From Vision to Prototype:

Decoding the Brand Style Guide

The journey from a digital concept to a physical object sitting on a retail shelf is a sophisticated transformation that begins with a deep respect for the creator's vision. In the style guide to retail product process, the initial translation stage is where the "Soul" of a brand is codified into a physical blueprint. A Style Guide is the legal and creative constitution of an Intellectual Property (IP); it contains the DNA of the characters, from the exact curvature of a smile to the specific Pantone shade of a costume. At Unstoyppable, we treat this document as a sacred roadmap. Our licensed product development team specializes in "Visual Interpretation"—the art of ensuring that when a fan holds the final product, they feel the same emotional connection they do when watching the character on screen. By bridging the gap between artistic intent and industrial reality, we ensure brand integrity in manufacturing is maintained at every touchpoint.

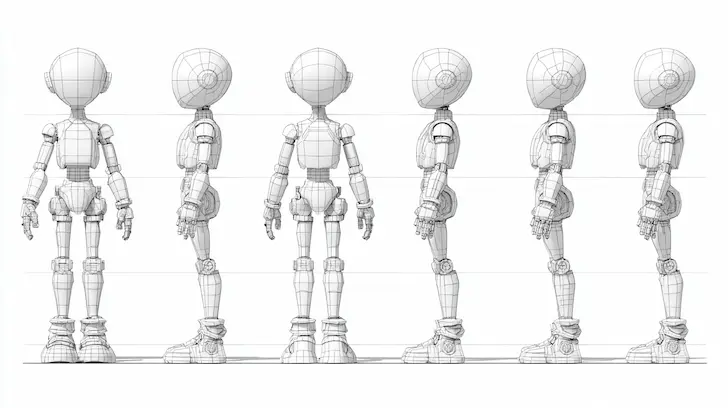

Character Turns and Orthographic Views

To begin character asset translation, we require "Character Turns"—front, back, side, and three-quarter views of the subject. These orthographic drawings are the foundation of professional toy prototyping. When a licensor provides these assets, our CAD sculptors use them to build a 3D digital model that maintains the character's proportions from every conceivable angle. We pay special attention to "Line Weight" and "Volume," ensuring that the transition from a flat 2D drawing into a 3D space does not lose the character's unique silhouette. This stage is vital for licensed product development because it allows us to identify potential structural challenges before they become manufacturing hurdles.

Color Science and Texture Callouts

A style guide is never complete without its color palette. We ingest Pantone Solid Coated references to establish the baseline for the product's appearance. However, translating 2D characters to 3D also requires interpreting textures. Is the character's skin matte or glossy? Is their armor metallic or brushed steel? Our creative directors analyze the style guide's texture callouts to determine the "Surface Finish" specifications. We document these requirements in a master technical file that follows the product through the entire style guide to retail product process, ensuring the final plastic or fabric matches the digital intent perfectly.

Engineering for Industrial Logic

During the audit, we also look for "Industrial Logic." We identify where parts need to be separated for molding (parting lines) and how to hide these seams within the character's natural features, such as belt lines or armor joints. This proactive engineering ensures that translating 2D characters to 3D results in a clean, high-end collectible rather than a toy that looks "mass-produced." We focus on creating a design that is as beautiful as it is manufacturable, protecting the aesthetic value of the IP at all times.

Ensure Your Character’s Soul is Preserved in 3D

Don't let your IP lose its magic in translation. Partner with a manufacturer that speaks the language of the Style Guide.

Learn About Character Production | Explore Our Prototyping Lab

The Paint Master:

The Ultimate Brand Reference

The "Paint Master" (or Hand-Painted Sample) is the pinnacle of the licensed product development stage. Our master painters apply colors by hand, following the Pantone callouts to the letter. This sample includes all the fine details—weathering, eye gradients, and metallic highlights. This Paint Master serves as the "Universal Truth" for the project. It is sent to the licensor for final sign-off and then stays in the factory as the visual benchmark for the style guide to retail product process. Every unit that comes off the assembly line months later must be a faithful replica of this master sample.

Managing Licensor Feedback:

The Iterative Loop

A critical, yet often overlooked, part of the style guide to retail product process is the feedback loop. At Unstoyppable, we act as the intermediary that manages this communication to keep the project on schedule while maintaining brand integrity in manufacturing.

The Unstoyppable Vision: True brand integrity in manufacturing is achieved when the physical product is indistinguishable from the digital dream. By mastering the style guide to retail product process, we ensure your IP is ready to conquer the market. Your vision is our blueprint.

Scaling Excellence:

Compliance Validation and Mass Production Setup

Moving from a single, hand-crafted "Paint Master" to a licensed product mass production run of tens of thousands of units is the most rigorous transition in the toy industry. It is the moment where artistic perfection must meet industrial repeatability without losing a shred of brand value. In the 2026 landscape, this transition is governed by strict legal frameworks and global toy safety standards 2026. Validation is the process of proving that the "Artist's Master" can be safely and legally replicated by a FAMA compliant factory in China. At Unstoyppable, we bridge this gap by implementing a "Validation Protocol" that scrutinizes every material, joint, and chemical compound. We ensure that your brand’s expansion is built on a foundation of legal security and physical safety, transforming a creative asset into a compliant global commodity.

The FAMA Checkpoint:

The Legal Prerequisite for Scalability

In licensed product mass production, the first step of validation is not physical, but administrative. Before a single pellet of resin is melted, the legal right to produce must be verified through the Facility and Merchandise Authorization (FAMA).

Authorized Facility Verification

Every brand under the Disney, Marvel, or Star Wars umbrella requires that production occurs exclusively within a FAMA compliant factory in China. This checkpoint ensures that the facility has passed the International Labor Standards (ILS) audit and is currently "Active" in the licensor's database. At Unstoyppable, we perform a pre-production FAMA check for every project. We verify that the factory's authorization covers the specific category of goods you are manufacturing. This legal validation protects you from the catastrophic risk of shipment seizure and ensures that your scaling licensed character production strategy is fully sanctioned by the IP owner.

Mechanical Safety and Age-Appropriate Engineering

Style guides often feature characters with pointed capes, thin antennae, or small detachable accessories. While these look great in a digital render, they pose "Sharp Point" or "Choking Hazard" risks in the real world. During scaling licensed character production, we re-engineer these features. We might suggest subtly blunting a sharp edge or over-molding a small part to ensure it exceeds the "Tension Test" requirements. This ensures the character's look is preserved while the toy becomes a 100% safe product for its intended age grade. We treat safety as a core design element, ensuring that "Good Design" is synonymous with "Safe Design."

Chemical Validation and REACH Compliance

In 2026, the chemical composition of toys is under more scrutiny than ever. Validation requires that every ink, pigment, and plasticizer used in licensed product mass production be documented and tested. We work exclusively with a FAMA compliant factory in China that utilizes third-party toy lab testing to verify the absence of phthalates, heavy metals, and BPA. By performing "Pre-Testing" on raw materials before they enter the production line, we guarantee that the final product will pass its official certification with ease.

Scale Your Brand with a Compliance Specialist

Don't let hidden safety risks or FAMA lapses stop your growth. Partner with Unstoyppable to navigate the 2026 compliance maze with ease.

Verify Your Factory Compliance | Explore Safety Standard Guides

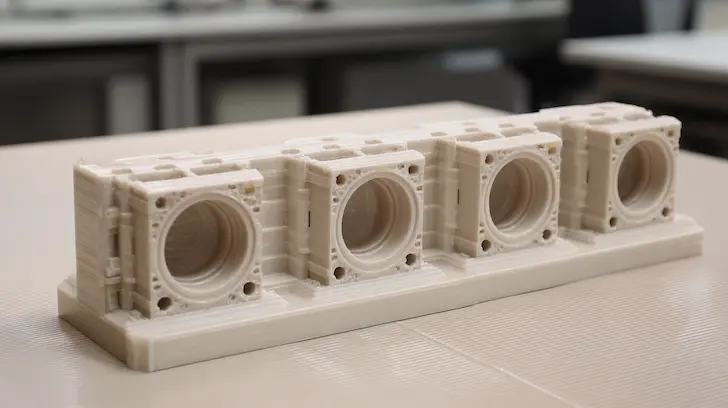

Surface Finish and Texture Replication

The "Hand-Feel" of the character—whether it is the soft matte of a face or the high-gloss of a helmet—must be consistent. During the validation stage, we define the "VDI Surface Finish" standards for the molds. This ensures that the texture callouts from the style guide are etched into the steel tools with microscopic precision. This level of licensed product mass production planning ensures that every unit feels like a premium, "Official" item, reinforcing the fan's trust in the brand.

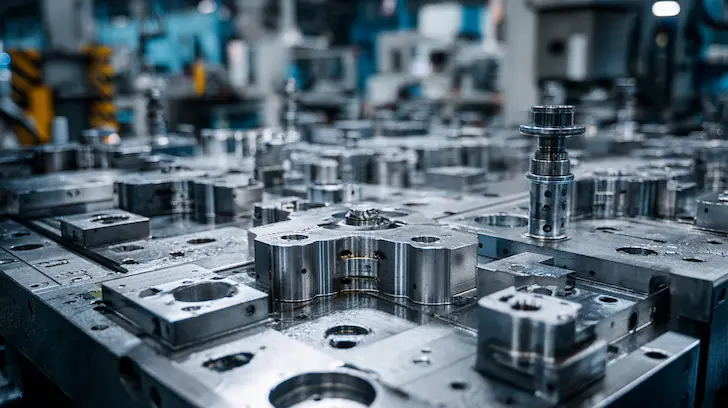

Tooling for High Fidelity:

The Steel Architecture of Success

Mass production scalability is ultimately limited by the quality of the tooling. For scaling licensed character production, we invest in "High-Fidelity Tooling" designed for multi-year usage.

The Validation Mandate: In the world of global licensing, scalability is nothing without compliance. By verifying your FAMA compliant factory in China and integrating global toy safety standards 2026 into your tooling, you create a product that is both commercially powerful and legally secure. We don't just scale production; we scale peace of mind.

The Shelf-Ready Finale:

Packaging, Logistics, and Global Launch

The journey from a creative vision to a tangible consumer purchase culminates in the "Market Entry" stage. This is the moment where toy manufacturing logistics and creative presentation converge to ensure your product survives the rigors of the global supply chain and shines on the retail shelf. Success in this phase is measured by "Shelf-Presence"—the ability of a product to capture a consumer’s attention while meeting every technical requirement of big-box retailers. As a comprehensive retail-ready packaging manufacturer, Unstoyppable manages the intricate choreography of the final push. We ensure that your global distribution for licensed products is synchronized with your marketing beats, providing a triumphant conclusion to the manufacturing cycle. From the first barcode scan to the final unboxing, we make sure your brand’s debut is flawless, compliant, and commercially powerful.

Packaging that Sells:

The "First Moment of Truth"

In the world of toys, the packaging is an extension of the character itself. It is the first physical interaction a consumer has with your brand, and it must communicate quality, authenticity, and excitement instantly.

Style-Guide-Compliant Graphics and Legal Copy

Our role as a retail-ready packaging manufacturer is to ensure that your box art is as iconic as the toy inside. We utilize the assets from your Style Guide—logos, character art, and backgrounds—to create high-impact blister packs, window boxes, and collector tins. Beyond the aesthetics, we manage the "Legal Blueprint" of the package. This includes the mandatory placement of safety icons, age grading, and licensor-specific legal lines. By integrating GTIN/EAN barcode labeling early in the design phase, we ensure that your packaging is both a marketing masterpiece and a masterpiece of retail compliance.

GTIN/EAN Barcode Labeling and RFID Integration

Accuracy in GTIN/EAN barcode labeling is the foundation of modern retail. A single unreadable barcode can lead to vendor chargebacks or even the rejection of an entire shipment. We implement a multi-point verification system to ensure every label is crisp, correctly positioned, and contains the accurate data for the specific SKU. For 2026 mandates, we also offer RFID (Radio Frequency Identification) tagging, allowing for real-time inventory tracking at the retail level. This level of technical detail ensures your global distribution for licensed products moves through automated sorting centers with maximum speed.

Palletization and Master Carton Standards

Retailers have strict requirements for "Master Carton" dimensions, weight, and labeling. We optimize our palletization to ensure maximum space efficiency while protecting the goods. By following the "Retail-Ready" (RRP) philosophy, we can ship goods in displays that are ready to be placed directly on the shelf, reducing labor costs for the retailer and ensuring your brand is always presented exactly as intended. This logistical efficiency is a core part of how we manage toy manufacturing logistics for high-volume franchises.

Finish Strong with Retail-Ready Fulfillment

Your global launch depends on bulletproof logistics and compliant packaging. Let our team plan your distribution strategy for 2026.

Customs Clearance Excellence:

The Perfect Paper Trail

The final hurdle for customs and export for toys is the "Documentary Audit." To avoid delays at the border, we ensure that every shipment is accompanied by a perfect "Paper Trail." This includes the active FAMA (Facility and Merchandise Authorization), the Declaration of Conformity (DoC), and the Children's Product Certificate (CPC). Our global distribution for licensed products team pre-validates these documents with customs brokers to ensure a "Clear to Land" status before the ship even arrives at the port. We eliminate the risk of demurrage and ensure your goods move from the sea to the store without hesitation.

Style Guide to Retail Shelf FAQ

How long does the journey from style guide to retail shelf take?

Can Unstoyppable help with the packaging design if the brand only provides character assets?

What are the most common bottlenecks in the licensed product process?

How is IP protected during the shipping and fulfillment stage?

Logistical Vision: A product is only successful when it reaches the hands of the fan. By mastering toy manufacturing logistics and the nuances of retail-ready packaging, we ensure that your brand's story has a triumphant ending on the global stage. We deliver the dream, on time and on brand.