Vinyl Toy Manufacturer:

Mastering the Rotocasting Process for Designer Art

In the world of high-concept intellectual property and urban art, the physical medium is just as vital as the character design itself. As a premier vinyl toy manufacturer, Unstoyppable specializes in the sophisticated art of rotational molding—a process that captures the soul of "urban vinyl" and elevates it to a professional, retail-ready standard. Unlike standard plastic production, designer vinyl toy production is a rhythmic interplay of heat, motion, and liquid science. We empower artists and media franchises to create figures with that unmistakable hollow-body feel, iconic soft-touch texture, and structural lightness that has defined the designer toy movement for decades. By choosing our custom art toys China services, you are accessing an engineering heritage that respects the organic curves and complex volumes of modern character design.

The Dynamics of Rotational Heat

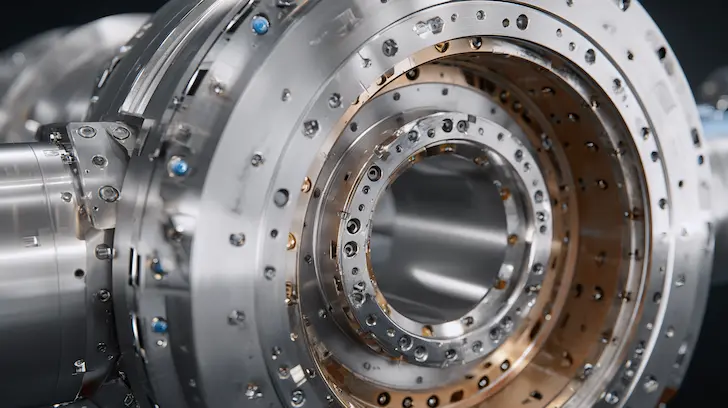

Our rotational molding toys China facilities utilize precision-timed machinery that rotates the molds on two axes simultaneously. As the mold spins within a high-temperature oven, the liquid plastisol is flung against the interior walls by centrifugal force, gelling into a uniform layer. This 2026 approach ensures that every crevice of the character’s geometry—from the tip of an ear to the fold of a sneaker—is perfectly captured. The result is a seamless, hollow figure that possesses an internal structural integrity far superior to traditional solid-molded items. This lightness is particularly beneficial for large-scale designer pieces, reducing shipping costs and allowing for easier shelf placement for fans.

Controlled Cooling and Demolding

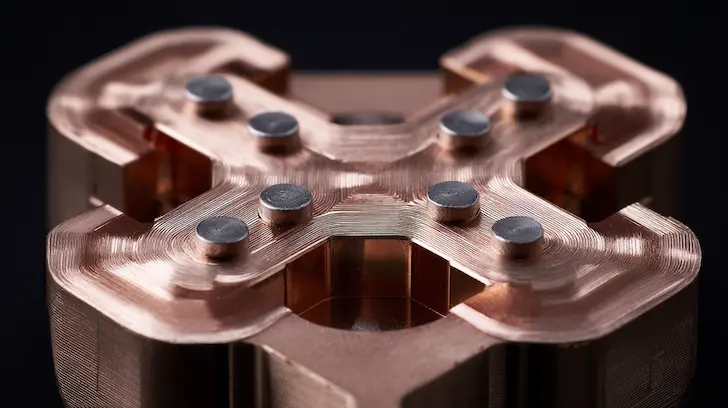

Success in designer vinyl toy production depends on the cooling phase. Once the desired thickness is achieved, the molds are transferred to a cooling station where the vinyl reaches its final, semi-rigid state. Our master technicians then perform "hot demolding," expertly extracting the warm, flexible vinyl from the copper tool. This flexibility during the demolding process is what allows for the extreme undercuts and "chunky" proportions that define the aesthetic of custom art toys China, which would be impossible to release from a rigid steel injection mold.

Handling Complex Undercuts

Because the vinyl is demolded while it is still warm and pliable, we can engineer designs with "illegal" geometries—undercuts and overhanging elements that would "trap" a part in a standard steel mold. This freedom allows for the radical, exaggerated proportions seen in high-end character design. By leveraging rotational molding toys China, we remove the technical barriers between your 3D vision and the physical product, ensuring the character’s silhouette remains exactly as intended by the creator.

Transform Your Art into a Cult Classic

Harness the heritage of urban vinyl with our specialized rotocasting and designer engineering services. Let's build a collectible that resonates with your fans.

Pigment Stability and Translucency

Our material engineers can adjust the opacity and "glow" of the vinyl at the molecular level. For designer vinyl toy production, we offer everything from opaque, solid-color "blank" bases to semi-translucent "jelly" effects and vibrant, neon-saturated pigments. Because the color is mixed directly into the liquid plastisol before molding, the base color of the figure is incredibly deep and stable, providing a perfect foundation for secondary custom vinyl toy finishing and decoration.

Wall Thickness Precision:

The Architecture of the Hollow Body

A common pitfall in lower-tier rotational molding toys China is inconsistent wall thickness, which can lead to "thin spots" that collapse or "heavy spots" that warp the figure. Unstoyppable utilizes advanced thermal sensors and calibrated rotation speeds to ensure total structural equilibrium.

The Vinyl Specialist: Unstoyppable combines the artisanal touch of electroformed copper tooling with the precision of 2026 rotocasting technology. We don't just manufacture toys; we engineer tactile art that honors your IP's legacy. Partner with a vinyl toy manufacturer that understands the nuances of the designer toy industry.

Beyond the Surface:

Advanced Finishing for Custom Vinyl Figures

In the high-velocity world of designer toys and urban collectibles, the visual "pop" of a figure is what transforms a simple silhouette into a coveted art piece. As a premier vinyl toy manufacturer, Unstoyppable provides an elite suite of custom vinyl toy finishing services designed to captivate the eye and command attention on the retail shelf. In 2026, the collector market demands more than solid colors; it craves depth, texture, and rare visual effects. We bridge the gap between industrial production and artisanal mastery, utilizing cutting-edge decoration technologies that allow for hyper-detailed aesthetics on the soft, tactile surfaces of rotocast vinyl. Whether you are aiming for the nostalgic charm of classic Sofubi or the high-tech precision of modern streetwear-inspired toys, our finishing department ensures your IP is represented with vivid, enduring brilliance.

Complex Spray Masking:

The Secret to the "Designer Toy" Aesthetic

The hallmark of a high-end art toy is often the presence of soft gradients, subtle "blushes," and perfectly crisp lines that define different character features. We achieve this through the sophisticated use of spray-masked vinyl figures, a technique that requires both mechanical precision and hand-finished artistry.

Precision-Cut Copper Spray Masks

To ensure consistency across thousands of units, we utilize precision-cut copper masks that fit perfectly over the 3D contours of the vinyl figure. These masks act as "stencils" for our master airbrush artists, allowing them to apply complex paint applications—such as a character's rosy cheeks or the weathered shadows of a post-apocalyptic robot—with absolute repeatability. This level of collectible art toy decoration provides an organic, layered look that standard pad printing simply cannot replicate. By layering multiple mask passes, we can build complex color stories that give the figure a premium, hand-crafted feel while maintaining the scalability of mass production.

HTF Integration for Hyper-Detailed Graphics

We utilize ultra-thin, high-elasticity printing film that bonds molecularly with the vinyl surface. Unlike standard decals, this 2026-spec heat transfer film for toys stretches and flexes with the soft PVC, ensuring that the graphic never cracks or peels, even on articulated parts. This technology allows for the inclusion of photorealistic details, fine-line typography, and complex patterns that are essential for collectible art toy decoration in the modern era. It is the perfect solution for media franchises looking to reproduce complex character costumes with 100% accuracy from style guide to physical product.

Full-Wrap Pattern Consistency

Applying graphics to a 3D, rotocast surface requires expert engineering. Our team specializes in "wrap-around" film applications that minimize distortion, ensuring that a pattern remains consistent from the front to the back of the figure. This precision is a cornerstone of our custom vinyl toy finishing, allowing for a level of complexity that makes your product a standout piece in any collector's gallery.

Craft a Visual Masterpiece

Your brand deserves a finish that sparks a "must-have" reaction. Explore our advanced decorative films and specialty vinyl finishes to elevate your next release.

"Sofubi-Style" Translucency and Pearlescence

For collectors who appreciate the Japanese "Sofubi" heritage, we offer semi-translucent vinyl bases infused with pearlescent powders or metallic flakes. This creates a depth of color that seems to shift as the figure is turned in the light. This collectible art toy decoration technique is popular for "ghost" versions of characters or "elemental" variants (fire, ice, energy). Because the effect is "baked in" to the material, it is permanent and provides a high-quality, jewel-like appearance that appeals to premium art toy markets.

Flocking and Soft-Touch Coatings:

A Multi-Sensory Experience

The tactile nature of vinyl is its greatest strength. To enhance this, Unstoyppable offers secondary surface treatments that invite the consumer to touch and interact with the figure, increasing the emotional connection to the brand.

The Visual Edge: In the world of vinyl, the finish is the message. By combining precision spray masking, high-resolution HTF printing, and specialty material additives, Unstoyppable delivers a level of "shelf-pop" that drives sales and collector loyalty. Partner with a vinyl toy manufacturer that understands the intersection of art, trend, and technology.

Secure Vinyl Production:

2026 Safety Standards and Digital Traceability

In the evolving landscape of 2026, the integrity of a designer collectible is measured by its safety as much as its aesthetic. As a leading vinyl toy manufacturer, Unstoyppable recognizes that the modern collector and global brand manager require absolute certainty in the chemical purity and ethical origin of their products. We have transformed our secure IP manufacturing China protocols to address the rigorous demands of the "Designer Toy" era, ensuring that your intellectual property is protected from both physical counterfeiting and regulatory risk. By merging the artisanal heritage of rotocasting with the high-tech requirements of digital product passport toys, we provide a foundation of trust that allows your brand to thrive in international markets. Our commitment to ethical vinyl toy manufacturing ensures that every figure is a testament to quality, safety, and social responsibility.

Meeting the 2026 Mandates:

Phthalate and Lead-Free Excellence

Vinyl production has historically faced scrutiny regarding chemical composition. In 2026, global regulations have reached a new pinnacle of strictness, specifically targeting endocrine disruptors and heavy metals. Unstoyppable stays ahead of these curves by utilizing only the most advanced, phthalate-free vinyl toy production techniques.

EN71-3 Compliant Plastisol and Advanced Stabilizers

Our liquid PVC plastisol is a proprietary 2026-spec material that is 100% EN71-3 compliant plastisol. We have eliminated traditional heavy-metal stabilizers, replacing them with organic, calcium-zinc based alternatives that provide the same structural flexibility without the toxicity. This ensures that even the most delicate custom art toys China are safe for handling and display in any environment. Our rigorous testing protocols verify that lead, cadmium, and all banned phthalates are absent from our supply chain, providing a "Brand Safe" guarantee for media franchises and independent artists alike.

Laser-Etched Traceability and Data Matrix Integration

Every figure we produce can be equipped with a high-resolution, laser-etched Data Matrix code, typically located on the foot or base of the figure. This code serves as the portal to the item’s digital product passport toys. When scanned, fans can access a wealth of information, including the ethical vinyl toy manufacturing reports for the specific factory lot, chemical safety certifications, and a verified carbon footprint breakdown. This level of transparency transforms the consumer's relationship with the product, moving it from a simple purchase to a verifiable "Origin Story" of the character.

Verified Carbon Footprint and Sustainability Data

In 2026, fans value the environmental impact of their collections. Our DPP integration allows you to showcase the use of recycled content or bio-based additives in your soft vinyl figure manufacturing. Providing this data builds immense brand loyalty and positions your IP as a leader in the sustainable collectible movement, all while fulfilling the latest global trade requirements for secure IP manufacturing China.

Future-Proof Your Art

Don't let regulatory shifts or counterfeiters devalue your IP. Partner with a manufacturer that delivers 100% compliant, digitally-verifiable vinyl collectibles for the 2026 market.

Secure Tooling and "Master Mold" Destruction

IP security at Unstoyppable extends to our physical facility. We manage all rotational molding toys China copper tools with extreme oversight. For strictly limited runs, we offer certified mold destruction services once the production quota is met, ensuring that "unauthorized 11th-hour runs" never occur. This is a critical component of our ethical vinyl toy manufacturing promise to our high-end artist and studio partners.

Disney FAMA & Social Audits:

The Standard for Global Franchises

High-end "Art Toys" often exist in a niche market, but they are still subject to the global standards of the world's biggest brands. Unstoyppable maintains a network of Disney FAMA compliant factories in China to ensure your brand is always protected from social scandals.