Toy Material Engineering:

Bridging Chemical Safety and Mechanical Performance

In the high-stakes world of entertainment merchandise, the physical substance of a product is as critical as its visual design. Toy material engineering is the invisible science that determines whether a collectible feels like a premium treasure or a generic commodity. At Unstoyppable, we recognize that "material is the message." Every polymer chosen for a project carries the weight of the brand’s reputation, affecting everything from structural durability to the precision of high-fidelity character finishing. For the 2026 market, polymer selection for toys has evolved into a multi-disciplinary challenge, requiring a balance between the molecular stability needed for complex injection molding and the rigorous non-toxic standards demanded by global regulators. Our engineering teams meticulously analyze the mechanical requirements of your IP to select resins that offer the perfect "hand-feel," weight, and longevity, ensuring that your licensed product validation China process begins with the highest quality raw materials available.

High-Impact ABS for Rigid Structures and Armor

When a design calls for sharp edges, intricate mechanical detail, or structural rigidity, high-impact ABS toy manufacturing is the definitive choice. Acrylonitrile Butadiene Styrene (ABS) provides the dimensional stability necessary for "snap-fit" assemblies and complex armor plating. Its high surface energy makes it an excellent substrate for printing film for toy materials, ensuring that fine-line graphics and metallic finishes adhere with permanent clarity. By utilizing premium-grade ABS, we ensure that the character's silhouette remains crisp and that the internal "skeleton" of the toy can withstand the stresses of global shipping and retail handling.

Flexible PVC for Organic Textures and Aesthetics

For the organic elements of a character—such as skin, flowing capes, or soft hair—we utilize flexible PVC toy production. Polyvinyl Chloride is uniquely versatile, allowing our engineers to adjust its plasticizer content to achieve a specific "squish" or flexibility. This adaptability is essential for character engineering for toys, as it allows for a seamless blend between a rigid torso and soft, posable limbs. Our 2026 PVC formulations are strictly phthalate-free, meeting all ASTM F963 material safety benchmarks while providing the vibrant color saturation that fans expect from high-end collectibles.

Defining Shore A vs. Shore D for Tactile Accuracy

We utilize the Shore A scale for flexible components (like a rubberized grip or a soft-touch cape) and the Shore D scale for harder plastics. During the golden sample development process, our engineers specify exact durometer ratings. For example, a character’s boots might be rated at Shore A 85 for a firm but slightly pliable feel, while the head sculpt might be Shore A 60 to allow for easier assembly onto a neck peg. This level of polymer selection for toys ensures that every part of the figure performs its mechanical role while providing a tactile experience that aligns with the character's onscreen persona.

The Impact of Durometer on Safety Compliance

Shore hardness is not just about feel; it is a safety parameter. A material that is too hard in a "pointed" area (like a sword tip) may fail ASTM F963 prototype testing for sharp points. Conversely, a material that is too soft might pose a choking hazard if a small part can be easily bitten off. Our toy material engineering team calculates these risks during the DFM phase, selecting materials that balance aesthetic flexibility with the "bite-test" and "tension-test" requirements of EN71 compliant toy manufacturer standards.

ENGINEER FOR DURABILITY

The lifespan of your IP depends on the molecular integrity of the resins you choose. Partner with polymer specialists who understand the intersection of chemistry and play.

Maintaining Dimensional Stability Across Large Production Runs

Warping occurs when internal stresses are "frozen" into the part during molding. We utilize toy mold flow analysis to select materials that have a predictable and consistent shrink rate. This is especially vital for multi-cavity injection molds, where every part must be identical. In 2026, we utilize AI-enhanced polymer monitoring to ensure that the resin's moisture content and temperature are perfectly controlled, guaranteeing that the 10,000th unit is as dimensionally accurate as the Golden Sample.

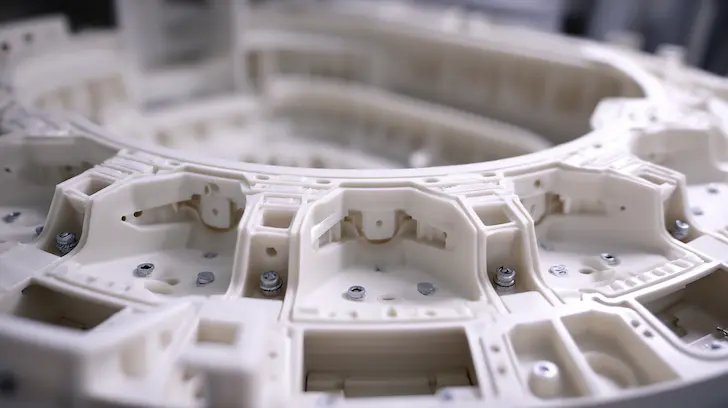

Hybrid Material Overmolding:

The Science of Bonding

One of the most premium techniques in toy material engineering is the bonding of disparate materials to create a unified, multi-textured component. This is often achieved through 2K (Two-Shot) molding or overmolding.

The Material Advantage: At Unstoyppable, we believe that toy material engineering is the foundation of brand trust. By meticulously selecting high-impact ABS, flexible PVC, and POM for joints, we deliver a product that is safe, durable, and visually stunning. Let us help you select the polymers that will define your character's physical legacy in 2026.

Sustainable Toy Manufacturing:

Navigating Bio-Resins and Recycled Polymers

As we advance into 2026, the toy industry is undergoing a profound transformation toward environmental stewardship. At Unstoyppable, sustainable toy manufacturing is a core engineering pillar, allowing brands to align their physical products with global ESG (Environmental, Social, and Governance) goals. The transition to eco-friendly toy engineering involves a sophisticated understanding of new-age polymers that offer a reduced carbon footprint without compromising the high-fidelity detail required for licensed IP. By integrating sustainable toy materials into our audited factory network, we provide a pathway for media franchises and retail giants to participate in the circular economy toy production model. This visionary approach ensures that the toys of tomorrow are as kind to the planet as they are engaging for the fans.

PCR vs. PIR Plastics:

Mastering the Recycled Stream

The foundation of circular economy toy production lies in the effective reuse of existing polymers. We distinguish between Post-Consumer Recycled (PCR) and Post-Industrial Recycled (PIR) resins to provide the most stable material stream for your project.

Maintaining Color Consistency in Recycled Batches

One of the primary challenges in recycled ocean plastic manufacturing is achieving the vibrant, "on-brand" colors required by style guides. PCR plastics often come with inherent tints from their previous lives. Our toy material engineering team utilizes advanced compounding techniques to "neutralize" these base colors, allowing for 100% accurate Pantone matching even in high-recycled-content resins. By utilizing PIR—which is high-quality scrap redirected from the manufacturing process—we maintain a nearly virgin-level purity while significantly reducing waste. This dual-stream approach ensures your character's aesthetics remain flawless while supporting sustainable toy materials initiatives.

Engineering for Narrower Molding Windows

Bio-resins like Bio-Acetate or PLA-blends are highly sophisticated materials that require a "soft touch" during the injection process. These materials have a narrower thermal window and higher moisture sensitivity than traditional petroleum-based plastics. Our toy material engineering protocols include specialized drying stages and low-shear screw configurations to prevent material degradation. By mastering these bio-based plastic toys, we allow IP holders to move away from fossil-fuel dependence while maintaining the crystal-clear transparency or high-gloss finish traditionally associated with standard plastics.

Balancing Degradability and the "Right to Repair"

The 2026 market demands a balance between end-of-life degradability and long-term durability. For high-end collectibles, longevity is a sustainable trait in itself—preventing products from entering the waste stream. For "blind box" components or promotional items, we implement biodegradable resins that break down in industrial composting environments. This nuanced application of sustainable toy materials ensures that the lifecycle of the product matches its intended use, a hallmark of eco-friendly toy engineering.

Build a Greener Future

Your brand's legacy should be sustainable. Discover our 2026 sustainable material catalog and lead the transition to eco-friendly licensed products.

Chemical Integrity:

Phthalate-Free Standards and High-Definition Finishes

In the premium licensed toy sector, the intersection of safety and aesthetics is where brand trust is truly forged. For 2026, toy material engineering must go beyond structural strength to encompass molecular purity. At Unstoyppable, our commitment to phthalate-free toy materials is a foundational promise, ensuring that every character produced is safe for global distribution and domestic play. We utilize advanced toy chemical compliance testing to monitor our supply chain at every stage, from raw pellet procurement to final surface decoration. By bridging the gap between non-toxic chemistry and high-fidelity character finishing, we provide IP holders with the confidence that their products meet the world’s most stringent safety mandates, including ASTM F963 material safety and EN71 standards. Our meticulous approach ensures that a toy is as healthy for the consumer as it is beautiful to the eye.

The Zero-Toxin Mandate:

Our 2026 "Clean Room" Compounding

Guaranteeing a toxin-free product requires more than just high-quality resin; it requires a controlled manufacturing environment that prevents environmental cross-contamination. Our toy chemical compliance testing protocols are integrated into the very air of our facilities.

Preventing Cross-Contamination of Heavy Metals and Lead

We utilize a "Clean Room" compounding process for all phthalate-free toy materials. This specialized environment ensures that no airborne particles or residues from heavy metals, lead, or cadmium can infiltrate the production cycle. By maintaining a segregated supply chain for our licensed partners, we guarantee that the material purity of the first unit is identical to the millionth. This proactive custom vinyl toy finishing foundation is essential for brands that prioritize ethical toy manufacturing China and absolute consumer safety.

Engineering Surface Energy for Permanent Bonding

To ensure that In-Mold Labeling (IML) or printing film for toy materials adheres without peeling or bubbling, we calibrate the dyne levels of the plastic surface. By treating the substrate with corona or plasma activation during the automated toy tooling process, we increase the surface tension, allowing the ink and film to "fuse" with the polymer. This scientific approach to custom vinyl toy finishing ensures that character graphics, logos, and intricate textures remain sharp and inseparable from the figure, even under the stress of vigorous play.

High-Fidelity Finishes with Micro-Precision

Utilizing high-fidelity character finishing, we can apply multi-layered graphics that mimic the look of metallic armor, weathered leather, or glowing energy effects. Because we engineer the material to be receptive to these films, we achieve a level of detail that traditional spray painting cannot match. This fusion of printing film for toy materials and polymer science allows IP holders to realize their most complex digital designs in physical form with zero loss of detail.

Guarantee Safety Without Sacrificing Style

Your IP deserves the safest materials and the sharpest finishes. Learn about our 2026 non-toxic sourcing protocols and our high-definition finish compatibility.

Review Our Safety Benchmarks | Explore Phthalate-Free Sourcing

UV Stability and Fade Resistance

Sunlight is a natural enemy of plastic and pigment. We incorporate UV-stabilizers into our phthalate-free toy materials and surface films to prevent yellowing or fading. By engineering the chemical resistance of our finishes, we provide a product that retains its "shelf-fresh" appearance, even in high-UV retail environments or sun-drenched collector rooms. This is ASTM F963 material safety applied to aesthetic longevity.

Traceability at the Molecular Level:

The Anti-Counterfeit Shield

To protect IP holders in a global market, we offer 2026-level security through "chemical fingerprints" integrated directly into the resin.