Precision Character Engineering:

Bridging the Gap Between Digital and Physical

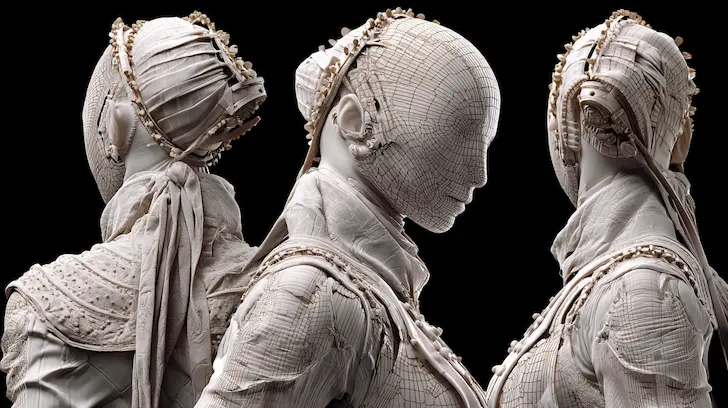

In the competitive collectibles market of 2026, the standard for success has shifted from mere resemblance to absolute Screen-to-Shelf accuracy. Fans no longer accept "approximate" likenesses; they demand physical manifestations of their favorite characters that are indistinguishable from the digital renders seen on screen. At Unstoyppable, we have mastered the transition from digital IP to tangible reality through a sophisticated character product manufacturing process. By integrating cutting-edge 3D technologies with traditional craftsmanship, we ensure that every curve, texture, and expression is preserved with mathematical precision. Our engineering team doesn't just replicate shapes; we capture the "soul" of the character, ensuring your IP maintains its integrity throughout the global supply chain.

When original assets are unavailable, or when translating 2D concept art into 3D forms, our 3D character sculpting China facilities utilize ultra-high-resolution 3D scanning. This technology allows us to capture every microscopic detail from physical maquettes or older prototypes, guaranteeing 100% proportional accuracy. By maintaining a closed-loop digital workflow, we eliminate the "sculptor's drift" that often plagues traditional manufacturing, where manual errors can slowly distort a character's features over time. With Unstoyppable, what you see on your monitor is exactly what lands on the retail shelf.

Advanced 3D Character Sculpting and Digital Artistry

Our sculpting process is where character IP engineering meets high art. Our digital artisans are masters of industry-standard tools like ZBrush and Maya, utilizing them to perform what we call "digital clay sculpting." This technique allows for a level of detail that was physically impossible a decade ago. We can digitally sculpt microscopic skin textures, the weave of a character's fabric, and even the subtle imperfections that make a character feel real.

Dynamic Posing and Structural Integrity

A static character is a flat character. To create high-fidelity character figures that captivate collectors, we focus heavily on "dynamic posing." Using advanced rigging techniques in Maya, we pose characters in mid-action, capturing the tension in muscles and the flow of garments. However, character product manufacturing isn't just about aesthetics; it's about physics. Our engineers perform center-of-gravity simulations to ensure that even the most aggressive, gravity-defying poses remain stable and balanced for retail display without the need for unsightly, oversized bases. This balance between artistic flair and toy material engineering is what defines a premium collectible.

Achieving Specialized Aesthetic Effects

Our toy material engineering team can mix materials within a single product to achieve hyper-realistic results. We use transparent PVC to create magical energy effects or flowing water, while matte-finished ABS provides the crisp, industrial lines needed for robotic characters or armor. By leveraging our position as a vinyl toy manufacturer with deep roots in injection molded toy manufacturer techniques, we provide a palette of possibilities that ensures your character's integrity is never compromised by material limitations.

Don't let your IP lose its soul in the manufacturing process.

Your characters deserve a partner who understands the nuance of every sculpt and the science of every material.

Explore Character Engineering | Request a Prototype to See Our Fidelity Firsthand

Industrial Mastery:

Bringing Iconic Characters to Mass Production

Transitioning a character from a 1-of-1 master prototype to a million-unit global rollout requires more than just industrial capacity; it requires industrial mastery. In the 2026 landscape, collectible figure manufacturing has evolved into a high-stakes engineering discipline where the difference between a retail success and a clearance-rack failure lies in the technical execution of the sculpt. At Unstoyppable, we bridge the gap between artistic intent and mass-market scalability. By utilizing a sophisticated array of injection molding for characters and advanced vinyl toy production techniques, we ensure that every unit rolling off the assembly line maintains the sharp detail and emotional resonance of the original design. Our facilities are optimized for high-fidelity reproduction, ensuring that your iconic IP is honored in every box delivered to a fan.

The Classic Aesthetic of Vinyl Toy Production

Conversely, for designer art toys and "chibi" style characters, vinyl toy production via rotocasting offers a warm, soft aesthetic that is highly prized by collectors. Rotocasting involves pouring liquid vinyl into a heated copper mold that rotates on multiple axes, creating a hollow, lightweight, and durable product. This process is ideal for characters with rounded forms and organic shapes. As a premier vinyl toy manufacturer, Unstoyppable has mastered the art of heat management during rotocasting to prevent the "shrinkage" and warping that often occurs in lesser facilities, ensuring that your vinyl figures remain true to their digital proportions.

Managing Complex "Undercuts" and Mold Geometry

A common failure in mass production is the simplification of character details—like hair spikes or flowing capes—to make them easier to remove from a mold. At Unstoyppable, we embrace complexity. We utilize multi-part sliding molds and collapsible cores to manage complex undercuts. This means we can produce a character in a single, dynamic piece that other factories would have to break into multiple ugly components. Our ability to engineer these "impossible" molds is why we are the leading PVC figure manufacturer for IPs with highly detailed, non-traditional silhouettes.

Master the Art of the Action Figure

Whether your IP requires the sharp precision of ABS or the classic feel of rotocast vinyl, we provide the industrial mastery to bring it to life.

Browse Our PVC Figure Gallery | Explore Mold Development & Tooling

Airbrushing for Organic Gradients and Realism

To achieve realistic skin tones and atmospheric weathering, we employ skilled artisans who use precision airbrushing. This technique allows for soft gradients and "blushing" that make a character feel alive. In 2026, we are also integrating digital inkjet printing for complex fabric patterns directly onto 3D surfaces, allowing for hyper-detailed camouflage or floral patterns that traditional masks cannot achieve. This ensures your collectible figure manufacturing project features textures that are as rich as the digital source art.

2026 Innovation:

UV-Reactive and Metallic Vapor Deposition

For "Special Edition" or "Chase" variants, Unstoyppable offers advanced 2026 finishes. We utilize UV-reactive paints that glow under blacklight—perfect for sci-fi or magic-themed IPs. Additionally, our Physical Vapor Deposition (PVD) and vacuum metalizing processes allow us to apply a "Chrome" or "Metallic" finish that is molecularly bonded to the plastic. This creates a high-end, reflective surface that is scratch-resistant and visually stunning, making your high-fidelity character figures stand out in any retail display.

Safeguarding Your Legacy:

IP Security and Safety Compliance

In the high-stakes arena of character product manufacturing, the value of a physical item is inextricably linked to the intellectual property it represents. For a brand owner, a character is not just a design; it is a legacy built over years of storytelling and fan engagement. Protecting that legacy requires a secure character supply chain that treats data security and physical asset protection with the same rigor as engineering precision. As we move through 2026, the threats of digital piracy and physical counterfeiting have become more sophisticated, necessitating a proactive, multi-layered defense. At Unstoyppable, we provide a sanctuary for your IP, combining anti-counterfeit manufacturing technologies with the prestigious oversight of a Disney FAMA certified manufacturer. We ensure your characters are produced ethically, safely, and exclusively for your authorized channels.

The Fortress of IP:

Anti-Counterfeit and Data Security

The foundation of IP protection for character products begins long before the first mold is cut. It starts with the digital assets—the 3D sculpts and texture maps that define your character's soul. Unstoyppable operates under a strict "Zero-Leak" policy designed to secure your vision from concept to completion.

Securing the Digital and Physical Blueprint

We implement military-grade encryption for all digital file transfers, ensuring that your 3D assets are only accessible to authorized engineers within our secure network. Within our FAMA compliant factory in China, physical security is just as stringent. Access to molding rooms is restricted via biometric authentication, and every mold is tracked using a serialized inventory system. Once a production run is complete, we provide our clients with a choice: physical molds are either stored in high-security, climate-controlled zones for future runs or destroyed under the supervision of a third-party auditor, with a certificate of destruction provided. This level of anti-counterfeit manufacturing ensures that "ghost shifts" or unauthorized overruns are a mathematical impossibility.

Managing Specific Risks:

Small Parts and Paint Chemistry

Iconic characters often come with "small parts"—accessories like weapons, hats, or interchangeable hands—that pose potential choking hazards. Our character engineering for toys team performs rigorous "tension and torque" testing during the prototyping phase to ensure these components are securely attached or clearly labeled for the appropriate age grade. Furthermore, the vibrant colors that bring characters to life must be chemically safe. We utilize exclusively phthalate-free toy materials and lead-free pigments. Every batch of paint is tested before application to ensure it meets the 2026 safety standards for chemical migration, protecting the health of your youngest fans and the integrity of your brand.

Compliance with ASTM F963 and EN71

Every character product we manufacture is engineered to meet or exceed the world’s most rigorous safety benchmarks. We are a recognized ASTM F963 compliant manufacturer for the North American market and an EN71 compliant toy manufacturer for Europe. Our direct partnership with third-party toy lab testing facilities like SGS and Intertek allows us to provide Children’s Product Certificates (CPC) and CE declarations with every shipment. By integrating safety into the design phase, we ensure that your high-fidelity character figures are as safe as they are beautiful.

Protect Your IP With a Global Gold Standard.

Don't risk your character's legacy with unverified factories. Secure your secure character supply chain today.