Retail-Ready Packaging Manufacturer:

Where Brand Identity Meets Structural Integrity

In the competitive ecosystem of 2026 consumer electronics and toy aisles, the packaging is the "First Moment of Truth." It is the decisive bridge between a fan’s passion and a completed sale. As a premier retail-ready packaging manufacturer, Unstoyppable understands that a box is far more than a protective shell; it is a high-performance marketing tool that must satisfy three distinct masters simultaneously: the licensor’s brand equity, the retailer’s logistical requirements, and the consumer’s desire for a premium unboxing experience. By integrating licensed toy packaging design into our core manufacturing workflow, we ensure that your product arrives on the shelf with a visual impact that commands attention. Our window box manufacturing China facilities utilize state-of-the-art structural engineering to ensure that even the most delicate collectible figures are showcased in high-definition while remaining protected by a fortress of reinforced cardstock and non-toxic films.

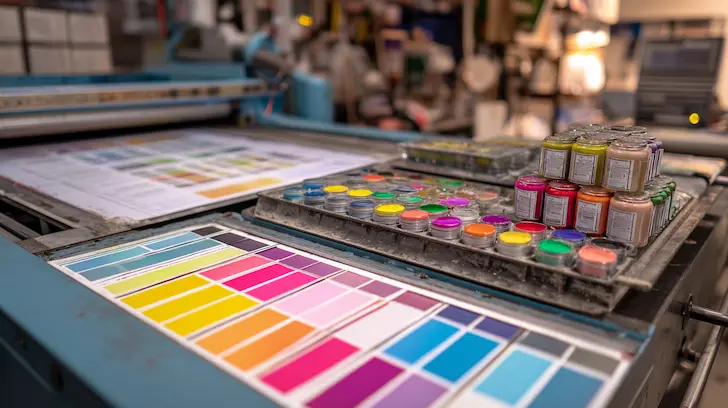

High-Fidelity Printing and Color Management

We utilize advanced offset lithography on 7-color Heidelberg presses to achieve a level of saturation and color accuracy that mirrors the digital source material. To maintain this vibrancy throughout the toy manufacturing logistics journey, we apply specialized printing film for toy materials that prevents oxidation and fading. This ensures that the "brand blue" or "heroic red" on your packaging remains consistent across millions of units, regardless of which audited factory network China location handles the final assembly. By mastering this translation, we provide big-box retail compliant packaging that honors the IP owner's vision while maximizing retail "pop."

Digital-to-Physical Asset Verification

Our engineering team works in tandem with our character product manufacturing specialists to ensure the 3D product and the 2D packaging artwork are perfectly synchronized. We utilize digital proofing systems that simulate various retail lighting conditions—from the cool LEDs of a Target aisle to the warm halogens of a boutique hobby shop—ensuring that the licensed toy packaging design performs optimally in every environment. This scientific approach to aesthetics is what makes us a leading partner for OEM licensed product manufacturing.

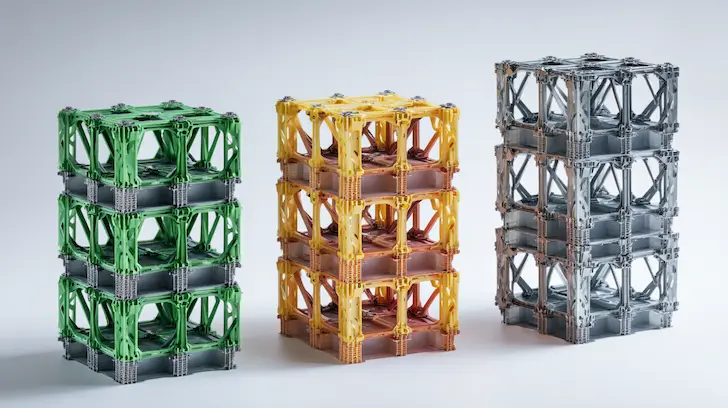

Structural Rigidity and Stackability

A window box is essentially a structural arch. Our retail-ready packaging manufacturer team uses CAD software to calculate the exact weight-bearing capacity of the box's "shoulders." Even with a large viewing window, we ensure the packaging can support the weight of a 10-high pallet stack. By integrating structural "ribs" and choosing high-density board, we produce big-box retail compliant packaging that remains crisp and upright, preventing the "shelf-wear" look that can devalue a premium collectible. This engineering ensures that your product is always presented in its best light, maintaining the "A-Grade" status required by major retailers.

Capture the Consumer's Eye & The Retailer's Approval

Packaging is the final frontier of product development. Contact our design team for a retail-ready packaging audit of your product line today.

Sustainable Toy Packaging Innovations

In 2026, sustainability is a core retail requirement. We offer sustainable toy packaging solutions that utilize FSC-certified paper, soy-based inks, and plastic-free alternatives to traditional blister trays. We help our clients transition to molded pulp inserts which provide the same "nesting" security as plastic while being 100% biodegradable. This commitment to the environment ensures your big-box retail compliant packaging meets the increasingly strict "Green Procurement" policies of retailers like Amazon and IKEA, future-proofing your brand's presence in the global market.

Retailer Specificity:

Mastering the Shelf-Ready Requirements

Every major retailer has a "Vendor Manual" that dictates the exact dimensions, labeling, and structural requirements for incoming goods. Our retail-ready packaging manufacturer expertise ensures you never face a compliance chargeback.

Technical Design Note: Effective packaging is a symphony of printing film for toy materials, window box manufacturing China expertise, and sustainable toy packaging innovation. At Unstoyppable, we don't just put your product in a box; we engineer a retail-ready asset that defends your IP and drives your bottom line. Make your first impression count with the world's most robust packaging engineering.

Precision Finishing:

High-Fidelity Printing and Protective Coatings

The manufacturing of high-end licensed packaging is an industrial discipline that demands zero-deviation from the original intellectual property. At Unstoyppable, custom toy box printing is treated with the same engineering rigor as the physical product itself. Our technical production phase is divided into high-speed lithographic processes and precision finishing, ensuring that every box serves as a premium billboard for your brand. By utilizing automated packaging assembly China systems, we maintain a level of consistency that is required for global retail distribution. In 2026, the complexity of character art requires advanced machinery that can reproduce billions of colors with surgical accuracy. From the application of anti-scratch lamination to the integration of structural internal trays, our production pipeline is optimized to deliver "Collector-Grade" quality at a mass-production scale. We ensure that the final packaging is a faithful physical representation of your digital style guide.

Advanced Printing Techniques:

Matching the Character Palette

Color drift is the enemy of brand equity. A character's skin tone or a superhero's suit must remain identical across millions of units to preserve the fan's trust. Our custom toy box printing centers utilize 7-color Heidelberg Speedmaster presses to achieve this absolute fidelity.

G7 Master Qualification and Spectral Accuracy

We implement the G7 Master Qualification across our audited factory network China, which means our printing processes are calibrated to maintain gray-scale balance and color consistency throughout the entire run. This is essential for licensed toy packaging design, where the "Character Colors" are legally protected assets. By using spectral color measurement, we ensure that the delta-E (the difference between the target color and the printed result) is kept to a near-imperceptible level. This level of custom toy box printing ensures that the character art on the box is as vibrant and accurate as the injection molded toy manufacturer output inside.

The Role of Matte and Gloss Lamination

We apply high-performance anti-scratch lamination to every retail unit. This specialized film serves as a transparent shield against "scuffing"—the micro-scratches that occur when boxes rub together during toy manufacturing logistics. Depending on the brand aesthetic, we offer soft-touch matte films for a premium, tactile feel or high-gloss films for a vibrant, energetic look. These films are chemically bonded to the board, ensuring they do not peel or bubble even when exposed to the humid conditions of international toy shipping. This protective layer is what maintains the "A-Grade" status of your big-box retail compliant packaging from the moment it leaves China until it is unboxed by the consumer.

Enhanced Durability for E-commerce

For brands focused on online retail, our anti-scratch lamination is formulated to withstand the additional handling involved in parcel delivery networks. This eliminates the need for excessive plastic over-wraps, contributing to our sustainable toy packaging goals while ensuring that the custom toy box printing remains pristine. By engineering the surface of the box to be resilient, we reduce return rates and increase customer satisfaction.

Elevate Your Product's Perceived Value

World-class toys deserve world-class finishing. Explore our library of spot UV finishing for toys, metallic foils, and anti-scratch lamination textures.

Anti-Counterfeit Systems and Hidden Security

IP protection is a pillar of the Unstoyppable philosophy. We integrate anti-counterfeit manufacturing systems directly into the printing run. This includes the application of holographic security stickers that are difficult to replicate, as well as hidden UV-fluorescent inks that are only visible under blacklight. For high-value licenses, we can also embed micro-perforations or unique serialized QR codes into the custom toy box printing. This provides an extra layer of IP security & factory compliance, ensuring that your fans always receive a genuine product.

Structural Molding:

Internal Trays and Nesting

The internal architecture of the box is as important as the exterior. We design custom inserts that "nest" the product, ensuring it remains centered and secure during transit.

Industrial Production Note: High-end packaging is the result of spectral color management, anti-scratch lamination, and precision structural molding. At Unstoyppable, we bridge the gap between artistic vision and industrial reality. Secure your brand's retail future with packaging that is as technically advanced as the product it holds.

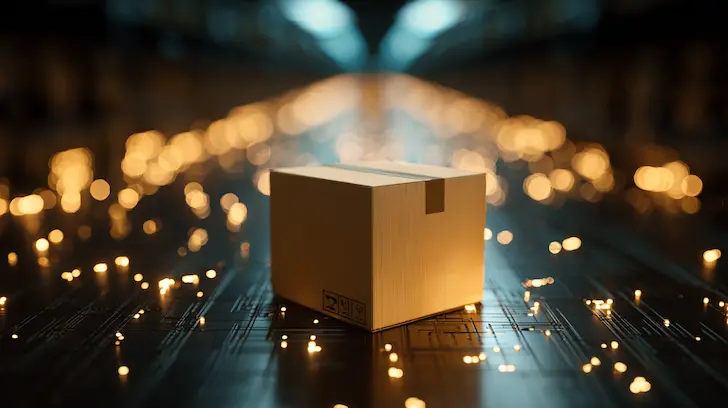

Logistical Readiness:

Barcoding, Compliance, and Distribution Protection

In the global supply chain of 2026, packaging serves as much more than a visual marketing tool; it is a vital piece of logistical infrastructure. At Unstoyppable, we ensure that every box is a high-functioning asset ready for the rigors of international toy shipping. As a retail-ready packaging manufacturer, our responsibility extends to the "Final Mile," where technical labeling and structural durability determine whether a product successfully enters a big-box distribution center or faces a costly rejection. By integrating GTIN / EAN barcode labeling and mandatory safety data directly into the structural design, we eliminate the friction between production and retail. Our logistics-optimized packaging design approach ensures that your goods are not only protected from the physical hazards of the ocean journey but are also digitally transparent and 100% compliant with the evolving US/EU toy export compliance landscape.

The Mandatory Data Layer:

Engineering Compliance into the Layout

Regulatory compliance is a non-negotiable component of licensed toy packaging design. Federal authorities and retail auditors view the packaging as the legal record of the product’s safety and origin.

Integrating CPSIA Tracking Labels and 16 CFR 1500 Warnings

Under CPSIA packaging requirements, specific data must be permanently visible and legible. Our design team integrates CPSIA tracking labels—including the manufacturer’s name, batch code, and date of production—into the "legal panel" of the box. We ensure that 16 CFR 1500 mandated warnings, such as choking hazard icons and age-grading statements, are placed with the correct font size and contrast ratios to pass third-party toy lab testing. By automating this data layer during the custom toy box printing phase, we provide a "Safe Harbor" for importers, ensuring that no unit hits US soil without the required legal disclosures. This meticulous attention to the federal toy safety mandates is a cornerstone of our retail-ready packaging manufacturer service.

Ensuring 100% Scan-Rate Accuracy

We implement a rigorous GTIN / EAN barcode labeling protocol where every batch is verified against ISO/IEC 15416 standards. Using high-resolution custom toy box printing techniques, we maintain the "Quiet Zones" and "Contrast Ratios" required for high-speed laser scanners at Walmart or Amazon distribution centers. This digital-physical alignment ensures that your licensed merchandise distribution flows smoothly through automated sorters without manual intervention. By treating the barcode as a technical component rather than a graphic element, we secure your position as a preferred vendor in the retail-ready licensed product production ecosystem.

Serialisation and Smart Packaging

For high-value collectibles and limited editions, our retail-ready packaging manufacturer capabilities include serialized QR codes and RFID integration. These tools provide digital supply chain visibility, allowing brand owners to track individual units and providing fans with a way to verify authenticity. This integration of anti-counterfeit manufacturing systems directly into the packaging layout adds an extra layer of IP security & factory compliance that modern fans and licensors demand.

Ship with Confidence: Optimize for Global Distribution

Logistics failure is the most expensive mistake in manufacturing. Ensure your packaging is 100% compliant and logistics-optimized for the global stage.

Eliminating "Corner Crush" and Shelf Wear

By using reinforced "B-Flute" corrugated master cartons and internal corner protectors, we prevent the "corner crush" that can make a product unsellable. Our logistics-ready packaging design ensures that the retail units inside remain perfectly upright and crisp, even if the outer shipping carton faces rough handling. This commitment to physical integrity is what allows Unstoyppable to maintain an industry-leading low damage rate for international toy shipping.

Sustainability Mandates:

2026 Eco-Compliance

Sustainability is no longer a choice; it is a retail requirement. We help our clients navigate sustainable packaging compliance without sacrificing protection or brand impact.