Mastering Global Compliance:

The 2026 Framework for Toy Safety

In the high-stakes world of international retail, compliance is the absolute ticket to entry for the world's most lucrative markets. As we move through 2026, the regulatory landscape has shifted from a series of guidelines into a rigorous, digitally-enforced legal framework. For brand owners and license holders, understanding these shifts is no longer just a legal necessity—it is a competitive advantage. At Unstoyppable, we have transitioned from a traditional manufacturer into a total regulatory consultancy, ensuring that every product moving through our audited factory network in China is engineered to meet the latest 2026 standards before the first prototype is even cast. Whether you are navigating the new EU Digital Product Passport requirements or China’s updated GB series, our global toy safety standards 2026 roadmap provides the security your brand deserves.

The Rise of the Digital Product Passport (DPP)

Under the new TSR, compliance is no longer a paper-based exercise. Every toy placed on the EU market in 2026 must now feature a Digital Product Passport (DPP). This digital "identity card," accessible via a mandatory QR code on the packaging, contains real-time safety data, chemical assessments, and EN71 compliance guide documentation. At Unstoyppable, we integrate the DPP generation into our ERP production tracking system, allowing customs authorities and consumers to verify your product’s safety with a single scan. This transparency is the benchmark of modern licensed merchandise production.

Expanded Chemical Prohibitions

The 2026 Regulation significantly tightens the noose on hazardous substances. It introduces a blanket ban on endocrine disruptors, respiratory sensitizers, and the intentional use of PFAS (Forever Chemicals). By leveraging our transparent supply chain manufacturing, we ensure that every material, from the internal foam to the external paint, is pre-screened to exceed these new EU health protections, effectively future-proofing your product against upcoming 2027 and 2028 chemical restricted lists.

New Performance Requirements for "Active" and "Smart" Toys

The 2026 updates to ASTM F963 introduce stricter requirements for battery accessibility—requiring captive screws even after high-intensity drop tests—and new safety thresholds for water-absorbent materials (water beads). As a leader in electronic toy manufacturer solutions, we have updated our internal engineering standards to exceed these ASTM F963 mandatory requirements, ensuring that even the most innovative "smart" toys are inherently safe.

China’s 2026 GB Standards:

The Mandatory CCC Gateway

For brands looking to manufacture in China for the domestic market, the new GB 6675-2025 series is the new mandatory benchmark. Effective from late 2025 and fully implemented in 2026, these standards represent a complete overhaul of China’s toy safety code.

Don't Navigate the 2026 Regulatory Maze Alone

Secure your global market access with a compliance-first manufacturing partner who understands the 2026 shifts in EN71, ASTM, and GB standards.

View Our Compliance Certifications | Compare Global Standards

The "Foreseeable Use" Doctrine:

Testing Beyond the Manual

The most profound change in 2026's approach to global toy safety standards is the legal emphasis on the "Foreseeable Use" doctrine. Modern regulators no longer ask if a toy is safe when used correctly; they ask if it is safe when a child interacts with it in the most imaginative—and potentially dangerous—ways.

Anticipating "Reasonably Foreseeable" Misuse

The foreseeable use doctrine requires us to test for scenarios such as a child attempting to swallow a small part that was "permanently" attached, or using a plush toy as a projectile. Our character engineering for toys team conducts "Use and Abuse" testing that mimics these real-world behaviors. This includes 2026-specific tests for "tension," "torque," and "compression" that go beyond the baseline requirements. By assuming the child will misuse the product, we build in safety margins that protect both the user and your brand’s reputation.

Expert Compliance Note: In 2026, compliance is not a checkbox; it is a continuous engineering philosophy. By aligning with EN71 compliance guide protocols and ASTM F963 mandatory requirements at the design stage, we eliminate the risk of retail recalls and customs delays. Precision in compliance is the ultimate foundation for brand growth.

Beyond Heavy Metals:

Advanced Chemical Compliance and Traceability

In 2026, the definition of toy safety has undergone its most radical transformation in decades. While the industry has historically focused on the migration of heavy metals like lead and cadmium, the modern regulatory era prioritizes the invisible: molecular safety and digital transparency. Technical buyers and compliance officers now face a landscape where "Forever Chemicals" and endocrine disruptors are subject to blanket prohibitions, and where paper certificates of conformity are being replaced by the mandatory digital product passport for toys. At Unstoyppable, we recognize that chemical integrity is a "Safety by Design" fundamental. By conducting a rigorous toy chemical safety assessment at the molecular level, we ensure that your IP is not only iconic but also chemically pure. Our 2026 manufacturing protocols are engineered to anticipate material rejections before they happen, providing a secure, transparent supply chain manufacturing solution that meets the highest bars set by the EU and North American authorities.

Navigating the EU and California PFAS Prohibitions

The new EU Toy Safety Regulation (TSR) 2025/2509, fully active in 2026, explicitly bans the intentional use of PFAS in toys and toy components. Simultaneously, in the United States, California’s AB 1817 and subsequent 2026 juvenile product updates have effectively shuttered the market for any children’s goods containing intentionally added PFAS. This is no longer a matter of "migration limits"—it is a zero-tolerance policy. As a leading partner in ethical toy manufacturing China, Unstoyppable has already audited our entire audited factory network in China to eliminate PFAS from coatings, textiles, and internal lubricants. We provide our clients with a "PFAS-Free Declaration" backed by Total Organic Fluorine (TOF) testing, ensuring your product remains compliant in every jurisdiction.

Material Substitution Without Performance Loss

Eliminating PFAS requires more than just removing a chemical; it requires advanced toy material engineering. We work with specialized polymer scientists to identify bio-based and silicone-based alternatives that provide the same haptic feel and durability without the toxic legacy. Whether it is a water-resistant plush character or a smooth-sliding mechanical joint in an action figure, our phthalate-free toy materials and PFAS-free alternatives ensure that your brand maintains its premium feel while adhering to the strictest toy chemical safety assessment standards of 2026.

Toxicological Risk Assessments (TRA) for Licensed Goods

A Toxicological Risk Assessment (TRA) is no longer an optional "extra" for high-end collectibles; it is a critical step in the 2026 production cycle. For products involving liquids (like snow globes), play cosmetics, or "slime" materials, a TRA conducted by a board-certified toxicologist is mandatory. This assessment looks at the "combined exposure" risk—how different chemicals in a toy might interact. At Unstoyppable, we integrate the TRA into the custom licensed product development phase, providing a comprehensive report that satisfies both the licensor's brand protection team and global regulators.

Future-Proof Your Chemical Compliance

Upgrade your supply chain to meet the new 2026 chemical standards including the PFAS ban in toys 2026 and bisphenol restrictions.

Empowering Customs and Consumers

The digital product passport for toys serves a dual purpose. For customs authorities, it allows for "automatic checks" at the border, significantly reducing the lead time for global distribution for licensed products. For the consumer, it builds immense brand trust. A parent can scan the toy in a retail aisle and instantly verify that it is free from bisphenol restrictions and PFAS chemicals. By adopting the DPP early, we help our clients turn a regulatory hurdle into a powerful marketing tool that demonstrates their commitment to child safety.

Safety by Design:

The Unstoyppable Protocol

Our 2026 approach to chemical safety is not reactive; it is foundational. We call this the "Unstoyppable Protocol."

Technical Insight: In 2026, the digital and chemical worlds have merged. Success in the licensed character product manufacturing process now requires a manufacturer who can manage both PFAS-free material sourcing and digital product passport data integration. Safety by Design is the only path to 100% retail readiness.

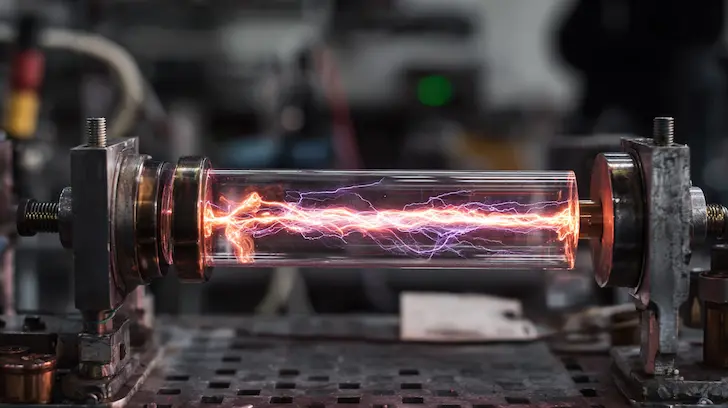

Industrial Physical Testing:

Guaranteeing Mechanical Integrity at Scale

In the high-velocity world of 2026 retail, a product’s physical integrity is its primary defense against liability and brand erosion. While chemical purity is essential, the "physical hardware" of safety—how a toy withstands the chaotic environment of actual play—is where retail-ready toy safety compliance is truly proven. At Unstoyppable, we move beyond basic checks to implement a "Zero-Risk Manufacturing" protocol. This involve a relentless suite of mechanical toy safety testing designed to simulate years of wear, tear, and "reasonably foreseeable" abuse in a matter of days. By the time your product leaves our audited factory network in China, it has been squeezed, dropped, pulled, and probed to ensure it meets every mandatory standard for the world’s most demanding retail shelves.

The Small Parts & Choking Hazard Protocol:

The 31.7mm Defense

Choking remains the leading cause of toy-related recalls globally. Our defense begins with the industrial application of the Small Parts Test Cylinder, a precision-engineered tool used to protect children under 36 months.

Simulating the Vulnerable Airway

The small parts cylinder is a hollow, truncated tube with an inner diameter of 31.7mm, specifically designed to simulate the fully expanded throat of a child under 3 years of age. During our mechanical toy safety testing, any component that fits entirely within this cylinder without compression is classified as a "small part." For toys intended for the 0-3 age bracket, such parts are strictly prohibited. We don't just test the toy as it is sold; we test it after "abuse conditioning." If a limb, a button, or a decorative element breaks off during a 90 Newton tension test and fits in that cylinder, the design is immediately sent back to character engineering for toys for reinforcement. This meticulous approach is why our licensed merchandise production maintains a flawless safety record.

Magnet Ingestion Mitigation

High-powered magnets, if swallowed, can cause catastrophic internal injuries. Our 2026 protocols for retail-ready toy safety compliance require that all magnets be "double-encapsulated" within the plastic mold. We perform destructive soak tests and cyclic impact tests to ensure that these magnets never become accessible, even if the toy’s outer shell is compromised. This level of physical security is what makes your product truly retail-ready for global franchises.

New 2026 Standards for "Water Beads" and Squeeze Toys

Following the significant CPSC rulings in December 2025, the landscape for expanding materials and "sensory" toys has changed. Unstoyppable is at the forefront of these new global toy safety standards.

Zero-Risk Manufacturing is Here

From the lab to the retail shelf—ensure your brand is 'Unstoyppable.' We synchronize third-party lab testing with daily production for 100% peace of mind.

Daily Inline Testing and Lab-to-Line Calibration

We don't just test at the beginning; we test throughout. Using AQL inspection in toy manufacturing (typically GII Level 0/2.5/4.0), our inspectors pull samples directly from the assembly line and perform "mini-lab" tests on-site. These include tension tests on joints and "drop-on-concrete" tests to ensure the 100,000th unit is as robust as the Golden Sample. If any batch shows a deviation in material density or weld strength, the line is stopped immediately. This synchronization between third-party toy lab testing and the factory floor is the only way to ensure 100% retail-ready toy safety compliance in a mass-production environment.