Manufacturing for License Holders:

Maximizing ROI in Licensed Toy Production

In the competitive landscape of 2026, manufacturing for license holders is a complex balancing act that requires a deep understanding of both creative fidelity and financial viability. As a licensee, your success depends on your ability to deliver high-quality products that satisfy the licensor's strict brand guidelines while maintaining healthy profit margins after royalty deductions. At Unstoyppable, we serve as a strategic financial ally, providing licensee production solutions that prioritize Return on Investment (ROI) without compromising the integrity of the IP. By leveraging our cost-effective toy manufacturing China network and advanced engineering protocols, we help you navigate the unique pressures of licensed commerce. Our goal is to ensure that your royalty-margin optimization is achieved through smarter engineering, efficient material selection, and scalable production models that reflect the reality of modern retail.

Overcoming the Margin Squeeze

The "Licensee Dilemma" is the constant pressure to hit a retail price point that consumers accept while paying out a percentage of every sale to the IP owner. We address this by focusing on licensed product ROI from the very first design consultation. We analyze your royalty structure and target MSRP to work backward, identifying the ideal manufacturing cost (COGS). Our cost-effective toy manufacturing China strategies are designed to find "hidden" efficiencies in the supply chain, such as optimizing shipping volumes or streamlining the assembly of character product manufacturing components. By aligning our production goals with your financial targets, we ensure that the license remains a profitable asset for your business.

Maintaining Licensor Approval via Efficiency

Efficiency is the primary driver of success for 2026 licensees. Our systems allow you to maintain the "premium" status required by major studios while utilizing licensee production solutions that reduce waste. We facilitate a transparent communication flow between the licensee and our production teams, ensuring that every cost-saving measure is documented and presented as a value-add. This proactive stance on royalty-margin optimization allows you to reinvest saved capital into further marketing or the acquisition of additional character tiers, fueling the growth of your licensed portfolio.

Strategic Tooling and Multi-Cavity Efficiency

To maximize licensed product ROI, we utilize multi-cavity molds that produce several character parts in a single injection cycle. This reduces the "shot cost" and speeds up the overall production timeline. By investing in advanced toy tooling R&D at the start of the project, we help license holders achieve a lower per-unit cost over the long term. We provide a detailed cost-benefit analysis for every tooling decision, ensuring that the license holder is always in control of their capital expenditure and royalty-margin optimization strategy.

Protect Your Margins Today

Consult with our licensee production solutions specialists to optimize your 2026 production costs without sacrificing quality.

Advanced Decoration as a Cost-Saver

Often, the "premium" look of a character can be achieved more cheaply through advanced printing than through complex molding. We utilize printing film for toy materials (such as Heat Transfer or IML) to replicate intricate patterns and textures. This allows the injection molded toy manufacturer process to remain simple and inexpensive, while the high-fidelity film provides the "Cinematic" detail the licensor demands. This intelligent use of advanced printing for licensed products is a key tactic in our royalty-margin optimization toolkit.

Volume Scalability:

Managing MOQs Across Character Tiers

License holders are often required to produce an entire "wave" of characters, including secondary figures that may have lower sales volumes than the main protagonist. Managing these varied volumes is essential for licensed product ROI.

Executive Business Note: Successful manufacturing for license holders requires a partner who treats your royalty statement as their own. Through DFM for profitability, strategic phthalate-free toy materials selection, and royalty-margin optimization, Unstoyppable ensures your license is a vehicle for growth, not just an overhead expense. Partner with us to engineer a more profitable 2026 for your licensed brand.

Technical Precision:

Meeting Licensor Standards through Advanced Engineering

For any 2026 license holder, the licensor approval process is the most critical milestone in the product lifecycle. IP owners like Disney, Warner Bros., and Netflix maintain rigorous style guides that demand absolute fidelity to the source material. A single deviation in character proportion or a slight shift in a "Hero’s" signature color can lead to costly rejections and production delays. At Unstoyppable, we eliminate this friction by providing high-fidelity character moulding and advanced printing for licensed products that align with studio expectations from the very first submission. Our engineering team acts as your technical liaison, ensuring that the transition from a digital style guide to a retail-ready licensed toy production unit is seamless, accurate, and optimized for immediate approval. We prioritize "First-Time Approval" as a standard, saving you time and protecting your contract milestones.

The Perfect Sculpt:

Engineering 100% Style Guide Accuracy

The "Golden Sample" must be a physical manifestation of the licensor’s vision. To achieve this, we utilize a data-driven approach to 3D sculpting and high-fidelity character moulding.

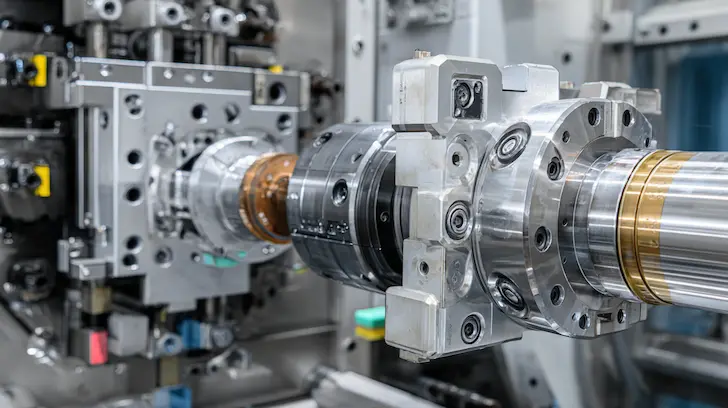

Matching Digital IP with Physical Tooling

We begin by ingesting the licensor’s high-poly digital assets into our advanced toy tooling R&D workflow. Unlike standard manufacturers, we perform a "Fidelity Audit" to ensure that the character engineering for toys accounts for every muscle contour, costume seam, and facial nuance. By using ultra-precision CNC machining, our injection molded toy manufacturer partners can produce molds that capture the microscopic textures—such as the "carbon fiber" look of a tech-suit or the organic skin texture of a creature—that premium licensors demand. This level of detail ensures that your sample is met with immediate praise during the licensor approval process, positioning you as a high-tier licensee.

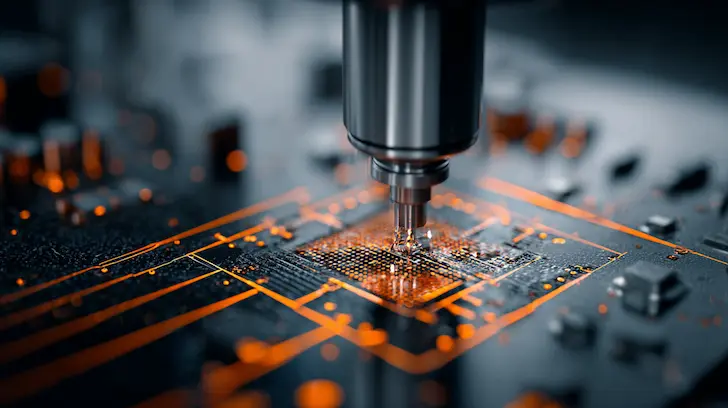

Spectrophotometer Precision in Pad Printing

To guarantee color-matching for licensed toys, we utilize industrial spectrophotometers to create custom ink formulas. Our 12-color pad printing stations are calibrated to the Pantone Matching System (PMS) and the specific "CMYK+" values provided in the studio style guide. Whether we are printing onto soft PVC or rigid ABS, our advanced printing for licensed products ensures that the "Hero's" colors remain vibrant and consistent. This technical obsession with color fidelity is a cornerstone of our licensee production solutions, ensuring that your product stands out on the shelf for its professional, high-end finish.

Consistency Across Plastic, Fabric, and Printing Film

A major challenge for license holders is ensuring that a color on a plastic figure matches the color on a licensed bag manufacturer accessory or the printing film for toy materials used on the packaging. We solve this through centralized color management. By coordinating the dye lots and ink batches across our audited factory network China, we provide a unified visual experience. This "Global Color Sync" is essential for retail-ready licensed toy production, as it satisfies the licensor's demand for brand uniformity across their entire merchandising ecosystem.

Get Your Golden Sample Approved Faster

Leverage our high-fidelity character moulding and spectrophotometer color-matching for licensed toys to bypass approval delays.

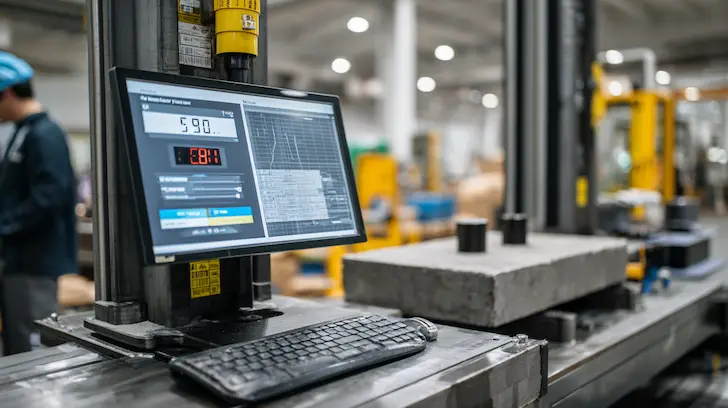

Durability and "Frictionless" Quality Control

Every decoration technique we use is tested for durability. Our advanced printing for licensed products must pass "cross-hatch" adhesion tests and "box-rub" simulations to ensure that the beautiful finish survives the journey to the consumer. This technical durability is a subtle but powerful part of the licensor approval process; it demonstrates that the licensee is committed to long-term quality and brand reputation. When the licensor sees that the decoration is as robust as it is beautiful, the "Golden Sample" approval becomes a formality.

Durability for Safety:

Recalls are Not an Option

The ultimate technical approval is safety compliance. A product that looks perfect but fails a "pull-test" or contains restricted chemicals is a liability for the license holder.

Technical Mastery Note: Manufacturing for license holders is a game of precision. By combining high-fidelity character moulding with scientific color-matching for licensed toys, we ensure your brand hits the market with "Studio-Approved" quality. Trust Unstoyppable to handle the technical hurdles while you focus on the growth of your franchise.

Secure Distribution and Ethical Compliance for International Licensees

For a dedicated license holder, the journey does not end when the product leaves the injection mold; it truly begins when the goods enter the global regulatory and logistical pipeline. In 2026, ethical manufacturing for license holders is a core contractual obligation that can determine the longevity of your licensing agreement. At Unstoyppable, we provide a comprehensive framework for licensee supply chain security, ensuring that every unit produced is backed by the certifications and data transparency that global IP owners demand. From navigating the complexities of FAMA compliant distribution to delivering customs-ready manufacturing data, we handle the administrative heavy lifting. Our mission is to provide the "Peace of Mind" that allows business owners to focus on market expansion, knowing their production is fully compliant, ethically sound, and logistically optimized for 2026 retail standards.

The "Audit-Ready" Supply Chain:

Fulfilling Ethical Obligations

Modern licensing contracts are explicit regarding social responsibility. To protect your license, you must prove that your products are manufactured in environments that respect human rights and safety standards.

A Network of BSCI & Sedex Audited Toy Factories

Our BSCI & Sedex audited toy factory network is the cornerstone of our ethical commitment. We maintain a constant state of "Audit-Readiness," meaning that at any moment, your licensor can verify the social compliance of the production line. This proactive approach to ethical manufacturing for license holders mitigates the risk of sudden contract terminations due to sub-tier supplier failures. By providing transparent access to audit reports, we help you demonstrate to your licensors that you are a responsible steward of their IP, strengthening your partnership and securing your future renewals.

Streamlined FAMA Compliant Distribution

As a studio-approved toy manufacturer, Unstoyppable understands the nuances of the FAMA application and maintenance process. We ensure that our facilities are correctly registered and that the FAMA compliant distribution paperwork is flawlessly integrated with your shipping manifests. This prevents the nightmare scenario of containers being seized or rejected at the port of entry due to lack of authorization. For a license holder, this level of regulatory mastery is essential for maintaining a secure supply chain for licensed products and ensuring that the high-stakes "Disney Audit" is a success every time.

Legal Compliance for Global Shipping

Navigating the legalities of licensed shipping requires a partner who understands the difference between a "trading company" and a "FAMA-authorized facility." We provide the clear documentation that links our audited factory network China to your specific licensing agreement. This ensures that customs officials in the US, EU, and UK can immediately verify your right to distribute the IP, facilitating faster customs & export for toys and reducing the time your capital is tied up in transit.

Secure Your License’s Future

Partner with Unstoyppable for a fully compliant, FAMA-certified, and transparent production experience.

Hitting Contractual "On-Shelf" Dates

Every licensing contract has strict "On-Shelf" deadlines. Missing these can lead to penalties or the loss of the license. We coordinate our toy manufacturing logistics to meet these dates with surgical precision. Our automated alerts keep you informed of any potential delays in cross-border toy shipping 2026, allowing you to proactively manage your retail partners' expectations. At Unstoyppable, we treat your "Street Date" as our own, ensuring your retail-ready licensed product production hits the market with maximum impact.

Global Retail Readiness:

Smooth Entry into Major Hubs

Entering retailers like Target, Walmart, or Amazon requires a level of technical preparation that many manufacturers overlook. We ensure your products are "Retail-Ready" the moment they are packed.