Retail Licensed Product Manufacturing:

Scaling Exclusive Collections for Global Shelves

In the high-velocity retail landscape of 2026, the ability to secure unique, high-demand inventory is the primary differentiator for global category managers. Retail licensed product manufacturing is the engine that drives this differentiation, allowing major retailers to move beyond generic offerings and into the realm of high-value, branded experiences. At Unstoyppable, we specialize in retail-ready toy sourcing that prioritizes the specific needs of big-box retailers, specialty chains, and digital marketplaces. We understand that a retail buyer’s success is measured by shelf velocity, margin health, and the exclusivity of the assortment. By partnering directly with our high-volume toy manufacturing infrastructure, retailers can bypass traditional middleman markups and secure private label licensed products that are engineered for both consumer appeal and logistical efficiency. Our strategic approach ensures that your shelves are stocked with retailer-exclusive merchandise production that cannot be found elsewhere, providing a compelling reason for consumers to choose your storefront over the competition.

Developing Unique SKUs for Brand Differentiation

Our team works closely with retail buyers to identify gaps in the current market. By utilizing custom licensed product development, we create unique variants, special edition colorways, or exclusive character bundles that are proprietary to your retail brand. These exclusive SKUs are vital for driving foot traffic into physical stores and increasing "add-to-cart" rates on e-commerce platforms. Because we manage the entire retail licensed product manufacturing pipeline, we can ensure that these exclusive designs remain strictly confidential until the launch date, protecting your competitive advantage and maximizing the impact of your marketing campaigns.

Building Long-Term Brand Equity via Private Labeling

For retailers looking to build their own internal brands, we offer private label licensed products. This allows you to leverage the immense pull of global IPs—such as major movie franchises or trending animation series—while housing them under your store-exclusive brand umbrella. This strategy is highly effective for 2026 retailers who want to control the customer experience and the price point. We provide the high-volume toy manufacturing capacity to ensure these private label lines are consistent, safe, and premium in quality, reinforcing your retailer's reputation for value and trend-right sourcing.

Engineering for Retail-Ready Unit Economics

Profitability is designed into the product from the prototype stage. We utilize design for mass production (DFM) to ensure that every toy is optimized for the lowest possible manufacturing cost without sacrificing the "hero" features that consumers love. Whether it is optimizing the weight for lower shipping costs or using injection molded toy manufacturer techniques that reduce assembly time, our goal is to improve your bottom line. We provide transparent cost breakdowns, allowing retail buyers to see exactly where their investment is going and how we are achieving royalty-margin optimization for their specific retail ecosystem.

Secure Your Retail Exclusives Today

Partner with a manufacturer that understands the pace and precision of global retail licensed product manufacturing.

Explore Retail-Ready Production | View Fulfillment Solutions

Agile Responses to Emerging Trends

While seasonal planning is critical, the ability to react to a "viral" toy trend is equally important. Our audited factory network China provides the agility needed to ramp up production for unplanned spikes in demand. If a specific private label licensed product begins to outperform expectations, we can trigger secondary production runs with shortened lead times. This responsiveness ensures that you capitalize on every revenue opportunity, maintaining high stock levels when the market is at its hottest.

Volume-Ready Infrastructure:

Handling the Scale of Global Retail

Scaling to meet the demands of a 1,000-store rollout requires more than just a factory; it requires a massive, studio-approved toy manufacturer infrastructure.

Retail Strategy Note: Retail licensed product manufacturing is about more than just making toys; it is about managing the complex intersection of IP, retail timelines, and margin protection. Through high-volume toy manufacturing and retailer-exclusive merchandise production, Unstoyppable provides the infrastructure you need to dominate the 2026 retail landscape. Let us handle the complexity while you focus on the sale.

Retailer-Ready Standards:

Technical Excellence and Compliance Integration

In the global marketplace of 2026, the "technical barrier to entry" for major retailers is higher than ever. To secure space on the shelves of giants like Walmart, Target, or Carrefour, retail-grade licensed merchandise must satisfy a dual mandate: it must meet the artistic expectations of the world’s leading studios while strictly adhering to the rigorous safety and ethical audits unique to each retail powerhouse. At Unstoyppable, we specialize in bridging this gap. Our mass-market toy engineering process is designed to ensure that every product is "Retailer-Ready" from the moment it is conceived. We provide the technical infrastructure and shelf-ready toy quality that allows retail category managers to bypass the typical friction of sourcing, ensuring that every SKU is pre-validated for global distribution. By integrating retailer safety compliance directly into our manufacturing DNA, we offer a seamless path to market for the world’s most ambitious retail collections.

Universal Safety Standards:

Engineering for Global Distribution

For retailers operating across multiple continents, inventory flexibility is vital. A product that is compliant in one region must be equally viable in another to prevent logistical bottlenecks. We solve this by engineering for the highest common denominator of safety.

Simultaneous ASTM, EN71, and CPSIA Validation

Every project under our retail licensed product manufacturing umbrella is developed to meet ASTM F963, EN71, and CPSIA standards simultaneously. This "Universal Compliance" approach allows retailers to move stock between North American and European distribution centers without fear of regulatory rejection. Our technical teams conduct rigorous chemical testing on all phthalate-free toy materials and perform mechanical stress tests on all injection molded toy manufacturer components. By providing a comprehensive "Technical File" for every product, we ensure that your retailer safety compliance documentation is always complete, satisfying the internal audit teams of even the most demanding global retailers.

Meet Every Retail Audit with Ease

Ensure your collections are 100% compliant and retail-ready. Explore our compliance-first manufacturing process today.

Engineering for "On-Shelf" Resilience

A damaged box or a broken accessory on the shelf is a lost sale for the retailer. We enhance the structural integrity of our products by using high-fidelity character moulding techniques that incorporate reinforced stress points in joints and appendages. We perform "Drop Tests" and "Compression Tests" on all retail-grade licensed merchandise to simulate the rough handling of high-traffic retail aisles. By delivering shelf-ready toy quality that remains intact, we significantly reduce return rates and the associated administrative costs for our retail partners. Every unit is engineered to be as durable as it is beautiful.

Longevity in High-Volume Play

Beyond the shelf, the product must perform in the hands of the consumer. Our high-fidelity character moulding process includes fatigue testing for articulated joints and abrasion resistance for all advanced printing for licensed toys. When a retailer stocks retail-grade licensed merchandise from Unstoyppable, they provide their customers with a product that lasts, which directly translates into higher customer satisfaction scores and repeat business. Quality is the most effective form of brand insurance for any 2026 retailer.

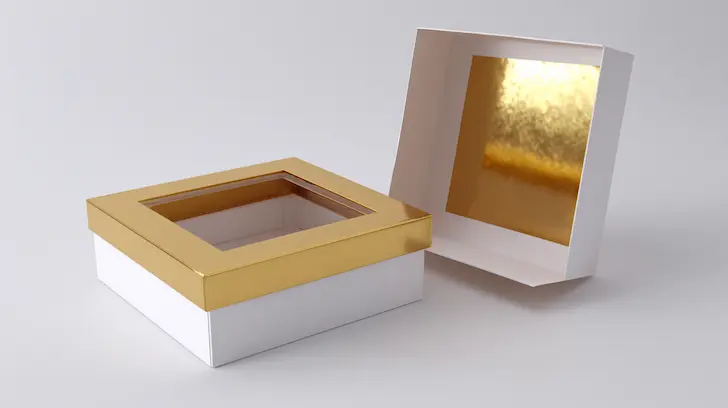

Packaging as a Quality Indicator

Retailers know that high-quality packaging signals a high-quality product. We utilize advanced printing for licensed products on our retail boxes, including specialty matte finishes, spot-UV, and reinforced window film that remains crystal clear. By providing retail-ready toy sourcing that includes premium, resilient packaging, we help retailers create a more prestigious shopping experience. This technical attention to detail ensures that your licensed collections are perceived as "Must-Have" items by consumers and retail category managers alike.

Technical Consistency:

Accuracy Across Millions of Units

Consistency is the hallmark of high-volume toy manufacturing. For a retailer with 5,000 locations, every unit must be identical to ensure a uniform brand experience and total retailer safety compliance.

Technical Compliance Note: Retail licensed product manufacturing is a commitment to excellence. By combining high-fidelity character moulding with rigorous retailer safety compliance, we ensure your brand hits the market with "Retail-Ready" confidence. Trust Unstoyppable to handle the technical hurdles while you focus on dominating your category.

From Factory Floor to Checkout:

Logistics for the Modern Retailer

In the high-stakes environment of 2026 consumer goods, the transition from production completion to the retail shelf is where the most significant value is either secured or lost. Retail fulfillment logistics for licensed products require a level of precision that goes far beyond standard shipping. At Unstoyppable, we bridge the gap between Asian manufacturing hubs and global points of sale with a sophisticated, data-driven approach. We understand that a retail buyer’s success depends on global retail distribution that is seamless, transparent, and fully compliant with the intake protocols of major Distribution Centers (DCs). Whether you are stocking 5,000 brick-and-mortar storefronts or managing a viral Amazon FBA licensed manufacturing campaign, our logistical framework ensures your products arrive on time, in perfect condition, and ready for immediate scanning. Our "Last-Mile" philosophy is built on the foundation of retail-ready supply chain data, ensuring that the final stage of the journey is as flawless as the manufacturing process itself.

EAN/GTIN Synchronization:

Ensuring POS Reliability

A barcode is more than a label; it is the digital DNA of your product. If a barcode fails at the Point of Sale (POS), the retail relationship is compromised. We prioritize digital synchronization to ensure 100% scannability.

Precision Barcoding via ERP Integration

Our ERP production tracking system is directly integrated with GTIN/EAN barcode labeling for retailers. This ensures that every SKU, including retailer-exclusive variants and limited-edition bundles, is assigned a unique, globally recognized identifier that matches your internal inventory system. We perform "Verification Scans" at the factory level using industrial-grade readers to guarantee that every label meets GS1 standards for contrast, quiet zones, and data density. This meticulous attention to retail fulfillment logistics prevents the administrative nightmare of manual entry at checkout or, worse, the rejection of entire shipments at the retailer’s inbound dock.

Custom Pallet Engineering and Labeling

We specialize in tailoring our output to meet specific global retail distribution intake rules. This includes engineering pallets to exact height and weight restrictions and utilizing specific materials, such as heat-treated ISPM-15 wood or heavy-duty plastic, depending on the retailer’s preference. For 2026, we have mastered "Green" pallet standards, ensuring that retail fulfillment logistics are as sustainable as they are efficient. Every pallet is equipped with SSCC (Serial Shipping Container Code) labels, allowing for automated receiving and instant inventory updates at the retailer’s DC.

Optimization for "Dock-to-Stock" Speed

Our goal is to minimize the time your product spends in a warehouse. By utilizing retail-ready packaging manufacturer solutions, we pack goods in a way that facilitates rapid cross-docking. This means that instead of being broken down and re-sorted, our master cartons are designed to be moved directly from the shipping container to the outbound delivery truck. This level of retail-ready supply chain data integration reduces handling costs and ensures that your licensed merchandise is the first to hit the shelf during a peak movie launch or holiday window.

Streamline Your Retail Operations

Partner with our retail fulfillment logistics team to eliminate chargebacks and accelerate your 2026 rollout.

Aesthetic Appeal for Physical Retail

While e-commerce requires durability, brick-and-mortar requires "shelf-pop." We balance these needs by using retail-ready packaging manufacturer techniques that protect the high-gloss finishes and transparent windows of your character toys while providing a rugged outer shipper for transport. This dual-purpose engineering ensures that whether a customer buys your product from a shelf in Paris or an app in New York, the unboxing experience is identical and premium. This is the hallmark of global retail distribution excellence.

Transparency and Tracking:

Border-Crossing Without Delays

The 2026 international trade environment demands total transparency. Customs-ready manufacturing data is the key to bypassing port congestion and regulatory holds.