Global Entertainment Merchandise Manufacturing:

Scaling Fan Experiences in 2026

In the high-velocity landscape of 2026, entertainment merchandise manufacturing 2026 has moved far beyond the traditional "logo-slap" on commodity goods. It is now a critical pillar of franchise world-building and a primary driver of fan engagement. At Unstoyppable, we recognize that fans are no longer just consumers; they are community members who seek tangible extensions of their favorite stories. Our approach to scalable merchandise production is designed to meet this demand with precision, agility, and a deep understanding of entertainment IP engineering. By bridging the gap between digital content and physical products, we empower media franchises to turn fleeting moments of viral hype into lasting brand loyalty through premium, high-fidelity merchandise.

The Rise of "Quiet Branding" and Subtle IP Integration

Modern fan communities value "if you know, you know" (IYKYK) design philosophies. We are seeing a massive shift toward tonal embroidery, minimalist typography, and secondary logo placements that favor sophistication over loud branding. Instead of high-contrast screen prints that feel like advertising, 2026 trends favor custom-dyed fabrics, high-GSM (Grams per Square Meter) weights, and premium hardware. This "quiet branding" allows merchandise to function as a lifestyle brand extension, ensuring that a hoodie or a bag remains a staple in a fan's wardrobe long after the initial movie premiere or game launch has passed.

Elevated Materiality and Tactile Storytelling

Every touchpoint of a product is an opportunity for storytelling. We use advanced textile manufacturing China techniques to introduce tactile elements like 3D puff prints, silicone patches, and bespoke metal zipper pulls that echo character motifs. By focusing on these high-touch details, we ensure that the merchandise feels premium, justifying the higher price points of 2026’s "collector-grade" retail market. This attention to detail is what separates a standard licensed merchandise manufacturer from a strategic franchise partner.

Augmented Reality (AR) and Interactive Collectibles

We are also leading the charge in AR-ready packaging and product design. By utilizing high-fidelity textures and specific anchor points in our 3D character sculpting, we make it possible for fans to "bring their toys to life" through their mobile devices. This interaction deepens the emotional connection between the fan and the character, providing a "value-add" that traditional toys cannot match. In 2026, entertainment merchandise manufacturing is as much about software compatibility as it is about hardware durability.

Is Your Franchise Ready for the 2026 Retail Landscape?

Don't let your brand get left behind in the transition to lifestyle-grade and phygital merchandise. Partner with the experts in entertainment IP engineering.

Tier 2:

Mass-Market Retail Rollouts

Once a product proves its "viral" potential, our ERP production tracking system facilitates the seamless transition to Tier 2 high-capacity hubs. These facilities are designed for mass-market merchandise manufacturing, capable of producing hundreds of thousands of units with total AQL-standard consistency. This "dual-track" system ensures that you can capitalize on a trend while it is hot, without the 6-month lead times typically associated with traditional merchandise manufacturing China.

Responsive Supply Chains and "Just-in-Time" Merch

Our infrastructure is built for "Just-in-Time" manufacturing, allowing for smaller initial runs followed by rapid re-orders based on real-time retail data. This reduces the risk of unsold inventory and overstock, aligning with the 2026 green mandate for responsible production. By utilizing digital textile printing and modular injection molding, we can modify designs mid-season to react to fan feedback, ensuring your merchandise remains relevant and profitable throughout the entire franchise lifecycle.

The Unstoyppable Advantage: By combining Screen-to-Shelf accuracy with secure supply chain manufacturing and scalable production, we ensure your entertainment franchise is ready for the demands of the 2026 market. We don't just make products; we manufacture the physical future of your IP.

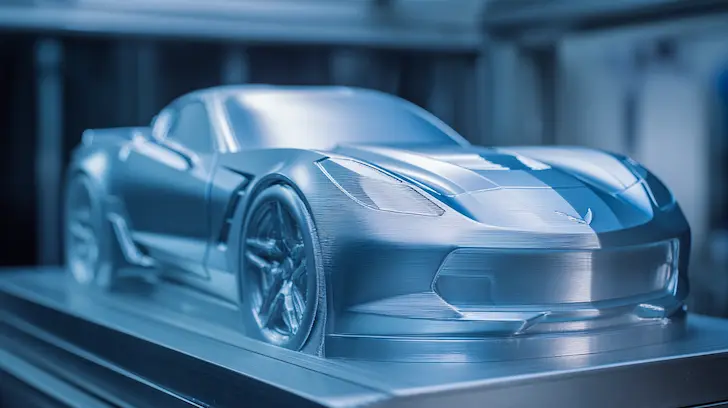

From Screen to Shelf:

Advanced Engineering for Media Franchises

In the competitive world of 2026 entertainment, the journey from a digital character design to a physical product is a masterclass in industrial artistry. Achieving high-fidelity brand reproduction requires more than just standard manufacturing; it demands a synergy between cutting-edge digital sculpting and precision material science. At Unstoyppable, our character IP engineering process is built to preserve the soul of your franchise while ensuring every item is durable, safe, and ready for global retail success.

Digital Sculpting and "Master Sample" Optimization

By leveraging ZBrush 2026, we can capture micro-textures—such as the weave of a superhero’s suit or the weathered skin of a legendary creature—that were previously impossible to replicate in mass production. Once the digital sculpt is finalized, we perform digital mold flow analysis to identify potential cooling or ejection issues before a single piece of steel is cut. This proactive engineering for toys ensures that the final product remains 100% faithful to the source material while being optimized for high-speed injection molded toy manufacturer cycles.

Digital Keying and Articulation Engineering

Precision is paramount when dealing with multi-part figures. Our engineers use advanced CAD/CAM software to "key" parts—creating interlocking joints that fit together with zero tolerance for error. This process includes the design of ratchet joints and ball-and-socket assemblies that provide a premium feel and long-term poseability. By simulating these movements in a virtual environment, we guarantee that the physical product will perform flawlessly under the rigors of fan interaction and retail display.

The Transition to rPET and Bio-Resins

Aligned with 2026 sustainability trends, Unstoyppable is a leader in integrating rPET (Recycled Polyethylene Terephthalate) into licensed products. By repurposing post-consumer plastic waste into high-quality toys and packaging, we help franchises reduce their carbon footprint. We are also pioneering the use of bio-based resins for non-structural elements, providing a safe and eco-friendly alternative that appeals to the values of modern parents and collectors alike.

Transform Your Digital Assets into Retail Masterpieces

Your IP deserves the highest level of technical precision. Let us help you navigate the ZBrush-to-Shelf journey with confidence.

Robotic Pad Printing for Perfect Facial Alignment

The "eyes" of a character are its most critical feature. A slight misalignment can ruin the perceived quality of a product. To eliminate human error, we employ automated robotic pad printing. These systems use vision-guided cameras to align the silicone printing pads with sub-millimeter precision. This ensures that every character—whether you are producing 5,000 or 500,000 units—has perfectly symmetrical eyes and crisp, vibrant facial details. This level of automated toy manufacturing is a hallmark of the Unstoyppable commitment to quality.

Sub-Surface Detailing and Layered Finishes

For high-end collectibles, we offer layered finishing techniques that include matte-over-gloss coatings and sub-surface "flesh" tones. By applying multiple translucent layers, we can mimic the depth of skin or the complexity of composite materials. This advanced toy tooling R&D is what allows our PVC figure manufacturer partners to consistently win awards for realism and craftsmanship in the global marketplace.

Technical Precision. Industrial Artistry. At Unstoyppable, we combine 3D character sculpting with PVD finishing and robotic pad printing to ensure your merchandise is not just a product, but a premium extension of your brand. Our engineering for toys is the foundation of your retail success.

Safeguarding the Legacy:

IP Security and Safety Compliance

In the high-stakes world of 2026 media, a brand's most valuable asset is its intellectual property. For major entertainment franchises, a pre-release leak or a safety-related recall is a catastrophic risk that can derail years of narrative planning. At Unstoyppable, we treat IP protection for character products with the same rigor as the engineering itself. As a premier licensed merchandise manufacturer, we provide a secure character supply chain that ensures your designs move from concept to retail shelf in total secrecy, while meeting the world’s most stringent 2026 safety mandates.

The "Zero-Leak" Protocol:

Fortifying Your Pre-Launch IP

For movie launches and secret streaming debuts, the "spoiler" is the enemy. We have developed a proprietary Zero-Leak Protocol designed specifically for confidential licensed product manufacturing. This system treats your digital assets and physical prototypes with maximum-security "air-gap" measures.

Digital and Physical Security Infrastructure

Our anti-counterfeit manufacturing systems begin at the server level. All character style guides and CAD files are stored on encrypted, offline servers with biometric-restricted access. On the factory floor, we utilize "Black Box" production zones where personal mobile devices are prohibited, and every prototype is serialized and tracked. To prevent the "ghost shifts" that plague the industry, we implement automated mold tracking—if a mold is used outside of authorized production hours, our ERP production tracking system triggers an immediate security alert. Upon project completion, we provide certified destruction of physical molds or secure long-term storage in vaulted facilities.

Protect Your Brand’s Future Today

Your IP is too valuable to risk with unverified suppliers. Partner with a Disney FAMA certified expert in secure supply chain manufacturing.

Logistics & Retail Fulfillment:

Mastering the "Day-and-Date" Launch

For the entertainment industry, timing is everything. A global distribution for licensed products must be perfectly synchronized with media premieres. Our toy manufacturing logistics team uses real-time data to navigate the complexities of international freight and "Just-in-Time" retail delivery.

ERP-Driven Production and Fulfillment

Our integrated ERP production tracking system gives you a live window into your order status. From the moment the golden sample is approved to the final container loading, every milestone is visible. We specialize in retail-ready packaging manufacturer services, ensuring products arrive at big-box retailers or theme parks pre-labeled with GTIN / EAN barcodes and compliant with specific "Planogram" requirements. This end-to-end control is what makes Unstoyppable the preferred partner for movie merchandise manufacturing preparation.