Beyond the Label:

Global Social Compliance and Ethical Manufacturing

In the high-stakes world of intellectual property, a brand is only as secure as the factory floor where its products are born. At Unstoyppable, we view social and ethical compliance not as a bureaucratic hurdle, but as a prestigious shield that safeguards your brand’s reputation and market access. As a premier Disney FAMA compliant manufacturer, we operate at the pinnacle of industrial ethics, ensuring that every unit produced within our network adheres to the most stringent global mandates. In 2026, the retail landscape is unforgiving toward supply chain opacity; consumers and regulators alike demand absolute transparency. By choosing a partner with a robust BSCI audited toy factory China network, you are investing in a secure future where your products are welcomed onto the shelves of the world’s most elite retailers. Our commitment to ethical toy production is the foundation upon which we build long-term, risk-free partnerships for the world's leading entertainment franchises.

Mastering the International Labor Standards (ILS) Program

The backbone of FAMA is the International Labor Standards (ILS) program. This initiative is designed to foster safe, inclusive, and healthy working environments across the global supply chain. We take an active role in managing the ILS program for our clients, ensuring that every facility is not only aware of these requirements but is actively exceeding them. Our ethical toy production protocols focus on the human element, recognizing that a respected workforce is a productive and precise workforce. By maintaining high ILS scores, we provide our clients with the peace of mind that their character product manufacturing is free from the ethical pitfalls that can derail a major product launch.

Adhering to MCS:

Minimum Compliance Standards

To remain active in the FAMA system, a factory must satisfy the Minimum Compliance Standard (MCS). These are non-negotiable benchmarks that cover critical areas such as fire safety, emergency exit accessibility, regulated working hours, and the absolute protection of labor rights. We perform our own internal quarterly audits to ensure that our MCS minimum compliance standards are strictly maintained. This proactive approach prevents the "emergency" situations that often occur when factories scramble to fix issues only when an official auditor is at the gate. With Unstoyppable, your production is always in a state of "Pre-Approved" readiness, protecting your supply chain from sudden suspensions or de-authorizations.

Differentiating Sedex 2-Pillar vs. 4-Pillar Audits

At Unstoyppable, we encourage our primary hubs to pursue the Sedex 4-Pillar audit. While the 2-Pillar audit covers the essentials of labor and health and safety, the 4-Pillar SMETA (Sedex Members Ethical Trade Audit) expands the scope to include environmental assessment and business ethics. By focusing on these additional pillars, we protect our clients from "secondary" risks, such as environmental fines or unethical business practices that could cause brand-damaging headlines. This comprehensive approach to social compliance in toy manufacturing 2026 ensures that your brand is associated with sustainability and integrity, which are increasingly vital factors for the modern, conscious consumer.

Protect Your Brand with Certified Excellence

Don't leave your compliance to chance. Partner with a Disney FAMA compliant manufacturer that treats your reputation as its own.

The Shield of Ethical Toy Production

Ultimately, our ethical toy production framework is a powerful marketing tool. In 2026, being able to prove that your toys were made in a BSCI audited toy factory China provides a competitive advantage. It allows your brand to stand tall in the face of NGO scrutiny and retail audits. We provide the documentation, the audit reports, and the daily oversight needed to turn compliance from a "cost center" into a "trust center." When you work with Unstoyppable, you are not just buying a product; you are buying the certainty that your brand is protected by the gold standard of global manufacturing ethics.

A Legacy of Trust: Our compliance infrastructure is designed to provide maximum protection for your Intellectual Property. By adhering to MCS minimum compliance standards and excelling in Sedex 4-Pillar audits, we offer a level of security that is unmatched in the industry. Partner with Unstoyppable and lead the market with a brand that is as ethical as it is successful.

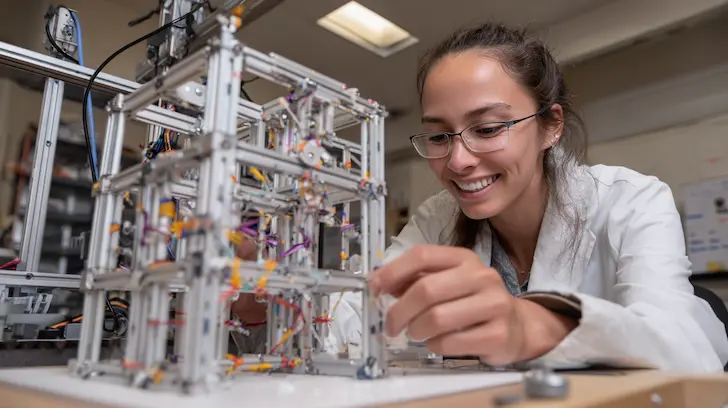

Technical Precision:

Meeting EN71, ASTM, and the New 2026 GB Standards

In the rapidly evolving landscape of 2026, technical compliance has shifted from a static checklist to a dynamic engineering challenge. At Unstoyppable, we recognize that staying ahead of the legislative curve is the only way to ensure uninterrupted market access for our partners. The regulatory environment in the European Union, the United States, and China has converged toward a high-transparency, low-chemical model. Whether you are aiming for ASTM F963-23 compliance in North America or navigating the EN71 toy safety regulation 2026 in Europe, our technical teams provide the precision required to pass every audit. We specialize in translating complex legal requirements into actionable manufacturing protocols, ensuring that your character product manufacturing remains fully compliant with the world's most rigorous safety benchmarks.

Advanced Chemical Restrictions:

PFAS and Endocrine Disruptors

The 2026 EU framework expands the list of prohibited substances to include "forever chemicals" (PFAS), bisphenols, and a wider range of endocrine disruptors. Our toy material engineering team works exclusively with verified suppliers to source materials that are 100% compliant with these new bans. By utilizing advanced chromatography and mass spectrometry testing through our lab partners, we confirm that every batch of plastic and paint is free from these restricted substances, ensuring your brand is positioned as a leader in child safety and environmental health.

Updated Chinese GB Standards:

GB 6675-2025 and Beyond

China continues to harmonize its national standards with international benchmarks while introducing specific local requirements. The transition to the New GB 6675-2025 standards China represents a major update in how toys are tested for the world’s largest emerging consumer market. As a China-based leader, Unstoyppable is perfectly positioned to navigate these local nuances for our international clients.

Stay Ahead of the Legislative Curve

2026 brings new challenges in global compliance. Ensure your character product manufacturing is ready for the New GB and EU standards with our expert technical team.

View EN71 Capabilities → | Learn About Material Safety →

Ensure your 2026 production meets the latest global standards

Phthalate-Free and Non-Toxic Material Sourcing

At the core of technical safety is the purity of the raw materials. Unstoyppable maintains a rigorous screening process for 100% phthalate-free toy materials, ensuring that every component—from the soft PVC of a figure to the synthetic hair of a doll—is safe for direct skin contact and mouthing. This commitment is vital for maintaining compliance with the US Consumer Product Safety Improvement Act (CPSIA) and the EU’s REACH regulation.

Rigorous Screening and Heavy Metal Limits

Our material sourcing protocols go beyond simple compliance; we aim for "Medical-Grade" purity in our toy resins. We perform comprehensive migration of certain elements testing to ensure that lead, cadmium, mercury, and other heavy metals are significantly below the most stringent legal limits. By utilizing high-purity virgin resins or GRS certified recycled plastics, we provide a consistent, non-toxic base for your IP. This technical precision ensures that when your product reaches the third-party lab for final certification, it passes the first time, every time.

Technical Mastery: Compliance is a science of precision. From digital product passport toys to phthalate-free toy materials, Unstoyppable provides the engineering expertise to navigate the complex regulatory waters of 2026. Trust our technical precision to protect your brand and empower your global growth.

Verifiable Safety:

Third-Party Lab Testing and AQL Inspection

In the high-stakes ecosystem of licensed merchandise, trust is earned through rigorous verification. At Unstoyppable, we move beyond mere claims of quality by implementing a multi-layered verification strategy that combines human expertise with 2026-grade technology. The quality assurance for licensed products we provide is rooted in absolute transparency and independent validation. We recognize that for a global brand, a single safety failure is an existential risk. Therefore, we have built a system where every component, every material, and every finished unit is subjected to a gauntlet of scrutiny. From the initial toy factory audit China to the final pre-shipment sign-off, our verification processes are designed to provide the physical and digital proof that your brand is protected by the highest safety standards in the world.

Strategic Partnerships with Global Testing Leaders

We maintain deep, integrated partnerships with the world's most prestigious accredited laboratories, including SGS, Intertek, and VDE. These facilities are the gatekeepers of global safety. By funneling our production through these certified labs, we ensure that every toy is tested against the most current 2026 iterations of EN71, ASTM, and ISO standards. This third-party toy lab testing covers everything from chemical analysis and element migration to flammability and mechanical endurance. By utilizing these global leaders, we provide you with a "Certification of Confidence" that is recognized by every major retailer and regulatory body on the planet.

The Children’s Product Certificate (CPC) and Declaration of Conformity

Navigating the paperwork of international trade is a critical part of our toy manufacturing logistics. For the North American market, we facilitate the creation of the Children’s Product Certificate (CPC), which serves as the official record that a product meets all applicable CPSC safety rules. Simultaneously, for the European market, we generate the comprehensive Declaration of Conformity (DoC). These documents are backed by the raw data from our third-party lab tests, creating an impenetrable legal trail. We ensure that your compliance documentation is always up-to-date, organized, and ready for instant digital retrieval, simplifying your customs & export for toys processes.

Protect Your Brand with Verifiable Safety

Our multi-layered AQL inspection China protocols and third-party toy lab testing partnerships ensure your brand remains above reproach.

Explore Testing Partnerships → | Learn About AQL Standards →

Future-Proofing Safety with AI and Real-Time Data

The future of toy quality and safety compliance is digital. At Unstoyppable, we are pioneering the use of a "Forever Record" for every product we manufacture. Through our advanced ERP systems, we capture and store every safety-related data point—from the batch number of the raw resin to the specific calibration settings of the automated toy safety testing equipment used during assembly.

The AI-Enhanced Safety Dashboard

By leveraging AI in toy manufacturing, we analyze safety data across multiple production runs to identify subtle patterns that could indicate future risks. This "Predictive Safety" model allows us to refine our toy factory audit China criteria and material specifications continuously. When a client asks for proof of compliance years after a product launch, we can provide a complete digital history of that product's birth and verification. This is the ultimate form of smart supply chain transparency, providing our clients with an indestructible safety legacy that grows stronger with every unit produced.

Compliance & Safety Verification FAQ

How do you ensure a factory maintains its FAMA status during production?

What is the difference between EN71 and ASTM F963 in 2026?

How do you handle the new EU Digital Product Passport requirements?

Can you provide testing for recycled or sustainable materials?

A Triumphant Future: At Unstoyppable, safety is our signature. By combining independent lab validation with automated toy safety testing and real-time data, we provide a fortress of protection for your brand. You can launch your next global franchise with the absolute certainty that your toys are the safest, most compliant products on the market. Your brand is in the safest possible hands. Start your compliant production today.