ERP Production Tracking System:

Real-Time Transparency for Licensed Toy Brands

In the competitive toy industry of 2026, the traditional opacity of overseas manufacturing is a relic of the past. At Unstoyppable, we believe that information is just as valuable as the physical product rolling off the assembly line. Our proprietary ERP production tracking system serves as the digital nervous system for every project, providing a seamless flow of data from the factory floor in China directly to our global partners. By replacing traditional, fragmented communication with digital manufacturing transparency, we empower brand owners with the insights they need to manage complex product launches with total confidence. This cloud-based architecture ensures that every stakeholder—from creative directors to logistics managers—has access to real-time toy production updates, transforming the manufacturing experience into a collaborative, data-driven partnership.

Granular Data vs. Vague Email Updates

The standard practice of receiving weekly, vague email updates is now replaced by a sophisticated dashboard that provides a live window into our operations. Every production line is equipped with data-entry terminals and IoT sensors that feed licensed product supply chain data into a centralized cloud-based manufacturing oversight platform. This means that when you ask for a status update, you are looking at live yield rates, machine uptime, and assembly progress. This level of detail is essential for oem licensed product manufacturing, where hitting specific retail windows is non-negotiable. By providing this visibility, we ensure that you are always in control of your brand’s journey.

Strengthening Client-Manufacturer Trust

Transparency is the cornerstone of trust. Our ERP production tracking system fosters a transparent environment where challenges are identified and addressed in real-time. This open-access model proves our commitment to excellence and our confidence in our audited factory network China. When a client can see the progress of their character product manufacturing at any hour of the day, the anxiety of overseas production evaporates, replaced by the reassurance of hard data and professional oversight.

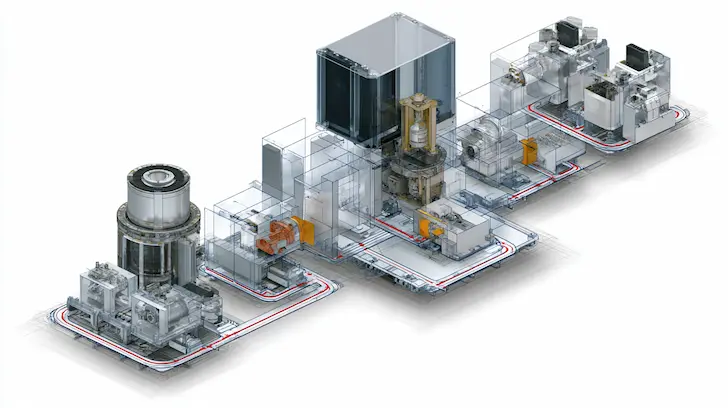

Synchronizing Multi-Stage Assembly

Modern licensed toys often involve complex assembly processes, combining injection molded toy manufacturer parts with electronic toy manufacturer components and soft goods manufacturing details. Our ERP production tracking system synchronizes these disparate streams, ensuring that components arrive at the assembly line at the exact moment they are needed. This "Just-In-Time" manufacturing model, managed by cloud-based manufacturing oversight, maximizes efficiency and minimizes the risk of damage during mid-production storage. Every phase, from painting and pad printing to the final "drop test" in toy quality and safety compliance, is logged and verified.

Take Control of Your Production Timeline

Experience the power of digital manufacturing transparency. Partner with Unstoyppable and gain access to our real-time toy production updates today.

Explore Licensed Product Manufacturing | Learn About IP Security

Managing Material Flux and Component Shortages

Supply chains in 2026 remain dynamic. Our ERP tracks the consumption of phthalate-free toy materials and printing film for toy materials against our inventory levels. This ensures that we never experience a "line stop" due to material shortages. By integrating licensed product supply chain data with our procurement modules, we can automatically trigger re-orders of raw resins or electronic components based on actual production speeds. This predictive capability is vital for retail-ready licensed product production, where any delay in the factory can have a domino effect on global retail distribution.

FAMA & BSCI Integration:

Automating Ethical Compliance

For Disney FAMA and BSCI certified manufacturers, compliance is not a periodic check; it is a continuous state of being. Our ERP production tracking system is specifically configured to monitor and log the ethical conditions of the factory floor.

Strategic Manufacturing Note: The ERP production tracking system is more than a tool; it is a commitment to the success of your brand. By prioritizing real-time toy production updates and licensed product supply chain data, we ensure that your manufacturing journey is efficient, ethical, and entirely visible. At Unstoyppable, your vision is managed with 2026 technology for 2026 retail demands.

Granular Traceability:

Tracking Materials, Molds, and Production Techniques

In the high-precision world of 2026 toy production, the physical and digital worlds are inextricably linked. Our ERP production tracking system extends its reach deep into the mechanical heartbeat of the factory floor, providing manufacturing quality data integration that begins at the molecular level. For a licensed merchandise manufacturer, quality is a function of consistency. By utilizing a network of IoT sensors and digital logging stations, we capture the technical variables of every production second. This granular approach to toy material traceability ERP ensures that every component—whether a rigid ABS limb or a soft polyester fabric—possesses a verifiable digital birth certificate. At Unstoyppable, we treat technical data as the ultimate guardian of brand integrity, ensuring that the final product delivered to the retail shelf is an exact physical manifestation of the approved engineering specifications.

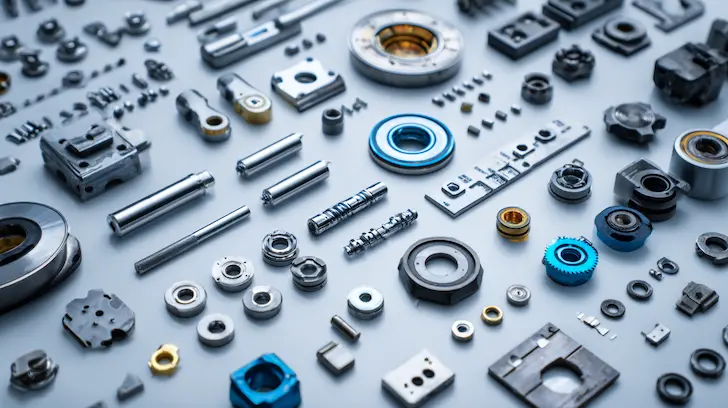

Material Batch Tracking:

The Digital Audit of Raw Resins

The safety of a toy is fundamentally determined by the purity of its inputs. Our ERP system implements a strict "lock-and-key" protocol for all incoming phthalate-free toy materials.

Raw Resin Digital Logs and Intake Verification

Every shipment of raw pellets—whether PVC, ABS, or PP—is assigned a unique raw resin digital log entry upon arrival at our audited factory network China. We utilize handheld scanners to link the supplier’s batch number and safety certification directly to our internal production ID. This ensures that only pre-verified, non-toxic materials can be released to the injection molded toy manufacturer line. If the ERP does not recognize the batch as "Safety Cleared," the system prevents the production order from advancing. This automated safeguard is a cornerstone of our toy quality and safety compliance, providing a level of material security that manual logs simply cannot match.

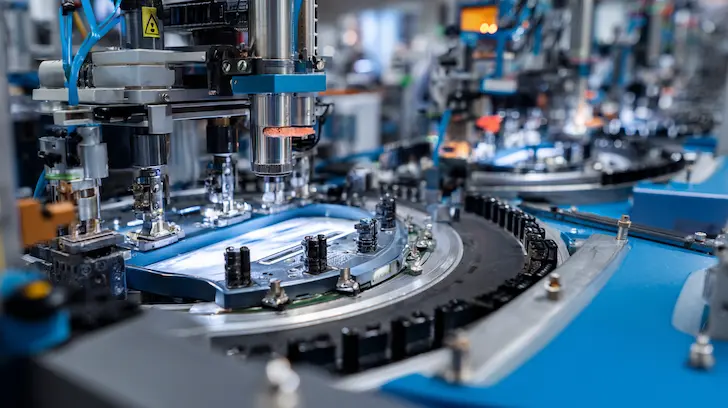

Injection Molding Cycle Tracking and Sensor Integration

Every injection molding machine in our network is integrated with the ERP to provide injection molding cycle tracking. We monitor critical industrial variables in real-time, including melt temperature, injection pressure, holding time, and cooling duration. These sensors ensure that the mold development & injection tooling operates within the narrow "Quality Window" defined during the golden sample development process. If the temperature fluctuates by even a single degree, the system flags the batch for immediate AQL inspection. This proactive monitoring ensures that every character figure possesses the structural integrity and surface finish required for high-end collectible figure manufacturer standards.

Predictive Maintenance for Tooling Longevity

By tracking the total number of cycles (shots) performed by each mold, the ERP manages a predictive maintenance schedule. This prevents the microscopic "mold wear" that can lead to flash or loss of detail in character sculpts. This manufacturing quality data integration ensures that the ten-thousandth unit is just as crisp and accurate as the first. At Unstoyppable, we utilize these technical insights to optimize toy material engineering, ensuring that the physical tools of production are always operating at peak performance to protect your intellectual property.

Ensure Total Material Integrity

Secure your brand with our technical ERP integration and manufacturing quality data. Discover how we protect your product quality at every stage of the cycle.

Automation in Pad Printing and Finishing

For complex paint applications, the ERP monitors the viscosity and drying times of the paints. In 2026, many of our electronic toy manufacturer and figure lines utilize robotic paint arms that feed performance data directly back to the central system. This manufacturing quality data integration allows us to detect subtle shifts in finish quality—such as "overspray" or "under-saturation"—instantly. By digitizing the finishing process, we provide a level of custom licensed product development oversight that ensures every item is a masterpiece of retail-ready art.

Waste & Yield Optimization:

Data-Driven Sustainability

Modern manufacturing is defined by its efficiency. Our ERP production tracking system serves as a powerful tool for minimizing environmental impact through waste & yield optimization.

Industrial Precision Note: Technical excellence is no longer an invisible process. Through injection molding cycle tracking, printing film batch management, and raw resin digital logs, our ERP provides the transparent evidence of quality that 2026 retail demands. Trust the engineers who verify every cycle and every gram.

From Factory Gate to Retail Shelf:

Automated Documentation and Logistical Precision

The final measure of a manufacturing partner's success is the seamless transition of goods from the assembly line to the retail shelf. In 2026, this movement is powered by ERP-driven logistics management. At Unstoyppable, our system serves as the definitive bridge between the physical factory and the global consumer market. By synthesizing the vast amounts of data collected during the injection molded toy manufacturer phases and final assembly, the ERP generates the critical customs-ready manufacturing data required for international transit. This integration eliminates the manual errors that traditionally plague toy manufacturing logistics, ensuring that every shipment is accurate, compliant, and visible in real-time. We provide a solution where documentation is an automated output of production, guaranteeing that your products are always prepared for immediate global distribution.

Automated Documentation:

The Pulse of Global Trade

In the high-stakes environment of customs & export for toys, the speed and accuracy of your paperwork are just as vital as the quality of the product. Our ERP system automates this entire documentary ecosystem.

Instant Generation of Commercial Invoices and Packing Lists

As products are scanned into their final shippers, our ERP initiates automated packing list generation. Because this data is pulled directly from the factory floor scanners, the packing list reflects the exact contents of every carton with 100% fidelity. Simultaneously, the system generates the Commercial Invoice, pre-populated with correct HTS code classification for toys and valuation data. This automation ensures that the documentation matches the physical reality of the shipment, which is the primary factor in facilitating customs clearance for toys. By removing the need for manual data entry, we provide a frictionless path for your licensed product SKU management across multiple international borders.

GTIN / EAN Barcode Synchronization

Our GTIN / EAN barcode labeling process is fully integrated into the ERP production module. This barcode synchronization ensures that the system only allows the printing of labels for the specific SKUs and quantities currently authorized for production. When a worker scans a character variant—for example, a "Limited Edition Villain" figure—the ERP verifies that it matches the assigned master carton's retail-ready barcode systems. This prevents the "mix-and-match" errors that lead to retail chargebacks and inventory discrepancies. By maintaining this digital-to-physical harmony, we ensure your licensed product supply chain data is accurate from the very first scan.

Real-Time Carton and Pallet Verification

During the palletization phase, the ERP tracks the aggregation of units into shippers and shippers onto pallets. Each pallet is assigned a unique SSCC (Serial Shipping Container Code), which provides global distribution visibility throughout the maritime or air freight journey. This level of ERP-driven logistics management allows you to know exactly which character variants are on which pallet, in which container, at any given moment. This is essential for retail licensed product manufacturing, where specific assortments must be delivered to specific regional distribution centers.

Streamline Your Global Distribution

Secure your supply chain and maximize your speed-to-market with our 2026-ready ERP production tracking system. Experience logistics with zero blind spots.

Landed Cost Transparency

By aggregating manufacturing costs, freight charges, and the duty rates identified during our HS code optimization process, the ERP provides an accurate "Landed Cost" for every SKU. This financial transparency allows manufacturing for license holders to adjust their retail strategies based on real-world shipping data. We provide the financial digital manufacturing transparency that allows your brand to remain profitable in a fluctuating global economy.

Post-Production Audit Trail:

A Permanent Digital Record

The value of our ERP production tracking system extends long after the goods have been sold. It provides a permanent, searchable archive of every production variable.