From Pixels to Plastic:

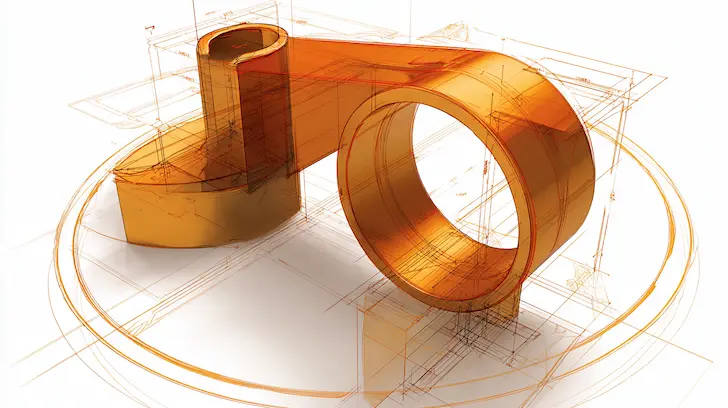

The Engineering Translation of Licensed Concepts

The licensed product mass production process is a journey of precision that begins long before the first injection molding machine is powered on. At Unstoyppable, we recognize that the digital assets provided by major studios—whether they are high-poly 3D renders from a blockbuster film or 2D vector art from a classic animation style guide—are works of art, but they are not yet blueprints for manufacturing. The "Blueprint Phase" is the critical bridge where creative vision meets industrial reality. By utilizing advanced character engineering for toys, we transform artistic concepts into high-fidelity technical data. This stage is where 90% of production errors are prevented. Through a meticulous combination of toy design for manufacturing (DFM) and master tool engineering, we ensure that every curve, texture, and expression of your IP is preserved while being optimized for a flawless, high-volume production run in China.

Gap Analysis for Manufacturability

We receive raw files from licensors like Disney or Marvel and perform a detailed gap analysis. Most digital assets created for film or gaming feature "impossible" geometries—infinitely thin capes, floating accessories, or joints that lack a realistic range of motion for a physical object. Our engineers identify these areas and propose structural solutions that maintain the character’s integrity. By using character engineering for toys, we build internal supports and wall thicknesses that provide the necessary durability for the licensed product mass production process without altering the external aesthetic approved by the brand owner. We ensure the transition from a digital screen to a physical hand is seamless.

Surface Detail Preservation

Digital sculpts often contain millions of polygons that standard manufacturing equipment cannot replicate without optimization. During the process of converting 3D assets for production, we utilize high-end retopology techniques to simplify the underlying mesh while preserving the high-frequency surface details like fabric textures, skin pores, or mechanical etchings. This ensures that the final master tool engineering phase captures every nuance of the original design, delivering a product that feels "premium" to both the collector and the casual consumer. Our technical team ensures that "mass-produced" never means "simplified."

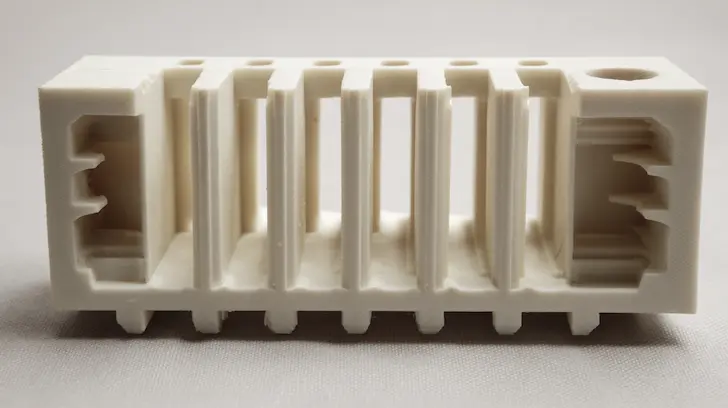

Uniform Wall Thickness and Sink Prevention

One of the most common toy structural defects is "sinking," caused by uneven cooling in thick plastic sections. Through advanced DFM, we implement "coring" techniques, hollowing out thick areas of the character while maintaining structural ribs. This ensures uniform cooling, which prevents surface deformities and reduces material waste. This precision in character engineering for toys is what allows Unstoyppable to maintain exceptionally high yield rates across production runs of millions of units.

Transform Your Character Assets into a Production-Ready Blueprint

Precision engineering is the only way to protect your IP likeness at scale. Let our master tool engineering team prepare your assets for a global launch.

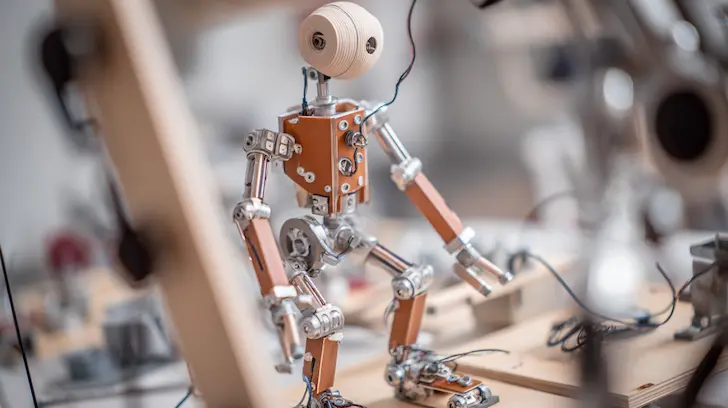

Functional Testing of Articulation and Mechanics

If the licensed product includes action features—such as spring-loaded launchers, sound modules, or complex articulation—the prototyping phase is where we stress-test these mechanics. We iterate on the internal character engineering for toys until the "Play Pattern" is perfect. Validating these mechanical functions during licensed toy prototyping ensures that the final mass-produced toy is both fun to play with and durable enough to pass rigorous safety standards.

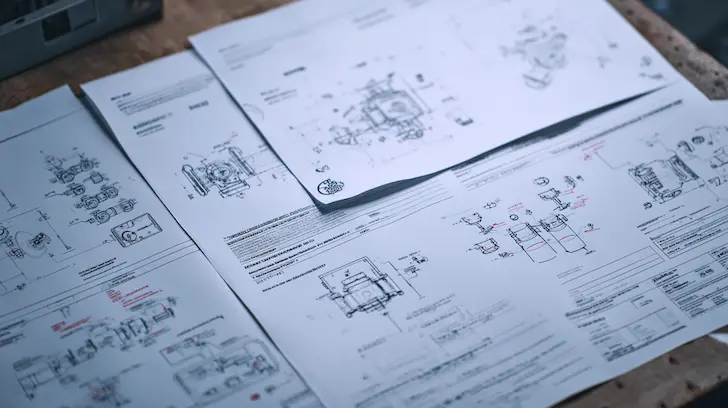

The Technical File (TF):

The Master Manufacturing Blueprint

The final deliverable of the Blueprint Phase is the Technical File (TF). This document is the "Single Source of Truth" for the entire licensed product mass production process. It ensures that every factory in our network produces an identical product, whether they are manufacturing the 1,000th or the 1,000,000th unit.

Expert Conclusion: The Blueprint Phase is the most influential stage of the licensed product mass production process. Decisions made here regarding toy design for manufacturing (DFM) and character engineering for toys dictate the quality, safety, and profitability of the entire product line. At Unstoyppable, we do more than just follow a style guide; we engineer success into the very foundation of your toy.

Hardening the Vision:

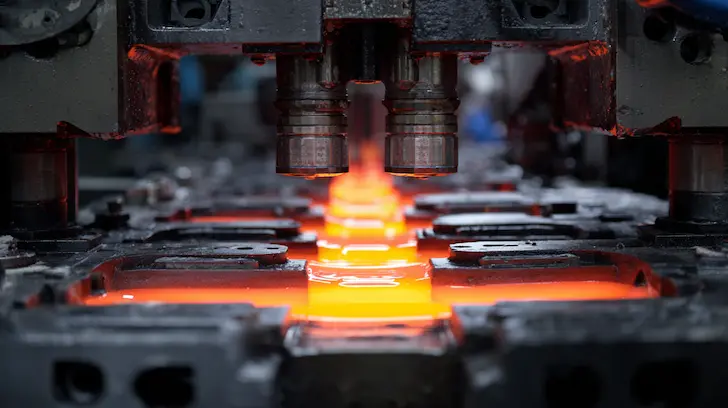

Tooling Strategy and Mass Production Mechanics

Once the digital blueprint is finalized, the licensed product mass production process moves into its most intensive phase: the creation of the industrial engine. This is where creative concepts are literally "hardened" into steel. In the realm of high-volume toy manufacturing, the quality of the tooling dictates the quality of every single unit that follows. At Unstoyppable, we manage mold development & injection tooling with a focus on longevity and microscopic precision. We transform the approved engineering files into high-performance molds capable of producing millions of identical components. By utilizing state-of-the-art CNC machining and electrical discharge machining (EDM), our automated toy manufacturing China facilities ensure that every detail—from the texture of a character’s armor to the tactile "click" of a joint—is perfectly replicated at scale. This stage is the heartbeat of mass production, where the theoretical design becomes a tangible, physical reality ready for the global market.

Steel Grade Selection:

Investing in Long-Term Sharpness

In high-volume toy manufacturing, the choice of steel is the most critical factor in maintaining brand integrity over time. While secondary manufacturers might use softer aluminum or P20 steel to save initial costs, Unstoyppable prioritizes S136 hardened stainless steel for all mass producing licensed figures projects.

The S136 Advantage for Licensed IP

Hardened S136 steel is prized for its extreme durability and corrosion resistance. In a licensed product mass production process that spans hundreds of thousands of cycles, inferior steel begins to "wash out," leading to rounded edges and lost detail. By utilizing S136, we ensure that the 100,000th unit ejected from the mold possesses the same razor-sharp detail as the very first sample. This is essential for character-driven toys where fans expect perfection. Furthermore, the high-polish capability of hardened steel results in a superior surface finish, reducing the need for secondary polishing and ensuring that licensed merchandise production meets the "Retail-Ready" aesthetic from the moment it leaves the mold.

Balancing Cavitation and Per-Unit Costs

A single-cavity mold produces one part per cycle, whereas a 16-cavity mold produces sixteen. While the initial investment in a multi-cavity tool is higher, the reduction in per-unit labor and machine-time costs is substantial. Our engineers perform a "Cavitation Analysis" for every project, calculating the optimal number of cavities based on your total order volume and desired seasonal manufacturing lead time. This ensures that mass producing licensed figures remains cost-effective without overwhelming the cooling capacity of the injection machines. We optimize your investment to ensure the highest possible Return on Investment (ROI) for your tooling budget.

Runner System Optimization

To further enhance efficiency, we implement "Hot Runner" systems in our high-volume molds. Unlike traditional cold runners, which create plastic waste with every shot, hot runners keep the plastic molten within the delivery system. This eliminates waste, reduces material costs, and allows for even faster cycle times. In a FAMA compliant factory in China, this level of technical sophistication is what allows us to scale production rapidly for major movie launches or global holiday surges.

Scale Your Production with High-Fidelity Tooling

Build your brand on a foundation of industrial excellence. Our molds are engineered for millions of cycles and uncompromising IP fidelity.

Explore Our Tooling Capabilities | Learn About Sample Validation

T2 to T3:

Refining Aesthetics and Fit

The T2 run incorporates the mechanical fixes from T1 and focuses on "Fit and Finish." If the toy has articulation or multiple interlocking parts, T2 is where we perfect the tolerances. By the T3 stage, the mold is fully optimized. The resulting parts are used to create the "Golden Sample"—the ultimate reference for mass production. This disciplined off-tool sample validation ensures that once the "Green Light" is given for mass production, the factory is capable of running at 100% speed with 0% deviation from the approved quality standard.

Automation Integration:

24/7 Precision in a FAMA Factory

In 2026, high-volume toy manufacturing is increasingly defined by automation. At Unstoyppable, our FAMA compliant factory in China network utilizes advanced robotics to maintain a constant cadence of high-quality output.

Industrial Leadership Insight: Mass production is not merely about making "a lot" of toys; it is about making millions of *identical* toys. By mastering mold development & injection tooling and embracing automated toy manufacturing China, Unstoyppable provides a level of industrial reliability that smaller trading companies cannot match. We build the machines that build your brand.

The Final Polish:

Decoration, Global Compliance, and Retail Readiness

The final stage of the licensed product mass production process is where a collection of industrial plastic parts is transformed into a world-class collectible. At Unstoyppable, we believe that the beauty of a character lies in the details—the sharpness of the eyes, the vibrancy of the colors, and the safety of the final build. Turning raw injection-molded components into shelf-ready masterpieces requires a sophisticated blend of licensed toy decoration techniques and rigorous toy quality assurance. This phase is governed by a commitment to 100% IP fidelity and uncompromising safety. From the first application of non-toxic ink to the final GTIN / EAN barcode labeling, every step is designed to ensure that your product not only passes global customs but thrives in the competitive retail environment. We treat the assembly line as a gallery where your brand's vision is meticulously brought to life.

High-Fidelity Decoration:

Bringing Characters to Life

For fans and collectors, the decoration of a character is its most defining feature. We utilize advanced licensed toy decoration techniques to ensure that every mass-produced unit reflects the premium quality of the original hand-painted prototype.

Precision Pad Printing and Multi-Color Registration

Character faces often require intricate detailing that standard printing cannot achieve. We utilize 12-color high-speed pad printing carousels that allow for complex expressions to be applied with sub-millimeter precision. By using custom-machined steel clichés and high-opacity inks, we prevent "color bleed" and ensure that eyes, logos, and fine insignias are perfectly registered. This precision is a core component of our toy quality assurance, ensuring that the "soul" of the character is never compromised by the speed of high-volume toy manufacturing.

Third-Party Toy Lab Testing and Certification

Before a single unit is packed, we coordinate extensive third-party toy lab testing. We work with globally recognized bodies like SGS, ITS, and BV to verify EN71 and ASTM safety compliance. This includes physical tension tests, flammability assessments, and chemical analysis for phthalates or heavy metals. By treating safety as a proactive engineering goal rather than a final hurdle, we ensure that your licensed product mass production process is a "Clean Run" that avoids the risk of recalls or border seizures. Our documentation is bulletproof, providing you with the Children’s Product Certificate (CPC) and Declaration of Conformity (DoC) required for rapid customs entry.

Material Purity and Non-Toxic Finishes

In our FAMA compliant factory in China network, we maintain strict control over the chemical composition of our paints and coatings. We utilize exclusively non-toxic, lead-free pigments that adhere perfectly to the base resin. This durability ensures that the toy remains safe and aesthetically perfect even after years of handling. This commitment to EN71 and ASTM safety compliance is what has made Unstoyppable a trusted partner for the world’s largest entertainment franchises.

Launch Your Licensed Product Line with a Proven Partner

From the first paint stroke to the global shipping container, we manage the entire journey. Ensure your brand’s triumphant arrival on the retail shelf today.

Soft Goods Integration

When a project requires "mixed media"—such as a plastic figure with a fabric cape or a plush toy with internal electronics—our soft goods manufacturing specialists work alongside the injection molding team. We ensure that the attachment points are structurally sound and meet all "Small Parts" safety regulations. This holistic approach to character product manufacturing ensures a harmonious final product that feels cohesive and premium.

Final Fulfillment:

GTIN Precision and Global Distribution

The journey from the factory gate to the retail shelf is the final hurdle. We ensure that your products are "Retail-Ready" the moment they are loaded into the container.

Mass Production Process FAQ

How long does it take for a licensed product to move from concept to mass production?

How is IP protected during the mass production phase in China?

What are the minimum order quantities (MOQ) for licensed product mass production?

Can I make changes to the product once mass production tooling has started?

A Product Ready for the World: The final masterpiece is a testament to a perfectly executed licensed product mass production process. By combining high-fidelity decoration, strict EN71 and ASTM safety compliance, and retail-ready fulfillment, we ensure your brand enters the market with strength and integrity. At Unstoyppable, your success is our final product.