Character Engineering for Toys:

Bridging Art and Industrial Reality

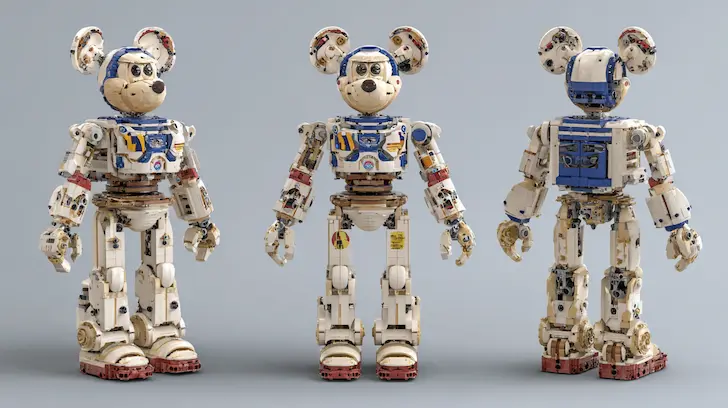

The journey from a creative style guide to a physical masterpiece is a complex transition where art meets advanced physics. At Unstoyppable, character engineering for toys is the vital discipline that translates a digital vision into a tangible, durable, and mass-producible asset. While an artist focuses on the silhouette and emotional resonance of a character, our engineers focus on the industrial DNA that allows that character to exist in the physical world. For 2026, we have pioneered a "blueprint-first" philosophy. This ensures that every curve, undercut, and texture is optimized for the factory floor before a single mold is cut. By utilizing 3D toy design optimization, we protect the integrity of your IP, ensuring that the final retail product is an exact, high-fidelity manifestation of your original concept, engineered to survive the rigors of global logistics and consumer handling.

Strategic Part Breakdown for High-Efficiency Molding

We analyze the character’s silhouette to identify natural seams and transition points. By breaking a figure down into multiple components—such as separate limbs, torsos, and hair pieces—we allow for high-efficiency molding that maximizes cavity space and reduces cycle times. This engineering choice is critical for manufacturing-ready toy sculpts; it allows us to utilize different materials or colors for specific parts of the character, such as using a higher-clarity resin for eyes or a softer PVC for flowing capes. This modular approach ensures that every detail is crisp and that the assembly process is foolproof, maintaining the "premium" feel across millions of units.

Optimizing Draft Angles and Undercuts

Artistic sculpts often contain "traps" or undercuts that make traditional molding difficult. Our character engineering for toys team meticulously adjusts these geometries, adding subtle draft angles that are invisible to the naked eye but essential for a clean release from the mold. This 3D toy design optimization prevents surface scuffing and ensures that the character’s aesthetic remains flawless throughout the injection process. It is this "invisible" engineering that separates a standard toy from a world-class collectible.

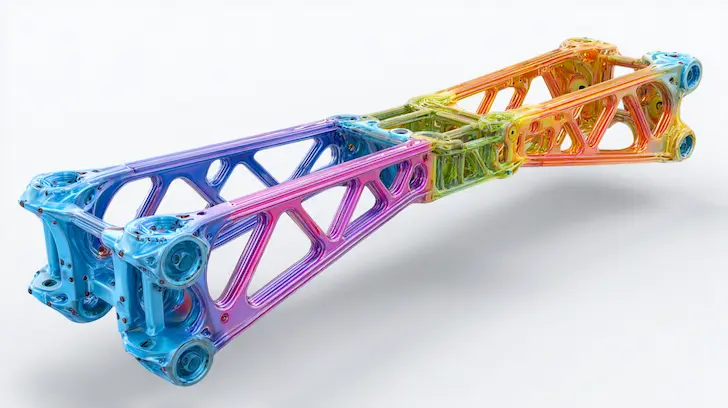

Load-Bearing Ribbing and Wall Reinforcement

By using CAD-simulated stress tests, we identify exactly where a character is likely to fail during a drop test. We then reinforce these zones with internal webbing. This proactive character engineering for toys approach means we can use thinner (and thus lighter/more cost-effective) walls for the non-structural areas while maintaining maximum strength where it counts. The result is a highly durable, manufacturing-ready toy sculpt that feels premium without unnecessary material waste.

Bring Your Character to Life with Precision

Your IP deserves a physical form that matches its digital brilliance. Partner with our engineering team to create masterpieces optimized for the 2026 global market.

Discover Engineering Solutions | Learn About DFM Optimization

Balancing Material Flow and Weight

Optimized wall thickness also allows for faster injection cycles, which increases production speed and reduces costs for the client. By engineering the character to use exactly the right amount of material, we provide a product that is both structurally sound and economically optimized. Our toy structural integrity standards guarantee that even with optimized walls, the figure remains resilient against the impacts of the retail supply chain.

Material-Specific Engineering:

Adapting to Shrinkage and Fit

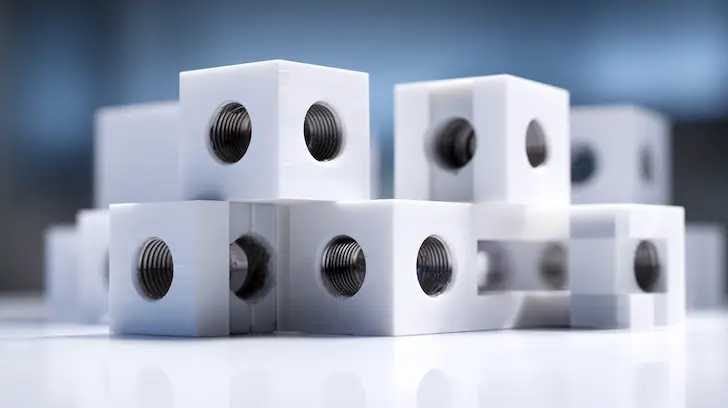

Every material—whether it is ABS, PVC, or POM—behaves differently when it transitions from a molten state to a solid. A core part of character engineering for toys is calculating the "Shrink Rate" to ensure that multi-part assemblies fit together with zero-gap precision.

The Technical Architect: Unstoyppable doesn't just "make toys"—we engineer character experiences. Through strategic part separation, internal ribbing, and material shrinkage compensation, we provide a 3D toy design optimization service that turns artistic visions into industrial realities. Ensure your IP is manufacturing-ready from day one.

Precision Articulation:

Engineering Dynamic Motion in Licensed Characters

In the premium collectible market, the quality of a character is often judged by the fluidity and stability of its movement. Toy articulation engineering is the high-stakes science of creating life-like motion while maintaining the structural balance of a figure. At Unstoyppable, we view every joint as a mechanical challenge that requires precise mathematical calibration. Whether we are developing a highly articulated 1/12 scale action figure or a simplified posable mascot, our goal is to ensure that every movement feels intentional, smooth, and durable. In 2026, posable character manufacturing has evolved beyond basic hinges; it now encompasses complex physics, material friction coefficients, and ergonomic design. By mastering the mechanics of motion, we allow IP holders to offer products that invite interaction and provide infinite display possibilities for fans and collectors worldwide.

The "Golden Tolerance" Rule:

The Micro-Math of Movement

The difference between a "luxury" action figure and a standard toy often comes down to a fraction of a millimeter. Success in toy tolerance engineering is found in the "Golden Tolerance"—the precise gap between a joint's male and female components that ensures perfect friction.

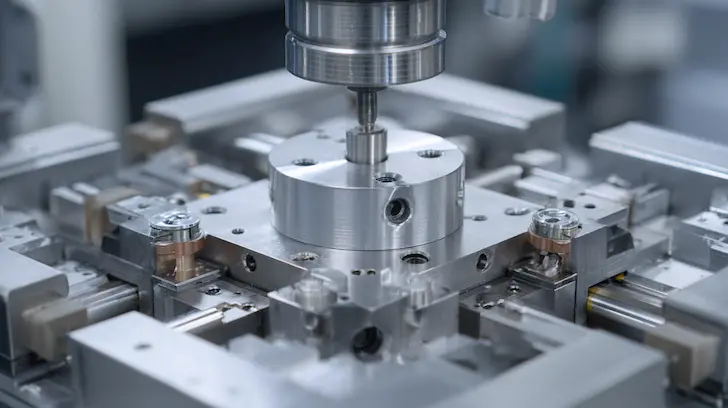

Engineering Microscopic Gaps for Consistency

Our engineering team operates within a strict tolerance range of $0.05mm$ to $0.1mm$. This microscopic clearance is essential for toy articulation engineering; it provides enough space for parts to rotate without grinding, yet remains tight enough to hold a pose indefinitely. In a mass-production environment where mold wear and cooling variances occur, maintaining this "Golden Tolerance" across a million units is a feat of industrial discipline. We utilize high-precision CNC machining for our mold cores to ensure that every ball joint toy design delivers the same level of resistance, ensuring a "tight" feel that collectors associate with high-end manufacturing.

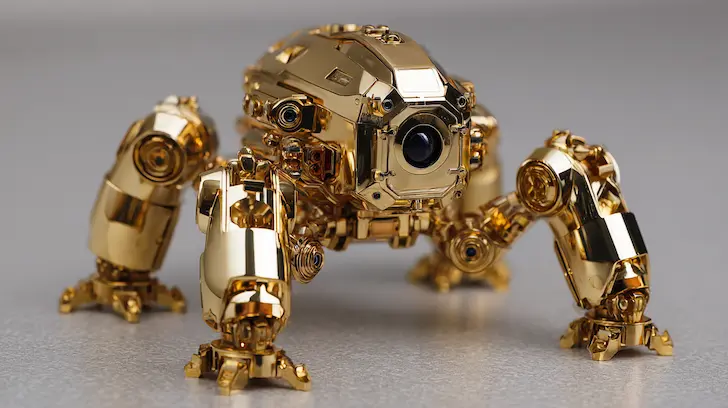

Utilizing POM for High-Wear Resistance

For joints that undergo constant stress, such as knees and elbows, we utilize Polyoxymethylene (POM), often known as Acetal. As an experienced injection molded toy manufacturer, we know that POM is the ideal "engineering plastic" due to its high stiffness, low friction, and excellent dimensional stability. By using POM for the internal "teeth" of a ratchet joint, we ensure that the "click" remains crisp even after thousands of cycles. This toy articulation engineering choice prevents the "limp joint" syndrome common in lower-quality products, ensuring that your licensed characters can hold heavy accessories and dynamic poses for years without fatigue.

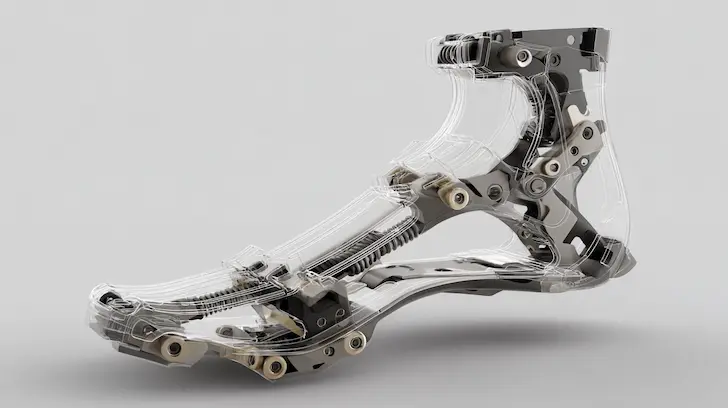

Ball Joint Toy Design:

360 Degrees of Expression

A well-engineered ball joint toy design is the cornerstone of character expression. We utilize a "socket-tension" system where the socket is slightly more pliable than the ball, creating a natural grip. This allows for a full range of motion—tilting, rotating, and pivoting—enabling the character to look "natural" in any position. Our engineers optimize the surface texture inside the socket to increase friction without causing plastic shavings, a common refinement in posable character manufacturing that enhances the premium user experience.

Master the Physics of Play

Give your fans the freedom to pose, play, and display. Discover how our articulation engineering creates the ultimate posable collectibles for your brand.

Optimize Your Tooling for Motion | Explore POM & High-Performance Plastics

Ankle Tilt and Footprint Optimization

To support various poses, we engineer "ankle rocker" joints that allow the feet to remain flat on the ground even when the legs are spread wide. By calculating the surface area of the foot and the tension of the ankle joint, we ensure the figure has a secure "footprint." This attention to toy articulation engineering ensures that your character is not only beautiful but also functional and shelf-stable, reducing consumer frustration and enhancing brand value.

Interchangeable Part Engineering:

Plug-and-Play Durability

In 2026, the trend for "swappable" parts—different hands, heads, or weapons—is a standard expectation for licensed goods. We engineer these connection points to be durable and intuitive, utilizing toy tolerance engineering to prevent breakage during the swapping process.

The Engineering Advantage: Unstoyppable transforms static art into dynamic motion. Through Golden Tolerance calibration, ratchet joint manufacturing, and POM material integration, we deliver toy articulation engineering that stands the test of time. Partner with a manufacturer that understands the physics of premium motion.

Engineering for Aesthetics:

Integrated Finishing and 2026 Compliance

In the high-stakes world of licensed collectibles, the visual fidelity of a character must be matched by its structural integrity and regulatory transparency. At Unstoyppable, character toy finishing engineering is not an afterthought; it is a foundational pillar of our 2026 development cycle. We recognize that the "look" of a toy is fundamentally dictated by its engineering. By integrating aesthetic requirements into the initial CAD phase, we ensure that complex decorations, such as hyper-detailed streetwear patterns or metallic gradients, are applied with zero distortion. Simultaneously, we engineer for the future of retail by embedding digital traceability and global safety benchmarks into the character's physical architecture. This holistic approach ensures that your IP remains iconic, compliant with ASTM F963 engineering standards, and fully prepared for the digital mandates of the modern marketplace.

Engineering for Printing Film:

Distortion-Free Decoration

The application of high-definition graphics on a 3D surface is a feat of geometric planning. To achieve a flawless finish, we utilize printing film for toys that requires specific "receptive zones" within the character's sculpt.

Optimizing Sculpt Geometry for Film Application

Our engineers analyze the character's body to designate "flat zones" and "controlled smooth curves." By subtly adjusting the radius of a character's shoulder or the flatness of a chest plate, we ensure that printing film for toys or water transfer decals can wrap around the part without wrinkling or stretching the graphic. This character toy finishing engineering foresight prevents the "pixel stretching" often seen in lower-quality production. We use digital mapping to simulate the film's application at the CAD stage, ensuring that complex logos or textures align perfectly across seams, maintaining the character's visual continuity and premium shelf appeal.

Designing Out Hazards at the CAD Stage

We utilize automated software to scan 3D models for potential "choke hazards" or "sharp points" before a mold is even cut. If a character design features a sharp sword or a pointed cape, we engineer these parts using "dual-durometer" technology—a rigid internal core for stability, overmolded with a safety-compliant character design soft-touch tip. This proactive ASTM F963 engineering ensures the figure passes rigorous puncture and bite tests while retaining the aggressive, sharp look intended by the artist. By designing out risks early, we accelerate the golden sample development process and ensure a smooth path through third-party lab testing.

Structural Reinforcement for Impact Resistance

Durability is a key component of safety. We engineer internal "impact ribs" into the character's torso and head to ensure it survives the standard 3-foot drop test required for global retail. This character toy finishing engineering ensures the figure remains intact without shattering into small parts, fulfilling our promise of safety-compliant character design. We provide peace of mind to IP holders by ensuring that their characters are as resilient as they are beautiful.

Secure Your Character's Future

In the 2026 market, beauty must be backed by data and safety. Partner with an engineering team that leads in global compliance, advanced finishing, and digital traceability.

Traceability and Anti-Counterfeit Engineering

The integration of the DPP serves as a powerful anti-counterfeit measure. By engineering a "digital twin" for every physical figure, we ensure that the value of the limited edition is protected. This 2026-ready safety-compliant character design provides a layer of security that "grey market" manufacturers cannot replicate, securing the long-term investment of the collector and the reputation of the brand.

Mold Flow & Gate Placement:

The Secret to a Flawless Skin

Where the plastic enters the mold determines where the visual "imperfections" will lie. Strategic mold flow and gate placement is the final touch in our engineering for aesthetics.