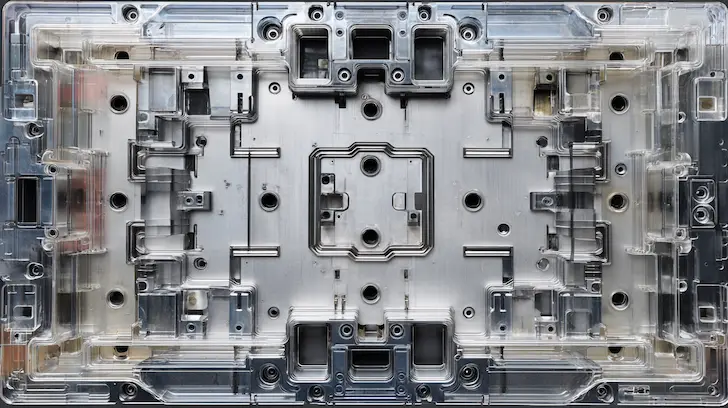

Engineering for Durability:

Identifying and Avoiding Physical Production Failures

In the competitive landscape of the global toy market, the physical integrity of a product is the most visible indicator of brand quality. Common failures in toy production often stem from a fundamental disconnect between aesthetic design and industrial engineering. When a toy fails structurally, it represents more than just a damaged unit; it signifies a breakdown in the toy material engineering process that can lead to costly recalls and irreparable damage to a brand's reputation. At Unstoyppable, we approach manufacturing through the lens of failure prevention. By analyzing the "Science of Failure," we identify potential toy structural defects during the pre-production phase, ensuring that every injection molded toy manufacturer in our network adheres to the highest mechanical standards. Engineering for durability is a proactive discipline that transforms a fragile concept into a resilient, retail-ready reality.

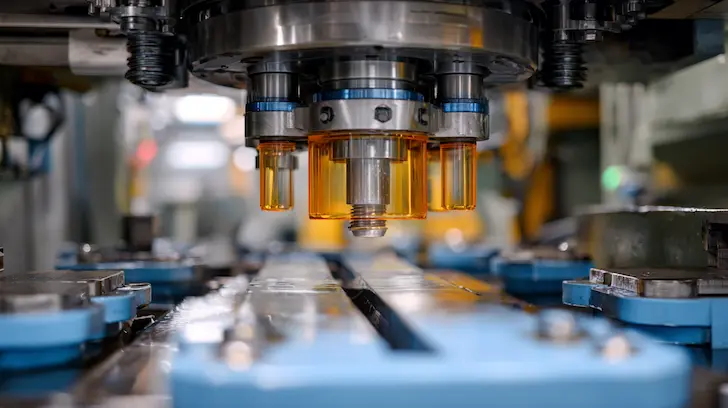

Improper Resin Drying and Molecular Degradation

Many high-performance resins, such as Nylon or ABS, are hygroscopic, meaning they absorb moisture from the air. If an injection molded toy manufacturer fails to utilize industrial-grade desiccant dryers, the moisture turns to steam during the heating process. This causes a chemical reaction called hydrolysis, which breaks the polymer chains and results in a structurally compromised, brittle part. We prevent this by enforcing strict material handling protocols, ensuring all resins are dried to the exact parts-per-million (PPM) moisture content specified in our toy material engineering Master File.

The Risks of Excessive "Regrind" Usage

While recycling excess plastic (regrind) is an important part of sustainable manufacturing, the over-use of recycled material is a leading cause of toy structural defects. Each time plastic is melted, its molecular bonds weaken. A high percentage of regrind leads to a significant drop in impact resistance. We maintain 100% transparency in our material ratios, ensuring that the use of regrind is strictly limited and monitored. This ensures that the structural "Toughness" of the toy remains consistent across the entire production run, maintaining the safety standards expected of a professional injection molded toy manufacturer.

Managing Wall Thickness to Prevent Sink Marks

Sink marks—unsightly depressions on the surface of a toy—are caused by localized shrinkage in thick sections of plastic. These are often the result of mold design errors where the transition between thick and thin walls is too abrupt. Through rigorous toy material engineering, we implement "coring out" techniques to maintain uniform wall thickness. This not only eliminates sink marks but also reduces material waste and speeds up the production cycle in automated toy manufacturing China facilities, creating a win-win for both quality and cost-efficiency.

Don't Let Structural Flaws Break Your Brand

A single engineering oversight can lead to a global recall. Request a professional technical review of your toy's engineering blueprints today to ensure a flawless launch.

Structural Reinforcement Through Geometry

Where weld lines are unavoidable, we integrate structural reinforcements such as internal ribs or gussets. By reinforcing the internal architecture of the part, we ensure that the toy passes the high-energy "Drop Tests" required by international safety standards. This attention to the "Invisible" details of the injection molded toy manufacturer process is what separates Unstoyppable from standard suppliers.

Stress Whitening:

Solving Durometer and Flex Issues

Stress whitening occurs when plastic is bent or stressed beyond its elastic limit, causing the polymer chains to reorganize and turn white. This is a classic example of common failures in toy production for articulated figures or toys with "living hinges."

Expert Conclusion: Physical defects are not inevitable; they are the result of unmanaged variables. By mastering the toy material engineering and mold development and injection tooling phases, Unstoyppable ensures that your product is built to last. We solve the engineering problems before they reach the factory floor.

Protecting the Likeness:

Preventing Aesthetic Deviations and IP Infidelity

In the world of high-stakes licensing, a character's likeness is its most valuable asset. The "Off-Model" crisis—where a physical product fails to capture the essence of the digital or animated original—is one of the most damaging common failures in toy production. For a passionate fan base, a superhero with the wrong eye shape or a cartoon character with a slightly off-hue skin tone is immediately recognizable as an inferior product. This lack of brand integrity in manufacturing doesn't just result in poor sales; it can lead to the termination of licensing agreements. At Unstoyppable, we view character product manufacturing as an exercise in high-fidelity replication. We implement licensed toy quality control measures that treat every millimeter of a character’s face as a critical dimension, ensuring that the transition from 2D art to 3D reality is executed with absolute fidelity to the source material.

The "Dead Eye" Syndrome:

Mastering Pad Printing Precision

The eyes are the "Soul" of the character. One of the most frequent aesthetic pad printing defects is poor registration, which leads to what industry insiders call "Dead Eye" syndrome—where the pupils are misaligned, making the character look vacant or "off-model."

Registration Accuracy and Multi-Hit Printing

In character product manufacturing, eyes often require five or more separate "hits" of color (the white, the iris, the pupil, the catch-light, and the eyeliner). If the jig holding the toy moves by even 0.1mm between these hits, the entire expression is ruined. We utilize high-precision pad printing for toys equipment with micro-adjustment capabilities. By using custom-machined nesting fixtures that lock the part into a fixed coordinate system, we ensure that every layer of ink is perfectly registered. This precision prevents off-model toy production and ensures the character’s personality shines through in every unit.

Scientific Pantone Matching and Light Box Verification

To prevent off-model toy production caused by color variance, we move beyond subjective visual checks. We utilize spectrophotometers to measure color at a molecular level, ensuring it stays within a strict "Delta E" tolerance from the approved Pantone reference. Our character product manufacturing process involves verifying samples under standardized lighting conditions (D65 light boxes) to account for metamerism—the phenomenon where colors look different under different light sources. This rigorous Pantone matching ensures that whether a fan buys a toy in London or Los Angeles, the colors are identical.

Resin Pigment Stability

Consistency starts with the raw material. We avoid the common failures in toy production associated with manual pigment mixing. Instead, we use pre-colored "Compounded Resins" where the color is integrated at the pellet level by the material supplier. This ensures that the color is consistent through the entire thickness of the plastic, preventing the "faded" look often seen in lower-quality licensed merchandise manufacturer outputs.

Ensure Your Characters Look Perfect Every Single Time

Don't let "off-model" defects ruin your brand's reputation. Partner with Unstoyppable to maintain 100% IP fidelity through our industry-leading quality control systems.

Explore Character Production Excellence | See the Asset Translation Process

Mold Maintenance and Cleaning Protocols

Even the best steel can suffer from "mold fouling"—the buildup of gases and residues that fill in fine textures. Our licensed toy quality control includes mandatory mold-cleaning intervals and ultrasonic cleaning of the inserts. This proactive maintenance ensures that the character asset translation remains high-definition throughout the entire licensed merchandise production lifecycle.

Secondary Process Failure:

Durability of the Aesthetic

The "Off-Model" crisis can also happen *after* the product leaves the factory if secondary finishes like flocking, electroplating, or "soft-touch" coatings begin to peel or flake off.

Brand Steward's Note: In the world of collectibles and licensed toys, the likeness is the product. By mastering pad printing for toys, Pantone matching, and high-fidelity tooling, we eliminate off-model toy production at the source. We don't just manufacture toys; we protect icons.

Navigating the Compliance Minefield:

Avoiding Customs Seizures and Safety Recalls

The transition from the factory floor to the global marketplace is governed by a complex web of legal and safety mandates. Licensed merchandise production failures in the realm of compliance are often the most devastating, as they do not merely result in a defective product, but in the total blockade of inventory at international borders. A single missing document or a minor chemical variance can lead to toy safety compliance failures that trigger mandatory recalls, heavy fines, and the destruction of thousands of units of inventory. At Unstoyppable, we recognize that logistical success is built on "Bulletproof Documentation." We ensure that every shipment is backed by verified certifications, protecting your investment from the catastrophic risks of customs seizures and retail rejection. In 2026, compliance is not an optional extra; it is the fundamental prerequisite for market entry.

The FAMA Lapse:

Preventing Administrative Disaster

For brands operating under the Disney umbrella, the Facility and Merchandise Authorization (FAMA) is the primary legal document that permits production. One of the most severe licensed merchandise production failures occurs when a factory’s FAMA status is neglected.

Maintaining Active Authorization Status

A factory must maintain an "Active" status in the Disney ILS (International Labor Standards) system to produce authorized goods. A Disney FAMA can be revoked or expire if the facility fails a social compliance audit (like BSCI or Sedex) or fails to submit timely paperwork. Manufacturing in an unauthorized facility is a breach of contract that allows customs authorities to seize and destroy the merchandise as counterfeit. We prevent this through continuous monitoring of our factory network’s authorization dates. By verifying the FAMA status before every production run, we provide the administrative security required for high-stakes character product manufacturing.

Preventing Phthalate and Heavy Metal Transfer

If an injection molding machine was previously used with low-grade plastics containing restricted phthalates or lead-based colorants, microscopic residues can migrate into your high-end licensed toy. This leads to licensed merchandise production failures during third-party toy lab testing. We mitigate this risk by partnering with specialized toy factories that maintain dedicated machinery for compliant materials. Our toy quality and safety compliance protocols include "Purging Audits," ensuring that machines are chemically cleaned before your production run begins. This level of oversight ensures that your products remain 100% compliant with REACH and CPSIA standards.

Packaging Mismatches:

Meeting 2026 Retail Standards

The "Border Blockade" is often caused by the smallest details on the exterior of a box. Packaging that fails to meet the specific requirements of the destination country or the retailer is a leading cause of inventory delays.

Secure Your Supply Chain Against Common Failures

A single compliance error can stop your business in its tracks. Partner with Unstoyppable to treat safety and documentation as a competitive advantage in the global market.

Implementing Independent AQL Inspection in Toy Manufacturing

The Acceptance Quality Limit (AQL) is the statistical threshold for defects. When an AQL inspection in toy manufacturing is performed by an independent third party, it provides an objective view of the shipment's quality. We utilize "Final Random Inspections" to check for everything from paint scuffs to mechanical functionality. By catching a 3% defect rate at the factory, we prevent a 100% rejection rate at the retail warehouse. This independent validation is the "Shield" that protects your brand’s reputation and your bottom line.

Transparency Through ERP Production Tracking

To further eliminate the AQL blindspot, our ERP production tracking system provides real-time data on scrap rates and inspection results. This transparency ensures that any spike in defects is addressed mid-production, rather than being discovered after the goods have already been loaded into a shipping container. We replace guesswork with data, ensuring your global distribution for licensed products is based on verified quality.

Compliance and Logistical FAQ

What is the most common reason for a toy to be seized at customs?

How can I tell if a factory is using "regrind" plastic without my permission?

What happens if my production run fails an AQL inspection?

How does Unstoyppable prevent "Ghost Factory" subcontracting?

Final Logistical Insight: Compliance is the ultimate insurance policy for your brand. By eliminating the AQL blindspot and securing your Disney FAMA documentation, Unstoyppable ensures that your products move swiftly across borders and into the hands of your fans. We deliver security, not just shipments.