Promotional Merchandise Manufacturer:

Scalable Solutions for Global Brand Launches

In the high-stakes environment of 2026 entertainment marketing, the window between a trailer drop and a global premiere has narrowed to a razor-sharp edge. As a premier promotional merchandise manufacturer, Unstoyppable is engineered to operate at the intersection of extreme speed and massive scale. We specialize in transforming intellectual property into millions of tangible touchpoints that drive consumer engagement across continents. For marketing agencies and brand managers, our infrastructure provides the "industrial horsepower" necessary to fuel movie tie-in merchandise campaigns that require flawless synchronization with theatrical or digital releases. We view every promotional item—whether it is a cinema popcorn topper, a fast-food premium, or a retail gift-with-purchase—as a critical ambassador for your brand that must be produced with uncompromising reliability under intense pressure.

Synchronized Global Releases

Success in 2026 relies on the simultaneous arrival of products in multiple territories. We utilize advanced AI-driven production scheduling to coordinate the output of our custom promotional giveaways across several certified factory sites. This decentralized yet highly controlled manufacturing model allows us to mitigate regional disruptions and guarantee that a movie premiere in London, New York, and Tokyo is supported by the same high-quality merchandise on day one. By choosing a promotional merchandise manufacturer with deep scalability, you ensure that your campaign’s momentum is never hampered by stock-outs or production bottlenecks.

Real-Time Inventory and Speed-to-Market

We leverage real-time data integration with our clients to adjust production volumes based on early engagement metrics. If a character goes viral, our high-velocity lines are capable of rapid pivots to increase the supply of specific mass-market licensed products. This agility is the hallmark of a modern manufacturing partner, allowing brands to capitalize on consumer sentiment with surgical precision.

Sustainable Bio-Polymers for Eco-Promotions

In response to 2026 environmental mandates, we offer bio-based polymers that maintain the durability of traditional plastics while significantly reducing carbon footprints. These sustainable options allow our partners to run "Zero-Waste" campaigns, aligning their custom promotional giveaways with corporate sustainability goals. This proactive approach to material engineering ensures that your promotional gear is both brand-safe and planet-safe.

Launch Your Campaign with Absolute Confidence

Harness the power of high-velocity production lines designed for millions of units and zero delays. Let's make your next movie launch unstoppable.

Explore Our Manufacturing Capacity | Solutions for Marketing Agencies

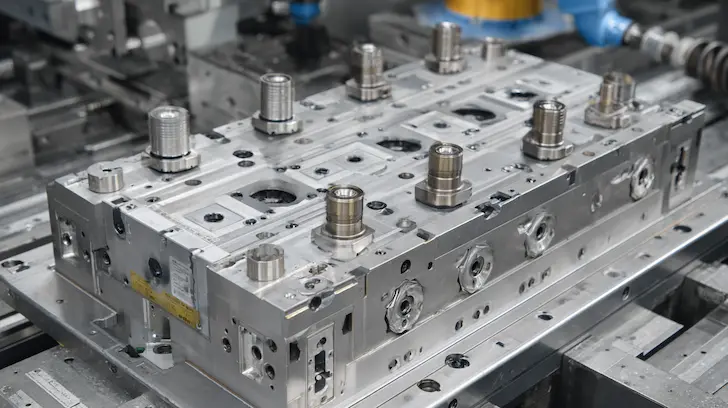

Robotic Take-Out and Inline Quality Control

Our production lines are equipped with 6-axis robotic arms that handle the "take-out" process, ensuring that delicate parts are not damaged during ejection. Simultaneously, high-speed vision systems perform inline quality checks, scanning for flash, short-shots, or color variances in real-time. This automated oversight ensures that the first unit in a movie tie-in merchandise run is identical to the millionth, protecting the character’s integrity throughout the campaign.

Modular Tooling:

Reducing CAPEX with Family Molds

Strategic budget management is vital for large-scale promotions. Unstoyppable helps clients optimize their investment through the use of modular "Family Molds." This innovative approach to mass-market licensed products allows for multiple character variations to be produced simultaneously from a single tool.

The Promotional Advantage: Unstoyppable is more than a promotional merchandise manufacturer; we are a high-capacity engineering partner. By combining multi-cavity automated molding, material optimization, and modular tooling, we deliver the scale you need with the precision your brand deserves. Power your 2026 global launches with a manufacturer that thrives under the pressure of the world's biggest brands.

From Concept to Cinema:

Rapid Prototyping and High-Definition Finishing

In the accelerated timeline of 2026 film marketing, the ability to transition from a digital style guide to a physical sample determines the success of a global campaign. As a premier promotional merchandise manufacturer, Unstoyppable utilizes a specialized "Fast-Track" department dedicated to shrinking the development cycle. We understand that for marketing agencies, seeing is believing. By deploying the latest in additive manufacturing and high-fidelity decoration, we ensure that even the most budget-conscious custom character keychains China or movie toppers possess the visual impact of high-end retail collectibles. Our mission is to bridge the gap between "promotional giveaway" and "fan keepsake" through superior finishing techniques that maintain character integrity across millions of units.

Accelerated Development:

2026-Grade 3D Promotional Prototypes

The first step in any successful promotion is the validation of the "Golden Sample." In 2026, we have eliminated the weeks-long waiting periods traditionally associated with international sampling. Our fast-track toy prototyping service allows for rapid iteration, ensuring your stakeholders can hold a physical product while the campaign strategy is still being finalized.

SLA and SLS Prototyping for 72-Hour Delivery

We utilize industrial-grade Stereolithography (SLA) and Selective Laser Sintering (SLS) to produce 3D promotional prototypes with incredible surface smoothness and structural integrity. SLA is our preferred method for character figurines, as it captures the minute facial expressions and costume details required by major studios. SLS, on the other hand, allows us to test the mechanical function of moving parts in promotional gear. These 2026-grade machines allow us to deliver "look-and-feel" samples to agency headquarters globally within 72 hours of receiving the 3D assets. This speed allows for immediate feedback and faster approval for mass-market licensed products.

Mastering 6-Color High-Speed Pad Printing

For intricate details on small or curved surfaces—such as the eyes of a character on a cinema topper—we utilize pad printing for licensed toys. Our automated 6-color pad printing lines are capable of applying multiple layers of ink with micron-level registration accuracy. This ensures that character faces are consistently vibrant and correctly aligned across millions of units. Our inks are specifically formulated for high adhesion and abrasion resistance, ensuring that custom character keychains China maintain their detail even after months of being handled by the user.

Heat Transfer Film (HTF) for Complex Cinema Art

When a promotional product requires full-color, photographic-quality imagery—such as a movie poster or a complex background scene—we deploy heat transfer film for promotions. This 2026-spec printing film allows for the application of high-resolution digital art onto plastic surfaces with a single thermal pass. Unlike traditional stickers, HTF bonds permanently with the plastic substrate, creating a seamless, "no-edge" look that is resistant to peeling. This technique is especially effective for flat or slightly curved surfaces on items like promotional mugs, lunchboxes, or tech accessories, giving them a premium, retail-ready appearance.

Elevate Your Promotional Giveaway

Your brand deserves more than a "cheap" giveaway. Discover how our advanced printing and molding techniques add premium retail value to your high-volume merchandise.

Explore Rapid Prototyping | See Character Engineering Services

Color-Match Precision in Dual-Material Parts

Our character engineering for toys team ensures that both the rigid and soft-touch components perfectly match the brand’s Pantone colors. By coordinating the pigments across different material types, we maintain a cohesive visual identity that reinforces the professional quality of the promotion. This attention to detail is what allows Unstoyppable to deliver "promotional" gear that fans are eager to collect and keep, rather than discard.

Vacuum Metalizing for Promotional "Hero" Items

For "Hero" promotional items—such as limited-edition cinema popcorn buckets or VIP event giveaways—we offer vacuum metalizing for licensed goods. This process applies a thin, mirror-like metallic coating to plastic parts, giving them the appearance of real chrome, gold, or silver. This high-end finish is achieved in a controlled vacuum chamber, ensuring a flawless surface that catches the light and the consumer's eye. When combined with pad printing for licensed toys, we can create stunning, multi-textured effects that stand out in a crowded retail or event environment.

The Creative Advantage: At Unstoyppable, we prove that "promotional" does not have to mean "low quality." By integrating rapid 3D promotional prototypes, high-speed 6-color pad printing, and premium overmolding, we create merchandise that honors the IP and delights the fan. Partner with us to create a high-impact visual identity for your next global campaign.

Guarding the Brand:

2026 Compliance and Digital Product Passports for Promotions

In the high-stakes world of global marketing, a promotional giveaway is more than a free gift; it is a legal extension of a multi-billion dollar intellectual property. For agencies representing major studios, the "Final Gate" of production is where the greatest risks reside. At Unstoyppable, we act as a comprehensive "Compliance Shield," ensuring that every unit in a million-piece run meets the rigorous safety and ethical benchmarks of 2026. As a Disney FAMA certified manufacturer, we understand that the cost of a non-compliant item far exceeds the price of production—it encompasses the risk of global recalls, legal litigation, and irreversible damage to brand equity. We provide compliance-safe promotional products that undergo the same stringent chemical and mechanical validation as high-end retail toys, backed by the latest in digital product passport toys technology for 2026.

Avoiding Social and Ethical Scandals

A brand’s reputation is only as strong as the weakest link in its supply chain. Working with an ethical supply chain China is the only way to ensure that promotional items are not tainted by labor violations. Unstoyppable provides total visibility into our manufacturing network, ensuring that every facility adheres to fair wage practices and safe working conditions. This ethical rigor is essential for maintaining the "Brand Health" that major entertainment conglomerates require for their global ambassadors.

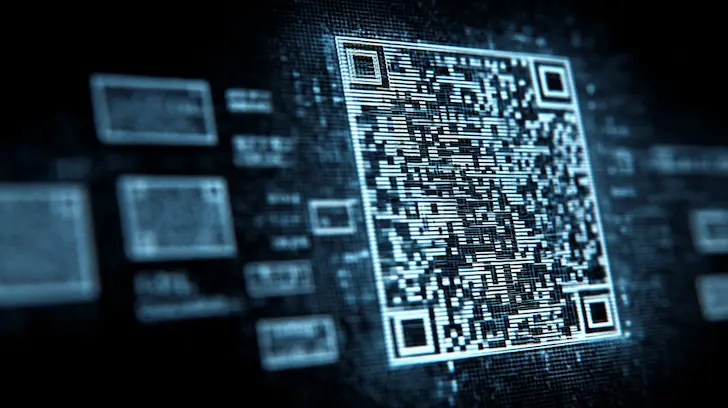

2026 Digital Product Passport (DPP):

Traceability for the End-Consumer

The 2026 legislative environment has introduced the Digital Product Passport (DPP) as a mandatory requirement for products entering the EU and North American markets. Unstoyppable has pioneered the integration of this technology into high-volume toy production China, turning a regulatory hurdle into a brand-building opportunity.

Protect Your Brand's Reputation

In 2026, compliance is your most valuable asset. Partner with a FAMA-certified manufacturer that masters 2026 safety standards and digital transparency.

Disney FAMA & NBCU Compliance:

The Gold Standard of Auditing

For agencies working with the world's leading media franchises, a Disney FAMA certified manufacturer is often the only acceptable partner. Unstoyppable operates within a strictly monitored ecosystem that meets the highest social labor standards in the world.

Navigating Strict Social Labor Audits

Our BSCI & Sedex audited toy factory network is subject to unannounced inspections, ensuring that every unit of your movie tie-in merchandise is produced ethically. We manage the complex "Facility and Merchandise Authorization" (FAMA) process for our clients, ensuring that all production sites are pre-approved by the licensor. This proactive management of ethical supply chain China protocols allows marketing agencies to focus on their creative strategy, knowing that the physical production is being handled by a partner who understands the legal gravity of IP-based manufacturing.

Bio-Plastics and Biodegradable Additives

We specialize in the use of bio-based polymers and biodegradable additives in the high-volume toy production China process. These materials allow our phthalate-free promotional toys to break down safely in industrial compost facilities or landfills at the end of their lifecycle. For 2026 "Zero-Waste" mandates, we offer corn-starch based PLA and recycled ocean plastics that maintain the premium "hand-feel" of traditional materials while telling a powerful story of environmental responsibility.

Optimized Packaging for Promotional GWP

Sustainability extends to the delivery. We design retail-ready packaging manufacturer solutions that minimize plastic use and maximize space efficiency for shipping. This "Eco-Engineering" reduces the carbon footprint of your custom promotional giveaways and lowers the overall landed cost, providing a double-win for both the environment and your campaign budget.