Automated Toy Safety Testing:

The Future of Zero-Error Compliance

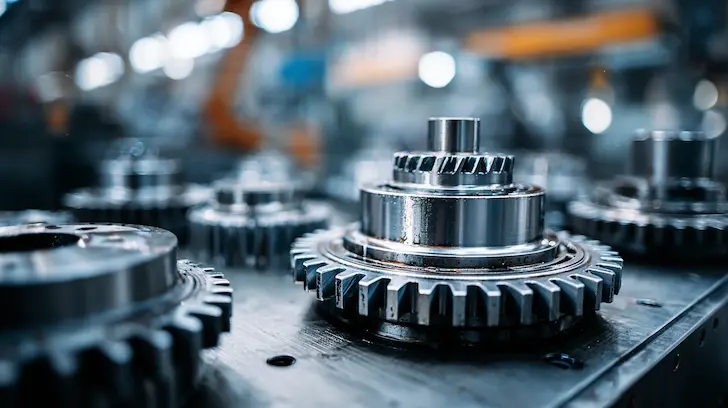

In the industrial landscape of 2026, the traditional methods of manual quality control are evolving into a high-tech ecosystem of digital precision. Automated toy safety testing is the cornerstone of this transformation, representing a shift toward "Safety 4.0." At Unstoyppable, we integrate robotic toy testing systems and advanced algorithms to ensure that every licensed product—from intricate action figures to complex electronic toys—meets the most stringent global mandates with mathematical certainty. By removing the variances of human subjectivity, we provide our partners with a high-speed toy safety screening process that is both faster and more reliable than conventional methods. This tech-forward approach ensures that your intellectual property is protected by a digital guarantee of safety, allowing for a seamless transition from the production line to the global retail shelf.

Overcoming Inspection Drift in High-Volume Runs

Human inspectors naturally experience fatigue, which can lead to a decrease in defect detection accuracy over a long shift. Automated toy safety testing systems, however, perform with the same level of intensity and precision 24 hours a day. Whether it is a check for sharp edges on an injection molded toy manufacturer part or the structural integrity of a joint, our robotic systems apply the exact same pressure and scrutiny to every single unit. This consistency is vital for maintaining mass production toy consistency, ensuring that the safety profile of your product remains uncompromised regardless of production volume or time of day.

The Power of Objective Verification

Automation brings an objective, data-driven standard to the factory floor. By utilizing automated compliance verification, we establish a "hard-coded" pass/fail threshold that cannot be influenced by production pressure or subjective interpretation. This technical impartiality is what allows Unstoyppable to serve as a licensed toy manufacturer China that premium brands trust for their most sensitive movie launches and seasonal product drops.

Precision Analysis of Printing Film and Surface Coatings

The application of printing film for toy materials requires absolute alignment to maintain character likeness. Our AI systems scrutinize the "registration" of every graphic, detecting pixel-level shifts, color variances, or adhesion gaps. By automating the verification of printing film for mass production, we ensure that every character’s expression is perfect and that the decorative surface meets all heavy metal migration analysis requirements by ensuring uniform coating thickness. This high-speed visual audit is essential for protecting the aesthetic value of your licensed merchandise.

Upgrade Your Safety Standards with Automation

Traditional QC is a thing of the past. Discover how our automated toy safety testing suites and AI vision modules provide a digital guarantee for your licensed products.

Explore Our Safety Compliance Pillars | See Our Automation Technology

Optimizing the Production Timeline

By automating the toy compliance testing services, we drastically reduce the lead time between the final assembly and container loading. These robotic toy testing systems function in parallel with the production process, providing real-time feedback. If a system detects a trend toward a non-conformity, our mold development and injection tooling engineers can make adjustments instantly, preventing the manufacture of sub-standard goods. This "right-first-time" approach is the ultimate way to achieve retail-ready licensed product production on a global scale.

Data Integration:

The Digital Pulse of Your Production

The true power of automated toy safety testing lies in the data it generates. Every test result is a digital asset that can be used to improve future production and satisfy regulatory auditors.

The Industrial Edge: In 2026, safety is no longer a manual task; it is a technological achievement. By leveraging automated toy safety testing and AI vision inspection toys, Unstoyppable provides a level of precision that manual labor simply cannot replicate. Protect your brand, your IP, and your customers by choosing the automated future of toy manufacturing.

Automated Mechanical Integrity:

Robotic Stress and Surface Analysis

In the technical domain of 2026 toy production, the "hand of the machine" has become the primary guarantor of physical safety. Automated toy safety testing at Unstoyppable leverages high-precision robotics to execute "use and abuse" simulations with a level of repeatability that far exceeds manual capabilities. By utilizing robotic tensile testing and advanced sensor arrays, we subject materials such as high-impact ABS, flexible PVC, and specialized TPE to calibrated stresses that mirror extreme real-world interactions. This clinical approach ensures that structural integrity is verified at the molecular and mechanical levels, providing a definitive safeguard for premium character IP. Through the integration of sensor-based toy verification, we transform raw manufacturing into a verified science, where every pull, drop, and surface scan is recorded as a data point of safety excellence.

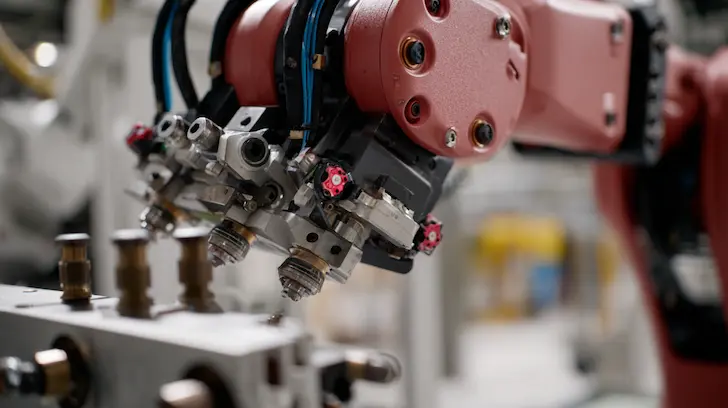

Calibrated Robotic Pulling:

Mathematical Consistency in Tensile Strength

Structural failures in toys often occur at attachment points—limbs, eyes, and functional buttons. To ensure these components remain securely fastened, we employ programmable robotic arms dedicated to robotic tensile testing.

Precision Tension for Character Components

Unlike manual pull tests where the force can vary based on the operator's technique, our robotic toy testing systems apply a perfectly linear force at a constant rate of acceleration. For a character product manufacturing project, the robot is programmed to grip the component and apply exactly the 70-Newton force required by ASTM and EN71 standards. This robotic tensile testing is performed on 100% of high-risk components in specific product lines, ensuring that buttons and small accessories remain permanently attached. This mathematical consistency provides the absolute assurance that no choking hazards will be created during the product's lifecycle.

Laser-Scanning for Printing Film Uniformity

Using high-frequency laser sensors, we perform a 3D topographic scan of the printing film for mass production. This automated toy safety testing protocol checks for uniform thickness of the film across the entire surface of the toy. By ensuring the film is applied within a tolerance of microns, we verify that the protective topcoat is thick enough to withstand friction and environmental exposure. This laser-based sensor-based toy verification ensures that the character’s colors and details remain vibrant and intact, preventing the degradation of the IP’s visual identity.

Automated Adhesion and Chemical Bond Testing

The stability of printing film for toy materials is paramount. Our automated suites perform standardized "cross-hatch" scratch tests using robotic styluses that apply a precise, constant pressure. This printing film adhesion automation confirms that the bond between the ink and the phthalate-free toy materials is permanent. By automating this process, we remove the variability of human touch, ensuring that every unit passes a rigorous durability benchmark before moving to the packaging stage. This is a vital component of our retail-ready licensed product production, guaranteeing a premium out-of-box experience.

Precision is Non-Negotiable for Premium IP

Structural failure is not an option for world-class brands. See how our robotic testing protocols and robotic tensile testing protect your character figures from mechanical failure.

Explore Injection Molding Precision | Learn About Character Engineering

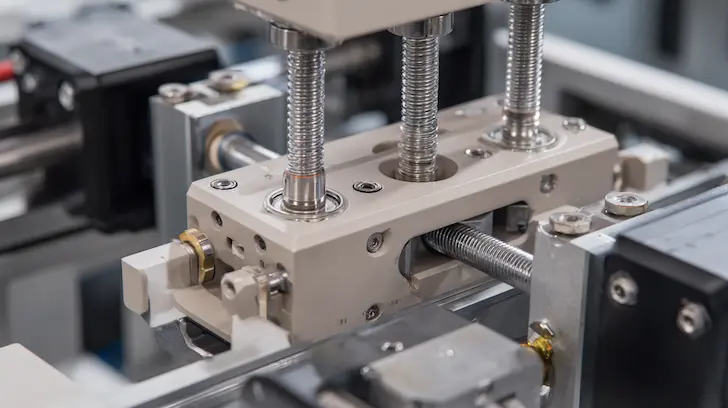

Sonic Weld Verification:

Acoustic Testing for Security

Many toys are assembled using ultrasonic welding to encapsulate batteries or sound chips. To verify the strength of these welds, we use automated acoustic testing. As the robotic assembly QC system completes a weld, a high-sensitivity microphone captures the frequency of the vibration. A "perfect" weld has a distinct acoustic signature; any deviation indicates a weak bond or a microscopic gap. This sensor-based toy verification ensures that internal components remain securely permanently encapsulated, providing a secondary layer of safety for electronic products.

Automated Drop Test Systems:

Simulating Real-World Impact

The "drop test" is the ultimate challenge for any rigid toy. We have replaced the manual dropping of toys with automated drop test systems that ensure every impact is documented and analyzed.

The Technical Edge: Mechanical safety is a science of measurement and repetition. Through robotic tensile testing, automated drop test systems, and sonic weld verification, we provide a level of structural certainty that protects both the child and the brand. Choose Unstoyppable for a manufacturing partnership where safety is engineered into every atom of the product.

Digital Safety Passports:

From Automated Data to Retail Readiness

In the modern manufacturing landscape, a physical toy is only as valuable as the data supporting its safety. The final frontier of automated toy safety testing is the translation of real-time sensor data into a digital toy safety technical file. At Unstoyppable, we bridge the gap between the factory floor and the global marketplace by creating a "Digital Safety Passport" for every production lot. This system leverages sensor-based batch traceability to record every automated test—from robotic tension checks to AI vision scans—into a secure, immutable database. This logistical transparency is designed to satisfy the rigorous digital auditing requirements of 2026, ensuring that your licensed merchandise is fully optimized for rapid retail onboarding and international trade compliance.

The Digital Audit Trail:

Building the Foundations of Trust

Every unit that passes through our automated testing suites contributes to a comprehensive data set that proves 100% compliance. This digital record-keeping is the primary tool we use to facilitate automated CPC generation and EU Declaration of Conformity (DoC) filing.

Creating the Digital Safety Passport

As each toy moves through the robotic assembly QC stations, the system logs its unique "Automated Pass." This data includes the exact Newton force applied during robotic tensile testing and the spectral analysis of the printing film for toy materials. This granular level of sensor-based batch traceability means that if a regulator or retail buyer requests proof of compliance, we can provide a unit-specific or batch-specific digital passport instantly. This proactive documentation strategy transforms a complex legal requirement into a streamlined competitive advantage for IP holders.

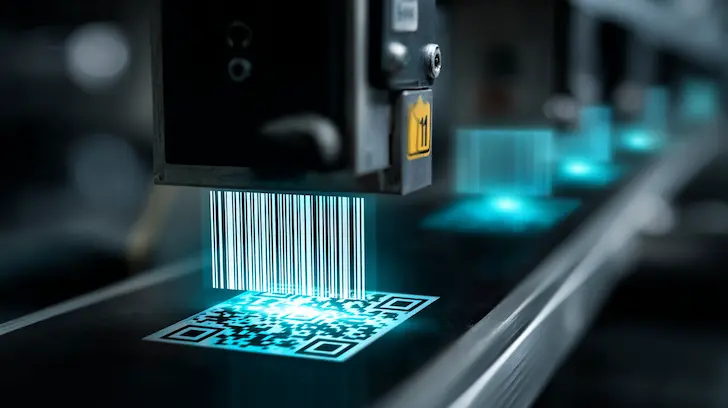

OCR Verification of GTIN/EAN Barcode Labeling

A barcode that fails to scan can trigger massive retail chargebacks or "stop-sale" orders. Our automated safety labeling verification systems use high-speed scanners to verify every GTIN/EAN barcode labeling application on the assembly line. The system confirms the barcode’s grade, ensuring it meets the ANSI/ISO standards for scannability. This level of retail-ready compliance automation guarantees that your product will move through the retailer's automated distribution centers without a single interruption.

Validating Mandatory Safety Warnings

Safety warnings and age-grading icons must be legible and correctly positioned to meet ASTM F963 compliant manufacturer standards. Our AI vision modules perform automated safety labeling verification by comparing the printed packaging against the approved digital master. The system checks for font size, contrast, and localized language accuracy. By ensuring that every "Small Parts" warning and "CE" mark is perfectly rendered, we provide an additional layer of retail-ready quality assurance that protects both the consumer and the brand.

Future-Proof Your Supply Chain

Data is the new currency of compliance. Let Unstoyppable manage your automated compliance workflow for 100% retail readiness and unshakeable IP protection.

Satisfying Amazon and Big-Box Digital Audits

Retail giants like Amazon, Walmart, and Target now utilize automated audit systems to screen products. By providing a digital toy safety technical file that is "machine-readable," we help our clients pass these digital gatekeepers effortlessly. Our retail-ready quality assurance data is formatted to meet the specific upload requirements of major retail portals, ensuring your listings remain active and your "vendor score" remains in the top tier.

Closing the Loop:

Feeding Failure Data into Tooling R&D

Automation does more than just find defects; it provides the insights necessary to prevent them. We use automated failure data to continuously improve our Advanced Toy Tooling R&D.