Custom Licensed Product Development:

Bridging Creative IP and Mass Production

In the competitive global marketplace of 2026, the transition from a 2D concept to a three-dimensional retail success requires more than simple replication. It demands a sophisticated custom licensed product development strategy that respects the artistic soul of the intellectual property while adhering to the rigid realities of industrial manufacturing. At Unstoyppable, we serve as the critical bridge between creative visionaries and the factory floor. Our process is designed to ensure that every bespoke toy manufacturing China project we undertake results in a product that is not only visually stunning but also structurally sound, safe, and ready for high-velocity retail distribution. By integrating IP-driven product engineering at the earliest stages of design, we empower brand owners to push the boundaries of what is possible in character merchandise.

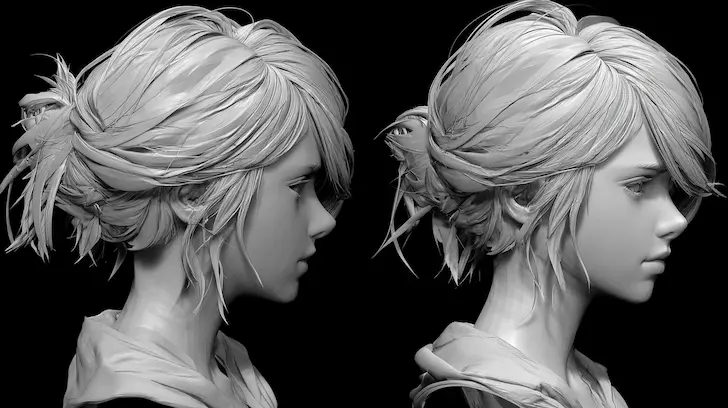

Interpreting 2D Vision for 3D Reality

Translating a 2D illustration into a physical form is a complex task. A character’s hair might look perfect from a front-facing drawing, but how does it look from the back? How does it interact with the character’s shoulders? Our custom toy development process begins with a deep-dive analysis of your IP’s visual language. We utilize advanced digital sculpting to ensure that every angle of the physical product honors the original intent. This meticulous attention to detail is why Unstoyppable is a trusted partner for custom licensed product development; we understand that for a fan, even a millimeter of deviation from the character’s "on-screen" look can diminish the product's value.

Color Fidelity and Texture Matching

Consistency is the hallmark of a professional licensed product. We utilize high-precision pigment matching to ensure that the colors approved in the digital stage are identical to the colors that come off the assembly line. Furthermore, we interpret the "implied textures" of concept art—such as the metallic sheen of a robot or the soft grain of a creature's skin—and select the appropriate manufacturing finishes to bring those details to life. This ensures a high-fidelity brand reproduction that satisfies both the licensor's brand managers and the end consumer.

Sustainable Bio-Resins and the 2026 Green Mandate

Modern custom licensed product development must prioritize environmental stewardship. We offer a range of sustainable bio-resins and recycled-content polymers that meet the 2026 Green Mandate without sacrificing aesthetic detail. By choosing these materials, brand owners can market their merchandise as "Eco-Friendly," a significant selling point for modern Gen Z and Gen Alpha parents. At Unstoyppable, we prove that bespoke toy manufacturing can be both beautiful and responsible.

Do You Have a Unique Character Concept?

Turn your 2D sketches into a market-ready retail sensation with our expert IP-driven product engineering team.

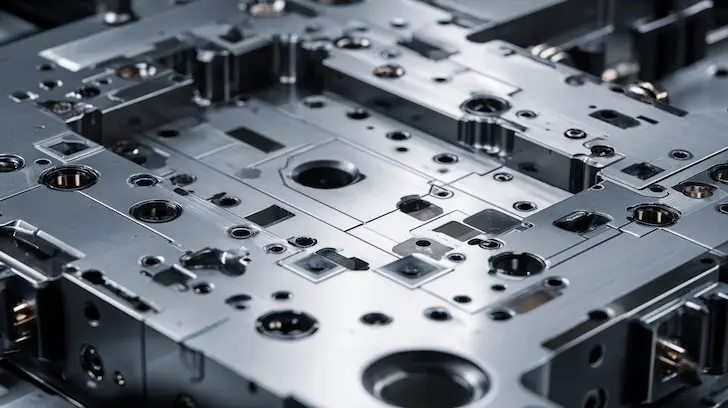

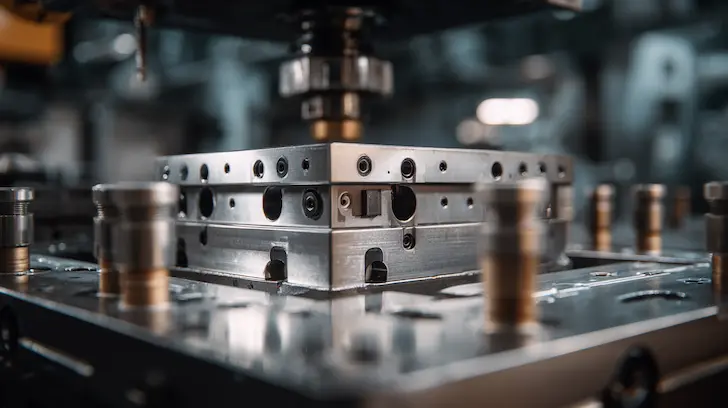

Optimizing for Assembly and Safety

A custom product often involves multiple parts that must be assembled by hand or machine. We engineer these parts to fit together with "snap-fit" precision, reducing the reliance on adhesives and improving the overall durability of the toy. Furthermore, our audits ensure that the design inherently meets 2026 toy safety standards, such as ASTM F963 and EN71. We verify that there are no sharp edges, no small parts that could become choking hazards, and that the material thickness is sufficient to withstand the "torture tests" required for global retail compliance. At Unstoyppable, our engineering makes your custom design "Retail-Ready" from the very first blueprint.

Cost-Engineering for Maximum ROI

Finally, our feasibility audits include cost-engineering. We look for ways to reduce material waste, optimize mold cavity counts, and streamline assembly steps without compromising the "Custom" feel of the product. This ensures that your custom licensed product development investment delivers the maximum possible ROI, allowing you to price your merchandise competitively while maintaining healthy margins. We believe that great engineering is the key to making high-end custom merchandise accessible to a global audience.

The Foundation of Custom Success: By blending licensed character product design with technical feasibility audits, Unstoyppable ensures your IP makes the jump from concept to shelf without a hitch. Our custom toy development process is built on the belief that your creative vision deserves the highest level of engineering excellence.

Precision Prototyping:

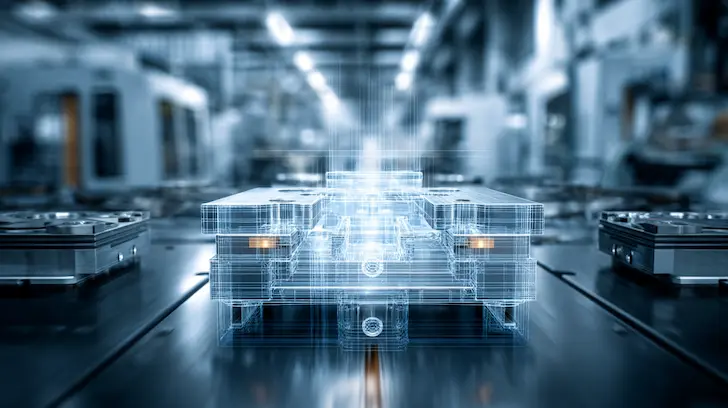

Validating Custom Designs for Global Licensors

The transformation of a digital asset into a physical masterpiece is the most critical phase of custom licensed product development. In the 2026 manufacturing landscape, custom toy prototyping China has evolved into a high-technology discipline that blends additive manufacturing with traditional artisanal finishing. At Unstoyppable, we recognize that for global licensors, the prototype is the ultimate proof of concept. It is the tangible evidence that a brand’s intellectual property has been treated with the reverence it deserves. Our high-fidelity toy samples serve as the benchmark for aesthetic perfection, structural integrity, and safety compliance, ensuring that every stakeholder—from the creative director to the legal compliance officer—is fully aligned before mass production begins.

Phase 2:

The Functional Engineering Prototype

Once the form is approved, we move to functional testing. For articulated figures or electronic toys, this prototype includes all moving parts, joints, and internal housings. We verify that the character engineering allows for the full range of motion required by the style guide and that all components fit together with the precision required for injection molded toy manufacturer standards. This is the stage where we ensure the toy "works" as well as it looks.

Phase 3:

The Paint Master and Decal Application

The final step in the loop is the creation of the "Paint Master." Our master painters apply the approved color palette by hand, using a combination of airbrushing, hand-painting, and precision pad-printing decals. This sample represents the exact visual standard for the finished product. It is this high-fidelity toy sample that is sent to the licensor for final "Green Light" approval. The Paint Master is the visual soul of the project, capturing the vibrancy and personality of the IP.

Golden Sample Archiving and Legal Compliance

We maintain a "Counter-Sample" system where one Golden Sample stays at the factory, one is kept at our headquarters, and one is held by the client. This ensures that in the rare event of a quality dispute, there is a physical, approved reference to consult. Furthermore, the Golden Sample is used for third-party toy lab testing, providing the baseline for all safety certifications like ASTM and EN71. It is the physical manifestation of your brand’s promise to the consumer.

Move from Digital Render to Physical Reality

Your vision deserves to be held in your hands. Partner with the experts in custom toy prototyping China to create your next masterpiece.

Color Matching:

Pantone & Iconic Brand Fidelity

For a licensed product, color is a primary identifier. There is no room for "close enough" when it comes to iconic character colors like "Mickey Red," "Yoda Green," or the specific blue of a superhero’s suit. Our custom licensed product development includes a rigorous color-matching protocol that goes far beyond standard Pantone guides.

Custom Pigment Mixing Across Multiple Materials

The challenge of color in 2026 is achieving consistency across different materials. A color that looks correct on a PVC figure may look different on an ABS accessory or an rPET fabric component. Our lab technicians perform spectrophotometer analysis to ensure that the light-reflection and saturation are consistent across every part of the product. We mix custom pigments for every project, ensuring that your brand’s visual identity remains vibrant and accurate under any lighting condition. This dedication to licensed character product design is what ensures your merchandise looks premium on the retail shelf.

Validation Through Precision. At Unstoyppable, custom toy prototyping is the foundation of our manufacturing excellence. From the first 3D character sculpt to the final Golden Sample, we ensure your custom licensed product is a flawless representation of your brand's legacy.

Scaling Custom Success:

Secure Production and Global Compliance

Transitioning from a perfected prototype to high-volume custom toy production is a milestone that requires both industrial muscle and surgical precision. In 2026, mass production is no longer just about quantity; it is about maintaining the "bespoke" soul of a custom item across hundreds of thousands of units while navigating an increasingly complex global regulatory landscape. At Unstoyppable, we specialize in secure IP production China, ensuring that your most sensitive character assets are protected from leakage while meeting the stringent new transparency mandates of the EU and North America. Our Disney FAMA certified manufacturing hubs provide the ethical and technical foundation necessary for global brands to scale with absolute confidence.

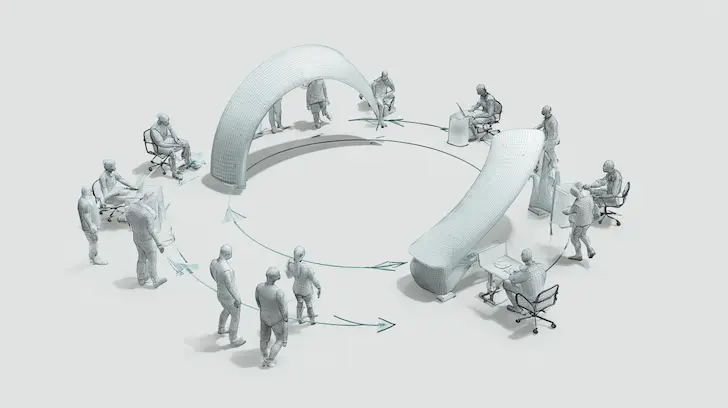

Siloed Manufacturing for Multi-Component Custom Goods

When a custom toy involves multiple materials (e.g., a figure with electronic lights and fabric clothing), we utilize a decentralized manufacturing strategy. Different components are produced in separate audited facilities, with final assembly occurring in a high-security hub. This ensures that no single factory has the complete "blueprint" for your custom licensed merchandise until the final stage of the secure character supply chain.

2026 Digital Product Passports (DPP):

The New Standard for Custom Goods

A significant shift in 2026 is the mandatory requirement for a Digital Product Passport (DPP) for toys entering the EU and US markets. While standard products use generic data, custom licensed product development requires a unique digital identity that reflects its bespoke origins and specialized materials.

Scale Your Custom Vision with Absolute Security

Protect your IP and meet 2026 global standards with the world's most secure licensed production network.

Quality Control at Scale:

Custom-Specific AQL Inspections

Custom products often feature hand-painted details or complex multi-part assemblies that automated systems might overlook. To maintain excellence in high-volume custom toy production, we implement "Specialized AQL" (Acceptable Quality Limit) inspections.

Human-in-the-Loop Inspection for Hand-Painted Details

For custom items with intricate paint apps, we use a GIII (General Inspection Level III) sampling plan. Our inspectors are trained specifically on your Golden Sample to recognize subtle color shifts or "bleed" in hand-painted areas. By focusing on these "custom-critical" features, we ensure that the artistry of your prototype is maintained throughout the entire 100,000-unit run.