sustainable Toy Manufacturing:

2026 Green Material Revolution

Environmental stewardship is now a mandatory requirement for global retail. With the 2026 EU Green Claims Directive in full effect, Unstoyppable provides the verifiable data and bio-based materials needed to claim true sustainability. We are moving beyond simple "recyclable" labels to active carbon-negative production.

Join the Green Revolution in Toy Manufacturing.

Meet the 2026 sustainability standards today. Verify our [Sustainable Toy Manufacturing] credentials or see how we use [PHA & Bio-Plastics] to protect the planet and your brand's future. Explore our Eco-Solutions.

Promotional Merchandise and Mass-Market Solutions

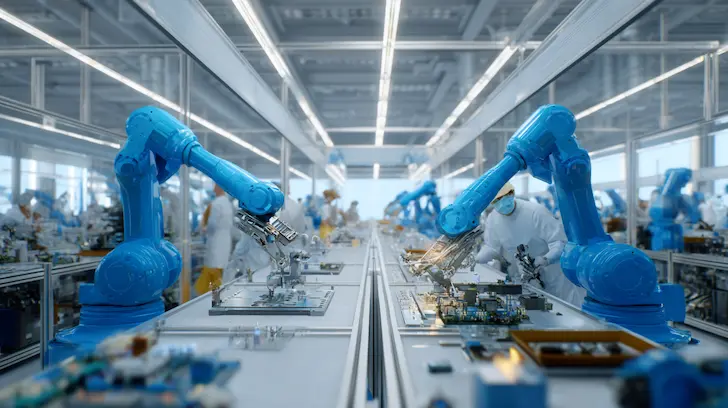

High-volume "Blind Box" and promotional merchandise manufacturer projects require a unique balance of speed, cost-efficiency, and absolute IP security. We help brands launch massive global campaigns without compromising on the quality that fans expect from their favorite franchises.

Scaling Success:

Blind Bags and High-Volume OEM

For large-scale retail events or movie launches, we scale production using automated assembly lines that can produce millions of units monthly. Even at this volume, we maintain AQL (Acceptable Quality Level) standards that exceed industry norms. Our "Blind Bag" systems are fully integrated with our ERP production tracking, ensuring that rare "chase" figures are distributed with mathematical precision across the global supply chain, preventing internal "skimming" and ensuring consumer trust.