Secure Supply Chain for Licensed Products:

Beyond Physical Protection

In the global retail landscape of 2026, the concept of a secure supply chain for licensed products has undergone a fundamental transformation. Security is no longer a localized concern restricted to factory gates and perimeter fences; it is an integrated, structural property of the entire manufacturing lifecycle. At Unstoyppable, we champion a "Security-by-Design" philosophy. This proactive framework ensures that every intellectual property (IP) asset is fortified from the first design sketch to the final retail delivery. By managing the complex intersection of physical security, geopolitical resilience, and digital brand protection, we offer our partners a "brand fortress" in China that is resilient against the sophisticated threats of the modern era.

Autonomous Anomaly Detection

Our toy supply chain security China protocols leverage agentic AI to monitor millions of data points across the factory floor. By establishing a baseline of "normal" operational behavior, our system can instantly flag deviations—such as an unauthorized shift start, an unusual data export from a CNC machine, or a sudden spike in raw material consumption. This AI-driven supply chain defense provides a level of granular oversight that human security teams simply cannot match, ensuring your IP is under 24/7 autonomous protection.

Risk Interpretation and Early Warning

Predictive security is about more than just stopping theft; it is about interpreting environmental risks. Our systems aggregate global threat intelligence to monitor local social stability, weather disruptions, and regional logistical bottlenecks. This allows us to activate contingency plans—such as rerouting secure retail fulfillment toys or shifting production to a redundant facility—well before a disruption hits your bottom line. At Unstoyppable, visibility is the first step, but predictive action is our ultimate goal.

Securing Tooling and Molds

In 2026, the value of a brand lies in its tooling. Unstoyppable uses IoT-enabled mold lockers that require biometrically verified authorization for removal. Every strike of an injection molding machine is digitally logged and compared against the official purchase order. This licensed product security 2026 standard ensures that your molds are never used for "ghost shifts," preserving both the exclusivity of your product and the lifespan of your expensive industrial assets.

Protect Your Brand from the Source

In 2026, a single security breach can devalue a multi-million dollar license. Build your brand fortress with Unstoyppable's anti-diversion manufacturing systems.

Verify Our Compliance Standards | See Our IP Protection Protocols

Grey Market Mitigation and Secure Logistics

To protect your brand from "grey market" interference, we utilize secure supply chain for licensed products shipping lanes. Every container is fitted with GPS/IoT seals that alert our control tower if a door is opened outside of a designated customs zone. This ensures that your toys move directly from our audited factory network China to your retail hubs without being diverted or tampered with. We protect the integrity of your distribution as fiercely as we protect the integrity of your manufacturing.

Strategic Sourcing Scrutiny:

Eliminating the "Shadow Factory" Risk

A chain is only as secure as its weakest link. In 2026, the risk of a "shadow factory"—an unvetted facility used by a primary supplier—remains a top concern for global brands. Our strategic sourcing scrutiny eliminates this variable through rigorous, multi-layered vetting.

The Fortress Advantage: By choosing Unstoyppable, you are opting for a manufacturing partner that views security as a core engineering requirement. From AI-driven behavior monitoring to real-time raw material reconciliation, we provide the comprehensive protection your IP deserves in 2026. Build a brand that is resilient, secure, and truly Unstoyppable.

Defending the Digital Thread:

Cyber-Security in Modern Manufacturing

In 2026, the vulnerability of a toy brand is no longer found solely in physical theft, but in the "digital thread"—the continuous stream of data connecting a concept to a retail shelf. As manufacturing in China becomes increasingly autonomous, the "Digital Twin" of your product and the IoT in toy manufacturing sensors on the shop floor become high-value targets for industrial espionage and sabotage. At Unstoyppable, we bridge the gap between Information Technology (IT) and Operational Technology (OT) by implementing a rigorous cyber-physical defense layer. Our infrastructure is designed to protect your digital blueprint with the same intensity we apply to physical mold security, ensuring your 100% IP safety in an interconnected world.

Agentic AI for Threat Detection:

Autonomous Supply Chain Defense

Traditional cybersecurity relies on static firewalls that can be bypassed by sophisticated 2026 social engineering or zero-day exploits. Unstoyppable has transitioned to AI-driven supply chain defense by deploying Agentic AI models that live within our ERP environment. These autonomous agents do not just watch for viruses; they monitor the "pulse" of production logic to detect the subtle signs of IP theft.

Intelligent ERP Behavior Monitoring

Our agentic AI for threat detection analyzes ERP production tracking system logs to identify "behavioral anomalies." For example, if a machine in our PVC figure manufacturer network suddenly requests a 20% increase in raw material without a corresponding work order, the AI identifies this as a potential unauthorized production "overrun" and triggers an immediate lockout. By treating every data point as a security signal, we provide a self-healing manufacturing cyber-security China framework that evolves as quickly as the threats do.

Zero-Trust CAD Environment

We utilize a proprietary, secure file transfer toys system that implements a "Zero-Trust" architecture. Your engineering files are never stored in an unencrypted state on a local drive. Instead, they are accessed via secure, virtualized workstations where "Print Screen" and "USB Export" functions are hardware-disabled. This digital blueprint protection ensures that even our own engineers only see what they need to see, when they need to see it, with every access event logged on an immutable ledger.

Dynamic Watermarking and Asset Tracking

To further bolster IP protection in China manufacturing, every file and physical prototype is embedded with a unique, invisible digital watermark. This allows us to trace the "digital DNA" of an asset back to its exact access point. If a low-resolution image of a prototype appears online, we can instantly identify the workstation and timestamp involved, providing a powerful deterrent against internal leaks. At Unstoyppable, your character engineering for toys remains a secret until the moment of its global reveal.

Don't Let Your Digital Assets Become a Liability

In 2026, your CAD files are as valuable as your bank account. Secure your IP with Unstoyppable’s encrypted toy prototyping and AI-driven supply chain defense.

Firmware Integrity and Edge Security

Every sensor used for real-time manufacturing data China is equipped with hardware-based "Roots of Trust." This means the firmware on our injection molded toy manufacturer equipment is cryptographically signed and verified every time the machine boots. Any attempt to modify the machine's software results in an instant shutdown. By processing data at the "Edge" before it ever hits the cloud, we minimize the data's exposure to the open internet, ensuring a secure supply chain for licensed products from the motor to the cloud.

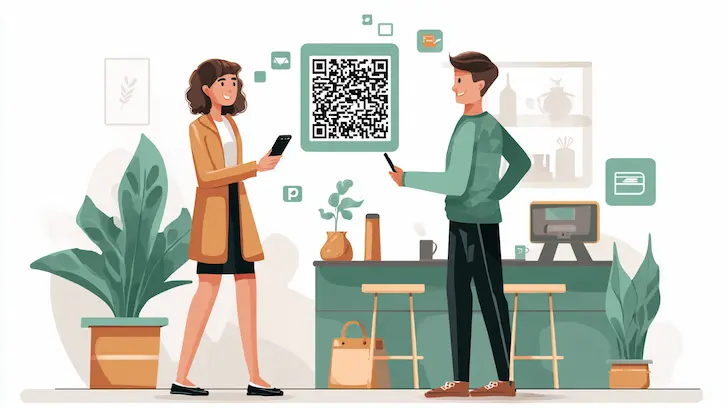

Digital Product Passport (DPP) Integrity:

Anti-Counterfeit Verification

The Digital Product Passport (DPP) is your product's 2026 legal requirement, but it is also a security vulnerability if not properly implemented. If a QR code can be easily cloned, the entire transparency chain collapses. Unstoyppable ensures DPP integrity through advanced physical-digital bonding.

The Technical Edge: In 2026, manufacturing is a digital game. By integrating agentic AI for threat detection, encrypted toy prototyping, and blockchain-backed DPP integrity, Unstoyppable provides the most advanced manufacturing cyber-security China available. We don't just build toys; we build secure digital ecosystems that allow your IP to flourish without fear. Make your digital thread unbreakable.

Zero-Trust Manufacturing:

The Ultimate Assurance for License Holders

In the high-velocity retail environment of 2026, trust is earned through continuous verification, not assumed through long-term relationships. Unstoyppable operates on a Zero-Trust supply chain China framework, a rigorous manufacturing philosophy where every component, every material supplier, and every individual handling your IP is treated as a security variable that requires constant authentication. This "never trust, always verify" approach is the bedrock of our brand protection manufacturing strategy. By moving away from perimeter-based security and toward a granular, data-backed validation model, we ensure that your licensed characters remain exclusive, your shipments remain intact, and your brand reputation remains flawless from the factory floor to the global retail shelf.

The Zero-Trust Philosophy:

Constant Verification in the Production Line

The Zero-Trust supply chain China model is built on the principle that security breaches often originate from within established perimeters. To mitigate this, Unstoyppable implements a multi-factor authentication (MFA) environment for the physical world. Every transition point in the manufacturing process—from the release of raw phthalate-free toy materials to the final sealing of a shipping container—requires a verified digital "handshake."

Granular Access Control and Identity Management

Within our partner facilities, access to sensitive production zones, such as the mold development & injection tooling area, is restricted via biometric identification and time-bound digital keys. This ensures that only authorized personnel can interact with your physical assets. By maintaining a strict "least privilege" access model, we ensure that unauthorized production prevention is managed at the individual level. Every strike of an injection mold is tied to a specific operator ID, creating a transparent and immutable log of licensed product authenticity.

Pre-Verified Security for Rapid Customs Entry

Because Unstoyppable maintains a verified ethical supply chain with high-security seals and GPS-tracked containers, our shipments are categorized as "Low Risk" by US and EU customs authorities. This status facilitates "Green-Lane" customs entry, where your products bypass lengthy physical inspections that can delay a movie-launch window. By integrating security data directly into the manifest, we provide the documentation that allows your retail-ready licensed products to move from China to your warehouse with unparalleled speed.

Eliminating Container Tampering Risks

Our secure supply chain for licensed products includes the use of smart-locking mechanisms that utilize light sensors and GPS geofencing. If a container is opened outside of a designated customs zone or a retail distribution center, an instant alert is sent to our 24/7 security operations center. This level of brand protection manufacturing ensures that "leakage" or "product swapping" is physically impossible, guaranteeing that the goods your customers buy are exactly what we shipped.

Future-Proof Your IP Today

In 2026, security is your competitive advantage. Secure your brand with Unstoyppable’s Zero-Trust manufacturing and C-TPAT compliant logistical network.

Explore Our Global Logistics | See Our Anti-Counterfeit Tech

The Consumer Trust Loop:

Closing the Transparency Circle

2026 consumers are active participants in supply chain security. By scanning the encrypted QR code or NFC tag on your product, the consumer enters a "Trust Loop." They can see the licensed product authenticity certificate, the date of manufacture, and the security milestones the product passed. This interactive transparency doesn't just prevent counterfeiting; it builds a powerful emotional connection between the fan and the brand. At Unstoyppable, we make transparency the ultimate consumer-facing feature.