Phthalate-Free Toy Materials:

Scientific Solutions for Soft-Touch Products

In the sophisticated landscape of 2026 consumer safety, the molecular composition of a toy is just as critical as its external design. For decades, the toy industry relied on ortho-phthalates to transform rigid resins into flexible, huggable products. However, modern phthalate-free toy materials have ushered in a new era of endocrine-safe manufacturing. At Unstoyppable, we lead this transition by engineering non-toxic toy polymers that maintain the premium "soft-touch" feel required for licensed character merchandise while adhering to the strictest global health standards. By replacing legacy plasticizers with advanced elastomers and bio-based alternatives, we ensure that every product is a benchmark for BPA-free toy production China. Our commitment to material science allows IP holders to deliver products that are safe for the most vulnerable consumers without compromising on durability or tactile appeal.

The Risk of Phthalate Migration

Traditional phthalates such as DEHP (Di-2-ethylhexyl phthalate), DBP, and BBP are not chemically bonded to the plastic; instead, they are physically mixed within the matrix. This leads to "migration," where the chemicals leach out of the toy over time, especially when in contact with oils or through oral contact. Because these substances are classified as endocrine disruptors, international bodies have established a 0.1% (1000ppm) limit for their presence in children's goods. This regulatory environment makes phthalate-free toy materials the mandatory standard for any brand looking to achieve REACH and CPSIA compliance. By selecting stable, non-migratory alternatives, we ensure that the flexibility of the toy is permanent and safe.

Global Regulatory Compliance as a Baseline

Global authorities, including the CPSC in the United States and ECHA in Europe, have expanded the list of restricted phthalates to include DINP, DIDP, and DnOP. Our toy quality assurance protocols are designed to exceed these baselines. We treat compliance as a starting point, moving beyond the bare legal minimum to provide non-toxic toy polymers that are free from all restricted esters. This proactive stance simplifies the licensed product shipping validation process, as our materials are pre-screened to bypass heavy customs scrutiny.

Advanced TPU for High-Durability Applications

For products requiring extreme abrasion resistance—such as wheels for toy vehicles or protective boots for robotic characters—we utilize Thermoplastic Polyurethane (TPU). TPU is a subset of the phthalate-free toy materials family that offers incredible tensile strength and low-temperature flexibility. This material ensures that the "soft" components of a toy do not degrade or become brittle over time, even under heavy play conditions. This technical resilience is a core component of our toy material engineering expertise.

Prioritize Consumer Safety at the Molecular Level

Protect your brand’s reputation by choosing materials that parents trust. Explore our catalog of certified phthalate-free toy materials and non-toxic toy polymers for your next project.

Learn About Material Engineering | View Our Sustainability Initiatives

Eliminating Phthalate Migration with Polymeric Plasticizers

For long-term mass production toy consistency, we often recommend polymeric plasticizers. These are large-molecule additives that are physically too big to migrate out of the plastic matrix. This ensures that the toy remains soft for its entire lifespan and does not develop the "sticky" surface residue often associated with cheap, low-grade plastics. This level of toy material engineering ensures that your character merchandise maintains its premium feel from the retail shelf to the collector’s display case.

Virgin Resin Integrity:

Preventing Cross-Contamination

Achieving a phthalate-free toy materials certification requires more than just the right recipe; it requires a sterile and controlled manufacturing environment. At Unstoyppable, we implement a "Virgin-Only" mandate to guarantee chemical purity.

Expert Material Insight: In 2026, the definition of quality is safety. By mastering the transition from PVC to TPE and utilizing citrate-based safe plasticizers for toys, Unstoyppable offers a manufacturing solution that is both high-performance and health-conscious. Choose a partner who understands the molecular weight of your brand’s promise.

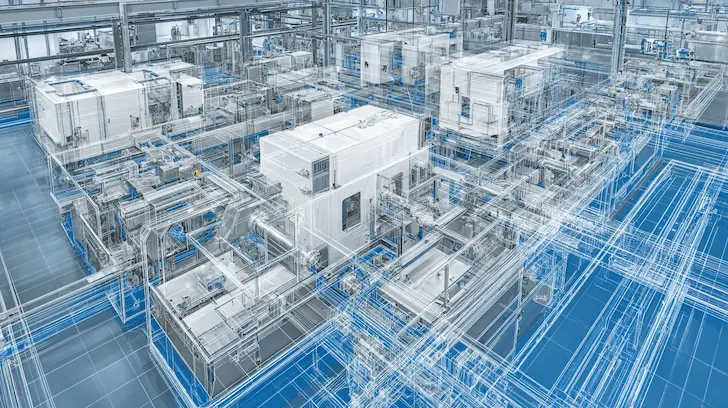

Technical Manufacturing:

Injection Moulding and Decoration of Safe Polymers

Transitioning to phthalate-free toy materials is a complex engineering challenge that requires a complete recalibration of traditional manufacturing workflows. At Unstoyppable, we recognize that injection molded phthalate-free toys behave differently under pressure and heat compared to legacy PVC. Safe polymers like TPE (Thermoplastic Elastomer) and TPU (Thermoplastic Polyurethane) possess unique rheological properties, necessitating advanced mold development & injection tooling to prevent defects such as warping or incomplete fills. Our production mastery extends beyond the mold to the application of safe toy decorative finishes. By refining the chemical compatibility between non-toxic substrates and high-definition printing technologies, we ensure that PVC-free figure production meets the aesthetic and durability benchmarks of the world's leading entertainment franchises.

Precision Moulding with TPE and TPU:

Overcoming Material Dynamics

The success of injection molded phthalate-free toys depends on the manufacturer's ability to control the flow and crystallization of non-toxic resins. TPE and TPU resins often exhibit higher viscosity and different shrinkage rates than phthalate-softened vinyl, which requires a specialized approach to tooling engineering.

Optimizing Flow Rates and Cooling Cycles

In PVC-free figure production, the absence of traditional plasticizers means the resin has a narrower processing window. Our engineering teams utilize advanced toy tooling R&D to design molds with optimized gate placements and balanced runner systems. These features ensure that the molten TPE flows evenly into every detail of the character's sculpt, preventing "short shots." Furthermore, we implement high-efficiency cooling channels within the mold development & injection tooling to manage the rapid set-time of TPE. This thermal precision eliminates internal stresses, ensuring that every phthalate-free toy material component maintains its dimensional stability and tactile "bounce" throughout its shelf life.

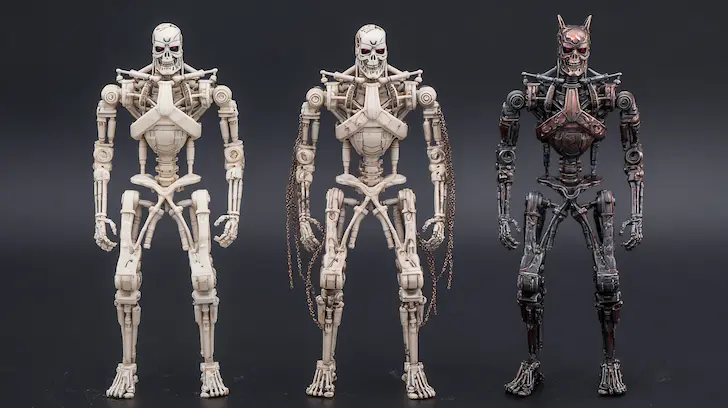

Bonding ABS Skeletons with TPE Skins

For premium action figures and interactive collectibles, we employ TPE overmolding techniques to bond a soft, rubberized exterior directly onto a rigid ABS (Acrylonitrile Butadiene Styrene) internal frame. This creates a "soft-skin" effect that is entirely phthalate-free. The technical challenge lies in achieving a perfect chemical bond between the two materials. Our character engineering for toys team selects specific grades of TPE that are chemically compatible with the ABS substrate, ensuring that the skin will never peel or delaminate, even during vigorous play. This non-toxic toy polymer integration results in a product that feels premium, looks realistic, and exceeds all US toy safety standards.

Enhancing Grip and Ergonomics

Beyond aesthetics, TPE overmolding techniques are used to enhance the functionality of toys. We apply soft-grip surfaces to handheld electronic toys and preschool learning tools. Because these materials are 100% phthalate-free toy materials, they are safe for prolonged skin contact and oral exploration by toddlers. This production mastery is a key differentiator for Unstoyppable, allowing us to deliver complex, multi-textured products that are 100% compliant with global safety mandates.

High-Performance Materials Require High-Performance Engineering

Precision moulding is the only way to ensure PVC-free figure production stays consistent at scale. See how our injection moulding experts handle phthalate-free toy materials with surgical accuracy.

Explore Injection Molding Capabilities | Learn About Our Tooling Process

Water-Based Inks and UV-Curable Coatings

To complement our phthalate-free toy materials, we utilize eco-friendly decoration methods. We prioritize water-based inks and UV-curable coatings that contain zero VOCs (Volatile Organic Compounds). These safe toy decorative finishes are cured instantly under ultraviolet light, creating a hard, protective shield that preserves the character's likeness. This non-toxic printing film application ensures that the final product is safe for children to handle and even mouth, fulfilling the ethical toy manufacturing China promise that Unstoyppable represents.

Clean-Room Production Environments:

Preventing Phthalate Migration

A "phthalate-free" claim is only as strong as the environment in which the toy is produced. Cross-contamination is a significant risk in multi-purpose factories, which is why we implement strict clean-room production environment protocols.

Industrial Precision Note: Manufacturing with phthalate-free toy materials is not simply a material swap—it is a technical evolution. From TPE overmolding techniques to non-toxic printing film application, Unstoyppable provides the engineering depth required to master these safe polymers. Partner with us to bring clinical manufacturing excellence to your next non-toxic toy line.

Verification and Vigilance:

Lab Screening for Endocrine Safety

In the high-stakes arena of global toy distribution, a "phthalate-free" claim is only as valid as the data that supports it. At Unstoyppable, we recognize that true safety is a result of a documented, repeatable process rather than a simple final check. We implement a rigorous third-party lab verification China protocol that subjects every production lot to the highest level of chemical scrutiny. By utilizing GC-MS phthalate screening, we ensure that our non-toxic toy polymers remain well within the 1000 ppm (0.1%) threshold mandated by international law. This clinical approach to non-toxic toy certification provides a transparent audit trail for regulators and IP holders alike, ensuring that your brand is protected by empirical evidence from the molecular level to the retail shelf.

GC-MS Testing Protocols:

The Gold Standard for Material Purity

To provide absolute certainty, we utilize Gas Chromatography-Mass Spectrometry (GC-MS), which is the most authoritative analytical method for the REACH toy material testing framework and US safety mandates.

The Technical Precision of GC-MS Screening

GC-MS phthalate screening is a two-step process that first separates the chemical components of a material sample and then identifies them based on their unique molecular mass. This technology allows our partnered third-party toy lab testing facilities to detect restricted phthalate esters—such as DEHP, DBP, BBP, DINP, and DIDP—at concentrations as low as 0.01% (100 ppm). This level of resolution is essential for phthalate-free toy materials verification, as it identifies even the slightest traces of migration or cross-contamination that manual inspection would miss. By establishing this high-definition chemical baseline, we ensure your product meets the most stringent CPSIA phthalate compliance requirements.

Facilitating 100% Retail-Ready Compliance Documentation

We provide a comprehensive technical file for every shipment, which serves as the primary evidence for CPSIA phthalate compliance (for the US) and REACH Annex XVII (for the EU). This file includes the Children’s Product Certificate (CPC) and the Test Reports from ISO 17025 accredited labs. By proactively managing these REACH toy material testing cycles, we eliminate the logistical bottlenecks often associated with customs & export for toys. Our documentation is presented in a digital-first format, facilitating immediate retail-ready compliance documentation for online marketplaces and big-box retail audits.

Proactive REACH SVHC Screening

Beyond the standard list of prohibited phthalates, we perform screening for Substances of Very High Concern (SVHC) under the REACH framework. This forward-looking non-toxic toy certification process ensures that our phthalate-free toy materials are prepared for future regulatory updates, protecting your product's shelf-life and brand reputation in the European Union. This commitment to ethical toy manufacturing China ensures that your supply chain is as sustainable as it is safe.

Deliver Peace of Mind to Parents and Retailers Alike

Security is a documented process. Contact our compliance team to start your certified, phthalate-free toy materials manufacturing journey with full third-party lab verification China.

Rigorous Supplier Auditing and COA Verification

Before a single pellet is loaded into an injection molded toy manufacturer machine, we perform a deep-dive audit of our resin suppliers. We mandate that every supplier provides a 100% phthalate-free Certificate of Analysis (COA) for every shipment. Our internal QC team then performs "spot-check" GC-MS phthalate screening on the raw material to verify the supplier's claims. This dual-layer verification is what makes us a leading licensed toy manufacturer China, ensuring that non-toxic toy polymers are guaranteed from the moment they enter our supply chain.