Retail-Ready Licensed Product Production:

Engineering for Zero-Touch Merchandising

In the high-velocity world of 2026 big-box retail, the distance between the shipping dock and the sales floor must be as short as possible. Retail-ready licensed product production is the strategic answer to the labor shortages and rising operational costs facing modern merchants. At Unstoyppable, we don't just manufacture toys; we engineer high-velocity retail fulfillment solutions that allow your products to transition from a shipping container to a consumer's hands with "zero-touch" from retail staff. By optimizing every millimeter of RRP manufacturing China, we ensure your brand captures the "First Moment of Truth" on the shelf while maintaining the lowest possible landed cost.

Labor Efficiency:

Reducing Stocking Time by 80%

The primary driver for retail-ready packaging (RRP) adoption in 2026 is the acute shortage of in-store labor. Every second a retail associate spends using a knife to open a box is a second they are not helping a customer. Unstoyppable’s automated retail-ready assembly reduces replenishment man-hours by up to 80%.

Eliminating the "Carton Cutter" Risk

Traditional "brown box" shipping often leads to accidental product damage—and employee injury—when knives are used to slice through tape. Our Retail-Ready Licensed Product Production uses glueless locking tabs and zipper-perforations. This not only protects your high-value character products from "shrinkage" due to surface scratches but also makes your brand a favorite among retail managers who are incentivized to reduce workplace hazards and inventory loss.

Is Your Product Shelf-Ready or Just Shipping-Ready?

Don't let your brand get stuck in the stockroom. Optimize your 2026 retail strategy with engineering-led RRP solutions from Unstoyppable.

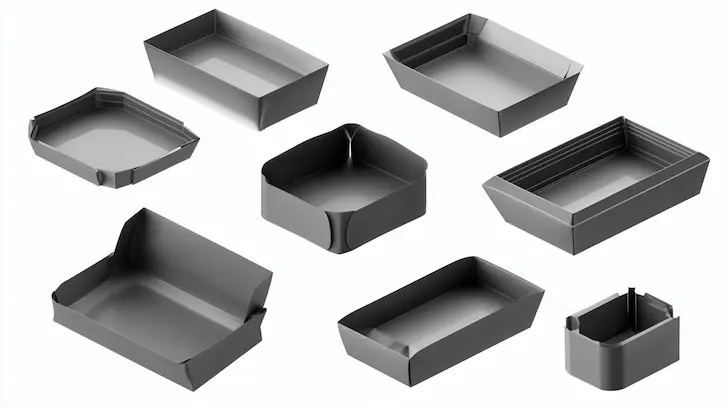

Tray and Hood Construction

Our most popular RRP manufacturing China format is the "Tray and Hood" system. The "Tray" provides a sturdy base and high-impact branding surface, while the "Hood" acts as a protective shield during transit. Upon arrival, the hood is simply lifted off and recycled, leaving a perfectly organized row of products. We engineer these with reinforced corners to ensure they can be double-stacked in the warehouse without crushing the internal character toys.

Wrap-Around Cases and Die-Cut Precision

For high-volume items, we utilize automated wrap-around casing. This method uses less material than a standard box, fitting snugly around the product to prevent shifting during toy manufacturing logistics. Combined with precision die-cut display windows, these wraps allow for maximum product visibility. In 2026, where "unboxing" starts on the retail shelf, these structural elements serve as your secondary salesperson, enticing customers with a clear view of the character’s high-fidelity engineering and PVD metallic finishes.

Retail Readiness is a Competitive Edge. By integrating the "Five Easies" into your licensed product production, you are not just selling a toy; you are selling a labor-saving solution to the world's largest retailers. Unstoyppable makes your brand shelf-ready from day one.

Maximizing Brand Impact:

From PDQ Displays to Digital Product Passports

Floor-Standing and Counter-Top PDQ Solutions

Our custom PDQ manufacturing services cover everything from compact counter-top units for impulse "blind box" buys to massive floor-standing "power-wing" displays. These units are engineered with high-crush-test corrugated fiberboard to support the weight of multiple units while resisting the wear and tear of a high-traffic retail environment. By shipping these pre-loaded from our hubs in China, we eliminate the risk of merchandise being misplaced in a stockroom, ensuring your high-velocity retail fulfillment targets are met on launch day.

Visual Merchandising and High-Impact Lithography

To make an impact on the 2026 shelf, we utilize offset lithography and digital wide-format printing with soy-based inks. This allows for vibrant, movie-quality graphics on every retail-ready surface. We incorporate "eye-tracking" design principles to place your character’s most compelling features at the shopper's sightline. When combined with matte and spot-UV finishes, your retail-ready packaging design becomes a powerful brand ambassador that communicates quality and authenticity before the customer even touches the product.

Labeling for Smart Inventory Management

Modern retailers now utilize RFID-ready labeling and 2D DataMatrix codes alongside standard UPCs. At Unstoyppable, we integrate these smart labels during the retail-ready licensed product production phase. This allows for real-time inventory tracking and automated replenishment, ensuring that your best-selling character toys are never "out of stock" during peak shopping seasons. This level of technical detail is a hallmark of a secure character supply chain.

Transform Your Shipping Boxes into Powerful Brand Ambassadors

Your packaging should work as hard as your product. Elevate your retail presence with engineering-led PDQ solutions and precision labeling.

Sustainability as a Core Retail Requirement

Retailers like Walmart and Target now have mandatory sustainability scorecards. To help our clients achieve "Category Captain" status, our retail-ready packaging design focuses on "The Green standard." This includes:

Dynamic Pricing and Promotional Windows

In a high-velocity market, retail-ready packaging must be adaptable. We offer modular PDQ designs that allow for easy updates to promotional messaging or "Holiday-Specific" branding via digital print overlays. This flexibility allows media franchises to pivot their retail strategy to match streaming series drops or theatrical shifts without redesigning the entire secure character supply chain. Our goal is to ensure your brand remains as dynamic as the entertainment it represents.

Digital Readiness Meets Physical Excellence. By combining PDQ display manufacturing with GTIN accuracy and Digital Product Passport compliance, Unstoyppable ensures your brand is optimized for the 2026 retail world. We handle the technical complexity so your IP can shine.

Global Fulfillment:

Synchronizing Production with Retail Launch Windows

In the high-stakes ecosystem of 2026 entertainment, the success of a franchise is measured by its ability to execute a "Day-and-Date" launch. This means merchandise must be available globally at the exact moment a film premieres or a streaming series drops. At Unstoyppable, we provide global retail fulfillment for toys that is powered by advanced data intelligence and a secure character supply chain. By integrating our high-volume licensed production with sophisticated logistics strategies, we ensure that your retail-ready units arrive in pristine condition, regardless of the distance traveled. Our goal is to eliminate the logistical friction that stands between your production line in China and the consumer’s shopping cart.

Automated Retail-Ready Assembly and Quality Control

To ensure total accuracy during high-volume runs, we utilize automated retail-ready assembly lines. These robotic systems precisely fold, glue, and load your products into their shelf-ready packaging (SRP). By removing manual handling at the final stage, we ensure that every PDQ display is packed exactly according to the style guide, with no missing units or misaligned branding. This automated precision is critical for maintaining the high standards required by high-volume licensed production partners.

Ensuring Pristine Arrivals:

ISTA Standards and Transit Testing

A "Retail-Ready" display is only effective if it arrives in retail-ready condition. Sea freight is a brutal environment involving high humidity, extreme vibrations, and heavy stacking pressures. To guarantee zero-damage arrivals, Unstoyppable subjects all packaging designs to rigorous ISTA (International Safe Transit Association) testing.

Master the "Day-and-Date" Global Launch

Ensure your merchandise is on the shelf and ready to sell the moment your fans arrive. Experience the Unstoyppable fulfillment edge.

Direct-to-Retail (DTR) Strategies:

Minimizing Landed Costs

In 2026, the most efficient supply chains are the shortest ones. Unstoyppable acts as more than just a manufacturer; we are a strategic global retail fulfillment partner. We specialize in Direct-to-Retail (DTR) shipping models that bypass traditional middle-man warehouses, significantly reducing your landed cost in manufacturing.

Regional Distribution Center (DC) Optimization

By shipping retail-ready pallets directly to a retailer’s regional distribution centers (DCs), we reduce handling costs and potential damage. Our logistics for licensed products team ensures that every pallet is built to the exact specifications of the destination DC—including height restrictions, pallet-wrap standards, and GTIN-14 case labeling. This "DTR-Ready" approach makes your brand the preferred supplier for big-box retailers, as you are providing a product that is ready for immediate cross-docking and store delivery.