Licensed Bag Manufacturer:

Engineering High-Performance Soft Goods

In the competitive arena of 2026 retail, a licensed bag manufacturer must provide more than just aesthetic appeal; they must deliver industrial-grade durability and uncompromising chemical safety. At Unstoyppable, we view character bag manufacturing through the lens of high-performance engineering. Every backpack, tote, or messenger bag we produce is built on a foundation of advanced textile science. For global entertainment brands, the physical longevity of a bag is a direct reflection of the brand's value. Our custom backpack production China infrastructure is designed to source and synthesize materials that withstand the rigors of daily use while meeting the most stringent global safety mandates. By focusing on superior substrates and reinforced construction, we ensure your licensed assets are perceived as premium, long-lasting investments by consumers.

Comparing 600D to 1680D Ballistic Polyester

For standard custom backpack production China, 600D Polyester is the industry baseline, offering a perfect balance of printability and abrasion resistance. However, for 2026 premium collectible lines, we often deploy 1680D Ballistic Polyester. Originally engineered for military use, 1680D offers a thick, basket-weave structure that is virtually immune to tearing. This high-denier approach ensures that even under the stress of heavy schoolbooks or travel gear, the bag maintains its shape and structural "memory." We also utilize high-tenacity Nylon (Cordura-type) for projects requiring extreme lightweight performance combined with high puncture resistance.

2026 Eco-Compliance:

The Rise of RPET Textiles

Sustainability is no longer an optional feature; it is a 2026 market prerequisite. Unstoyppable has integrated RPET (Recycled Polyethylene Terephthalate) into our primary textile supply chain. RPET is created by breaking down post-consumer plastic bottles into flakes, which are then spun into high-quality polyester yarn. This process allows our sustainable textile toys and bags to boast a significantly lower carbon footprint without sacrificing tensile strength. Our RPET fabrics are GRS (Global Recycled Standard) certified, providing license holders with the documented transparency required for ethical toy manufacturing China initiatives.

Moisture Vapor Transmission and Hydrostatic Head

We measure our coatings using the "Hydrostatic Head" test, ensuring our fabrics can withstand water pressure of 5,000mm to 10,000mm. This technical precision ensures that high-denier polyester bags remain dry in heavy rain. For lifestyle products, we also offer breathable membranes that allow moisture vapor to escape while preventing water droplets from entering, a feature highly sought after in lifestyle product manufacturer sectors for active-wear bags.

Build a Bag That Lasts into the Future

In the 2026 landscape, material failure is not an option. Ensure your soft goods are engineered for durability and 100% chemical compliance.

Explore Soft Goods Capabilities | View Lifestyle Case Studies

Custom 3D Silicone and PVC Patches

Branding in 2026 has moved beyond simple screen printing. We utilize specialized tooling to create multi-color 3D silicone patches that are heat-welded or stitched onto the bag. These patches offer a tactile, premium feel that is immune to fading or peeling. By using medical-grade silicone, we ensure these decorative elements are phthalate-free and safe for all age groups. This integration of molding technology into character bag manufacturing allows for a level of detail that traditional embroidery cannot match.

Load-Bearing Science:

The Engineering of Reinforced Construction

A bag is only as strong as its weakest seam. Unstoyppable applies load-bearing science to every stress point, ensuring our products survive the "extreme play" and heavy load requirements of modern consumers.

The Textile Advantage: At Unstoyppable, we treat soft goods with the same technical rigor as hard-plastic engineering. By combining high-denier ballistic polyesters, phthalate-free TPU coatings, and EVA molded components, we create a product that is structurally superior and aesthetically flawless. Trust our 2026 material engineering to elevate your next licensed bag collection.

Visual Mastery:

Printing, Embroidery, and Custom Hardware for Bags

In the high-velocity world of licensed retail, the visual identity of a product is the primary driver of consumer engagement. At Unstoyppable, we recognize that a licensed bag manufacturer must be a master of color science and precision decoration. Transforming a complex character style guide into a durable, flexible textile product requires a sophisticated array of application techniques. Our 2026 production lines integrate high-definition imaging with bespoke mechanical components, ensuring that every backpack and accessory is a perfect physical manifestation of the brand's IP. By utilizing advanced character bag manufacturing technologies, we ensure that colors remain vibrant and logos stay crisp, even under the stress of daily environmental exposure and heavy mechanical use.

Advanced Printing Techniques:

The Art of Character Fidelity

Achieving the perfect character likeness on soft surfaces demands more than standard ink application. It requires a deep understanding of fabric absorption, ink elasticity, and thermal bonding. Unstoyppable utilizes a tiered printing strategy to ensure every custom backpack production China project meets the aesthetic benchmarks of the world's leading animation studios.

Sublimation Printing for Full-Bleed Character Art

For designs that require edge-to-edge graphics, sublimation printing for bags is our premier solution. This process uses heat to turn ink into a gas, which then penetrates the fibers of the polyester fabric before reverting to a solid. Unlike surface printing, sublimation becomes a permanent part of the textile. This results in a "zero-hand" feel where the graphic cannot be felt on the surface, and it is entirely immune to cracking, peeling, or fading. It is the ideal method for silk-screened licensed backpacks that feature complex gradients, photographic textures, or vibrant 2026 "neon" character palettes. Our wide-format sublimation presses ensure perfect color matching against Pantone and digital style guides.

Zinc Alloy Injection Molding for Zipper Pulls

Our custom zipper pulls China service utilizes high-precision zinc alloy injection molding. This allows us to create intricate, three-dimensional character shapes or embossed logos that serve as the primary "interactable" on the bag. Every pull is finished with an electroplated anti-oxidation coating to prevent tarnishing or chipping. We ensure these pulls are ergonomically designed for children's hands while maintaining the tensile strength necessary to withstand thousands of opening and closing cycles. This attention to custom licensed product development elevates a simple bag into a sophisticated brand asset.

Load-Bearing Buckles and Adjusters

For load-bearing components, we utilize high-impact POM or branded zinc alloy buckles. Every piece of hardware is subjected to salt-spray testing to ensure environmental durability and pull-strength testing to guarantee it remains secure under maximum load. By integrating these custom zipper pulls China and hardware sets, we provide a cohesive visual and tactile experience that reinforces the brand's quality with every use.

Make Your Brand Stand Out on the Shelf

Your character deserves more than a flat print. Give your fans a premium experience with 3D hardware and high-definition textile art.

High-Visibility 2026-Spec Inks

Our sublimation printing for bags can include specialized high-visibility inks that react to direct light sources. These "stealth" safety features appear as standard colors during the day but provide intense luminosity at night. By utilizing these 2026-spec materials, we ensure that your product meets and exceeds the latest European and North American pedestrian safety guidelines for children's accessories.

Internal Lining & Branding:

The "Retail-Ready" Premium Finish

The interior of a bag is just as important as the exterior for consumer perception. A high-quality internal finish justifies a premium price point and protects the internal contents. Unstoyppable prioritizes a "Full-Package" branding approach for every licensed merchandise manufacturer project.

The Visual Advantage: At Unstoyppable, we believe that character bag manufacturing is a form of high-definition storytelling. By combining sublimation printing, zinc alloy hardware, and integrated safety finishes, we create a product that is visually stunning and industrially durable. Elevate your 2026 product line with our mastery of textile decoration and customization.

2026 Bag Safety Standards:

From Load Tests to Digital Passports

In the globalized economy of 2026, the regulatory requirements for soft goods have evolved into a rigorous multi-tier framework. At Unstoyppable, we recognize that a licensed bag manufacturer must act as more than a supplier; we are the primary guardians of your brand’s legal integrity. Every product that leaves our bag quality control China facilities is subjected to a battery of physical and chemical validations that exceed traditional standards. By integrating advanced mechanical stress testing with 2026-mandatory digital traceability, we provide a secure, transparent path to market. Our ASTM F963 soft goods compliance ensures that every strap, zipper, and fabric panel is engineered for safety, shielding our clients from the operational and reputational risks associated with product recalls or supply chain failures.

Mechanical Stress Testing:

Simulating the School Day Lifecycle

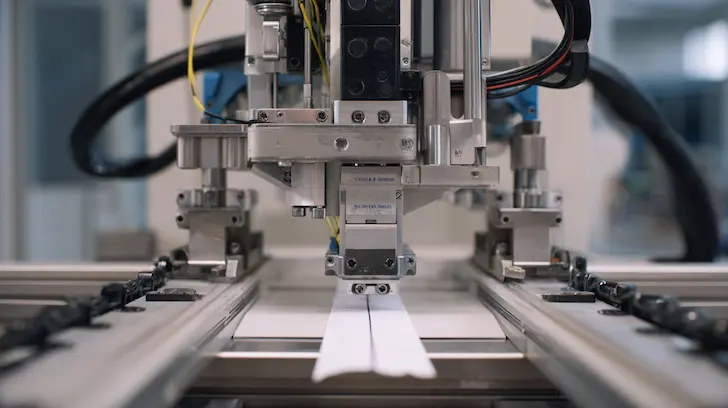

A licensed bag is often the most heavily used item in a child's daily routine. To ensure longevity, our bag quality control China protocols move beyond visual inspection to high-velocity mechanical validation. We utilize robotic testing environments to ensure that every structural component survives the equivalent of over 500 days of aggressive use.

Automated "Jerk Testers" and Handle Strength

The most common failure point in backpacks is the shoulder strap or top handle attachment. We utilize automated "Jerk Testers"—robotic rigs that lift a weighted bag (typically 15kg to 25kg) and drop it suddenly to simulate a child grabbing their bag in a hurry. This dynamic stress testing ensures that our reinforced "X-box" stitching and high-tenacity nylon threads remain intact. By meeting these 2026 EN71 compliant bags benchmarks, we guarantee a product that maintains its physical form under the most extreme domestic and travel conditions.

Rigorous Screening for Lead and Azo-Dyes

Every textile batch is screened in third-party accredited labs for heavy metals and restricted Azo-dyes. Lead, often found in low-quality zippers or pigments, is strictly eliminated from our supply chain. Our licensed bag manufacturer protocols ensure that all metal hardware and printing inks are verified "non-toxic" before assembly begins. This level of oversight is essential for ASTM F963 soft goods certification, providing a safe product for consumers of all ages.

Transition to Phthalate-Free Plasticizers

Many traditional bags utilized PVC with harmful phthalates for flexibility. In 2026, Unstoyppable has transitioned entirely to phthalate-free bag manufacturing, utilizing TPU (Thermoplastic Polyurethane) or eco-friendly TPE (Thermoplastic Elastomers). These materials provide the same waterproof performance and flexibility without the endocrine-disrupting risks. By choosing these advanced polymers, we ensure your brand aligns with the modern consumer’s demand for ethical toy manufacturing China and health-conscious products.

Future-Proof Your Soft Goods Line

Regulatory landscapes are shifting. Ensure your brand is protected by a manufacturer that leads in 2026 safety and digital traceability.

Blockchain-Backed Supply Chain Traceability

For high-value licensed merchandise manufacturer projects, our DPP system is backed by secure data ledgers. This ensures that the provenance of the RPET recycled fabrics and the phthalate-free bag manufacturing processes is verified and tamper-proof. This transparency is a powerful marketing tool, allowing brands to tell a story of sustainability and safety that is backed by hard, accessible data.

Disney FAMA & Social Audits:

Avoiding Supply Chain Risk

For a world-class license holder, the "Where" and "How" of production are as important as the product itself. Unstoyppable’s network consists exclusively of BSCI and Sedex audited toy factories, ensuring that your brand is never associated with unethical labor practices.