A Master-Planned Supply Chain:

Our Strategic Toy Manufacturing Hubs in China

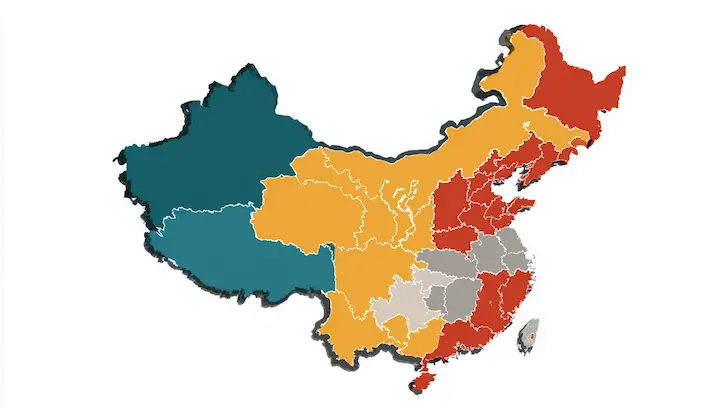

Success in the global toy market is deeply rooted in geographic intelligence. At Unstoyppable, we recognize that the China toy manufacturing hubs are not a monolith; rather, they are a highly specialized ecosystem where each city and province offers distinct industrial advantages. Our Guangdong toy factory network is the backbone of our operations, but we strategically extend our reach into Zhejiang and Jiangsu to capture specific material expertise. By aligning your product's technical requirements with the regional strengths of our audited factory network, we optimize every variable of production—from material purity and assembly precision to the final landed cost of toys. Understanding the "Strategic Geography of Excellence" is the first step in building a resilient, high-fidelity supply chain that protects your IP while maximizing retail margins.

The Power of Guangdong:

Shantou and Dongguan

Guangdong province remains the undisputed heart of global toy production. Within this province, our Shantou Chenghai plastic toys network serves as the global epicenter for injection molding. Chenghai is home to a hyper-concentrated infrastructure of mold-makers, resin suppliers, and injection molded toy manufacturers. When a project requires millions of high-fidelity plastic figures with complex geometries, Chenghai is the industrial soil where these projects thrive. The speed of iteration in this hub is unmatched, allowing us to move from tooling to mass production with incredible efficiency.

Further west, our Dongguan toy assembly hubs provide the technical sophistication required for complex electronic toy assembly and high-end collectibles. Dongguan has evolved into a high-tech manufacturing center where robotic integration and precision decoration are the standard. This is our primary destination for interactive licensed products that require integrated IC chips, motorized components, and multi-stage AQL inspection in toy manufacturing. By utilizing the regional toy production advantages of Dongguan, we ensure that the most advanced character products are built with the same precision as high-end consumer electronics.

Discover the Ideal Hub for Your Brand

Maximize your production efficiency by leveraging our regional toy production advantages. We place your project in the heart of its specialized industry.

Explore Injection Molding Hubs | View Plush Manufacturing Centers

Seamless Sourcing of Raw Materials

In our Shantou Chenghai plastic toys cluster, a resin shortage can be resolved in hours rather than weeks. Because our audited factory network is embedded within these clusters, we have immediate access to the latest material innovations, such as phthalate-free plastics or specialized metallic inks for character armor. This localized sourcing reduces the logistical complexity of the supply chain and ensures that toy quality and safety compliance is maintained, as we only source from pre-vetted, local material suppliers who understand our rigorous standards.

Optimized Internal Transport and Fulfillment

Logistical efficiency is not just about the final ship to the US or Europe; it is about the movement of components between specialized facilities. In our Dongguan toy assembly network, the proximity of paint shops to assembly lines means that parts spend less time in transit and more time in production. This reduces the risk of transit-related damage and contamination, which is critical for high-fidelity character products. By minimizing internal transport times, Unstoyppable provides a faster "speed-to-market" for your movie launches and seasonal retail windows.

The Insider’s Advantage: Navigating the China toy manufacturing hubs requires more than a map; it requires the deep-rooted relationships and technical oversight that only Unstoyppable provides. We don't just pick a factory; we engineer a geographic strategy that optimizes every cent of your toy manufacturing logistics. By placing your product in its natural industrial home, we ensure it is born into a world of expertise. Unstoyppable: Strategic geography for unstoppable brands.

Beyond the Certificate:

The Rigorous Unstoyppable Factory Vetting Process

In the high-stakes world of intellectual property, a paper certificate is merely the beginning of the journey. To ensure the absolute integrity of your brand, Unstoyppable has developed a comprehensive factory audit checklist China that goes significantly deeper than standard industry requirements. We understand that for a global brand owner, the factory is the most significant point of risk. Our mission is to transform that risk into a controlled, high-performance asset. Vetting licensed toy manufacturers is a complex, multi-dimensional discipline that requires local boots on the ground and a deep understanding of Chinese industrial law. At Unstoyppable, we take on the full burden of liability and the operational "headache" of vendor management. Every facility within our audited factory network has passed our proprietary "Unstoyppable Protocol," ensuring they possess the financial stability, technical precision, and ethical foundation to support the world’s most demanding entertainment licenses.

Tier 1:

Legal and Financial Stability

Before we evaluate a single toy, we evaluate the business. A factory must demonstrate long-term viability and absolute legal transparency. Our technical audit for toy factories begins with a deep dive into corporate records. We verify valid business licenses, export permits, and tax compliance. Crucially, we assess "Banking Transparency"—ensuring that the factory operates within the formal financial system to prevent the risks associated with shadow banking or unstable cash flows. By verifying the financial health of our partners, we guarantee that your production run will never be interrupted by sudden facility closures or material supplier disputes. We provide you with a partner that is as stable as your own corporation.

Tier 2:

Compliance Infrastructure

For any brand associated with major studios, being "Audit-Ready" is a 24/7 requirement. Our vetting process ensures that a facility is not just passing an annual check, but is fundamentally built on a Disney FAMA compliant framework. We examine the facility's internal documentation systems, their history with BSCI audited toy factory China standards, and their ability to host unannounced inspections from third-party bodies. We verify that the factory has a dedicated compliance officer whose sole job is to maintain the standards required by the Disney ILS audit requirements. When you choose a facility through Unstoyppable, you are choosing a site that welcomes scrutiny and upholds the gold standard of global manufacturing ethics.

Protect Your Reputation with a Vetted Supply Chain

Don't leave your brand's integrity to chance. Our factory audit checklist China is designed to catch risks before they become problems. Let our experts manage your facility vetting.

The "Active Management" Difference:

A Dynamic Ecosystem

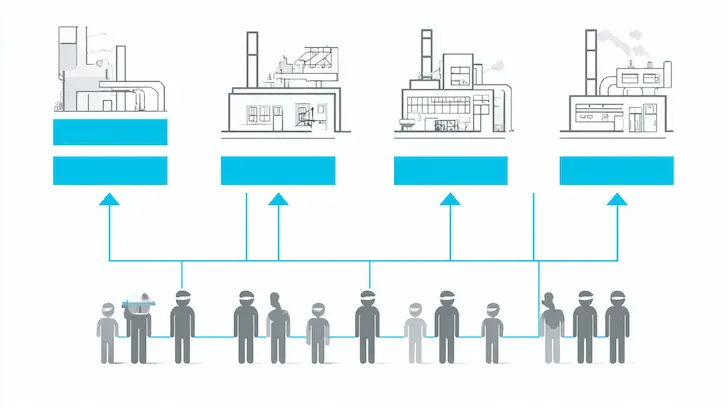

A primary failure of traditional "trading companies" is the "Place and Forget" mentality. They find a factory, place an order, and hope for the best. Unstoyppable operates on an entirely different philosophy: **Active Management**. Our audited factory network is not a static list; it is a dynamic, high-performance ecosystem that is monitored in real-time by our on-site teams.

Weekly Technical Inspections

Maintaining the technical audit for toy factories standard requires constant presence. Our localized engineers perform weekly on-site visits to every active production line. During these visits, we don't just look at the final product; we look at the process. We check the temperature settings on injection molding machines, the calibration of paint-mixing equipment, and the humidity levels in the assembly rooms. This level of ongoing factory monitoring allows us to detect and correct microscopic deviations before they impact the final AQL (Acceptable Quality Level) results. We provide you with the peace of mind that comes from knowing your product is under expert surveillance every single week.

Professional Insight: A factory is only as reliable as the management system overseeing it. By utilizing the Unstoyppable Audit Protocol, you are moving beyond simple vendor selection and into a world of managed manufacturing excellence. We provide the industrial fortress your IP deserves. Verified. Audited. Unstoyppable.

Built for Scale:

Risk Mitigation and Redundancy in Licensed Production

In the high-pressure world of global retail, the ability to scale rapidly while mitigating industrial risk is the hallmark of a successful brand. At Unstoyppable, we have engineered a manufacturing ecosystem that prioritizes mass production risk management through the power of a diversified network. While a single-factory model is inherently vulnerable to localized disruptions, power restrictions, or labor shortages, our scalable toy manufacturing China infrastructure provides an "elastic" capacity that expands to meet your most ambitious growth targets. We provide the peace of mind that comes from supply chain redundancy for toys, ensuring that your movie launch or seasonal holiday window is never compromised by a single point of failure. By partnering with Unstoyppable, you are not just securing a production line; you are investing in a future-proof toy supply chain designed to withstand the complexities of the 2026 global market and beyond.

Eliminating Single-Point Failures through Active Redundancy

The greatest threat to a high-volume toy manufacturing capacity is dependency on a single facility. Our audited factory network is specifically designed to eliminate this vulnerability. By maintaining identical technical specifications and mold development & injection tooling standards across multiple pre-vetted sites, we create a fail-safe production environment.

Seamless Production Shifting

If a specific region in China faces a temporary industrial disruption or if one facility reaches its peak high-volume toy manufacturing capacity, Unstoyppable can seamlessly shift production to an identical, Disney FAMA and BSCI audited facility within our network. Because we manage the technical data and quality protocols centrally, the transition is invisible to the end consumer. This supply chain redundancy for toys ensures that your "Street Date" is a certainty, not a variable. We provide a level of industrial security that independent factories simply cannot offer, protecting your retail shelf space and your brand’s reputation for reliability.

Unified Management of Multi-Disciplinary Projects

Instead of forcing your project into the limited capabilities of one factory, we decompose the product into its core technical requirements. We assign the plastic components to our Shantou Chenghai plastic toys experts, the electronics to our high-tech Dongguan assembly partners, and the textile elements to our Yangzhou plush specialists. This future-proof toy supply chain approach ensures that every inch of the product is made by a master of that specific material. Most importantly, these separate streams are unified under a single Unstoyppable project manager, providing you with one point of contact, one consolidated invoice, and one cohesive quality standard. We handle the complex toy manufacturing logistics of sub-component synchronization so you can focus on brand strategy.

Secure Your Production Future Today

Partner with a network that never stops growing. We provide the high-volume toy manufacturing capacity and redundancy your brand deserves.

Digital ERP Production Tracking

Transparency is the ultimate goal of a future-proof toy supply chain. We utilize a proprietary ERP production tracking system that links our various factory hubs into a single digital dashboard. As a client, you receive real-time updates on mold progress, material sourcing, and assembly milestones. This level of data integration allows us to predict and resolve potential bottlenecks weeks before they impact the final delivery date. We are moving beyond the era of "Email Updates" and into an era of live industrial visibility. At Unstoyppable, we don't just tell you your production is on track—we show you the data that proves it.

Audited Factory Network FAQ

How many factories are currently in the Unstoyppable network?

How often are the factories re-audited?

Does Unstoyppable own these factories or partner with them?

Can a client request production in a specific province of China?

A Partnership for the Future: The era of relying on a single, unmanaged factory is over. In today’s fast-paced, IP-sensitive market, success requires the supply chain redundancy for toys and the technological edge that only a managed network can provide. By choosing Unstoyppable, you are buying into a resilient, innovative, and ethically sound industrial system that grows with your brand. Secure your legacy with the network that never stops.