Future-Proof Play:

Advanced Toy Manufacturing Technology and Automation

The landscape of global play is undergoing a digital and mechanical metamorphosis. At Unstoyppable, we recognize that the transition from manual labor to automated toy manufacturing is not merely an efficiency upgrade—it is a strategic necessity for brands managing high-value intellectual properties. As we navigate the complexities of 2026, the reliance on traditional assembly is being replaced by a smart factory toy production model that prioritizes precision, speed, and absolute consistency. By integrating cutting-edge 2026 toy industry technology into our audited factory network, we provide our clients with a competitive edge that manual facilities simply cannot match. This technological shift ensures that your character’s journey from a digital file to a retail shelf is governed by mathematical accuracy and robotic reliability.

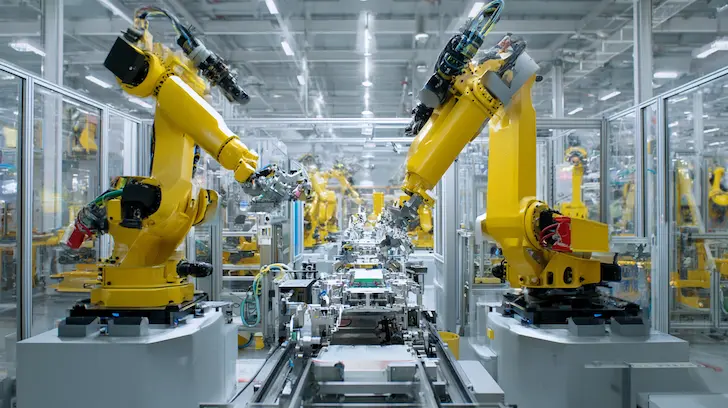

Intricate 3D Painting and Pad Printing

For complex pvc figure manufacturer projects, the eyes and fine facial details of a character are the "make or break" elements of quality. Our network utilizes 6-axis robots equipped with high-resolution vision systems to perform 3D spray painting and pad printing. These robots can adjust their trajectory in real-time to account for microscopic variations in the plastic mold, ensuring that every iris is perfectly centered and every logo is flawlessly aligned. This level of robotic toy assembly China effectively eliminates the "human error" variable, such as hand-fatigue or inconsistent paint application, which often plagues large-scale manual production runs.

Flawless Secondary Part Insertion

In high-volume manufacturing, the assembly of small internal components—such as electronics, springs, or articulated joints—requires extreme consistency to avoid "rattle" or structural failure. Our automated lines use vacuum-sealed robotic grippers to perform secondary part insertions with micron-level accuracy. This ensures that in a 100,000-piece production run, the 100,000th unit is an identical twin to the "Golden Sample." By stabilizing these critical assembly points, we significantly improve the "First-Pass Yield" and ensure that your brand’s reputation for quality remains untarnished.

Ready for High-Precision Scaling?

Don't let manual inconsistency slow your brand down. Partner with Unstoyppable to leverage the most advanced robotic toy assembly China has to offer.

The 2026 Edge:

AI-Driven Production Scaling

The most significant leap in our 2026 toy industry technology roadmap is the integration of AI in toy manufacturing for predictive operations. In the past, a mold failure during a critical movie-launch window could result in weeks of lost shelf time. Today, we use AI-driven predictive maintenance to eliminate that risk entirely.

Predictive Maintenance and Zero Downtime

By analyzing the vast amounts of data generated by our IoT-enabled machines, our AI systems can predict exactly when a mold's core pin might show signs of wear or when a heating element is nearing the end of its lifecycle. This allows our engineers to perform maintenance *before* a failure occurs, usually during scheduled shift changes. This "Self-Healing" approach to smart factory toy production ensures that your production line never stops moving, protecting your "Street Date" and ensuring your inventory is ready for global distribution exactly when the marketing heat is at its peak.

A System of Certainty: Automation at Unstoyppable is about more than just robots; it is about providing our clients with a system of industrial certainty. By combining high-precision injection molding with AI in toy manufacturing, we remove the guesswork from the supply chain. Your IP deserves the precision of the future, delivered today. Secure your production future with a network that never stops innovating.

The Digital Pulse:

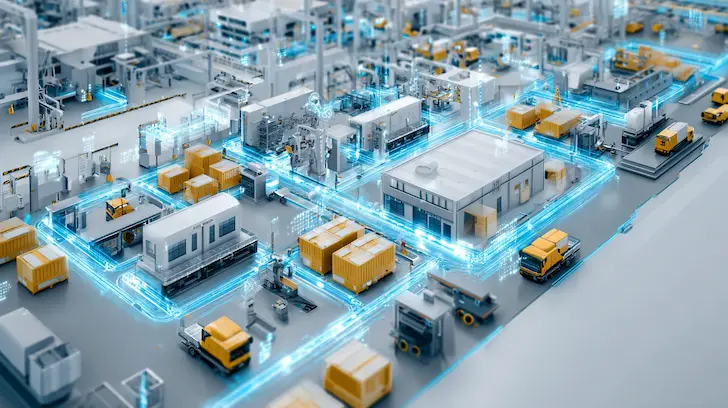

Real-Time ERP Production Tracking System

Live-Feed Production Milestones

When you partner with Unstoyppable, you gain access to a real-time "live feed" of your production cycle. This system tracks critical phases including material sourcing, where we verify the arrival of GRS-certified resins; mold testing, where T1 through T4 sample results are uploaded instantly; and final assembly. This level of smart supply chain transparency allows project managers to identify potential bottlenecks before they impact the shipping date. If a specific component is delayed or a mold requires unexpected refinement, you know about it the moment our factory floor managers do. This proactive data sharing transforms the manufacturer-client relationship from one of suspicion to one of collaborative partnership.

Automated Quality Control (AQC) Systems

Precision is the hallmark of a successful licensed product, and human eyes—while skilled—are subject to fatigue. To ensure that every unit meets your rigorous standards, we have integrated Automated Quality Control (AQC) systems directly into our production lines. By leveraging automated quality data, we provide a level of oversight that is both objective and infallible.

Take Control of Your Supply Chain

Stop guessing and start seeing. Experience the power of ERP production tracking for toys and gain full visibility into your 2026 manufacturing cycle.

Protecting IP through Digital Encryption

In the world of entertainment merchandise manufacturing, data security is just as important as physical security. A leaked 3D file or style guide can result in counterfeit goods reaching the market before your official launch. Our cloud-based manufacturing management system is designed with a "Security-First" architecture to prevent such breaches.

Restricted Access and Encrypted Data Flow

We utilize advanced digital encryption to protect all proprietary assets. Access to your 3D engineering files and production specifications is strictly restricted through multi-factor authentication and role-based permissions. Only authorized engineers within our audited factory network can access the specific segments of the data required for their task. This ensures licensed merchandise data security across the entire supply chain. Furthermore, all data transfers between your headquarters and our servers are protected by industrial-grade SSL encryption, preventing any unauthorized "cyber-snooping." By digitizing the workflow within a secure ecosystem, we provide a level of IP protection in China manufacturing that traditional, paper-based factories simply cannot provide.

Visibility is Power: Our ERP production tracking for toys gives you the data you need to make informed decisions in real-time. From automated quality data to encrypted 3D files, we provide a secure, transparent environment for your most valuable assets. Unstoyppable: Your window into the future of manufacturing.

Scalable Efficiency:

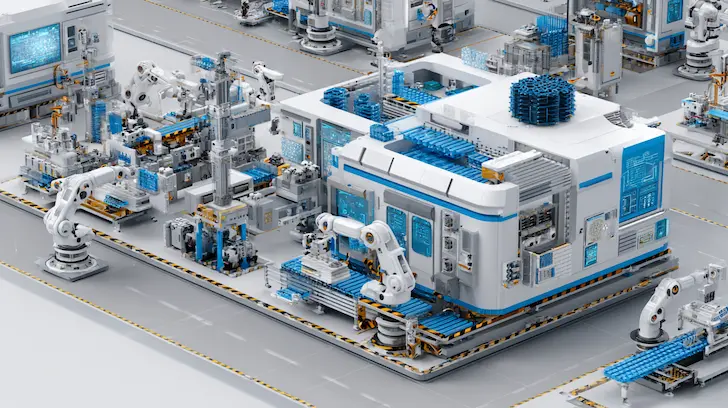

Reducing Costs Through Industrial Automation

In the competitive global marketplace of 2026, the ability to scale production rapidly while maintaining price leadership is the ultimate strategic advantage. At Unstoyppable, we have mastered the art of low-cost automated manufacturing by integrating advanced robotics into the very fabric of our production lines. Automation is the engine that drives our scalable toy production China model, allowing brand owners to expand their reach without the traditional risks of labor-intensive scaling. By replacing manual variables with mechanical constants, we provide a future-proof toy supply chain that is resilient to fluctuating labor costs and geopolitical shifts. Our investment in 2026 industrial robotics trends ensures that your brand remains agile, profitable, and capable of meeting the explosive demand of a global movie launch or a viral holiday season.

Enhancing Artisan Craftsmanship

In the production of high-end collectibles and detailed licensed figures, certain "finishing touches"—such as weathered paint effects or hand-applied fabric elements—require a human eye. Our Cobots handle the heavy lifting, such as precision gluing and primary component alignment, allowing our artisans to focus exclusively on the high-value aesthetic details. This synergy in cobots in toy manufacturing maximizes output while maintaining the "soul" of the character. By utilizing robots for the high-volume, repetitive movements, we achieve a significant increase in units per hour without the massive overhead of a 100% manual workforce. It is a win-win for quality and cost-efficiency.

Rapid Reconfiguration for Diverse SKU Ranges

Because Cobots are easily programmable and portable, they allow our audited factory network to pivot between different product lines in a matter of hours. This flexibility is essential for entertainment merchandise manufacturing, where a single franchise may require a diverse range of SKUs including action figures, vehicles, and play-sets. We provide you with the ability to scale your production up or down with surgical precision, ensuring that your inventory levels are always perfectly aligned with retail demand.

Chemical Analysis at the Speed of Production

We utilize automated XRF (X-ray fluorescence) scanners on our intake lines to verify that raw materials are 100% phthalate-free toy materials and lead-free before they even enter the molding machines. By automating the chemical screening process, we catch potential contamination at the source. This proactive approach to toy quality and safety compliance means that by the time your product is boxed and ready for global distribution for licensed products, it has already passed a gauntlet of digital and mechanical safety checks that far exceed the industry standard.

Optimize Your Margins with Automation

Lower your costs while increasing your quality. Our low-cost automated manufacturing model is designed for brands that refuse to compromise.

The Future is Unstoyppable

As we look toward the 2026 industrial robotics trends, the divide between traditional factories and smart networks will only widen. Brands that choose the path of automation are choosing a future-proof toy supply chain that is faster, safer, and more profitable. At Unstoyppable, we provide you with the most advanced industrial system on the planet. We don't just build toys; we build the future of play. Partner with a network that never stops innovating and make your brand truly Unstoyppable.