Soft Goods Manufacturing:

Precision Engineering for Licensed Textiles

In the competitive arena of character-based branding, the tactile quality of a product often dictates its perceived value. At Unstoyppable, we have redefined soft goods manufacturing by elevating it from traditional needlework to a rigorous engineering discipline. For brand owners and IP holders, the "Final Touch" is everything. Our 2026 manufacturing protocols ensure that every piece of licensed textile production meets the exact specifications of the original style guide, providing a seamless transition from screen to fabric. Whether it is custom plush accessories China or high-end apparel-grade merchandise, our facility utilizes advanced material science and automated construction to deliver products that are durable, compliant, and luxurious to the touch. By treating textiles as an engineered component, we eliminate the variability found in standard workshops and provide a consistent, high-end result for global retail.

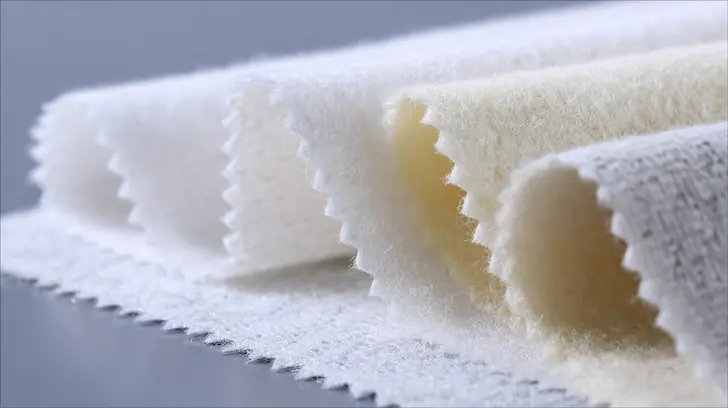

High-GSM Performance Fabrics

Unstoyppable utilizes high-GSM (grams per square meter) fabrics that provide a substantial, weighted feel. By selecting performance textiles typically reserved for luxury apparel, we ensure that our premium fabric merchandise possesses a superior "hand-feel" and structural integrity. These high-density weaves allow for deeper dye penetration and better shape retention, ensuring that a plush character or textile accessory remains "shelf-fresh" even after thousands of consumer interactions. This commitment to density and weight is a hallmark of our licensed textile production, positioning your brand at the apex of the market.

Advanced Texture Engineering

Tactile diversity is essential for character accuracy. Our engineering team selects specific fabric grains—from ultra-soft minky and brushed tricot to complex jacquards—to replicate character textures such as fur, scales, or tactical armor. In 2026, we have introduced "intelligent pile" fabrics that resist matting and clumping, maintaining the original aesthetic of the custom plush accessories China over its entire lifecycle. This focus on texture ensures that the physical product evokes the same emotional response as the digital character.

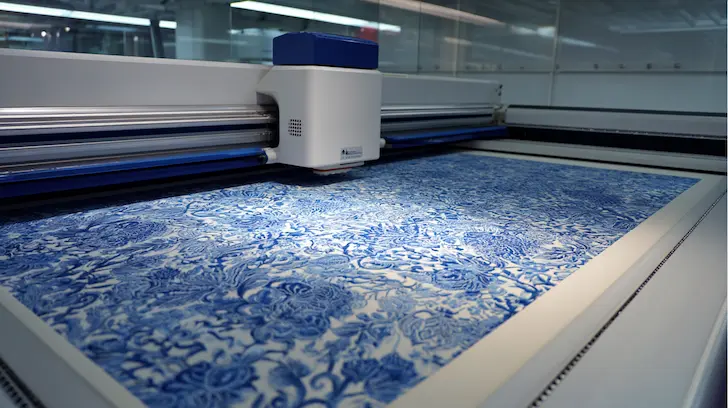

High-Volume Pattern Consistency

Traditional die-cutting tools can wear down or shift over time, leading to minor variations in a million-unit run. Laser cutting, controlled by high-precision digital CAD files, ensures that unit #1 is identical to unit #1,000,000. This consistency is mandatory for licensed textile production, where even a millimeter of deviation can alter the facial expression of a character or the fit of a miniature garment. Our automated systems allow for rapid scaling while maintaining the "boutique" quality that premium fabric merchandise demands.

Transform Your Character into a Tactile Experience

Don't settle for standard needlework. Partner with a manufacturer that treats textiles with the precision of engineering.

Explore Specialized Plush Production | View Lifestyle Soft Goods

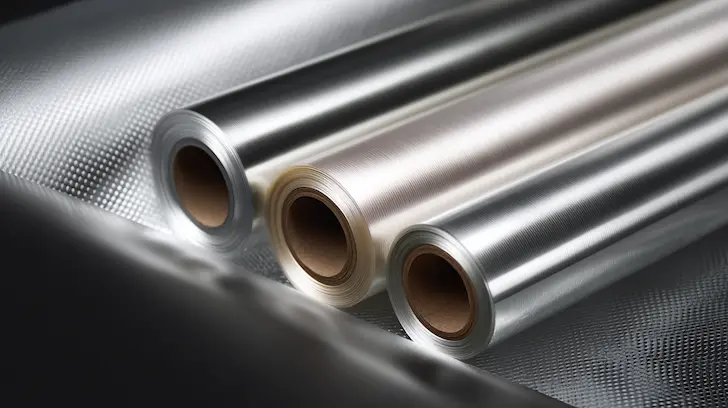

High-Definition Printing Film for Textures

For specialized finishes—such as metallic sheen or hyper-realistic textures—we apply high-density printing film that bonds molecularly with the textile. This allows us to add "hard" visual elements (like armor plating or mechanical details) to "soft" components. By combining these digital printing techniques with our licensed textile production, we create a multi-dimensional product that stands out on the retail shelf and captures the fan's imagination.

Material Selection:

Meeting the 2026 Sustainability Mandates

In 2026, "Green is the New Gold." Sustainable sourcing is no longer an option; it is a regulatory and consumer-driven requirement. Unstoyppable leads the way in soft goods manufacturing by offering a vast library of eco-certified materials that do not compromise on quality or hand-feel.

The Unstoyppable Edge: We believe that soft goods should be as precisely manufactured as any high-tech electronic. Through automated laser cutting, sublimation printing, and certified sustainable materials, we deliver a premium fabric merchandise solution that is future-ready. Experience the intersection of textile art and industrial precision.

The Hybrid Frontier:

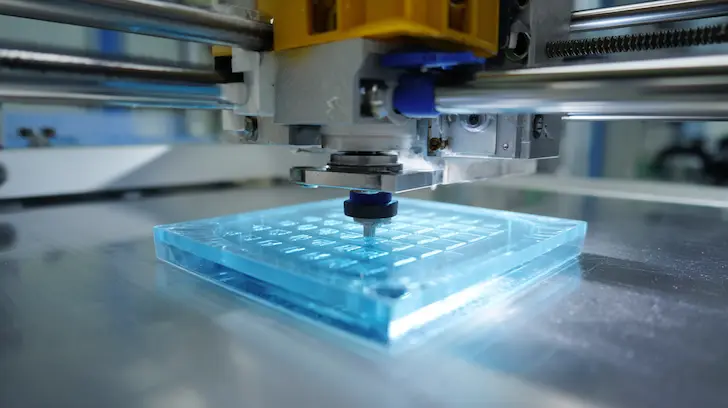

Integrating Textiles with Injection Molding

In the high-end collectible and luxury merchandise sectors, the boundary between "hard" and "soft" products is effectively dissolving. At Unstoyppable, we are leading the 2026 "Mixed Media" revolution by mastering the technical fusion of high-performance textiles with rigid industrial components. This hybrid toy manufacturing approach allows IP holders to create products that possess the structural integrity of a statue with the tactile warmth of a plush. By integrating textiles directly with injection molded toy manufacturer cores, we produce soft-touch character merchandise that feels more "real" and premium than traditional single-material items. Our facility specializes in the complex engineering required to bond, overmold, and sew across disparate material groups, providing a seamless "retail-ready" finish for the world’s most demanding entertainment brands.

Overmolding Textiles:

The Permanent Bond of Form and Feel

One of the most advanced techniques in our hybrid toy manufacturing repertoire is 2026-grade fabric-over-plastic molding. This process creates a permanent, molecular-level bond between a rigid plastic structure and a soft outer textile shell, eliminating the need for traditional stitching in specific design areas.

The 2026 Fabric-Over-Plastic Molding Technique

Our engineers utilize specialized fabric-over-plastic molding protocols where pre-cut, heat-resistant textiles are placed directly into the injection mold cavity. As the molten ABS or PVC is injected, the plastic permeates the back-weave of the fabric, locking it into the structure as it cools. This results in a mixed media licensed goods piece that has the impact resistance of plastic but the aesthetic elegance of silk, suede, or canvas. This technique is highly effective for creating ergonomic grips on electronics, protective panels on licensed bags, or specialized "soft-shell" armor for high-end character figures.

Engineering Plastic and Metal Armatures

We utilize multi-jointed armatures, often referred to as "skeletons," which are produced through our injection molded toy manufacturer lines using high-tensile POM or nylon. These armatures are designed to mimic anatomical joints, providing a satisfying "click" or smooth tension when posed. Our soft goods manufacturing team then expertly sews the character’s "skin" around this core. The result is a hybrid toy manufacturing masterpiece: a figure that can stand, sit, or hold a dynamic pose while retaining the huggable softness of a premium plush.

Padding and Volume Management

To ensure the internal skeleton is not visible or felt as a "hard spot," we utilize multi-density foam layering and siliconized fiberfill. This engineering ensures that the transition from the hard core to the soft exterior is gradual and natural. This technique is favored by mixed media licensed goods creators who want to offer a "professional-grade" character replica that transcends the limitations of a standard stuffed toy.

Bridge the Gap Between Hard and Soft

Your vision shouldn't be limited by material constraints. Explore our innovative mixed-media manufacturing solutions and redefine what your brand can offer.

Eco-Friendly and Non-Toxic Formulations

Consistent with our commitment to ethical toy manufacturing China, all our adhesives are low-VOC and free from harmful solvents. This is essential for meeting the safety requirements of major licensors like Disney and NBCU. By prioritizing these safe, high-performance glues, we provide a hybrid toy manufacturing solution that is as responsible as it is durable.

Technical Bag & Case Construction:

Hard Shell, Soft Heart

The synergy between our textile department and our structural molding division is best exemplified in our custom bag manufacturer China services. We specialize in tech-focused accessories that require both protection and a premium aesthetic.

The Mixed-Media Expert: Unstoyppable represents the pinnacle of hybrid toy manufacturing. Whether it is fabric-over-plastic molding, skeletal integration for figures, or technical licensed bag manufacturer solutions, we provide the engineering depth to make "impossible" designs a reality. Elevate your brand with the premium retail feel of mixed-media engineering.

Secure Fabric Production:

Compliance and Traceability for Soft Goods

In the globalized market of 2026, a textile product is only as valuable as the trust it inspires. As a specialized partner for high-tier IP holders, Unstoyppable provides secure textile manufacturing China services that prioritize the safety of the end-consumer and the legal integrity of the brand. Soft goods—ranging from plush figures to licensed apparel—face unique regulatory hurdles, particularly regarding chemical treatments and fiber origin. We act as the guardian of your brand’s reputation by ensuring every square inch of fabric is EN71 compliant soft goods grade. Our facility integrates the latest 2026 digital identity protocols with traditional social accountability, providing a transparent and ethical fabric supply chain that meets the uncompromising standards of the world’s largest entertainment conglomerates. By choosing a manufacturer that leads in both safety and digital traceability, you ensure that your product is not only retail-ready but future-proofed against evolving global mandates.

2026 Chemical Mandates:

Beyond Surface-Level Safety

The regulatory landscape for textiles has intensified significantly in 2026, with a focus on eliminating "forever chemicals" and harmful colorants. At Unstoyppable, our AZO-free textile manufacturing process is strictly monitored to ensure that every dye lot is pure and safe for all-ages interaction.

AZO-Free Dyes and REACH Compliance

We utilize exclusively AZO-free textile manufacturing protocols to eliminate aromatic amines that are restricted under REACH and CPSIA. Our 2026-spec dyes are molecularly stable, ensuring that colors remain vibrant without the use of heavy metals or restricted sensitizers. This is particularly vital for licensed textile production intended for children, where saliva-fastness and skin contact safety are paramount. Every fabric roll is batch-tested in third-party labs before it enters the cutting phase, providing a documented trail of chemical purity that protects the IP holder from liability.

Smart Tags and Woven QR Labels

We offer the integration of "Smart Tags"—ultra-thin, high-durability woven labels featuring unique QR codes or Data Matrix identifiers. These are sewn into the internal seams of plush or apparel, serving as a permanent link to the product’s digital product passport toys. By scanning this tag, consumers can verify the ethical fabric supply chain, viewing everything from the factory’s BSCI audit status to the specific recycling certificates of the rPET fibers used. This transparency is a powerful marketing tool, turning a compliance requirement into a story of brand integrity.

End-to-End Traceability via Blockchain

For high-value licensed merchandise manufacturer projects, we offer blockchain-linked traceability. This ensures that the data within the DPP is immutable and verifiable. Collectors can see the exact journey of their item, from the textile mill to the secure textile manufacturing China facility and finally to the retail shelf. This digital provenance is essential for high-end boutique plush and limited-edition soft goods where authenticity is the primary driver of value.

Protect Your Brand and Your Customers

In 2026, compliance is not just a checkbox—it's your brand's shield. Partner with a FAMA-certified leader in secure and compliant soft goods manufacturing.

Explore IP Security Protocols | Review Global Safety Standards

Non-Replicable High-Density Printing

By using proprietary 3D-raised silicon printing and specialized metallic films that require industrial-grade heat-press calibration, we create tactile logos and details that low-cost counterfeiters cannot replicate. This physical security, combined with our digital product passport toys, creates a dual-layer defense system for your most valuable character assets.

Disney FAMA & Social Audits:

Ethical Excellence in Textiles

The textile industry requires the highest level of social oversight. Unstoyppable ensures that your ethical fabric supply chain is backed by the industry’s most prestigious certifications, protecting you from the reputational risks associated with unverified labor.