Deciphering Global Toy Safety:

The Fundamental Differences Between EN71 and ASTM F963

Navigating the complex world of international commerce requires a profound understanding of the regulatory pillars that uphold consumer trust. For any brand looking to expand its footprint, mastering the nuances of EN71 vs ASTM toy standards is a primary strategic requirement. These frameworks represent more than just a list of tests; they are the gatekeepers to the world’s most lucrative retail markets. As a leading EN71 compliant toy manufacturer, Unstoyppable operates at the intersection of European precision and American rigor, ensuring that every product we facilitate meets the highest global toy safety regulations 2026. In this modern era of "Dual-Compliance," high-performing brands prioritize a unified engineering approach that satisfies both the European Union and the United States simultaneously. This proactive methodology streamlines the path to the retail shelf and fortifies the brand against the financial risks of non-compliance.

The EU Toy Safety Directive (2009/48/EC)

In Europe, toy safety is governed by the EU Toy Safety Directive, which provides the legal "essential requirements" that products must satisfy. The EN71 series of standards is the technical roadmap used to prove that a toy fulfills these legal mandates. This system is designed for a multi-national market, where the CE mark acts as a passport across all member states. Compliance with EN71 is a mandatory prerequisite for any EN71 compliant toy manufacturer wishing to access the European Economic Area. This directive is known for its "Precautionary Principle," often setting the world’s most stringent limits on chemical substances to ensure maximum protection for the youngest consumers.

The US Consumer Product Safety Improvement Act (CPSIA)

Across the Atlantic, ASTM F963 toy safety requirements are integrated into the federal law of the United States through the Consumer Product Safety Improvement Act (CPSIA). Regulated by the Consumer Product Safety Commission (CPSC), this framework is characterized by its rigorous third-party testing mandates and strict tracking label requirements. In the US market, ASTM F963 is a comprehensive "Standard Consumer Safety Specification for Toy Safety." It covers a vast array of hazards, from acoustics to magnets, ensuring that every ASTM F963 compliant manufacturer adheres to a federally enforceable safety benchmark. Understanding this jurisdictional reach allows brands to allocate resources efficiently during the global toy safety regulations 2026 planning phase.

Impact on Testing Protocols

The age grade assigned to a toy affects every laboratory test, from the force used in tension testing to the allowable limits of certain chemicals. By establishing a "Global Age Grade" during the toy material engineering phase, we ensure that the product is engineered to the most restrictive standard applicable. This "Highest Common Denominator" approach is a hallmark of our global toy safety regulations 2026 strategy, providing our partners with the peace of mind that their products are safe for their intended audience, regardless of where they are sold.

Planning a Multi-Region Launch?

Don't navigate the complex world of EU and US regulations alone. Ensure your 2026 designs are market-ready from day one.

Critical Gaps in Chemical and Heavy Metal Limits

Despite the progress in mechanical harmonization, the chemical requirements—specifically regarding phthalates and heavy metal migration—remain distinct. EN71-3 (Migration of certain elements) tracks a wider array of elements than the standard US requirements. Similarly, the EU has more extensive restrictions on certain fragrances and allergenic substances. A sophisticated toy material engineering strategy is required to ensure that the raw materials used are compliant with the strictest limits from both regions. By focusing on these remaining gaps, we ensure that "harmonization" does not lead to complacency; our products are formulated to exceed the minimum requirements of every jurisdiction.

Mechanical & Physical Properties:

The Physics of Safety

The core of EN71 vs ASTM toy standards lies in the physical abuse tests designed to simulate years of play in a matter of minutes. These tests ensure that a toy remains safe even after it has been dropped, bitten, or pulled.

Compliance Strategy Note: In 2026, safety is the ultimate brand asset. Choosing a partner who understands the granular differences between EN71 vs ASTM toy standards ensures that your global distribution is built on a foundation of technical excellence. Engineer for the world, not just a region.

Beyond the Surface:

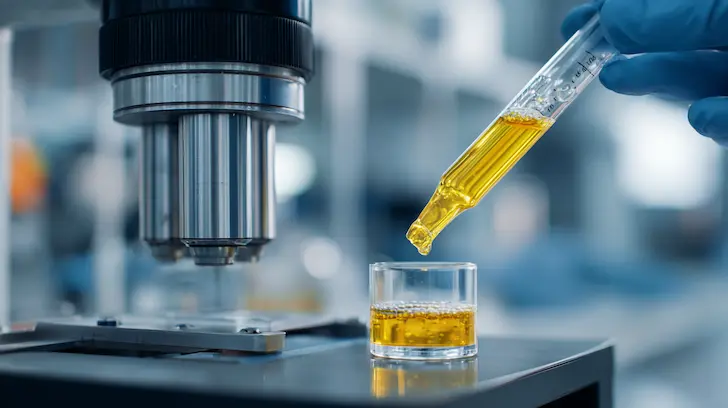

Chemical Migration and Laboratory Testing Rigor

In the high-stakes world of licensed product manufacturing, the most significant dangers are often the ones that remain invisible to the naked eye. While a toy may look perfect and pass physical stress tests, its chemical composition determines its ultimate viability for the global market. Chemical safety compliance for toys is not merely a checkbox; it is a discipline of material science that protects children from long-term health risks. Many generalist factories fail here because they lack the technical infrastructure to prevent cross-contamination or the expertise to navigate the diverging heavy metal limits of different jurisdictions. At Unstoyppable, our toy material engineering process ensures that every polymer, pigment, and adhesive is vetted at the molecular level before it enters the assembly line. By integrating third-party toy lab testing into the very early stages of development, we guarantee that the final product is as safe as it is beautiful.

Migration of Elements:

The 19 vs. 8 Element Challenge

The most technical hurdle in global distribution is managing the "Migration of Certain Elements." This refers to the amount of heavy metals that can be extracted from a toy if a child were to swallow or suck on it. As of 2026, the gap between EU and US requirements remains a primary point of technical toy engineering mistakes for inexperienced manufacturers.

EN71-3:

The 19-Element European Standard

Under the European EN71-3 standard, the list of tracked substances is extensive, covering 19 distinct elements including Aluminum, Boron, Manganese, and Cobalt, alongside more common threats like Lead and Cadmium. This standard categorizes materials into three types: dry/brittle, liquid/sticky, and "scraped-off" (which includes most plastic and painted toys). The migration limits for "scraped-off" materials are incredibly tight; for instance, the limit for hexavalent chromium is so low that it requires specialized third-party toy lab testing equipment just to detect it. Our toy material engineering team specifically formulates our PVC and ABS resins to stay well below these 19 thresholds, providing a margin of safety that satisfies even the most cautious licensor.

The Risk of Cross-Contamination

The primary reason factories fail phthalate-free toy materials inspections is not intentional use, but accidental contamination. If a factory runs a generic, non-licensed product using cheap, phthalate-heavy plastic on Line A, and your licensed PVC figure on Line B, the airborne dust or residue on shared molds can be enough to push your product over the 0.1% limit. We solve this by utilizing a "Certified Clean Room" approach for high-sensitivity materials. Our supply chain for phthalate-free toy materials is isolated and audited, ensuring that from the raw resin pellet to the finished figure, no contamination occurs.

Verified Resin Sourcing

Our material selection process ensures that we only use virgin medical-grade or high-purity food-grade resins for our toys. We do not use "regrind" or recycled plastics of unknown origin, which are common sources of hidden phthalates and heavy metals. By maintaining chemical safety compliance for toys at the source, we protect your brand from the catastrophic financial and reputational damage of a chemical-based recall.

Don't Risk a Chemical-Based Recall

Hidden toxins are the #1 cause of licensed product seizures at customs. Learn how our engineering team guarantees phthalate-free production and 100% heavy metal compliance.

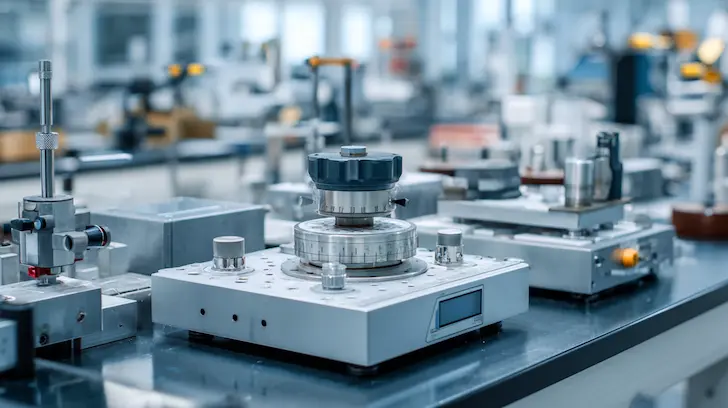

The Role of Accredited Labs:

Why ISO 17025 is Mandatory

In the world of licensed merchandise manufacturing, a test report is only as good as the lab that issued it. Licensors like Disney, Marvel, and Warner Bros. will only accept reports from specific, highly accredited facilities.

The Authority of ISO 17025

An ISO 17025 accreditation is the global benchmark for laboratory competence. It ensures that the lab has the technical personnel, calibrated equipment, and validated methodologies to produce accurate results. For US markets, the CPSC (Consumer Product Safety Commission) maintains a list of "Accepted Labs." Using a non-accredited "in-house" lab at a factory for final certification is a recipe for disaster. We exclusively partner with world-renowned third-party toy lab testing giants like SGS, Intertek (ITS), and Bureau Veritas (BV). This ensures that your Children’s Product Certificate (CPC) or Declaration of Conformity (DoC) is bulletproof during a customs audit.

Technical Perspective: Chemical safety is the most complex part of the "Visual DNA." If the molecules aren't right, the character isn't right. Our toy material engineering ensures that your products are safe to the touch and compliant by design. Trust is built at the atomic level.

Implementing a Zero-Failure Compliance Strategy for Licensed Brands

In the high-velocity retail environment of 2026, compliance is the engine of market access. Successfully managing toy quality and safety compliance requires a shift from reactive testing to a proactive "Compliance Lifecycle" management approach. For global brands, the goal is to eliminate the variance between a laboratory-approved prototype and the thousands of units destined for retail shelves. Achieving a zero-failure rate is possible when safety is engineered into the production workflow rather than treated as an afterthought. At Unstoyppable, we simplify the path to global distribution by providing a unified strategy that encompasses engineering, automated oversight, and rigorous documentation. By choosing a partner that manages the entire regulatory spectrum, you protect your intellectual property from the delays and costs associated with non-compliance, ensuring your characters reach their fans exactly as intended.

Maintaining the "Golden Sample" Standard

A passing lab report on a prototype is only the beginning. To ensure every unit shipped is safe, we incorporate critical safety checks into the Acceptable Quality Level (AQL) sampling plan. This means that during AQL inspection in toy manufacturing, our QC teams perform "destructive testing" on a randomized sample of the mass-produced batch. We verify that the tension strength of small parts and the impact resistance of plastic housings remain identical to the "Golden Sample" originally tested in the lab. This continuous verification loop ensures that the safety profile of the first unit is identical to the 50,000th unit, providing a robust defense against retail recalls.

Reducing Human Error with Automated Safety Testing

As part of our 2026 innovation initiative, we have implemented automated toy safety testing stations on our assembly lines. These robotic systems perform repetitive physical stress tests—such as consistent torque application and drop-height precision—with a level of accuracy that exceeds human capability. By utilizing automated toy safety testing, we remove the subjectivity from safety inspections, ensuring that every character accessory and articulation point meets the required Newton-meters of force specified by EN71 and ASTM standards. This technological edge allows us to identify potential failures in real-time, long before the goods reach the shipping container.

Iconography and Age Warning Precision

A frequent point of friction in retail is the incorrect application of the "0-3" age warning symbol. We meticulously review all retail packaging to ensure that age warnings are prominent, correct in color, and accompanied by the specific "Choking Hazard" text required by law. By perfecting the iconography during the retail-ready packaging manufacturer phase, we eliminate the need for expensive "over-labeling" or re-boxing once the goods arrive in the destination country. This attention to detail is a key component of our strategy for managing toy compliance costs.

Ready to Secure Your Global Distribution?

A single labeling error can halt a multi-million dollar launch. Let our compliance directors perform a comprehensive safety and labeling review of your 2026 product line.

The Power of the Declaration of Conformity

The DoC is your formal statement that the product fulfills all legal requirements of the EU/UK or US markets. By partnering with a manufacturer that provides a transparent, verified paper trail, you transfer the burden of "Technical Search" to us. We ensure that your DoC is updated with the latest global toy safety regulations 2026, allowing you to sign off on your shipments with total confidence. This "Compliance-as-a-Service" model allows you to focus on marketing and expansion while we handle the technical rigors of the global supply chain.

EN71 vs ASTM: Compliance Strategy FAQ

Can a toy be both EN71 and ASTM F963 compliant?

What is the difference between the 'Small Parts' test in the US vs EU?

How often do I need to re-test my licensed toy line?

Who is responsible for toy safety compliance—the brand or the manufacturer?

Logistical Insight: Compliance is the ultimate facilitator of speed. When your paperwork is perfect and your labels are accurate, your goods move through customs without delay. Invest in precision today to save on logistics tomorrow.