Beating the Clock:

The Strategic Calendar for Seasonal Toy Manufacturing

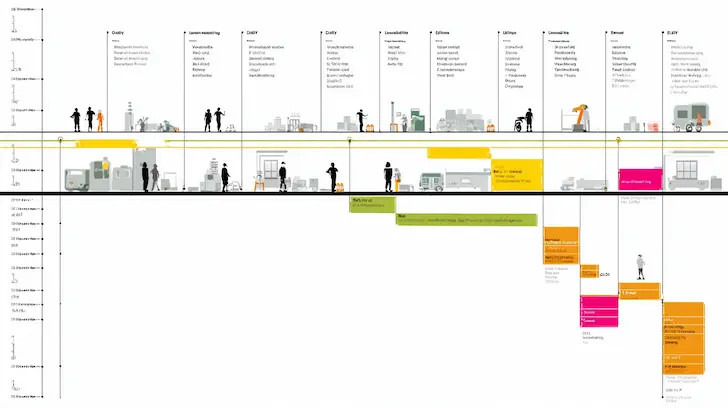

In the high-stakes world of global retail, time is the most valuable currency. For brand owners and license holders, understanding the seasonal manufacturing lead time is the difference between a sold-out holiday hit and a missed opportunity. While consumers see the finished product on shelves in November, the reality of a successful launch is that a "Christmas Toy" begins its journey nearly a year in advance. At Unstoyppable, we view holiday toy production timeline management as a strategic discipline. By mastering the macro-calendar of the China supply chain, we help our partners navigate the complexities of peak demand, material shortages, and international holidays. A proactive toy production calendar ensures that every milestone—from the first digital sculpt to the final shipping container—is hit with precision, providing the stability needed to dominate the Q4 retail season.

Q1:

The Creative and Engineering Foundation

January through March is dedicated to character engineering for toys and initial prototyping. This is the period where the style guide is translated into manufacturable geometry. Because this phase coincides with the aftermath of Chinese New Year factory shutdowns, early engagement is essential. Successful brands use this time to finalize the "Golden Sample," ensuring that all aesthetic and safety hurdles are cleared before the factory floor enters its busiest season. Setting the technical benchmark in Q1 provides a "Clear Path" for the high-volume months ahead.

Q2:

Tooling, Molds, and Safety Validation

April through June is the "Industrialization" phase. During these months, the focus shifts to mold development and injection tooling. Creating high-fidelity steel molds takes approximately 45 to 60 days. This period also includes the critical safety testing phase. By securing lab certifications in Q2, you ensure that any necessary engineering adjustments can be made without threatening the final delivery date. This is where seasonal manufacturing lead time planning pays the highest dividends, as it prevents the "Panic Re-Engineering" that often occurs when testing is left too late.

The Strategic Importance of Pre-CNY Shipping

Managing Chinese New Year factory shutdowns requires more than just noting the date on a calendar. It requires an understanding of the "Labor Migration" that occurs. Workers often leave factories a week early, and some do not return until a week after the official holiday. This creates a massive "Pre-CNY Rush" where production capacity is at a premium. At Unstoyppable, we recommend that all prototypes intended for spring launches be finalized and "Tooling-Ready" at least six weeks before the holiday. This ensures your project is at the front of the queue when the machines start spinning again, effectively bypassing the post-holiday backlog.

Mitigating the "Post-Holiday Quality Fade"

When factories reopen, there is often a period of recalibration. New staff may be hired, and machines require maintenance. Our holiday toy production timeline management includes a "Post-CNY Audit" to ensure that the quality of your licensed merchandise production remains consistent with the pre-holiday samples. By maintaining a constant presence on the factory floor, we ensure that the transition back to full capacity is seamless and that your seasonal manufacturing lead time remains intact.

Don’t Let the Calendar Dictate Your Success

The best time to plan for the holiday season was yesterday; the second best time is today. Secure your Q4 production slot with our strategic planning experts.

See the Full Manufacturing Process | Explore Risk Mitigation Strategies

Coordinating with Movie and Media Launches

For toys tied to a specific theatrical release or media event, the deadline is non-negotiable. Missing a movie launch window can reduce sales by up to 70%. We specialize in "Day-and-Date" fulfillment, where we coordinate the seasonal manufacturing lead time with the studio's promotional calendar. By leveraging our ERP production tracking system, we provide brand managers with real-time updates, ensuring that every stakeholder is aligned on the countdown to the premiere.

Golden Sample Deadlines:

The April Milestone

In the world of seasonal manufacturing lead time, the "Golden Sample" is the point of no return. This is the final, licensor-approved version of the toy that serves as the blueprint for mass production.

Strategic Lead Time Insight: In seasonal manufacturing, being "on time" is the same as being "late." The winners of the holiday season are those who treat February with the same urgency as December. By mastering the toy production calendar and respecting the Chinese New Year factor, you turn time into a competitive advantage. We manage the clock, so you can focus on the sales.

Maintaining High Fidelity Under Pressure:

Capacity and Quality Control

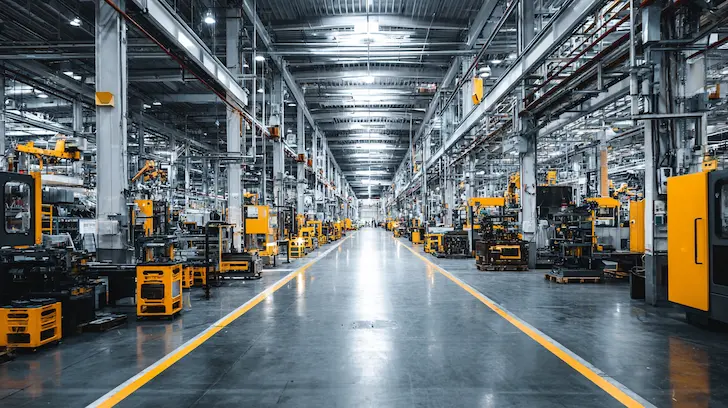

As the global toy industry moves toward the third quarter, the manufacturing landscape in China undergoes a dramatic shift. Every tier-one facility reaches 100% capacity, and the demand for skilled labor and raw materials reaches its zenith. During this intense period, the risk of "Quality Fade"—the subtle degradation of product standards to meet delivery deadlines—becomes a primary concern for brand owners. At Unstoyppable, we define peak season toy quality control as a non-negotiable standard. We utilize a combination of priority production scheduling and rigid oversight to ensure that licensed merchandise production maintains its "Golden Sample" excellence, even when the factory floor is under maximum pressure. Our approach is built on the principle that speed is a requirement, but safety is an absolute; therefore, we implement robust systems to ensure your brand’s reputation is protected during the most profitable months of the year.

Priority Line Booking:

Securing Your Manufacturing Window

In a saturated market, factory capacity management China is about more than just finding a manufacturer; it is about holding your ground. Unstoyppable leverages its long-term relationships within an audited factory network to provide our clients with "Priority Line Status."

The Power of Locked-In Production Windows

While many trading companies struggle to find space during the Q3 rush, we operate on a "Reserved Capacity" model. Because we provide our partner factories with consistent, year-round volume, we are able to secure "locked-in" production windows for our seasonal clients. This priority production scheduling ensures that your licensed merchandise production starts on the exact date promised, bypassing the delays that often plague unmanaged supply chains. By securing these windows months in advance, we provide the operational stability needed for scaling production for movie launches and global holiday campaigns.

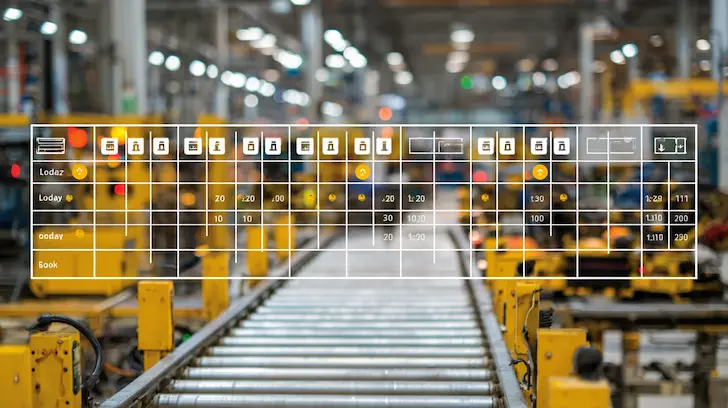

AQL Inspection:

The Rigid Guardrail

Our AQL inspection in toy manufacturing remains the final word on quality. Regardless of the seasonal pressure, our Acceptable Quality Levels do not move. We perform multi-stage inspections, from "Initial Production Checks" to "During Production Inspections" (DUPRO). By catching minor deviations in paint registration or joint tension early, we prevent the "Quality Fade" that can occur during high-volume licensed merchandise production. This rigorous seasonal toy quality control ensures that every unit in the container meets the high standards of the original approved prototype.

Automated Quality Verification

To support our human inspectors, we utilize automated toy safety testing equipment that provides objective, data-driven results. In 2026, we have integrated AI-driven visual inspection systems that can detect surface defects at speeds impossible for the human eye. This allows us to maintain scaling production for movie launches without sacrificing the intricate details that fans demand. By blending technology with traditional oversight, we ensure a "Zero Defect" mentality is maintained throughout the peak season.

Scale Your Seasonal Volume Without Quality Risks

Protect your brand from "Quality Fade" during the peak season rush. Partner with the experts in factory capacity management China.

View Our Audited Factory Network | Explore Our Quality Control Standards

Securing Electronics for "Smart" Toys

In 2026, the supply chain for specialized ICs (Integrated Circuits) used in interactive toys remains competitive. Through our early procurement strategy, we secure these components during the "off-peak" months of Q1 and Q2. This foresight is what allows us to maintain a stable seasonal toy quality control process, as we are never forced to use "alternative" components that might fail safety or functional testing.

The Movie Launch Pivot:

Secrecy Meets Scalability

Scaling production for movie launches requires a unique blend of extreme security and extreme speed. These "Day-and-Date" releases have zero margin for error; if the toy isn't on the shelf when the movie opens, the commercial opportunity is lost.

Capacity Resilience Insight: Peak season success is not about working harder; it is about planning smarter. By securing priority production scheduling and maintaining a rigid AQL inspection in toy manufacturing, you ensure that your brand stands out for its quality while others are struggling with delays. At Unstoyppable, we don't just find capacity; we create it.

From Factory Gate to Retail Shelf:

Navigating the Seasonal Logistics Bottleneck

The final "Sprint" of the seasonal manufacturing cycle is where the most meticulous production planning meets the reality of global trade. In the world of toy manufacturing logistics, the months of September and October are the most challenging, as thousands of brands compete for limited vessel space and container equipment. Success during this window is defined by "The Clean Arrival"—the ability to move goods from a China-based factory gate to a Western retail shelf without a single day of unnecessary delay. At Unstoyppable, we treat global distribution for licensed products as a precision science. We navigate the complexities of peak season shipping surcharges and port congestion by implementing a proactive logistical framework that prioritizes "Clearance Readiness" and "Landed Cost Optimization." When your seasonal window is only a few weeks long, every hour saved in transit is a direct contribution to your bottom line.

Ocean Freight Realities:

Managing Port Congestion and Transit Times

Ocean freight remains the backbone of global distribution for licensed products, but the peak season requires a sophisticated understanding of maritime dynamics to avoid the "September Stall."

Overcoming Port Congestion and "Slow Steaming"

As the holiday rush intensifies, major ports in both China and the West experience significant congestion. Carriers often engage in "Slow Steaming"—the practice of reducing vessel speed to save fuel—which can add 5 to 7 days to a transpacific voyage. We counteract these toy manufacturing logistics risks by booking space on "Premium Express" strings that guarantee faster transit times and priority berthing. By selecting carriers with direct-to-rail connections at the destination port, we ensure your licensed merchandise production bypasses the truck-chassis shortages that often paralyze coastal terminals during October.

When to Deploy the Air-Freight Strategy

If a production approval delay occurs in the toy production calendar, or if a specific SKU becomes a viral "must-have" hit, air-freight serves as the "Emergency Exit." While the per-unit cost is higher, we utilize consolidated air-freight shipments to deliver "Hero SKUs" to key retailers. This ensures that even if the bulk of the shipment is at sea, your brand maintains its retail presence. This hybrid approach to toy manufacturing logistics allows for a "Triumphant Launch" while the rest of the inventory follows via sea, balancing budget with market availability.

Optimizing Air-Palletization for High-Density Toys

To keep costs manageable, our retail-ready packaging manufacturer team optimizes the "Volumetric Weight" of the shipping cartons. By reducing air-gap space within the packaging, we fit more units per air-pallet. This meticulous attention to detail is a core component of landed cost optimization, making air-freight a viable tactical option for high-value licensed figures and electronic toys during the peak season sprint.

Secure Your Containers Before the Rush Begins

Don't get stranded at the port. Partner with our toy manufacturing logistics experts to plan your comprehensive seasonal fulfillment strategy today.

Explore Global Logistics Solutions | Learn About Global Distribution

Managing Peak Season Shipping Surcharges

In 2026, peak season shipping surcharges (PSS) are a reality of the September-October window. We help our clients manage these costs through early-bird rate lock-ins. By committing to seasonal volumes in Q1, we negotiate "All-In" rates that protect you from the volatile spot market. This is a vital part of landed cost optimization, ensuring that your profit margins remain intact even when global shipping prices fluctuate.

Fulfillment Speed:

Factory-Level Retail Readiness

To achieve maximum speed during the holiday window, we shift the "Fulfillment Burden" from the domestic 3PL to the China-based factory.

Seasonal Manufacturing Logistics FAQ

When is the latest I can start production for a Christmas retail launch?

How does Chinese New Year affect my toy samples and prototypes?

What are 'Peak Season Surcharges' and how can I avoid them?

How do you handle production surges for unexpected viral hits?

The Triumphant Arrival: A successful seasonal launch is not an accident; it is the result of logistical mastery. By navigating the peak season shipping surcharges and port congestion with a "Paperwork Fortress," Unstoyppable ensures your products arrive on time, every time. We bridge the gap between the factory gate and the fan's hands.