Advanced Toy Tooling R&D:

Engineering the Future of Character Precision

In the competitive arena of licensed merchandise, the boundary between a standard toy and a masterpiece of high-precision toy molds is defined by the depth of Research and Development (R&D) invested in the tooling phase. At Unstoyppable, we operate as a specialized technical partner for brands that demand perfection. Advanced toy tooling R&D is the core of our operation, allowing us to bridge the gap between ambitious digital character designs and high-volume manufacturing reality. For 2026, our engineering focus has shifted toward hyper-fidelity, where every facial expression, fabric weave, and mechanical joint is meticulously etched into high-grade industrial steel. We provide solutions for complex character mold engineering that traditional factories often find insurmountable. By treating the mold not just as a cavity, but as a high-performance engine, we ensure that your intellectual property is manifested with absolute fidelity and structural integrity across every unit produced.

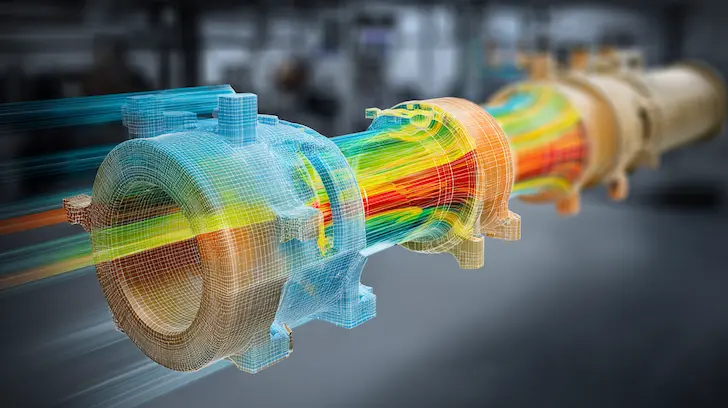

Compensating for Molecular Polymer Behavior

Our advanced toy tooling R&D process involves creating a digital "twin" of the molding environment. We utilize predictive modeling to calculate exactly how different polymers—from high-impact ABS to sustainable bio-resins—will shrink and flow. This allows us to engineer molds that compensate for these variables at a microscopic level. Instead of reacting to defects after they happen, we "pre-solve" issues like air traps or sink marks within the tool's design. This level of complex character mold engineering ensures that the final product remains true to the original character engineering for toys specifications, maintaining the sharpest possible details on the most intricate sculpts.

Airflow and Venting Sophistication

One of the "Special Ops" secrets of high-detail production is the mastery of gas venting. In high-precision toy molds, trapped air is the enemy of fine detail. Our R&D team implements microscopic venting channels and porous steel inserts that allow air to escape without creating "flash" (excess plastic). This ensures that the plastic fills the furthest extremities of a character’s hair or fingertips with 100% density. By perfecting this airflow, we deliver multi-cavity injection tooling that produces perfect parts in every cycle, maximizing efficiency for our global brand partners.

Thermal Conductivity for Faster Cycles

By integrating specialized Beryllium Copper (BeCu) inserts into high-heat areas of the mold, we accelerate the cooling process. This R&D-driven approach to multi-cavity injection tooling allows for faster cycle times without sacrificing the structural integrity of the plastic. Faster cooling leads to less warping and higher output, directly contributing to a lower landed cost for the IP holder while maintaining the premium high-precision toy molds standard.

Engineering Perfection Starts with the Steel

Your character deserves more than a standard factory mold. Partner with our specialized R&D team to solve your most complex character molding and tooling challenges today.

Eliminating Visible Seam Lines

Visible seams are the hallmark of basic manufacturing. At Unstoyppable, we use our advanced toy tooling R&D to place parting lines in hidden areas—along hair gradients, costume seams, or accessory edges. By engineering the mold splits with such precision, we ensure that the character retains a "sculpted" feel. This micro-detail toy molding technique is what separates elite licensed merchandise from standard retail fare, giving your brand a distinct competitive edge.

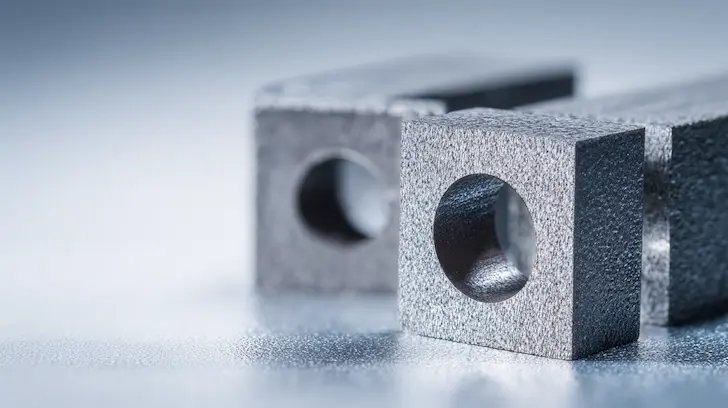

Micro-Texture Etching:

The Digital Skin of 2026

The final touch in advanced toy tooling R&D is the application of surface textures. In 2026, we have moved beyond chemical etching to a more precise digital process.

The Unstoyppable Standard: By combining high-detail steel selection with advanced undercut management and laser ablation texturing, we provide an R&D framework that solves the industry's most difficult manufacturing problems. Trust our Special Ops engineering team to turn your most complex IP into a reality of precision and performance.

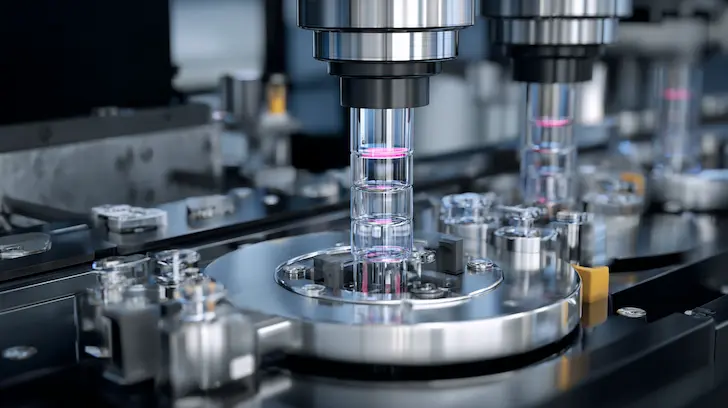

Integrated Tooling Tech:

In-Mold Decoration and Digital Traceability

In the rapidly evolving landscape of 2026, the distinction between a simple molded part and a premium licensed product is defined by technical integration. At Unstoyppable, we move beyond the traditional "mold-then-paint" workflow. Our advanced toy tooling R&D focuses on automated toy tooling that incorporates finishing and identity directly into the injection cycle. This integrated approach ensures that aesthetics are not just surface-level, but are physically bonded to the material itself. By leveraging IML toy manufacturing and multi-material injection, we provide IP holders with a streamlined production path that reduces secondary labor costs while significantly increasing the "perceived value" of the final product. This visionary manufacturing model is designed to satisfy the rigorous demands of the modern collector market and the strict transparency requirements of global retail networks.

In-Mold Labeling (IML) for Toys:

Permanent High-Definition Graphics

Traditional pad printing and spray masking are effective, but for the highest level of durability and detail, in-mold labeling for toys is the superior solution. This process transforms the mold into a decorative canvas, ensuring that every graphic is as resilient as the plastic itself.

Fusing Printing Film with Molten Polymers

The core of IML toy manufacturing involves placing a pre-printed, high-resolution printing film for injection molding into the mold cavity before the resin is injected. As the molten plastic fills the mold, it thermally fuses with the film, creating a singular, monolithic part. This technique eliminates the risk of peeling or scratching, which is a common failure in high-play-value items. Our R&D team uses robotic placement systems to ensure 100% positional accuracy, allowing for complex, full-wrap graphics that would be impossible to achieve through manual painting. This integration is essential for retail-ready licensed product production, ensuring the character’s likeness remains vibrant for the entire life of the toy.

Engineering Dual-Material Injection Cycles

Our high-precision toy molds are engineered to inject two distinct materials—such as a rigid ABS skeleton and a soft-touch TPE (Thermoplastic Elastomer) skin—within a single, automated cycle. This 2K tooling process creates a perfect molecular bond between the materials without the need for adhesives or manual assembly. This is the gold standard for creating ergonomic grips, life-like skin textures, or "battle-damaged" armor effects. By eliminating the seams and gaps found in traditional two-part assemblies, 2K overmolding ensures a seamless, high-quality finish that fans associate with premium brands.

Reducing Assembly Complexity and Labor Costs

Beyond the aesthetic benefits, overmolding is a strategic choice for design for mass production toys. By integrating soft and hard components into a single part directly from the tool, we reduce the total part count and the labor required for final assembly. This efficiency allows us to reallocate the project budget toward higher-quality resins or more complex packaging, maximizing the overall quality of the product while maintaining a competitive landed cost. This is the essence of advanced toy tooling R&D: using technology to create more value with less waste.

Future-Proof Your Production

Don't let your manufacturing stay in the past. Leverage our automated 2K tooling and in-mold decoration technologies to deliver a smarter, more premium character launch.

Learn About Advanced Materials | See Our IP Security Protocols

Automating Compliance for Global Markets

By engineering the DPP identity into the tool, we automate the most difficult part of the toy supply chain transparency process. The code becomes a permanent feature of the plastic part, ensuring that even if the outer packaging is lost, the product’s compliance data remains accessible. This foresight is what makes Unstoyppable a leader in secure supply chain for licensed products, allowing our partners to enter European and North American markets with absolute confidence in their regulatory standing.

Interchangeable Inserts:

Maximizing Tooling ROI

Tooling is a significant investment. Our advanced toy tooling R&D team utilizes modular mold designs to maximize the utility of every steel block, offering a high-ROI solution for character variants.

The Integration Advantage: At Unstoyppable, we believe the mold is the heart of the product's identity. By integrating in-mold labeling for toys, 2K overmolding, and digital product passport toys into a single automated workflow, we deliver a "smart" product that is ready for the 2026 global market. Empower your brand with tooling that does more than just mold—it builds trust.

Efficiency and Sustainability:

The R&D Approach to High-Volume Fulfillment

In the high-volume world of licensed merchandise, profitability and environmental responsibility are driven by the precision of the manufacturing process. At Unstoyppable, our advanced toy tooling R&D is focused on maximizing Return on Investment (ROI) while adhering to the stringent 2026 toy manufacturing standards. We achieve this through a dual-focus strategy: optimizing the mechanical performance of our injection systems and pioneering the use of eco-conscious materials within industrial frameworks. By employing high-efficiency injection molding techniques, we ensure that every gram of resin and every second of cycle time is utilized to its maximum potential. This R&D-led approach reduces the landed cost for the IP holder and minimizes the ecological footprint of the production run. For Unstoyppable, efficiency is not just an operational goal; it is a technical discipline that ensures your brand can scale globally without compromising on quality or sustainability.

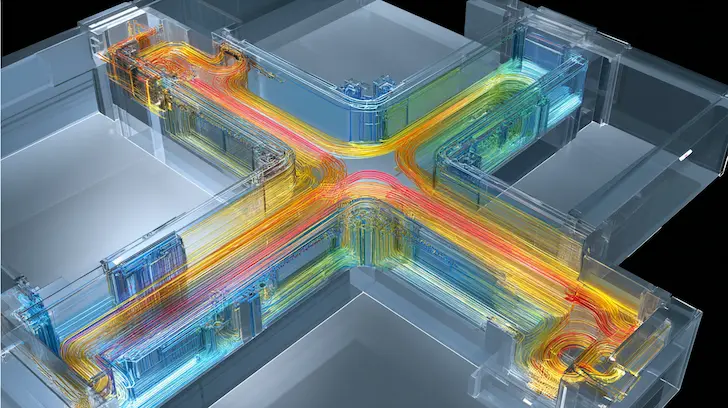

Scientific Injection Molding (SIM):

Predict, Prevent, Perfect

The transition from a digital CAD file to a flawless physical product relies on Scientific Injection Molding (SIM). This data-driven methodology allows our engineers to master the variables of pressure, temperature, and velocity before the physical mold ever enters the press.

Utilizing Toy Mold Flow Analysis Software

The core of our SIM process is toy mold flow analysis. By simulating the injection process in a virtual environment, we identify potential failure points such as gas traps, weld lines, or "sink marks" on thick-walled character sections. This predictive R&D allows us to optimize gate placement and cooling channel geometry within the mold steel. By solving these issues digitally, we eliminate the costly "trial and error" loops associated with traditional manufacturing. This ensures that the first shot from the tool is structurally sound and aesthetically perfect, accelerating your time-to-market while maintaining high-efficiency injection molding standards.

Eliminating Sprues and Runners

Traditional "cold runner" molds create a significant amount of scrap plastic—the sprues and runners that connect the part to the injection nozzle. By implementing high-efficiency hot runner systems, we keep the plastic in a molten state throughout the manifold, injecting it directly into the part cavity. This eliminates the "waste tree" entirely. For a high-volume production of a million units, this sustainable toy tooling innovation can save tons of raw material. This directly translates into lower material costs for the IP holder and a cleaner, more transparent supply chain manufacturing process.

Valve Gate Precision for Cosmetic Excellence

For premium collectibles, the "gate mark" (where the plastic enters the mold) must be invisible. We use R&D-grade valve gate systems that mechanically close the entry point, leaving a perfectly flush surface. This eliminates the need for manual trimming or post-mold sanding, further reducing manufacturing waste toys and labor costs. This is the hallmark of retail-ready licensed product production, where the product emerges from the tool ready for the retail shelf with zero defects.

Optimize Your Manufacturing ROI

Efficiency in the mold leads to profitability in the market. Explore how our advanced R&D reduces waste and accelerates your character's time-to-market.

Future-Proofing Mold Life for Recycled Resins

Recycled ocean plastics can be abrasive due to microscopic impurities. We implement "Tooling Hardening" R&D, using specialized PVD (Physical Vapor Deposition) coatings on the mold cavities to increase wear resistance. This ensures that when you produce a character using recycled ocean plastic manufacturing, the mold life is not compromised. We guarantee that the 500,000th unit will maintain the same razor-sharp detail as the first, upholding the golden tooling standard for the entire duration of your contract.

The Golden Tooling Standard:

Maintenance and Performance

At Unstoyppable, the R&D process does not end when the tool is finished; it continues through a rigorous maintenance and benchmarking protocol that ensures perpetual quality.