Synchronized Success:

Planning Your Movie Merchandise Manufacturing Countdown

In the high-octane world of global entertainment, timing is the difference between a retail sensation and a missed cultural opportunity. Success for a blockbuster franchise is anchored in the precision of its movie merchandise manufacturing preparation. When the red carpet rolls out and the first trailer drops, your product must already be positioned in the hands of consumers or prominently displayed on retail shelves. At Unstoyppable, we specialize in reverse-engineering the premiere date, transforming a cinematic release into a meticulously timed manufacturing surge. In 2026, the cinematic product launch timeline has become more compressed and digitally integrated than ever before. We move beyond standard lead times to offer franchise merchandise synchronization that ensures your brand’s physical presence matches its digital hype. In entertainment manufacturing, a missed deadline is a missed cultural moment; we ensure your brand is always front and center when the lights go up.

From "Gray-Box" Renders to Physical Reality

Our 18-month strategy begins with the ingestion of early-stage assets. Long before a final VFX shot is rendered, our character product manufacturing team works with "gray-box" 3D models and early concept sketches provided by the studio. This early start allows us to begin the complex process of character engineering for toys, establishing articulation points, internal electronic housing, and material specifications. By starting during the film’s pre-production, we provide the necessary runway for multiple rounds of refinement, ensuring that the final toy is a perfect physical manifestation of the on-screen hero. This proactive approach turns early concept art into a golden sample development process that is ready for mass production the moment the final character design is locked.

Iterative Development in Parallel with Production

Manufacturing for unreleased media requires a fluid, iterative mindset. As the film's production evolves, so does our engineering. We maintain a "live" development loop, allowing for adjustments in color palettes or costume details even after the initial molds are cut. This parallel development is essential for licensed toy production for films, where a mid-production character tweak can render an entire product line obsolete if the manufacturer is not agile enough to adapt. At Unstoyppable, our agility is your insurance policy against last-minute studio changes.

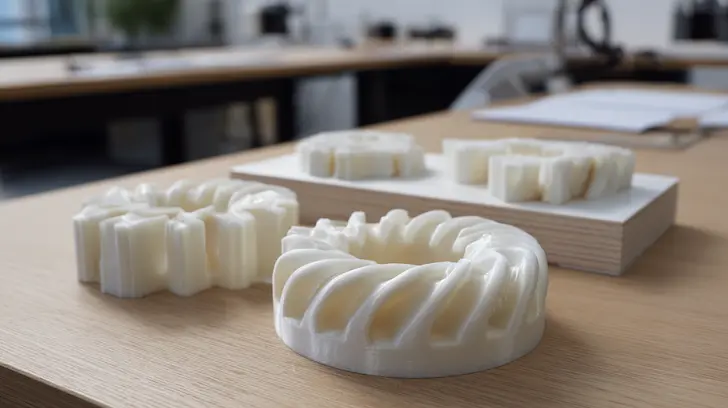

Bridging the Gap Between Concept and Tooling

The transition from a style guide to a physical mold is the most critical phase. We utilize advanced 3D printing and rapid prototyping to create "Proof of Concept" models within days of receiving new assets. This allows licensors to hold a physical version of the character, verifying the character merchandise manufacturing direction before we commit to expensive mold development & injection tooling. This speed is what allows Unstoyppable to maintain a "First-to-Market" advantage for our clients.

Don't Let Your Premiere Go Un-Merchandised

The 2026 production windows for blockbuster releases are filling fast. Secure your spot in the master toy licensee manufacturing cycle now.

Explore Character Manufacturing | Learn About Our Prototyping

The Teaser Wave vs. The Feature Wave:

Strategic Phasing

To maximize the cinematic product launch timeline, we often split production into two distinct phases. The "Teaser Wave" consists of core characters and iconic vehicles revealed in the first trailer, designed to build hype and drive pre-orders. The "Feature Wave" includes "Mystery SKUs"—characters, costumes, or plot-relevant accessories that remain hidden in our confidential licensed product manufacturing vaults until the film's opening weekend. This strategy drives secondary sales and keeps the "unboxing" culture alive on social media without spoiling the film’s narrative surprises.

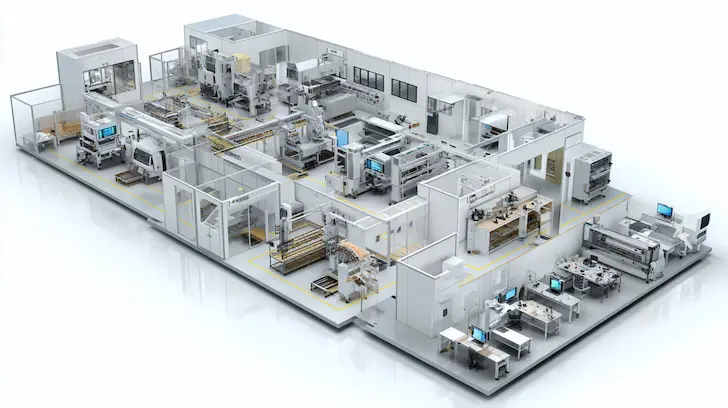

Mastering the Master Toy Licensee Mindset

Acting as a master toy licensee manufacturer means more than just filling orders; it means managing the heartbeat of a franchise. We take on the burden of movie merchandise manufacturing preparation so you can focus on the red carpet.

The Entertainment Insight: A movie toy line is not just a product; it is an extension of the storytelling experience. By reverse-engineering your launch from the premiere date and utilizing franchise merchandise synchronization, we turn cinematic viewers into lifelong collectors. Precision timing is the ultimate brand builder.

Stealth Manufacturing:

Protecting Movie Spoilers in the Supply Chain

In the age of instant social media leaks and drone-assisted corporate espionage, protecting the narrative secrets of a multi-billion dollar film franchise is a mission-critical operation. For global entertainment giants, a leaked character reveal or a plot-spoiling toy accessory can diminish months of carefully orchestrated marketing and devalue the cinematic experience. At Unstoyppable, we provide an "IP Vault" environment that goes far beyond standard factory protocols. Our approach to confidential licensed product manufacturing is built on the principle of absolute containment. By treating every unreleased character as a high-security asset, we ensure that your unreleased media product security remains impenetrable from the first 3D render to the final retail pallet. When you trust us with your film IP, you are securing more than a production line; you are securing the mystery and magic of your story.

The "Need-to-Know" Assembly Line:

Compartmentalized Production

Human curiosity is the primary source of supply chain leaks. To mitigate this, we have pioneered the "Need-to-Know" assembly protocol, a system designed to ensure that no single individual below the management level has a full view of the final product until it is ready for the "Black Box" packaging phase.

Segmented Component Manufacturing

During secure character production China, we split the manufacturing of sensitive characters across different physical locations or isolated clean rooms within our audited factory network in China. For example, one specialized facility might produce the articulated mechanical joints, another handles the specific costume textures or capes, and a third produces the weaponry or accessories. By isolating these components, we ensure that factory personnel are only aware of the specific part they are crafting. This compartmentalization is the cornerstone of our anti-leak manufacturing protocols, making it impossible for a single smartphone photo to reveal a major character spoiler.

Biometric File Access and Digital Fingerprinting

Every digital asset we receive is housed on an air-gapped server with multi-factor biometric authentication. Our confidential licensed product manufacturing workflow utilizes advanced digital watermarking on all 3D files. This means that if an unauthorized screenshot or file transfer were to occur, the source would be instantly identifiable through an invisible digital signature. This "Virtual Vault" ensures that your character engineering for toys data remains within our secure ecosystem. Furthermore, all physical prototypes and 3D-printed "Golden Samples" are etched with tracking numbers and stored in fireproof, locked safes when not in active use by our engineering leads.

The Role of the BSCI & Sedex Audited Environment

Security is an extension of ethical management. By utilizing our BSCI & Sedex audited toy factory network, we ensure that every facility manager is trained in the legal ramifications of IP theft. These audits verify that our security personnel are not only present but are following the strict anti-leak manufacturing protocols required by top-tier studios like Disney, Marvel, and Netflix. This culture of compliance ensures that every worker understands the value of the IP they are protecting, creating a human barrier against leaks.

Your IP is Your Most Valuable Asset

Discover how we provide the industry's most secure "IP Vault" environment for confidential licensed product manufacturing.

GPS Tracking and Geofenced Shipments

For ultra-sensitive "Wave 1" launches, we utilize GPS-tracked pallets that alert our logistics team the moment a shipment deviates from its planned route. This level of secure character production China extends into the ocean and air, ensuring that your merchandise is monitored until it reaches the safety of your regional distribution center. By maintaining a transparent supply chain manufacturing process, we can account for every single unit produced, ensuring zero "shrinkage" or unauthorized "early sales."

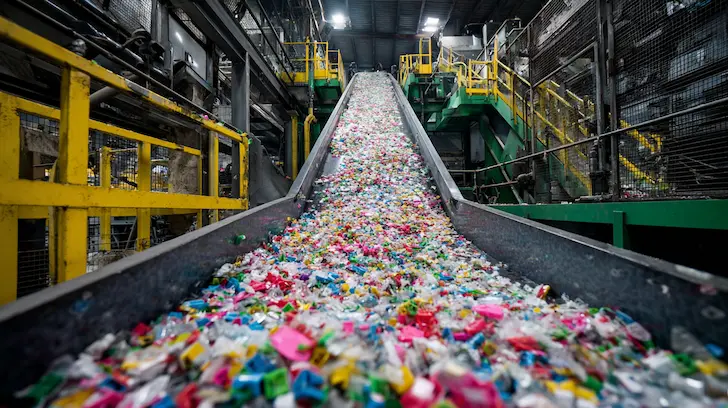

Spoiler-Free Scrap Disposal:

Eliminating the "Bin Leak"

Many of the most damaging movie leaks occur not from the final product, but from the factory’s waste bin. Defective parts, overflow plastic from a pvc figure manufacturer mold, or rejected paint samples can still reveal a character's secret design.

Security Expert Note: In the world of film merchandising, silence is profitable. By implementing "Need-to-Know" assembly and spoiler-free scrap disposal, we turn the manufacturing floor into a high-security extension of the film studio. Your secrets are safe in our Vault.

Scaling the Hype:

Rapid Re-Order Systems for Viral Movie Hits

In the entertainment industry, lightning can strike twice, but only if you have the bottle to catch it. A movie that transitions from a standard release to a global viral phenomenon creates a "demand spike" that can overwhelm traditional supply chains in hours. When a character goes viral on social media or a film shatters opening-weekend projections, the window to capitalize on that momentum is incredibly narrow. At Unstoyppable, we build movie toy supply chain resilience into the very fabric of our operations. We specialize in scalable toy manufacturing for films, ensuring that our partners can double or even triple their output in a matter of weeks. By shifting from a static production model to a dynamic, high-velocity response system, we transform "out of stock" disasters into "Wave 2" retail victories. Our infrastructure is designed for infinite scalability, ensuring your brand stays relevant as long as the cameras are rolling.

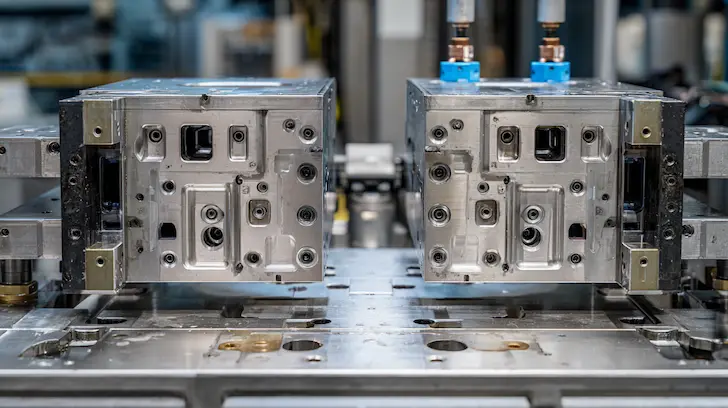

The "Shadow Mold" Strategy:

Instant Capacity Doubling

The most significant bottleneck in high-volume licensed production is the physical limitation of the injection mold. A single mold can only produce a set number of units per hour. To solve this, Unstoyppable employs the "Shadow Mold" strategy for major cinematic launches.

Engineering Redundancy for Rapid Replenishment

During the initial mold development & injection tooling phase, we recommend the creation of duplicate high-precision "Shadow Molds." While the primary molds are running at 100% capacity for the "Wave 1" launch, the Shadow Molds are held in a state of ready-reserve in our audited factory network in China. If the film's box office performance triggers a rapid re-order, we can mount these duplicate molds on additional injection machines within 24 hours. This effectively doubles your production throughput overnight, bypassing the typical 45-60 day lead time required to cut new steel. This is the cornerstone of rapid movie merchandise replenishment, allowing you to feed the "viral" beast while the hype is at its peak.

From the Big Screen to the Retail Shelf

Ensure your franchise is 'Unstoyppable' with scalable toy manufacturing for films. We handle the volume so you can handle the fame.

See Our Media Franchise Solutions | View Retail-Ready Production

Multi-Category Synchronization:

The "Retail Takeover"

A viral hit isn't limited to a single toy; it consumes the entire retail landscape. To maintain brand dominance, your theme park merchandise manufacturing must scale in perfect harmony with your mass-market toy lines.

Unified Scaling Across All SKU Types

Our ERP production tracking system allows us to synchronize the scaling of disparate product categories. When we ramp up production of action figures, we simultaneously trigger increased output in licensed bag manufacturer lines and lifestyle goods. This ensures a cohesive "Retail Takeover" where the consumer sees a full, refreshed assortment of merchandise rather than a few isolated items. By managing this high-volume licensed production under one umbrella, we maintain color consistency and quality across every category, from high-end resins to soft plush.