Toy Prototyping Manufacturer:

Accelerating Character Development in 2026

In the high-velocity world of licensed entertainment, the ability to transition from a digital sculpt to a physical asset is the definitive competitive edge. As a premier toy prototyping manufacturer, Unstoyppable has revolutionized the pre-production workflow by integrating 2026-spec additive manufacturing technologies. The "guesswork" of traditional hand-sculpting has been replaced by high-precision digital workflows, allowing IP holders to hold their characters in their hands within hours of finalizing a CAD file. Our high-fidelity toy samples serve as the critical bridge between artistic intent and industrial reality. By utilizing 3D printed toy prototypes, we provide brand managers with the tangible proof they need to greenlight mass production, ensuring that every curve, expression, and structural joint is perfected before significant capital is committed to steel tooling. This is where your character's physical journey begins—defined by speed, accuracy, and uncompromising quality.

Simulating Hard and Soft Textures in a Single Print

Our 2026-grade 3D printed toy prototypes can feature a rigid internal skeleton with a soft-touch outer "skin" printed simultaneously. This allows us to simulate the feel of an overmolded figure or a character with flexible clothing using a single additive run. For licensed character engineering, this means we can test how a soft PVC cape drapes over an ABS body at the earliest possible stage. By choosing a toy prototyping manufacturer that masters multi-material MJF, you gain the ability to evaluate the tactile "premium feel" of your product long before the assembly line begins to move.

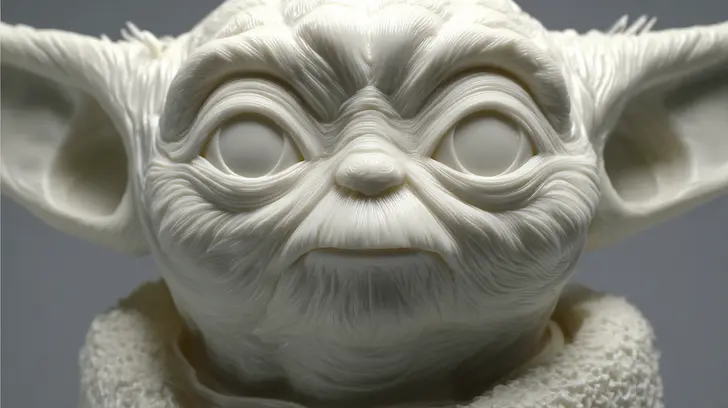

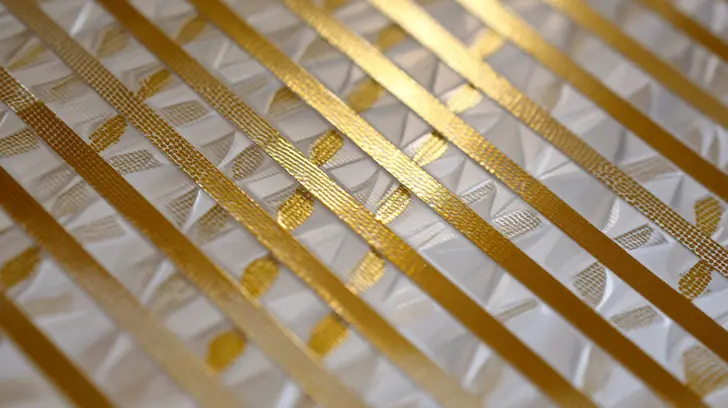

Full-Color CMF Prototyping

Color, Material, and Finish (CMF) are essential to a character's identity. Our advanced 3D systems allow for the printing of high-resolution textures and colors directly onto the high-fidelity toy samples. This includes simulating metallic finishes, fabric weaves, and complex eye gradients. It is a vital tool for stakeholder presentations, as it provides a "Look-Like" model that is nearly indistinguishable from a final production piece, accelerating the approval process for major media franchises.

High-Stiffness Resins for Mechanical Testing

We use specialized ceramic-filled and engineering-grade resins for rapid character modeling that requires structural testing. These materials allow us to print functional joints and thin-walled structures that possess the same rigidity as production ABS. This ensures that the 3D printed toy prototypes are not only visual models but also structural benchmarks that can be used to verify the character’s balance and pose-ability during the design phase.

Visualize Your Character Today

Eliminate the risk of production errors. Explore our high-fidelity 3D prototyping and rapid modeling services to bring your IP into the physical world with 100% accuracy.

See Our Engineering Capabilities | Explore Character Design Optimization

Volume and Weight Estimation

By producing a physical 3D print, we can accurately calculate the final volume of material required and estimate the product's weight. This engineering data is vital for logistics planning and for ensuring the toy has the "premium heft" expected by collectors. It is an integral part of being a comprehensive toy prototyping manufacturer—providing data-driven insights that inform the entire manufacturing-ready toy sculpt process.

Rapid Iteration Cycles:

Reducing the Feedback Loop

In 2026, the speed of development is as important as the quality of the product. Unstoyppable has optimized its facility to support rapid character modeling iteration cycles that keep your project moving forward without delay.

The Prototyping Advantage: We combine 2026 SLA resin prototyping with multi-material 3D printing to deliver the world's most accurate high-fidelity toy samples. By reducing iteration times and verifying every detail in physical space, Unstoyppable ensures your character is ready for the global stage. Bring your digital vision to life with industrial precision.

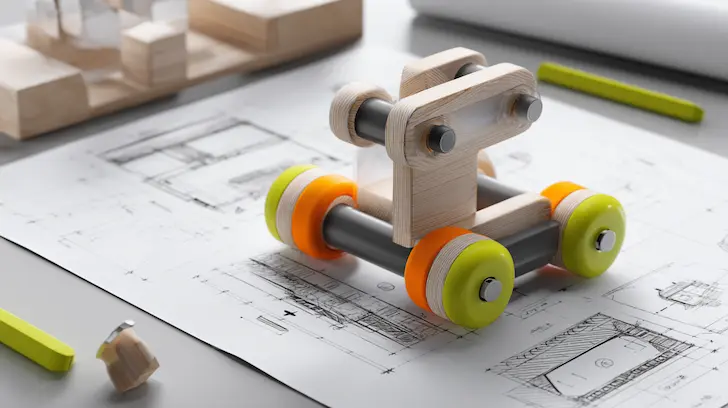

Functional Toy Prototyping:

Engineering Motion and Material Integrity

In the high-stakes environment of 2026 licensed manufacturing, a prototype must do more than look accurate; it must perform under stress. At Unstoyppable, functional toy prototyping is the rigorous phase where we validate the mechanical viability of a design. While 3D printing is excellent for aesthetics, it often lacks the material properties required to test real-world durability. Our engineering team utilizes a combination of CNC machined toy samples and advanced vacuum casting for toys to replicate the mechanical behavior of mass-produced resins. This stage is critical for toy articulation testing, ensuring that joints hold their tension and that internal mechanisms operate without friction. By testing with production-grade materials early, we eliminate technical risks and provide IP holders with a "proof of concept" that is structurally identical to the final retail product. We ensure that every snap-fit, hinge, and battery compartment is engineered for longevity before the first injection mold is even cut.

Vacuum Casting for Small Batches:

Mimicking Mass Production

When a project requires multiple high-quality samples for play testing or internal reviews, vacuum casting for toys is the gold standard. This process allows us to bridge the gap between a single 3D print and a full production run of thousands.

Replicating Shore Hardness and Material Feel

Using a high-fidelity master pattern, we create flexible silicone molds that can produce small batches of 10 to 20 functional toy prototypes. The advantage of this system is material versatility; we use specialized polyurethane resins that precisely mimic the Shore hardness and tensile strength of production ABS, PVC, or PP. For characters requiring a specific "squish" or "snap," our prototype material engineering team calibrates the resin mix to ensure the hand-feel is perfect. These cast samples allow for accurate paint adhesion testing and provide a realistic representation of how the material will behave during the assembly phase of licensed toy manufacturer in China protocols.

Validating Toy Articulation Engineering

A ball joint or a ratchet mechanism must survive thousands of cycles without losing its "grip." Because 3D printed layers can sheer under stress, we use CNC machining to produce joint components that possess the same isotropic strength as injection-molded parts. This allows for rigorous toy articulation testing where we can measure the exact torque and friction required to move a limb. This engineering-first approach ensures that the "clacking" sound of a ratchet joint is satisfying and that functional toy prototypes can hold a dynamic pose indefinitely. It is the definitive way to prove that your posable character manufacturing plan is ready for the rigors of the market.

Precision Tolerance Verification

CNC machining offers a level of dimensional accuracy ($±0.01mm$) that exceeds most additive processes. This precision is required for testing toy tolerance engineering in complex assemblies. We use these machined samples to verify "press-fit" pins and "snap-together" housings, ensuring that every part of the character fits together with zero-gap perfection. By utilizing CNC machined toy samples, we provide a definitive blueprint for the final mold designers, reducing the need for costly "T1" mold modifications.

Build a Prototype That Works

Your brand’s reputation depends on a product that performs. Partner with Unstoyppable to engineer prototypes that pass every mechanical and material test.

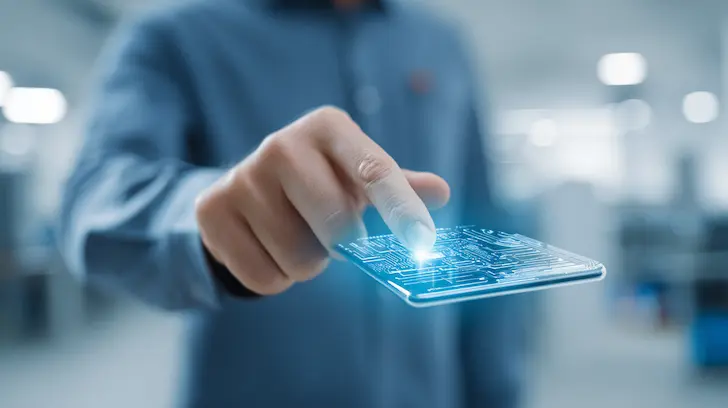

App-Connectivity and Sensor Calibration

If your character interacts with a digital app, we use our functional toy prototypes to calibrate accelerometers and touch sensors in real-world scenarios. This ensures that the "physical-to-digital" experience is lag-free and intuitive. We treat the electronics as a core part of the prototype material engineering, ensuring the battery compartments are easy for consumers to access yet secure enough to pass all international safety standards.

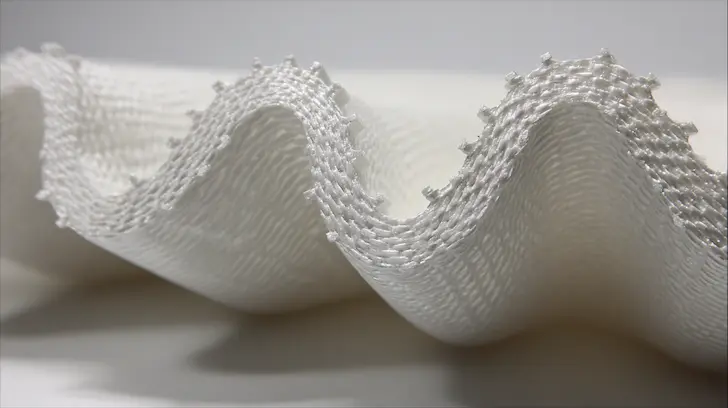

Testing 2026 "Mixed Media" Fits:

The Hard/Soft Interface

One of the most complex challenges in 2026 is the "Hybrid" product—where textiles and plastics meet. Our functional toy prototyping includes a dedicated phase for testing these material interfaces.

The Precision Advantage: At Unstoyppable, functional toy prototyping is where we break things so they don't break for your customers. Through vacuum casting for toys, CNC machined toy samples, and toy articulation testing, we provide the empirical data needed for a flawless mass-production run. Experience the power of a prototype that actually works.

The Golden Sample:

Finalizing Aesthetics and Safety Compliance

The "Golden Sample" represents the pinnacle of the pre-production journey. It is the definitive, physically perfect version of a product that serves as the "North Star" for the entire mass production run. At Unstoyppable, golden sample development is a meticulous process where we transition from functional engineering to artistic perfection. This "Look-Like, Feel-Like" model is what the IP holder signs off on; it becomes the legal and aesthetic contract between your brand and our factory network. In 2026, creating a Golden Sample involves more than just a high-quality paint job. It requires the integration of high-definition printing film application samples, rigorous ASTM F963 prototype testing, and the embedding of digital product passport toys technology. By perfecting every gradient, seam, and safety requirement at this stage, we eliminate ambiguity and ensure that the final millionth unit off the line is as flawless as the hand-crafted original.

Master Hand-Painting & Finishing:

Setting the Production Standard

While mass production relies on automation, the Golden Sample is a work of art. Our master artisans use a combination of traditional skill and modern tools to define the visual soul of your character.

Artisanal Airbrushing and Gradient Mastery

For the Golden Sample to truly represent the IP, color accuracy is paramount. Our master painters utilize Pantone-calibrated pigments and specialized airbrushing techniques to create life-like skin tones, weathered textures, and vibrant comic-style cel-shading. This golden sample development phase establishes the "Paint Master" that our factory technicians will follow using pad printing or robotic spray systems. By achieving the perfect finish on the prototype, we provide the reference point for custom vinyl toy finishing in mass production, ensuring that the character's emotional expression is captured perfectly in every unit.

Validating Pattern Alignment and Stretch

During the creation of the Golden Sample, we apply high-definition printing film to the complex 3D surfaces of the prototype. This allows us to verify that the pattern does not distort or stretch across muscular curves or sharp edges. By perfecting the printing film application samples at this stage, we provide the engineering team with the exact data needed to calibrate the final production transfer jigs. This ensures that the retail-ready licensed product production run maintains absolute graphic fidelity, with no "broken" patterns at the seams or blurry textures in deep recesses.

Testing Durability of Decorative Films

The Golden Sample also serves as a testbed for finish durability. We subject the printing film application samples to preliminary "scratch and scuff" tests to ensure the protective clear-coat is sufficient for consumer use. This proactive engineering ensures that your high-fidelity toy samples are not just beautiful for a moment, but durable enough for a lifetime of play or display.

Set the Standard for Your Brand

Your Golden Sample is the blueprint for success. Partner with a toy prototyping manufacturer that treats every sample as a masterpiece of engineering and art.

Explore the Golden Sample Path | Review Our Safety Benchmarks

Chemical and Material Verification

We verify that all paints and films used on the Golden Sample are lead-free and non-toxic, matching the phthalate-free toy materials that will be used in the final production. This 2026 "Safety-First" approach positions Unstoyppable as a leader in secure supply chain for licensed products, providing a sample that is representative of the final product in every legal and physical sense.

Traceability Integration:

The Smart Golden Sample

In 2026, the Golden Sample is a "Smart Sample." We embed digital product passport toys technology into the prototype to streamline the approval and production tracking process.